A screw is a product belonging to the category of threaded fasteners. Its appearance is approximately the same as that of a bolt, but these connecting parts differ in the preferred installation method. So, if a bolt is most often used together with a nut, then a screw is used mainly as an independent fastening device. In terms of design, it looks like a rod with threads rolled along its entire length or on some part. The transmission of torque is carried out, as stated in GOST 27017-86, by a special structural element placed at one of the ends of the rod. This can be a flat round head with side notches or a hat with a slot. It is also possible to make screws without a cap/head. But then there must be a slot at the end of the rod.

Main types of bolts

In accordance with GOST 27017-86 “Fastening products. Terms and definitions "bolt" is a fastener in the form of a rod with an external thread at one end, with a head at the other, forming a connection using a nut or threaded hole in one of the connected products. Note that a screw receives a similar definition in the standard: a fastener for forming a connection or fixation, made in the form of a rod with an external thread at one end and a structural element for transmitting torque at the other.

There is still no complete clarity on the question of how a bolt differs from a screw. For example, a bolt is sometimes considered to have an incomplete thread, although there are bolts with full threads. If the thread is not made along the entire length of the bolt, then the diameter of the smooth part of the rod is approximately the same as the diameter of the thread measured at the tops of its turns. But there are also exceptions.

Sometimes they say that a bolt must have a hex head. But, at the same time, bolts are products with a semicircular and countersunk head. Let's look at the most popular bolt options available in the TsKI assortment.

The hex head is produced in several modifications: basic, with a support ledge, with a collar, with a flange.

Bolts with hexagonal head and main thread are divided into bolts with full (DIN 933) and partial thread (DIN 931) and fine and ultra-fine thread pitch (DIN 960 and DIN 961).

Separately, hex head bolts with an increased spanner size are available for highly loaded prestressed threaded connections in steel structures DIN 6914.

Bolts with a reduced wrench size are available in a variety of designs.

Along with hex heads, bolts can have a semicircular head:

low with square head (DIN 603) with mustache (DIN 607)

And the secret head:

with mustache (DIN 604) with high and low square head (DIN 608)

The definition of “furniture” is consistently applied to such bolts. This is partly due to the fact that some of them are widely used in furniture production. At the same time, the mustache and headrests prevent the product from turning during assembly.

Examples of bolts called by purpose are “hinged” and “welded”.

Instead of the usual head, the DIN 444 hinged bolt has a bushing with a through hole - it is also called a ring. Typically, the bushing sits on an axle and the bolt rotates around it. The thickness of the ring and the length of the thread in the design may vary.

A welded bolt looks little like a bolt at all. In place of his head there is a small cylindrical protrusion. Often this product is also called a welded pin.

It is he who ensures butt welding of the bolt and the base. Instead of a threaded cylinder, other external elements can be welded.

The formal name “bolt” also includes anchor and fitting bolts.

Anchor bolts are designed to be embedded in concrete. Their rod has a thread at one end - the one that goes out. The shape of the other end may vary.

Its task is to provide maximum resistance to the anchor being pulled out from the base. Therefore, the second end is given an expanding shape. When installing the bolt, this part is lowered into the hole and filled with concrete.

A fit bolt is a bolt whose diameter of the smooth part of the rod allows it to be installed without a gap in a precisely machined hole. For this purpose, the threaded part is made of a deliberately smaller diameter.

A “fit” bolt DIN 609 is a distortion of “precision”, that is, high accuracy. Also used as fitting bolts are “Bolts with a hexagonal reduced head of accuracy class A for holes from under the reamer. GOST 7817-80".

Tightening fasteners on alloy wheels

If during installation you encounter a problem with the size of the bolts on the wheel disc not matching, you can solve it by purchasing eccentric bolts (having a movable cone). For example, if the PCD size in the discs is 97 mm, and 99 mm is required, the eccentrics will compensate for this value due to the cone that is on the product. The presence of a minimum distance between the internal fit and the outer diameter of the element will provide the possibility of movement, indicated on the product with the word Variation.

When you select connections for wheels with alloy wheels, pay attention to the size of the threaded surface of the products that are screwed into the hub. If the number of turns is less than 10 mm or 6 threads, you should buy a larger product, as short bolts significantly reduce the reliability of wheel installation

Screw classification

Let us now consider the screws available in the TsKI assortment. The largest group of them are general purpose screws. We meet them every day in everyday life and at work. They all have a fully threaded shaft (although there are exceptions) and different shaped heads. The heads have slots or recesses for different types of keys.

- Screw with a cylindrical head (actually slightly beveled to a cone) and a straight slot DIN 84.

- Pan head screw with straight slot DIN 85.

- ISO 7380 Pan Head Hex Socket Screw.

- Round head screw with shoulder and hexagonal socket ISO7380 version. 2.

- Socket head screw with sphere and Phillips recess Pz, Ph DIN 7985.

- Pan head screw with sphere, radial holes and straight slot. Sealing, DIN 404.

- Countersunk head screw with straight slot DIN 963.

- Countersunk Phillips head screw DIN 965.

- Countersunk hex socket head screw DIN 7991.

- Slotted head screw DIN 964.

- Semi-countersunk Phillips head screw DIN 966.

- Oversized flat head screw with straight slot DIN 921.

- Screw with a semicircular low head, with a collar and a cross-shaped combination slot.

- Hex socket head screw DIN 912.

- Low socket head screw with hexagon socket DIN 7984.

- Low socket head screw with hex socket and key guide DIN 6912.

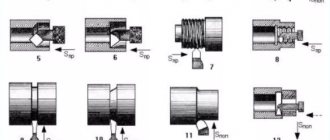

Another large group of screws are set screws. The name comes from their purpose. For the most part, they are designed for precise installation and fixation of parts in mechanisms. To do this, they have various protrusions or recesses at their ends.

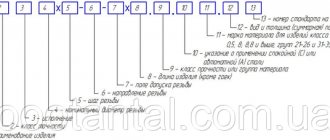

According to GOST 12414-94 (ISO 4753:1999): “Ends of bolts, screws and studs. Dimensions" the following setscrew ends are provided:

The torque is driven by the following elements:

The summary table shows the actual, most common combinations of setscrew heads and ends, indicating the DIN standard.

| Conical | Flat | Cylindrical | Drilled | |

| Straight spline | DIN 553 | DIN 551 | DIN 417 | DIN 438 |

| Hexagonal with key socket | DIN 914 | DIN 913 | DIN 915 | DIN 916 |

Furniture screws are presented in two products:

- a screw for furniture handles with a semicircular head, a shoulder and a combined slot;

- furniture screw with a flat head and a hexagonal socket:

A group of screws has different types of hook and loop heads:

- hook screw

- loop screw

- L-hook screw

- spiral hook screw (twisted)

The wing screw DIN 316 is available in two modifications, differing in the shape of the wings. The more pointed ones belong to the so-called. "American" form.

Classic thumbscrew “American” form of thumbscrew

The DIN 7516 thread cutting screw has a tap-like end with which it cuts metric threads in a pre-drilled hole.

As for the heads, there are quite a lot of them used:

- AE – cylindrical head with a sphere and a cross-shaped slot;

- DE – countersunk head with a cross-shaped slot;

- EE – semi-countersunk head with a cross-shaped slot;

- A – hexagonal head;

- BE – cylindrical head with straight slot;

- FE – countersunk head with straight slot;

- GE – semi-countersunk head with a straight slot.

Another screw that independently forms a thread - DIN 7500 extrudes it in the initially applied smooth hole. This is convenient when installing products with one-way access and significantly increases the connection density, especially with a metal sheet. Its end has the shape of a triangular rod with a leading part and a smooth thread run-out.

What is a screw?

A screw, like a self-tapping screw, is a cylindrical rod with different types of heads and external threads. Designed for attaching various elements to soft bases. It has a head and a cylindrical part, which is partially covered with threads, which makes it different from a self-tapping screw.

When screwing in a screw, it is necessary to drill a hole with a diameter of up to 70% of the thickness of the screw. This is the main difference that shows how a screw differs from a self-tapping screw

When working with this fastener, it is important to select the diameter of the drill in order to properly connect materials. Screws provide a durable and, most often, non-separable connection of parts

Comparison

Outwardly, they may be very similar, but they have quite a lot of signs of difference:

- The technology for making self-tapping screws is much more complex. For the production of self-tapping screws, for example, only high-quality and durable steel alloys are needed, which undergo further heat treatment. In other words, this fastener is made from hardened steel.

- In order to screw a screw, you must first make a hole on the surface. The self-tapping screw can be attached without such preparatory work, which significantly simplifies the fastening process.

- The strength of self-tapping screws is the reason for a wide range of applications. For example, products are used as fasteners for a wide variety of materials, including wood, plastic, metal and even concrete.

- The screw has a smaller height and thread pitch. This directly affects the versatility of the product and the technology of the work performed. In this regard, the self-tapping screw has a noticeable advantage.

- In most cases, you can notice another significant difference: the end of the screw is noticeably sharper. Although some screws can also be found with a sharp end.