In furniture manufacturing, wood dowel joints have proven their durability. The capabilities of the dowel milling cutter can significantly simplify marking and drill holes exactly to size, increasing work productivity several times. In one go, 2 places are immediately selected for landing keys with a precisely fixed center-to-center distance. Setting the angle of inclination and other parameters is similar to the design of a router for dowels and grooves. The difference is in the cutting tool and the shape of the keys used.

Design and principle of operation

The design solution is the same as that of all hand-held power tools of this class - conventional milling cutters, drills, grinders. Torque from the electric motor is transmitted through the gearbox to the spindle (shaft). There is a collet on the spindle in which the cutter is fixed.

What does such a tool look like:

To accurately position the cutter relative to the workpiece, a support platform (work table) and guides (parallel stops) are used. On most models, the stop has angular adjustment, which makes it possible to sample at the desired angle. By moving the platform along the guide posts, it is possible to adjust the height relative to the top edge of the workpiece.

Adjustment system for lamellar router

- Milling depth.

For “lamella cutters”, the immersion depth of the cutter is set using a turret stop, which limits the longitudinal stroke of the tool body. - The distance from the top edge

is adjusted by raising or lowering the support “visor” on the base of the router (the desired value is selected on the scale). - Tilt angle. The vertical milling angle is adjusted by tilting the “visor” up or down. Accuracy in the horizontal plane is achieved thanks to marks indicating the middle and edges of the disk cutter. Simply align the center mark with the drawn line, and the groove will be formed exactly in the right place.

Varieties

There are two main groups of such instruments that differ from each other:

- simple fillers (dowels);

- lamella (keyed).

In the first, the spindle with collet and cutter are located like a conventional router (like a chuck and drill in a drill), along the longitudinal axis of the tool. There are one- and two-spindle models. Single-spindle, according to the name, works with one cutter, like a regular router.

Two-spindle - in the image:

The advantage of such a tool is that two holes are made simultaneously with an absolutely precise distance between them. When the same two holes are made according to the markings on the second part of the furniture parts to be connected, they will absolutely exactly match in size between the holes and the dowels driven into them.

Also, longitudinal grooves are selected with such cutters. To drill holes, they are inserted into the workpiece in one position. To select a groove, the router is moved along the workpiece to the required length.

The second type of milling cutter (lamella) uses a disk cutter, which is located like a disk in an angle grinder (angle grinder), at 90 degrees to the longitudinal axis of the tool.

The image shows a lamellar router and the result of its work:

The power of filler milling machines of all types is on average 500W - 800W. This is quite enough to solve such problems.

Main technical characteristics

Tool end

The choice of filler milling cutter model depends on the planned scope of work. Professional tools of this type are designed for heavy loads, which do not affect the quality of processing of wooden workpieces. But at the same time, their cost relative to household models is high.

One of the indicators of the tool is the ability to quickly adjust milling parameters - changing the angle of inclination of cutting components, adjusting the offset of cutters. Since this tool belongs to the manual category, the weight of the entire structure must be taken into account. The quality of processing and the complexity of further furniture assembly depend on the accuracy of positioning.

In addition to these parameters, when choosing filler milling cutters, the following must be taken into account:

- drilling depth. Typically this parameter varies from 0 to 40 mm depending on the tool model;

- The angle of inclination of the working part can be from 45° to 90°;

- cutter rotation speed. Since the tool is quite small, it does not have a mechanism for changing the rotation speed;

- electric motor power consumption rarely exceeds 1 kW;

- landing diameter for cutters;

- maximum cutter diameter.

As an example, we suggest watching a video review of a professional filler milling machine:

Which to choose

For a small workshop, for the home the most rational option is Interskol FMS 12 710 .

The first products released around 2011 were raw and unfinished. The entire batch of goods was not defective, but there were some milling cutters with defects. Since 2012, Interskol has increased the warranty on its products to 2 years. The tool was refined and weak points were eliminated. However, when purchasing, you must fill out a warranty card and keep receipts. If, nevertheless, you come across a substandard specimen with a violation of the alignment of the cutters, it can be replaced.

For production where a filler mill is required every day and works for many hours, the best option from the 5 above is Mafell DDF40 maximax im t max 918602 . It is expensive, but any industrial equipment is not cheap. When you need to work, and not adapt to the features of a low-quality tool, a completely German router is best suited.

In large productions, an expensive tool always pays for itself many times over. And there is a rule - it is better to buy a reliable tool once than to buy a low-quality cheap one several times.

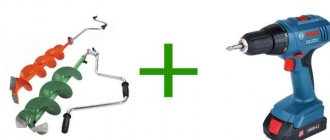

For very small volumes or one-time work, holes for dowels can be drilled with a drill or a regular router. In this case, the most important thing will be accurate markings and compliance with them when drilling.

The best dowel lamellar routers

This type of dowel milling cutter is distinguished by the presence of one cutter, which, in addition to depth, also goes along the sides. This allows you not only to create round holes for dowels, but also longitudinal grooves of various widths for domino connections. The machines are in demand in the manufacture of wooden gratings and bedroom furniture.

Festool DOMINO DF 500 Q-Set - economical and reliable

This dowel router is best for all-day professional shelving and other building projects as it only consumes 420 watts. But at the same time, the car develops 25,500 rpm at idle.

The diameter of the cutters can vary from 5 to 10 mm (the smallest cutter is already included in the kit). The set contains various attachments on the sole for miter milling or even making holes in the ends of the bars.

Pros:

- the ability to work in various spatial positions thanks to the compact size of the machine and the base with markings on the reverse side;

- convenient stop handle for directing the longitudinal stroke of the tool;

- glass window with markings for precise installation of the tool along the drawn lines;

- convenient step switch for the cutter stroke width to quickly create grooves of various sizes;

- power 420 W;

- the system equipment is also suitable for other models of milling cutters from this company, if there is a need to expand the functionality;

- makes holes for standard dowels 4x20 or 10x50 mm;

- the housing has a built-in connector for dust removal;

- The set includes a stop square and a stop for the planks, a cross stop;

- milling depth 28 mm with quick setting of limit to 12/15/20/25 mm;

- low noise;

- The start button is on the top, so the device is suitable for both right-handers and left-handers.

Minuses:

- the cost of the set is from 74,000 rubles;

- without connection to a dust removal system, it is not effective, since chips quickly clog the grooves and vibration begins from the impact of the cutter;

- weight 3.2 kg;

- The cutter diameter is limited to 10 mm.

Makita PJ7000 - for thin grooves

This is the best dowel router for creating holes for narrow veneers, flat dowels and lamellas. They can embroider grooves up to 12 mm in height and give them any width. It can be held well with one hand, for which a U-shaped handle is provided.

The part of the body with the motor is made of plastic to lighten the weight. An aluminum casing is provided around the gearbox. The sole is cast from the same metal.

Pros:

- adjustable handle tilt depending on the operator’s needs;

- on the right side there is a pipe for connecting a dust collector;

- powerful wire with double protection;

- the height of the cutter approach and the angle relative to the plane are set and fixed quickly using two thumbs;

- clear scale on the main sole;

- six-stage depth setting with a maximum value of 20 mm;

- two clamps at 45 and 90 degrees;

- 710 W power ensures high performance regardless of the hardness of the wood;

- weight 2.5 kg lighter than most analogues;

- Idle speed 11000 per minute.

Minuses:

- cost from 18,000 rubles;

- the button is convenient for right-handers;

- The garbage disposal is not included.

Festool DOMINO XL DF 700 EQ-Plus – for very deep routing

When you need to assemble a frame structure, doors or windows, the best dowel router is the XL DF700 model.

The cutter stroke into the depth of the material is 70 mm, which will help to firmly connect the wooden parts. Only with such a machine can you use 140x14 mm tenons, which ensure the highest reliability of joining tabletops, furniture facades or trim bars.

Pros:

- high-precision milling principle thanks to patented technology;

- versatility for working in a spatial position (can also be used as a machine);

- two comfortable handles for high productivity;

- connecting a corrugated hose from a vacuum cleaner;

- the carved degree scale will not be erased over time;

- power 720 W;

- cutter rotation speed 21000 rpm;

- adjustable entry depth from 15 to 70 mm;

- possibility of changing the drilling height from 10 to 50 mm;

- with a corner connection, the angle varies from 0 to 90 degrees;

- Comes with a container and two drawers for stud storage.

Minuses:

cost from 94,000 rubles.

How to make a dowel milling cutter with your own hands

In principle, a conventional universal (vertical) router can perform the same tasks as a filler router. The difference is that a regular one has one spindle (cutter) and additional guides are required for precise positioning of the cutter.

The image shows a regular router with homemade guides for these purposes:

You can clearly see how a regular milling cutter is converted into an additive one in the following video:

Obtaining relief surfaces

Climbing with a milling cutter tilted approximately 10° in two directions ensures good surface quality and reliable performance. A ball nose or radius cutter will produce a surface with a specific ridge height, h, depending on:

- cutting width, ae

- feed per tooth, fz

Other important factors are the depth of cut, ap, which affects the cutting forces, and the tool runout indicator (TIR) reading. For optimal results:

- Use a high-precision hydroplastic chuck with a Coromant Capto connection

- Reduce tool overhang to a minimum

Roughing and semi-finishing

If the feed per tooth is much less than the width and depth of cut, then the resulting surface will have a much smaller height of ridges (transitions) in the feed direction.

Finishing and processing

The aim should be to achieve a smooth, symmetrical surface texture in all directions, which can then be easily polished regardless of the polishing method chosen.

This is achieved at fz ≈ ae.

For optimal surface texture, always use a two-flute angled cutter when finishing.

Semi-finishing with fz much smaller than ae Finishing with an inclined cutter at fz = ae

Profile milling performance: uniform allowance

A: Roughing B: Semi-finishing C: Finishing and finishing

Uniform allowance is one of the basic criteria for high and constant productivity in profile milling, especially high-speed milling.

To achieve maximum productivity in profile milling, which is common in mold making, it is important to adapt the cutter size to the specific operation. The main goal is to obtain an evenly distributed allowance to ensure consistency in the magnitude and direction of the cutting force

It often makes sense to work with different cutter sizes, moving from larger to smaller diameter tools, especially in light roughing and semi-finishing operations, rather than using just one cutter diameter for each operation.

- Optimal quality in finishing is achieved when, after previous operations, a minimum and uniform residual allowance is achieved

- The main task of profile milling is to ensure that the machined surface matches the specified parameters as accurately as possible.

- Safe cutting process

Advantages of uniform stocking

- Some semi-finishing and virtually all finishing operations can be performed with little or no operator intervention

- The impact on machine guides, ball screws and spindle bearings will be less negative

Machining a cavity in a solid material

When machining a cavity, it is important to choose a method that keeps ap to a minimum and the allowance for subsequent profile milling to be uniform. Shoulder/end mills and long-edge cutters leave a step allowance that must be removed. In this case, changing cutting forces and tool deflection occur.

The result is an uneven finishing allowance that affects the geometric accuracy of the machined surface. Round insert cutters create smooth transitions between passes and leave a smaller, more uniform allowance for profiling, thereby producing higher quality parts. The third alternative is to use high-performance cutter for cavity processing. This also results in a smaller and uniform allowance (with small differences in the height of the steps) - thanks to the small cutting depth

Cutter for processing rectangular shoulders, leaves an uneven allowance of greater thickness

Cutter with round inserts, leaves a small allowance

High-performance cutter, leaves a small allowance

Heavyweight Festool DF 700 EQ-Plus

This unit is distinguished by an ergonomic body, the internal mechanism of which is reliably hidden from mechanical damage. The large weight of the power tool is due to its technical equipment and operational functionality. Milling accuracy is at the level of proprietary technologies. At the same time, the absence of recoil and vibration reduces the likelihood of getting defective. The device belongs to the expensive price segment.

Advantages:

- professional type;

- power 720 W;

- productivity 21000 rpm;

- soft start option to prevent workpiece defects;

- for all types of wood;

- maximum milling depth 70 mm;

- when under load, constant speed is maintained;

- fixed spindle for easy replacement of cutters;

- works with 8, 10, 12 and 14 mm cutters;

- a movable step stop 10 – 40 mm is provided;

- you can connect a vacuum cleaner;

- Includes 2 support squares.

Flaws:

- no carrying case;

- weighs 5.2 kg;

- cost from 95,000 rub.

Profile Milling Checklist

To correctly select the tool and the optimal processing method, you should carefully study the profile of the part:

- Determine the minimum radii and maximum depth of cavities

- Estimate the volume of material removed

- To avoid vibration, check the tool assembly and workpiece clamping. To obtain good geometric accuracy of the profile, all machining must be performed on optimized machines

- The use of separate, high-precision finishing machines reduces and sometimes eliminates the need for labor-intensive hand polishing

- Higher level programming may be required to achieve significant savings. Use solid carbide end mills and high cutting speeds to achieve close-to-spec shapes and the highest quality possible.

- Roughing and semi-finishing of large parts is usually most productive using conventional methods and tools. The exception is aluminum, which also uses high cutting speeds for roughing.

What is

Several decades ago, wooden furniture elements were fixed to each other using tenon joints. However, during the period of widespread use of board materials, such as chipboard, MDF, there was a need to create a more reliable fastening method. The problem that arose was due to the need to mark a large number of holes to combine the elements. Without the use of a furniture additive machine, it is quite difficult to implement it - the time costs increase many times over. To ensure that all measurements are accurate, an additive card is installed in the device. This is a special drawing on which the points where the holes are supposed to be made are located in appropriate places.

Varieties All furniture machines are divided into several groups in accordance with different characteristics and criteria:

- appointment;

- number of spindles and traverse;

- number of drilling heads.

Each type of device has certain characteristics. The choice of equipment depends on the needs of the master, furniture configuration and production volumes.

By purpose

All devices for furniture production can be divided into two large groups:

- Universal machines. They are used not only for creating holes, but also for their subsequent processing. In mass industry, this type of equipment is used, since it combines many capabilities at the same time. Instances of low productivity and small size are perfect for beginners in this craft.

- Specialized devices. They are mainly used on conveyors, so one machine is capable of processing several parts together. Can be easily customized for different use scenarios. Most of the filler devices fall into this category.

Methods for creating antique furniture with your own hands, drawings and diagrams. There are also special mechanisms that are used exclusively for processing blanks of the same type. They cannot be reconfigured for other sizes and configurations.

Universal

Specialized

By number of spindles and traverse

According to this criterion, machines can be classified into:

- semi-automatic;

- positional;

- with programmable settings;

- additive mechanisms for hinges.

The most common are positioning machines, as they are easy to operate and reliable.

Semi-automatic

Positional

With automatic settings

For loops

By number of drill heads

A homemade furniture additive machine can have a different number of heads installed. Depending on this, the operating principle of the device changes significantly. Designs with a single head differ in that the workpiece must be clamped by pistons on a special table, and also correspond to the direction of the ruler. This was done to ensure that the part was positioned as needed. When the motor is turned on, the head moves towards the workpiece. Then the person, using the controls, releases the clamps and, if necessary, replaces one part with another. Due to the fact that the spindles move at an angle of 90°, high functionality of the installation is achieved. This makes it possible to select grooves and process beveled sides, which is why these devices are used in small companies with a low flow of parts.

Machines with multiple heads have different attachments: one for edge processing and several for drilling. A support is installed on the frame, which serves to fasten the part. The workpiece is placed on special strips and then clamped with clamps. When the engine is running, all heads work. Additionally, speed and position regulators are installed, which makes the equipment very expensive.

Single head

Multi-spindle

Interskol FMP 12/1000E: opening in 2022

If the previous model does not have enough power for you, then the new product of the Russian brand surpasses it in this indicator. The milling cutter, in high-precision mode, makes paired holes for round dowels at a standard distance between the axes of the cutters. In comparison with foreign analogues, the budget device is devoid of some of their disadvantages. So, you can pre-set the distance from the edge to the axis or the edges themselves, which are not necessarily located at a right angle. This location is maintained even during serial operation.

Advantages:

- professional equipment;

- works with soft and hard woods;

- power 1000 W;

- productivity 18500 rpm;

- milling at a depth of up to 43 mm;

- for cutters with a diameter of 5 – 12 mm with a collet of 8 mm;

- transparent window on the depth gauge stop for good

- visibility of markings;

- clear symbols and scales;

- the emphasis is adjustable;

- the spindles are fixed;

- the presence of a stepped template for step accuracy;

- adapter for connecting a vacuum cleaner;

- maintaining weight at 3.6 kg;

- average cost 15,000 rub.

Flaws:

At the moment the model is not widely available for sale.