Anchors for fastening objects and elements to a brick wall allow you to ensure the reliability and safety of the resulting connection. They are characterized by a sophisticated design and are easy to install. No special effort is required, just strict adherence to technology.

Anchor

What it is?

A brick anchor is a popular type of fixing element that can be used both during construction and during repair and restoration work. This product looks like a regular construction bolt, but has design features that allow you to reliably connect all brick elements, as well as fix parts of different weights on their surface.

The fixing element must be placed in a pre-prepared hole , and during the process of deepening, a special sleeve begins to increase, which creates the maximum level of adhesion between the object and the wall.

Manufacturers artificially increase the level of adhesion on anchors by applying special notches to them.

This is interesting: Square pipe - production and application

The principle of working with fasteners

One of the features of mounting an anchor is the location where it will be installed. Installation should be carried out clearly in the brick, and not in the gap of the masonry.

Also, when drilling, you cannot use a hammer drill. This can destroy the body of the brick, especially if it is hollow.

When drilling, you need to make sure that the hole is horizontal and does not deviate. The strength of the structure depends on this.

When driving, you should remember to use the anchor carefully so as not to damage the fastener itself or its parts. For example, carving.

Tools for starting renovations in an apartment: dowel-nail, hanger and level

One of the main elements for the manufacture of a “lathing”, a frame made of a ceiling profile (PP), onto which plasterboard is subsequently attached, is a direct suspension. To secure it, you need screws, nails or dowel nails. The construction of a wall or ceiling using this device is the simplest and most reliable.

The straight suspension, the photo of which you see, allows you to adjust the distance between the main wall and the new one (the one we plan to mount) without any difficulties. If necessary, insulation, hydro- or sound insulation is placed in the gap between the gypsum board and the wall; there is now a huge selection of various types of insulation on the construction markets.

Requirements common to all anchors

It is pointless to list the nuances of using all types of anchor fasteners that exist today - each manufacturer provides detailed recommendations for their hardware, in accordance with their design and purpose. But there are a number of requirements common to all products that are intended for installation in brick walls:

Holes for mounting any types of anchors are drilled exclusively in the body of the brick. Drilling masonry joints is prohibited, since they are most often not able to hold fasteners. In addition, the destruction of part of the seam leads to a weakening of the load-bearing capacity of the wall in this place.- Any anchor is installed strictly perpendicular to the brick structure. Even a slight slope is a gross violation of construction technology and leads to weakening of the fastening.

- When calculating the hole depth and drilling, the thickness of the finishing layer - plaster or putty - must be taken into account. It must be taken into account that the anchor is fixed in the thickness of the wall, and not in its cladding. Errors in the depth of fasteners can lead to the most unpleasant consequences.

- Before installing the anchor, the hole in the brick must be cleaned of dust and debris that got into it during drilling. This can be done using a special brush, an industrial vacuum cleaner or improvised means.

These requirements are mandatory, since the quality of installation of anchor fasteners directly depends on their compliance.

Anchor for hollow bricks - installation rules

This fastening system is best suited for brickwork. Properly selected and secured, it can withstand a load of more than one hundred kilograms. Anchors are used to secure curtain facades, canopies, furniture and enclosing structures. The anchor for hollow bricks is attached in two stages: the appropriate type is selected and its installation is carried out. The parameters and type of system are selected taking into account the functional purpose; increased load will weaken the fixation system. Certain standards are required for installation, since the slightest violation will lead to the appearance of cracks in the wall, partial destruction or complete loss of the anchor.

- What does it represent?

- Classification

- Features of hollow brick

- General installation rules

- Installation

- Recommendations

- Conclusion

What does it represent?

The anchor for brickwork includes a minimum set of a couple of parts - a spacer part and a non-spacer part, screwed into the first. When the screw is tightened, the special petals straighten out and engage the masonry material like an anchor, creating a strong connection.

Classification

Two types of anchor systems are installed in a brick wall - mechanical and chemical.

The systems of the first group are more popular.

Based on the purposes of application and design nuances, anchors are divided into several types:

- driving. The simplest hardware installed in monolithic block stones. Structurally, it consists of a spacer zone driven into the brick surface with a hammer, a bolt and a nut. In addition to the nut system, fastenings with a hook, ring and angle are used. The ability to hold a load is determined by the parameters and degree of reliability of the metal element. This type of anchor system is the simplest. Having installed the driving part, screw in the threaded element.

- wedge Equipped with anchor edges that expand when twisted and a recessed type head. This type can withstand significant loads and is recommended for fastening directly through the part. Such systems are used to secure curtain façade elements, stained glass, and shelving. The fastening system has a second name - an anchor bolt for bricks;

- double-spacer It is used to fix heavy steel reinforcement and is used to create increased resistance to tearing out. This expansion anchor is represented by a pin with expansion shells of varying lengths, a nut and a non-pressed washer. Installed in strong solid brick material, sometimes used for hollow block stone;

- MSA is a system made from brass alloy and knurled to improve the quality of the external connection to the internal conical cavity. At the time of installation, it expands, securely adjacent to the walls of the created hole. The maximum diameter inside is up to eight millimeters; not very large objects are fixed to bricks with this anchor;

- anchor bolt. This hexagonal head fastener is used to combine decorativeness and alignment resistance. The disadvantage of hardware is complex installation work, which requires a power tool to ensure high-quality fastening;

- rod retainer. This system is considered an extended version of the wedge anchor and is used for fastenings through multi-layer cladding. The main advantage is considered to be placement at a slight slope, but this property is not recommended for use with brick stone. The rod is cut to length if necessary, and the system is secured on the back side of the wall with a nut and washer;

- chemical. Fixation is carried out in the prepared hole using a special glue that fills the internal cavity, ensuring that the bolt is firmly held. This fastener is easy to install. A hole is drilled in the wall, a capsule containing an adhesive composition is inserted, and a bolt is placed. Note that for the final hardening of the glue, some time is required, depending on the components of the glue and the air temperature. The necessary information can always be found on the packaging material.

The review presents only the most popular anchor systems used for walls built from brick material. Manufacturers produce a large number of anchors that have similar applications. Such systems differ in design and technical parameters, which should be taken into account when making the final choice.

Features of hollow brick

The number of void areas in such material ranges from thirteen to fifty percent of the total volume. As a rule, such bricks are used for cladding, although they have a good strength indicator.

Single hollow stone is considered the most common option, for the manufacture of which a low-melting clay material is used.

The main difference from the solid analogue is the through or non-through slots, which have different shapes and sizes. Thirty-five percent is considered their optimal indicator, since with such a number of voids the brick is still considered quite durable.

Hollow brick material is often used to construct interior partitions.

General installation rules

Before fixing the anchor bolt in a brick wall, it is recommended to clarify the specifics of using the types of hardware selected for the work. It will not be possible to find out everything, since each manufacturer provides detailed information only for its own fastening system, taking into account its design features and purpose. But there are general rules for anchoring brickwork that must be followed:

- The installation hole for any system is made directly in the stone. It is forbidden to drill inter-masonry seams, because in most cases they do not hold the fastener. In addition, partial destruction of the suture section reduces the load-bearing capabilities of the wall in this location;

- The anchor bolt is fastened at right angles to the brick wall. The slightest deviation refers to a serious violation of technology and leads to weakening;

- When calculating the depth of the hole and performing drilling, the thickness of the finishing layer of plaster or putty must be taken into account. Remember that the anchor is fixed directly in the wall and not in the facing material. A mistake made in choosing the depth of the fastening will result in dire consequences;

- The hole drilled for installation must be cleaned of dust and remnants of wall material. To do this, use a brush, vacuum cleaner or improvised means.

The quality of anchoring depends on compliance with the above rules.

Installation

Today in the construction industry, the modern anchor is an indispensable fastening system.

The algorithm for installing an anchor in a hollow brick is as follows:

- First of all, marking is done. It should be noted that erroneous actions will not allow you to move the anchor a few centimeters to one side, as is possible in the case of a concrete surface. Hollow brick stone is considered a fairly brittle material and, in most cases, is destroyed when drilled again;

- To make holes, special drills are used that correspond to the diameter of the anchor system and the depth of its placement. The most important condition on which the subsequent quality of work depends is maintaining perpendicularity. The drilled hole is cleaned of dirt and its depth is checked;

- When installing the fastening system, watch how it fits into the prepared hole - a minimum gap should be ensured. If the hardware moves freely, you should take a fastener with a larger cross-section, drilling the hole a little;

- The drive-in anchor is installed carefully, just like the expansion version.

Remember that excessive force when hammering damages both the hardware and the wall area surrounding it.

Recommendations

The hollow brick anchor bolt has successfully replaced the nails, bolts, screws and self-tapping screws that were previously used for fastening. This method, which allows you to hang something or connect elements with hollow brick masonry, is considered the most reliable today. True, to obtain durable fasteners, it is recommended to follow some rules.

When installing a slotted brick anchor, do not use a hammer drill. Its impact will create cracks in the fragile material, and a new hole will have to be made.

It is prohibited to select seam sections of masonry as a point for drilling and mounting an anchor. Cement and sand do not guarantee the required strength, and if there is a significant load on the fasteners, the anchor system will soon fall out.

When hammering in the anchor structure, place a piece of wood under the hammer so as not to damage the threaded area. Before you start screwing, clean the inside of the sleeve to avoid damaging the threads.

Purchase anchor fastening systems that have appropriate quality certificates.

Types of fastening systems

A chemical dowel or anchor is most often used for installation in hollow bricks. The peculiarity of this type of fastener is its high resistance to the negative effects of alkalis and water.

Each type of fastener is used in a specific situation.

To attach various objects to walls made of brick and aerated concrete, several types of anchors are used. The difference between fasteners is their size and technical parameters. Each type of anchor corresponds to specific tasks. When choosing an anchor system, it is important to take into account the specifics of the bond and the brick from which the wall is made. For example, clay brick is stronger than silicate brick, and the advantages of porous building materials include all the qualities of faucet brick and gas block. The cladding can be clinker stone masonry, and a certain type of anchor must be selected for it.

Driven type

Anchor systems of this type are considered the most common and easiest to install. They are used to fix a profile pipe or any structure on walls made of solid and slotted bricks. The peculiarity of the driven anchor is that after it is installed in the wall, the spacer part is activated, providing adhesion. Only after this, additional threaded fasteners are inserted into the sleeve using a nut, which is removed at the end of the work. Instead, a corner, hook or ring can be used.

Wedge view

Such fasteners are also suitable for fixing metal channels.

This type of masonry anchor has a special element that is wedged during installation. By expanding inside the wall, this fastener holds heavy objects. With its help, you can even fix a metal channel to the wall. Often these anchor systems have countersunk screws. It is better to use wedge anchors if you need to install through the fixed object.

MSA type fastener

The anchors are made of brass and have a special notch that improves the level of adhesion to the building material. The inner sleeve has a conical shape with a narrowing towards the base. This structure allows the anchor to expand and the device to be fixed in the wall as the bolt is screwed in. Such fasteners are used for hanging light equipment.

Chemical fasteners

This anchor is suitable for hollow and solid bricks, but when working with slotted building materials, chemical anchors are indispensable. After the necessary calculations have been made, an ampoule of polyester resin is installed in the prepared hole. Then drilling is carried out using a pin, which provides a physical and chemical method of fastening. It takes time for the compound used to harden. For slotted bricks, at least 20 minutes.

To reliably connect the components of multilayer structures with air channels and cladding, a flexible ligament anchor with wavy bends is used. Calculating the required quantity is simple: per 1 m² there are 4-5 pieces of flexible anchor connections.

Double spacer system

Such fasteners are usually used for hollow-type bricks.

An anchor or dowel for hollow bricks has a spacer sleeve in 2 places at once. This guarantees a secure fit. This type of fastener is also suitable for solid building materials, but its most popular use is for slotted bricks. If there are 2 spacers, there is a high probability that at least one of them will hit a solid part. Shows itself well in terms of breaking out.

This is interesting: Casing pipes for wells - characteristics, application features

Hollow brick fasteners

Introduction

In the construction of apartment buildings and especially private houses, the most popular building material has been, and probably will remain, brick.

If you look at the range of bona fide sellers of building bricks, for example, here https://moskeram.ru/catalog/kirpich/stroitelnyy_kirpich/, we will see that the number of types and types of bricks sold is approaching 40. Brick is used at every stage of construction, from the construction of the foundation and plinths of private houses, to cladding of concrete high-rise buildings.

Construction brick has a lot of useful and necessary qualities. Each type of brick is needed to perform certain jobs. For example, hollow brick remains the most popular option for exterior and interior cladding of a house.

However, it is the hollow brick that creates certain difficulties in the further finishing and improvement of the house. To hang something on the facade of a brick house or to secure a structure, or to hang a shelf on a brick wall inside the house, you will need to use special fasteners for hollow bricks.

Hollow brick fasteners

The operation of a standard fastener is based on the expansion of the basic fastener structure, called a dowel, by screwing a screw or bolt into it. This does not work for hollow brick because the walls are too thin to provide a holding surface for the dowel.

Steel dowels for hollow materials, plastic butterfly dowels and chemical anchors solve this problem. Each of the listed types of fasteners can be used as fasteners for hollow bricks, but for different loads.

Steel dowels

In the photo you see a steel drop-down dowel in a metal version. Quite suitable for fastening medium loads in hollow bricks. It is important to choose the right type of dowel according to the thickness of the butterfly opening.

Plastic butterfly dowel

These fasteners are positioned to work with drywall. However, in plastic versions for small loads they are suitable for hollow bricks.

Chemical anchors

In appearance, a chemical anchor is very similar to simple assembly adhesive. Same tube, but not the same application.

Chemical anchors are two-component resin-based compounds. They are used in combination with various metal anchor fasteners, such as studs, bolts, and fittings.

For example, you need to hang a certain structure on a hollow brick wall. To do this, buy metal studs and a chemical anchor for hollow bricks. Drill holes in the wall, fill them with a chemical dowel compound, and immediately insert a pin or dowel with a pin into the hole, which is “tightly” fixed in the hollow brick.

Conclusion

As you can see, fasteners for hollow bricks are somewhat different from classic expansion dowels. It is important to know this and correlate the planned load with the choice of the type of fastener.

Rules for installing anchor systems

Make a hole for the anchor using a hammer drill in drilling mode

With the advent of household hammer drills, the installation of fastening systems in the walls of buildings has become significantly simplified. The older generation remembers the pain it took to install the anchor.

Using a special metal tube (bolt), under the blows of a hammer, a hole was slowly made in the brickwork. Now such an operation takes minutes.

To correctly and safely install anchors in a brick wall, you must adhere to the following rules:

- Whenever possible, the hammer drill is used in drilling mode. Brick is a rather fragile material and can simply crack and collapse under impact load. The resulting hole will not fulfill its purpose.

- The temptation is to make the work easier for themselves, they drill holes in the cement joints of the masonry. However, this position of the anchors can lead to dire consequences. Under heavy loads, the cement crumbles and hanging objects can simply fall to the floor.

- When drilling, you need to strictly control the horizontal position of the drill. At the slightest downward inclination of the cavity, there is a risk of the anchor falling out under the influence of an increased pull-out load.

- When driving the supports with a hammer, place a spacer (wooden plank) under the anchor. This allows you to protect the stud threads from damage.

- Before installing the anchor system, you need to check the cleanliness of the surfaces of the sleeve and rod. For more information about working with an anchor bolt, watch this video:

By following these fairly simple rules, you will always be confident in the strength and reliability of the fastening of hanging furniture and other items.

How to drill a hole in a brick wall

How to attach a sink to a wall

Installation of timber walls

Wall cladding with clapboard on lathing

How and with what to fill a hole in the wall

Installation of beacons for plastering walls

Drawing the perimeter for the guide profiles

The lower part should not touch the floor; there should be a small gap of half a centimeter.

Then, at two points (closer to the ceiling and closer to the floor), we apply a tape measure to the wall to determine where the blockage is. We take a tape measure and measure 5 cm from the wall (near the ceiling) and mark a point on the ceiling. We need 5 cm, since insulation will also be laid between the gypsum board and the wall. Without insulation, 3-3.5 cm would be enough:

fiber panels for external facade finishing

After this, we take a plumb line and apply it with one end (thread) to this marked point on the ceiling, lower the weight down, thereby transferring this point to the floor. That is, we stop the weight at the bottom so that it does not swing and mark exactly the same point on the floor right under the tip of the weight:

Let's move to the other edge of this wall. And in the same sequence we perform the same actions: mark 5 cm from the wall on the ceiling, lower the plumb line to the floor, stop the weight so that it does not swing and carefully place a point under the tip of the weight.

And then, using a tapping thread, we beat along our marks (the tapping thread acts as a long ruler, with the help of which we draw a long straight line along the marks):

A straight line should form on the ceiling from one edge of the wall to the other.

You need to try to beat the thread to the very end of one and the other edge, since after this you will need to transfer the marks to the side walls. Having hit the ceiling, we go to the floor and also hit (we also get a straight line on the floor). Using a pencil or felt-tip pen, transfer the marks to the sides. After the marks are transferred to the sides, stretch the beating thread and beat off:

The perimeter for the guide profiles is marked. Now it is more or less clear how to attach the drywall profile to the wall.

How is the installation carried out?

To install fasteners for hollow bricks, it is recommended to adhere to the following rules:

- The diameter of the prepared hole must be equal to the diameter of the fastening system.

- Before installing the sleeve into the wall, you need to clear the hole in the brick from dust and debris.

- Tightening the inner bolt should ensure that the inside of the anchor is fully expanded. This guarantees the reliability of the fastener.

- The anchor system is inserted only into the body of the brick, and not into the layer of cement mortar.

- The brick wall must be strong and without damage. Cracks weaken connections.

Anchor systems are used as part of external and internal work. For fixation, you need a preliminary calculation of the number of ties, the shear strength of the masonry and the level of resistance, the peculiarities of the fastening principle relative to the type of brick, etc. Sometimes it becomes necessary to use additional devices, for example, a corner for an anchor system.

Loosening the clip

Loosening the clip is an option for getting rid of the anchor. This happens when the screw is turned. Freshly screwed fasteners cannot be removed (if installation was carried out correctly).

Hold the fastener with pliers and loosen the screw. Do this until the mounting frame becomes visible. You will have to scratch the bolt a little with pliers for better grip.

If the fastening is made of metal, it is lubricated with oil to loosen it.

Weakening occurs by hammering the bolt into the cage - the thrust becomes larger and weaker.

Overview of species

The high level of demand for fixing elements and their wide range of applications have forced manufacturers to develop a wide range of parts that differ in size, design and technical characteristics. These features have a direct impact on the specific operation of the elements, and some parts are designed to solve a narrow range of tasks of increased complexity. Expansion anchors for brick walls and masonry can be used for solid, hollow and hollow building materials , as well as sand-lime and facing bricks. In order to more carefully study all types, it is better to consider each separately.

Double-spacer

A new version of fixing devices is double-spacer anchor elements, which have a spacer sleeve that opens in two directions.

This feature makes it possible to enhance the fixing effect not only in conventional masonry, but also in products made from hollow material.

Drivers

The most common fastener used for working with solid bricks. The principle of operation of a drive-in anchor is the opening of a spacer element in a pre-prepared hole, followed by screwing the threaded part into the drive-in part.

Wedge

Wedge fasteners are special fixing elements that are equipped with a special wedging part.

A distinctive characteristic is reliable fixation after full expansion in the prepared hole, the presence of screws and a recessed head.

M.S.A.

MSA type products are advanced fixing devices that are equipped with special brass sleeves. A design feature is the presence of longitudinal cuts that divide the surface of the product into separate expanding elements.

To maximize expansion of the spacer sleeve, the internal part is cylindrical.

Hex Bolts

Hex head anchor bolts are a fixing element that uses a classic bolt instead of a rod and nut. A distinctive feature is the fastening of the element in the brick cavity at the moment of tightening the nut, which leads to deformation of the sleeve.

Manufacturers also produce models that can be tightened with a screwdriver.

Chemical

Anchor products, the operating principle of which is based on a chemical reaction, are a popular and popular device for working with hollow and porous bricks. The difference is that the drilled hole is filled with adhesive after placing the anchor inside it. Advantages: high fixation level. The disadvantage is that it is impossible to use the structure until the glue has completely hardened. This period of time depends on the components and features of the composition; it must be indicated by the manufacturer in the instructions.

The glue capsule can be located either inside the product or in a separate bottle.

ROOF AND PANELS FASTENERS

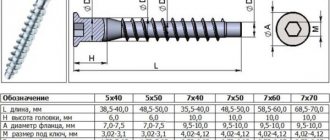

Concrete screw SSP-C

Galvanized steel screws with Ruspert coating with a hexagonal head and thread (like FRS-S), equipped with a washer with a conductive EPDM gasket for fastening façade laminated slabs to concrete and/or brick bases.

Brick has long been one of the most popular building materials, and structures made from it can be found in the vast majority of both old and modern buildings. To mount various objects on such structures, different types of fasteners are used, but the most effective and reliable of them are anchor bolts specially designed for brick, taking into account the strength characteristics and internal structure of this building material.

Chemical anchor, fastening with glue

Fastenings based on filling the inside of a metal rod embedded in the wall are used to provide strong connections in stone, brick, sandstone, shell rock, limestone, and cellular concrete. Such connections involve the use of chemical anchors, for example the popular all-season type moment fastener CF900. A metal insert, which is a reinforcement rod, a threaded stud or a sleeve with a thread on the inner surface, goes deep into a prepared hole, the diameter of which exceeds the anchor parameter by 2 mm. After this, a capsule with glue based on polyester, polyurethane or acrylic resinous substances, a hardener and filler in the form of sand is inserted into the sleeve. Then the glass cylinder is destroyed and a metal rod is inserted into it and the binder is waited for setting.

Materials

Due to the fact that anchor rods on monolithic cladding are used in cases where it is impossible to tie with a load-bearing wall, manufacturers use basalt plastic and fiberglass for the manufacture of fixing elements. These materials not only have a high level of strength, but are also able to withstand a wide temperature range , and also have a low thermal conductivity coefficient, which significantly reduces the likelihood of the formation of cold islands. During operation, fiberglass products behave best.

Experts do not recommend purchasing steel anchors, which during operation are capable of accumulating condensate, which will inevitably provoke corrosion processes.

Fastening

To create reliable buildings, experts recommend strengthening structures with special fixing elements - anchors. Anchor fixing parts are simple products, the installation and fastening of which should not cause difficulties even for novice builders. Despite the simplicity of the procedure, before fastening the part, it is necessary to make a pull-out calculation and follow all the recommendations of specialists in order to securely fasten it.

Basic Rules

To obtain maximum results, experienced craftsmen recommend taking into account a number of rules and technological features during the installation of anchors. The size of the drilled hole must strictly correspond to the diameter of the fastener. Do not install small anchors in large holes.

It is strictly forbidden to install anchors at the joints between bricks that are filled with cement mortar. It is also undesirable to choose weak areas with a large number of cracks and chips for work.

To protect the thread from deformation, experts recommend avoiding direct contact of the hammer with the metal and using wooden or rubber spacers.

Before starting work, it is necessary to accurately mark the work area and determine the location of the anchor. It is strictly forbidden to drill recesses close to each other, since the structure of the brick is porous and fragile, which will certainly provoke the destruction of the structure. When carrying out insulation work, clamps can be purchased separately.

If necessary, you can carry out not only horizontal reinforcement, but also vertical reinforcement - the main thing is to avoid the appearance of even a minimal bevel.

When choosing a fixing device, experts recommend adhering to the following standards:

- the length of the sleeve should not be less than 6 cm;

- the optimal level of insertion of the rod into the wall is 9 cm;

- the recommended number of anchors per 1 m2 is 4 pcs.;

- areas near openings and at joints must be reinforced.

Incorrect selection of the size, type and material of the fixing element can provoke weakening of the structure, as well as the appearance of cracks and faults on the walls.

Special brushes, a vacuum cleaner, or any convenient means at hand will help remove debris and dust from the recess.

Technology

In order to obtain a reliable and durable design, experts recommend following the following sequence of actions:

- carrying out marking work and accurately determining the location of clamps;

- drilling a hole of the required diameter in the selected work area;

- complete cleaning of the recess from dust and foreign debris;

- installation of the fixing part;

- Fully tighten the bolt head.

An important point is that the depth of the hole should not take into account the thickness of the finishing layer, which will not allow creating the maximum level of fixation.

You can learn how to use a chemical anchor from the video below.

Anchor system design

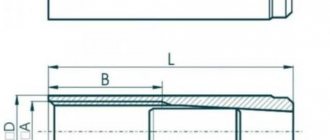

The device consists of a rod and a spacer sleeve

The principle of operation of the system is the same as that of dowels. The system consists of two parts: a support rod (bolt) and a spacer sleeve. Anchors for brick walls are made in various lengths and diameters, that is, a certain type of fastener is selected for each load value.

To install supports in brickwork, you need the following tool:

- perforator;

- brick drills;

- hammer;

- spanners;

- brush for cleaning holes.

Choosing anchors for a brick wall

You simply can’t think of a better fastener for hanging structures than an anchor for a brick wall.

They are also used with no less success for hanging heavy structures on concrete walls. Installation of anchor for brick.

Special anchor designs have now been developed for other materials. After all, when deciding to make wall furniture in the kitchen or installing a boiler in the bathroom, the owner will have to use some kind of durable fasteners.

- Anchor and dowel - what's the difference?

- Types of anchors for working with brickwork

- What to remember when installing anchor systems

The principle of operation of anchors - how do they cope with loads?

The principle of operation lies in their technology and special prefabricated structure, due to which the load has a completely different character. The fact is that when installed, the anchor bolt already expands in the wall; it cannot be pulled back out with any effort, like a nail, dowel or screw.

In this case, the load is distributed over a small surface area into which the bolt was installed, and not at one point, as with standard fixations. To enhance its ability, a metal sheet is additionally mounted with it, which takes up most of the load and distributes it across the entire plane of the sheet, and the larger the sheet area, the more load the bolt can withstand.

Newbie mistakes

Now, I propose to consider some mistakes that are possible when choosing a material for attaching a ceiling profile (PP). In the photo below, the installers completely abandoned the use of direct hangers for drywall measuring 60x27. Mistakes made with this:

1. The ceiling profile is tightly screwed to a wooden beam, in violation of all instructions and technologies. 2. The wooden beam, just like the profile, is fixed to the main wall without the slightest hint of elasticity of the fastening. 3. Apparently, the people who performed this work had not even heard of the use of direct hangers. The design has two or three suspensions, but they are located in a chaotic order.

The result of such work will be a crack on the surface in a couple of years. And all this is due to a violation of installation technology.

Another common mistake made by beginners is improper fastening. When installing an elongated direct suspension on a wall, you can attach it both to the central holes and to the petals. But when constructing a ceiling sheathing, it is recommended to attach the suspension only to the internal holes of the main backrest with a stiffener. A sheet of drywall has a decent weight, and fastening to the wider part is more reliable.

It is strictly not recommended to bend them if you have secured the 60x27 profile out of level with the others; it is better not to be lazy and twist a few screws. Each leg, before attaching the PP to it, must be pulled as far as possible from the wall in a straight line. Suspension traction is necessary to achieve full extension of its legs.

Only by observing all the technical rules and conditions for installing a 60x27 direct hanger under plasterboard, you will achieve a smooth, beautiful, and most importantly, high-quality, long-term surface.

If you have any questions about the use and installation of lathing for gypsum boards, or just want to share your opinion, I am always ready to answer or discuss in the comments to this article.

Source

Anchors: their effectiveness and types

The effectiveness of anchor bolts speaks for itself, this is the latest modern device that is quickly gaining popularity due to its ease of use and practicality. At the moment, there are no analogues for them that could compare in terms of economy and physical characteristics. Taking the physical laws of load distribution along a plane as a basis, experts came to a very effective solution and created this device.

Anchors come in different types, have approximately the same properties and functions, each has a fundamental difference. They are divided into the following types and subtypes:

- Mechanical: – mortgage; – spacer; – driving; – wedge; – a bolt with a ring or hook; – frame; – hairpin; – façade; – ceiling; – spring.

- Chemical: – monolithic fasteners; – for external and internal work; – for fastening in loose and thin-walled substrates; – resistant to vibrations; – long-serving;

- Plastic.

- Ground.

- For foundation construction.

- Height adjustable.

What are anchor bolts for masonry

A brick anchor is a universal fastener that is equally successfully used both in the field of capital construction and when performing simple repair and improvement work on buildings and premises for various purposes. With the help of such fasteners, which are a bolt of a special design, objects and elements of even significant weight can be securely fixed on the surface of a brick wall. Such anchor bolts, in particular, can be used to secure furniture and interior items, lamps and chandeliers, suspended ceilings, wall-mounted facades and much more.

The design features of this type of bolt and the principle by which it operates are contained in its name: anchor in German means “anchor”. The element that ensures reliable adhesion of such fasteners to the inner walls of a pre-drilled hole in the brick is a special sleeve. Placed in a hole in the wall, when the head of the anchor bolt is twisted, it begins to increase in diameter, pushing out the inner walls of the hole and coming into reliable engagement with them.

In order to make the adhesion of the anchor bolt sleeve to the walls of the hole in the brick even more reliable, a special notch is applied to the side parts of its outer surface.

» data-lazy-type=»iframe» src=»data:image/gif;base64,R0lGODlhAQABAIAAAAAAAP///yH5BAEAAAAALAAAAAABAAEAAAIBRAA7″>

Installation of guide profiles for drywall

We begin to attach the guide profiles from the floor, since the line that we have cut out is very easy to trample. We take a guide profile (UD or PPN) 28x27 mm, measure and cut off the required distance.

If the floors are concrete, then to attach the profile you will need a hammer drill and dowels.

If the floors are wooden, then the profile is fastened with self-tapping screws using a screwdriver.

We place the profiles flush with our broken line on the floor inward so that the edge of the profile and the line coincide. We press the profile to the floor with one hand, install the screw and tighten it. Next, we correct the profile, if it has moved, so that the line is flush with the edge of the profile, insert the self-tapping screw and tighten it.

We fasten the screws in increments of 40-50 cm (accordingly, for a concrete floor you will have to drill a decent number of holes: do not forget about noisy work around the house!) This is the principle of fastening all the guide profiles. Having completely secured the profile to the floor, we move on to the ceiling:

and screw the profile to the wall.

We do the same with the other side:

How to Attach an Anchor Bolt: A Reliable Anchor for Any Application

Despite its resistance to loads, installation is very simple, in three stages:

– drill a hole in the wall with a drill or hammer drill; – install a bolt in the hole; – spread out the anchor base.

This installation guarantees reliable use for any purpose and load. The anchor base will cope perfectly with any type of application.

Varieties

Anchors differ not only in size. There are design features of technical parameters. Anchor products for brick walls are divided according to their intended use. A specific type of hardware is used for certain installation work.

Important! To ensure reliable fixation of an object in a brick wall, it is recommended to take a responsible approach to the choice of anchor products.

Driven type

Allows you to secure critically heavy weights. Made from high-strength material or carbon steel. It is treated with a specialized anti-corrosion coating, which ensures an increase in service life. The product is manufactured in one piece, which increases the reliability of the fasteners. A popular type of hardware is the collet anchor.

Drivers

The anchor is driven into the brick with a hammer. Its working part becomes wedged. This way the element is securely fixed in the wall. Then the bolt or stud is screwed in.

Wedge type

The scope of application is identical to the hammer type analogue. The method of installation in a stressed and unstressed concrete plane is allowed. Refers to reliable fastening elements. Capable of withstanding high loads. Used in dry rooms.

Made from various types of steel. Differs in specific execution. On one side there is a stud with a metric thread, onto which a nut is screwed. On the other hand, there is a spacer system in the form of a coupling with an internal shank.

Wedge

MSA type

Brass products, the outer side of which is characterized by the presence of a special sleeve with a large notch. The design allows you to increase the density of fixation of fasteners in the wall cavity. The permissible intra-sleeve cross-section is in the range of 8-10 mm.

Chemical principle

The external design is a cylindrical tube. Inside there are two ingredients - organic and inorganic. Reacting with each other, they harden and provide the required degree of strength.

Chemical

Important! Chemical-type fastening structures are in high demand because their use is allowed in places with high humidity, in porous substrates. Even in such extreme conditions, they are able to hold the elements together.

The name of the hardware was given in view of the chemical principle of operation - a chemical reaction. Has no smell. It is an environmentally friendly product. Does not harm the environment and the human body.

The negative aspects of using the product include the high price and different setting times of the composition. The latter depends on the variety of adhesive mixtures.

With ring

The peculiarity of the product – the presence of a ring – ensures its scope of application. It is convenient to install suspended structures on wall and ceiling surfaces. In construction it is used for securing scaffolding. Allowed to be used for bricks with a dense internal structure - only solid ones. In porous and hollow materials, fasteners lose their effectiveness.

With ring

Double-spacer

Additionally, a spacer sleeve is provided that opens simultaneously in two places. The first spacer element does not come into contact with the solid masonry surface. The reliability of fixing the product in the wall increases. The sample shows good results in the tensile test, therefore it is used in difficult operating conditions.

Double-spacer

Rules for fastening anchors

Before proceeding with installation, it is worth clarifying a few important points. Firstly, it is worth understanding what kind of brick the masonry is made of. Depending on this, you choose the type of anchor. Secondly, after this it is also worth taking into account the functional significance of the fastener (what exactly it will hold and what weight and size). After this, you can proceed to the next stages of installation.

The rules for installing anchors depend on the above types of fasteners.

In the case of flood anchors, you need:

- a hole needs to be drilled. It corresponds to the size (length and diameter) of the fastener. The hole must be thoroughly cleaned of dust and brick shavings;

- install the anchor in the hole. The wedge located inside the anchor is driven in. It is driven to the very end of the hole;

- The attached part is attracted.

Installation features

In the practice of modern construction, anchors are in demand. They provide a reliable way to install equipment and fix massive objects and structures on the walls and ceilings of a building. It is important to choose the right hardware for the job.

Fastenings for solid bricks will not provide the necessary adhesion to hollow material. Therefore, it is important to first determine the base raw materials from which the enclosing structure was erected.

Sequence of work:

- The plane is marked. The work is done with the utmost care. Hollow ceramic bricks are fragile. If you make two holes with a small interval between them, the material will most likely be deformed.

- The hole in the brick is made with a specialized drill. The cross-section of the anchor element and the depth of its placement are taken into account. The perpendicularity of the hole produced is a guarantee of high-quality work.

- After creating the hole, it is cleaned of dust and debris. Depth accuracy is checked.

- When inserting the anchor, make sure that the gap between it and the wall is minimal. If it turns out that the product is loose, it is better to take larger hardware. It should be selected according to the diameter of the resulting hole.

Important! Installing a hammer-type product is the same painstaking process as installing a spacer analogue. If you apply excessive force when hammering, not only the fastener itself will be damaged, but also the wall.

Brief description of the dimensions and characteristics of the suspension

Let's consider a 60x27 straight suspension, the technical characteristics of which speak for themselves. Its entire structure consists of three parts:

Schmitz floor level crane rod

A straight hanger measuring 30 cm is standard. The length of each foot is 12 cm. There are also options with a foot length of only 7.5 cm. The average metal thickness is 0.7 mm. As mentioned above, the thickness and appearance of the product itself may vary slightly from each other.

The steel from which plasterboard hangers are made undergoes a special chemical treatment, which increases the service life of the product. The metal is not subject to corrosion, which allows it to be used not only for internal, but also for external work.