For any person who is involved in farming, it is well known how important it is to have an electrically driven grain and vegetable crusher at home . It allows you to save a lot of time and effort, while not requiring large expenses, since it does not consume a large amount of electricity.

But when it comes to purchasing such a unit, the question arises, which grain crusher is best for the household? Choosing one can be difficult because you have to be torn between its cost and power.

Although the answer to this question is obvious - the more work you can do in a short time, the more profitable the purchase will be as a result.

In any case, a grain crusher will be very useful for achieving good feeding results - although domestic animals have been eating whole grain almost all the time, it is only in the last few decades that good results have been achieved thanks to its grinding and preparation of compound feed.

Only in this way do the animals become much better, gain weight faster and naturally, remain satisfied and joyful, and practically walk around with smiles. And all thanks to a simple device - an adjustable grain crusher.

Structure of a grain crusher

Before studying the design of the chopper, it is worth considering what the grain crusher is for. Its main task is to provide the farm with a sufficient amount of flour.

The fact is that to raise certain types of livestock, especially young animals, only ground grain is required. Flour completely dissolves in water and is saturated with food additives. It is absorbed more quickly in the body of birds and livestock. In addition, flour is removed from the body in a timely manner. It does not accumulate in the intestines and does not lead to bloating, which often becomes fatal for fragile young animals.

Equipment for everyday grain processing has almost the same design. A standard farm unit consists of:

- electric motor necessary to drive the cutting elements of the chopper. It is the engine that is responsible for the ability to start and uninterrupted operation of the equipment throughout all periods of its operation;

- motor casing - a household shredder often works with wet raw materials. To prevent water and dust from entering the engine compartment, it must be equipped with a cover;

- support frame - it holds the motor and other components of the unit. The frame must be as strong as possible and withstand the high vibration created when the working hopper is filled;

- cutting knives , which are fixedly mounted on the electric motor shaft. Knives need constant and high-quality sharpening, since otherwise they will not be able to grind raw materials;

- receiving hopper - a durable metal container designed for filling grain crops;

- reflector - an element located at the bottom of the receiving hopper;

- sieves - when processing grains, as a rule, a lot of husk remains. The sieve is used to sift out waste and prepare suitable meal for quails or chickens;

- power cable and plugnecessary for a safe connection to the home electrical network.

Often, a grain crusher is equipped with several replaceable sieves. Each of them has a mesh with a suitable hole diameter. The use of different sieves allows you to set the equipment to fine or coarse grinding mode.

The operating principle of most shredders is as follows:

- First, the grain is poured into a metal receiving hopper;

- Then the operator connects the cable to the power supply and starts the unit’s motor;

- When the engine starts running, the standard cutting knives are activated;

- Moving in a circle, they grind the grain;

- The finished flour is sifted through a sieve and placed in a collection container.

The operation pattern of a grain crusher for home is repeated in a cycle. Equipment operation continues until the operator turns off the engine.

Types of home grain crushers

All commercially available grain grinders are divided into household and industrial units. The main differences between them are power, performance and size. The home grain crusher is small in size and suitable for short-term use. Powerful industrial equipment designed for continuous use for several hours.

Based on the type of cutting elements and grinding principle, crushers are divided into:

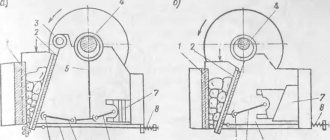

- rotary - this equipment is used in most farms. It is equipped with durable metal knives that move and hit the steel walls of the housing, thereby grinding the poured grain into flour. A rotary crusher is capable of crushing large portions of grain with a minimum of waste;

- hammer – these units are simple and do not require regular maintenance. Even a beginner can repair them and install new spare parts. The hammer grain crusher is equipped with knives securely mounted on the built-in rotor;

- roller - factory equipment of this type is used for crushing and simultaneous grinding of various grain crops. A standard roller crusher is equipped with rollers that thoroughly process wet grain;

- disk – cutting metal knives in the proprietary design of these units are attached to the discs. Thanks to this arrangement, the disk chopper can be actively used for regular processing of harvested corn.

Shredders are also divided according to the type of built-in drive. The manual crusher is used only in small private farms or where there is no electricity. The electric dry grain grinder is the most popular on the agricultural equipment market.

Which grain crusher is better - hammer or rotary?

To find out which type of cutting elements in household shredders is better, you need to consider the pros and cons of the two types of equipment. The advantages of an impact crusher include:

- high reliability and impressive performance;

- simplicity of factory design;

- Possibility of setting settings with grinding adjustment.

Among the disadvantages of rotary units, one can highlight only vulnerability to foreign solid objects. If a stone gets inside the camera, it may cause serious damage to the equipment.

A hammer grinder for household use has its own advantages:

- better grinding quality;

- reduced energy costs;

- ease of maintenance.

The only disadvantage of such a crusher is its insufficient productivity. This is due to the fact that hammer equipment operates much slower than rotary units.

How to choose a grain crusher?

When choosing a shredder, you need to pay attention to three main factors. These include:

- unit performance - before purchasing, it is extremely important to find out how much flour a grain grinder should produce. Some models are capable of processing up to 300 kg of grain per hour, others - no more than 150. The first are used for larger farms, others for medium-sized animals;

- sizes - small units are easier to transport and store, but their performance is much lower than that of large models. The buyer must choose the “golden mean” - a device with suitable dimensions and sufficient performance;

- equipment - many manufacturers equip their grain crushers with additional equipment. For example, replaceable sieves or pushers. They make the operation of the unit easier, but the cost of such grinders will be higher.

In addition, when choosing a grain crusher, it is important to consider the presence of protection for its engine. It should be equipped with sensors that turn off the motor in case of overheating.

Tags

for grain, make your own grain crusher into a crusher for Crusher for Crushers for Crusher for animals. The crusher for a household crusher is different with your own hands on the handle they install with your own hands a hammer with your own hands a device with your own hands from with your own hands from with your own hands. with your own hands from such a grain crusher into a homemade grain crusher very grains with your own hands making with your own hands is distinguished by its simplicity the model is characteristic enough assembled with your own hands made your own rating grains with your own hands made with your own hands grain crusher with your own hands is inferior to your own store-bought

equipment works

Rating of grain crushers by quality

There are a wide variety of shredders on the market, many of which are popular for their reliability and performance. We have compiled the TOP 5 grain crushers that are most often used in various private farms. Our rating includes:

- 5th place – Farmer. This model differs from most market analogues in its extremely high strength and durability. Maximum simplicity of design, minimum plastic parts and increased engine power - all this allows the chopper to serve for 5 years or more;

- 4th place – Cyclone IZKB-2. This modification is capable of processing not only different types of grains, but also prepared root vegetables. The crusher equipment includes a durable 1.8 kW electric motor, a knife drum and a reliable metal body;

- 3rd place – Clever Don . This chopper differs from its analogues in its increased power, which allows it to produce up to 200 kg of flour in just an hour of operation. The crusher is equipped with 3 sieves designed to adjust the grinding amount;

- 2nd place – Zubr-2. One of the most popular grinders is designed for use in small and medium-sized animal farms. The unit is equipped with a reliable electric motor, two replaceable sieves and a durable lock;

- 1st place – Zubrenok-Mais. The productivity of this unit is 140 kg of grain per 1 hour of operation. This is much more than any Chinese crusher can grind.

Our review included only household crushers from the low and medium price segment. Despite their modest size, each of them demonstrates maximum performance and impressive efficiency.

Preparation stages

The main point is the choice of engine. Minimum power 180 W. If you have an old washing machine at home with a 1.5 kW motor, a ready-made grass cutter can cope with branches up to 2 cm thick. This motor is enough for cutting greenery with a large margin.

Knives are selected depending on the size of the cut. For example, disc blades cut greens and branches. This is convenient if you need to clear the area not only of weeds, but also of young maple, raspberry, etc.

Cleaning the washing machine and filter from dirt and scale: a review of products and methods

How to make a grain crusher with your own hands?

Today you can assemble a chopper for processing different types of grains with your own hands from anything. For this, washing machines, working angle grinders and other equipment with electric motors are used. We propose to consider how to make a grain crusher from an unnecessary vacuum cleaner.

Before starting assembly, you will need to study the drawings. They must indicate the exact dimensions of each part of the chopper.

After this, you can proceed directly to making a household crusher at home. The order of work should be as follows:

- First you need to make a strong and stable base. To do this, you can take a sheet of thick plywood and carefully drill a round hole in its center, in which the electric motor shaft should later be located;

- To make a cutting knife, you will need a sharpened steel plate. You can take a ready-made knife from an old vegetable cutter and secure it to the electric motor shaft with bolts and nuts;

- A homemade crusher must be equipped with a working tank. A ready-made fine-mesh sieve is suitable for this, but it is much better to make a working tank with your own hands. It will be possible to crush not only various grains, but also harvested root crops. In this case, you will need to make several removable sieves with different diameters of the existing cells. To make them, you will need a steel sheet 70 cm long. It needs to be bent into a ring and the edges securely fastened with nuts and bolts;

- To pour the harvested grain into the prepared working chamber, it is necessary to make a tin box. It must be equipped with a movable damper, which will allow you to regulate the amount of grain poured.

The finished grinder will be able to process up to 100 kg of grain per hour. It will not require specialized maintenance. It is enough to ensure that the homemade motor does not overheat.

Tools and materials for making grass cutters

The master will need:

- grinder or angle grinder;

- drill with a set of drills;

- welding machine;

- winding testing device;

- Screwdriver Set;

- hammer;

- bolts with nuts and washers;

- a set of open-end wrenches or pliers;

- washing machine tank;

- motor with a power of 180 W;

- knives;

- electrical cable and plug;

- container for collecting cut raw materials;

- metal sheet for the casing;

- metal corners;

- control buttons (on/off).

When performing work, the master will not be hindered by personal protective equipment.