A circular saw, or simply a circular saw, is the most necessary equipment, primarily for independent wooden construction. If you buy rough sawn timber at a sawmill, condition it and cut it into long lengths yourself using a circular saw, the estimated cost of construction literally drops significantly. A circular saw is also necessary for various types of finishing work, for those who like to tinker, and it will be useful just around the house. A factory-made stationary circular saw is very, very expensive, but it is quite suitable for household needs or, say, building a shed, it can be built from scrap trash; only a few turned parts will have to be ordered externally. This article describes how to make a stationary circular saw with your own hands, how to adapt it for jointing and sawing across or at an angle, and also describes homemade accessories for using a manual circular saw as a stationary one.

Do-it-yourself circular: how to properly assemble a functional device

During the construction of a new house, when wood material is used in large quantities, a homemade circular saw will not be enough. And such a device will require more functionality. But when performing minor repairs, a homemade homemade circular saw becomes an indispensable technical assistant. We will tell you how to make a circular machine with your own hands in this article. Stationary circular saw: popular models (read more)

A DIY circular saw allows you to carry out safe work and speed up the construction process.

Quite often, the dimensions of wooden elements are determined directly during the work. The ability to independently provide the process with the necessary materials significantly saves money and time. And often the quality of wooden blanks is guaranteed to be higher.

Using a homemade homemade circular saw, you can cut boards into bars, make planks, slats, trim blanks, saw slabs of wood materials into fragments of the required sizes.

Using a homemade circular saw, you can make such types of furniture as a table, shelf, rack. A similar stationary home tool is applicable when creating wooden sports equipment, making containers, etc.

When installing a disk with certain technical characteristics on a sawing machine, the mechanism can be used as a circular saw for metal. It is allowed to saw soft aluminum and sheets of other types of metal, the thickness of which does not exceed 2 mm. When working with thicker material, the mechanism will overheat, triggering an automatic shutdown.

For harvesting firewood and simply cutting pieces of wood, a firmly fixed table with a slot for a saw is enough.

Manual with gauge

A home craftsman rarely has to cut deeply and “long”, and a hand-held circular saw is a useful thing in itself. In addition, with a hand-held circular saw with a guide rail, you can cut wood both across and along the grain, and at any angle. And a cutting length of up to 1.5-2 m is quite enough for almost all finishing works and embodied creativity.

There are enough reisshins for manual circular saws on sale, and they are inexpensive, but there is no universal one. The principle of the construction of a branded rod is illustrated in the figure: the base plate (shoe) of the saw is made with a longitudinal groove, and the rod is stamped accordingly. comb (shown by the arrow in the figure).

Using a hand-held circular saw with a guide rail

It’s convenient to work with: you only need to press the tool from above, and it won’t go sideways or become skewed. And it’s also convenient during competition: we make our saws so that they don’t sit on the guides of our “partners.”

It’s inconvenient for craftsmen - you can’t find a cheaper tire. And a circular saw with a groove for the guide is disproportionately expensive compared to the same one, but with a smooth shoe. Amateurs do the opposite: a crossbar with a groove made of laminated plywood, and a pair of bosses are attached to the shoe (item 2b in the large figure at the beginning). But for this, firstly, you need a wood milling table, which you still need to make (not easy) or buy (expensive). Secondly, the already small cutting depth is reduced by 16-20 mm. Thirdly, if the tool is still under warranty, then drilling holes in the shoe will void the warranty. Fourthly, if the saw is rental, then nothing can be modified in it.

There is another way, but the tool will need to be held in 3 planes during operation: pressing, from moving to the side and from turning. In this case, the plywood base of the guide can be thinner, 6-8 mm. The actual crossbar will be a flat strip (or a piece of steel angle, etc.) attached to it, see next. rice.:

How to make your own guide for a manual circular saw

“Setting up” the device comes down to simply cutting off the excess from the base with a circular saw. This guide is attached to the board/sheet of material with clamps, just like the branded one. When working on a workbench, spacers with a thickness slightly larger than that of the material are placed under the base; depth of cut from this resp. decreases.

How to make a circular saw with your own hands: preparatory stages of work

Before putting an end to the question of the advisability of making a circular saw yourself, you need to get acquainted with several similar devices firsthand and watch videos on the Internet. During observations and inspections, special attention should be paid to the main elements, parts, and methods of fastening. To understand how to make a circular, you need at least theoretical knowledge.

The manufacturing process can be implemented in two ways:

- a set of elements for the future design is available, you just need to complete the assembly;

- The components of the circular must be purchased.

In the case of the latter option, the task becomes somewhat more complicated, since parts and mechanisms are most often purchased in different places, but they must comply with technical and functional characteristics.

Scheme for making a circular saw with your own hands.

On a note! It is necessary to purchase elements for the future design of the circular only after a detailed installation drawing has been developed.

Without a drawing, it is impossible to take into account the dimensions of the elements and select a complete set. Quite often, this stage (drawing work) is omitted by home craftsmen due to lack of execution skills. There is no need to do this, since it is quite enough to draw a saw. At a minimum, this will allow you to visualize the future unit. Imagining what the end result will be is extremely important.

Only after you have a drawing or sketch and all the necessary elements, you can proceed directly to the assembly process.

Disk speed and security

Without ensuring high speed of the toothed disk, it is impossible to guarantee the quality of the cut. However, for homemade equipment operated in a home workshop, safety during operation is no less important.

It is necessary to provide protective devices that are traditionally equipped with industrial designs. The opinion that one can completely do without such protection at home does not stand up to criticism.

TB rules are “written in blood.” All it takes is one awkward movement to end up on the surgeon's table. Therefore, security should be given the utmost attention.

Design elements of a self-made wood sawing machine

To make a stationary machine for sawing materials at home, you first need to know what structural elements it consists of. Whether it’s a homemade machine made from a manual circular saw, a grinder, or a tool assembled from disparate elements, the set of basic parts is the same.

The surface of the table must be made smooth for a higher quality product at the output.

The main elements of stationary circular installations are:

- Table for connecting and securing mechanisms. If the circular saw is powerful and massive, it is better to use a metal table. Options made from chipboard, wood, plywood are suitable, the main thing is that the surface is smooth.

- Shaft. The most important detail. When making it, a lathe is used separately. The dimensions should be calculated accurately to avoid runouts.

- Casing. This element ensures safe use of the circular saw.

- Engine. When using a grinder or circular saw, it is part of the power tool.

On a note! If the design is supposed to be prefabricated, then when creating a circular machine with your own hands, the engine from a washing machine will be the most successful option.

The design of the circular must necessarily have moving parts of the drives, and a button must be built into the power supply circuit to stop the engine in emergency situations.

Circulars of any fixed type consist of main parts.

Main parameters - calculation of power, speed, gear

The characteristics of the circular saw, the engine and the maximum thickness of lumber that can be cut are interconnected. The maximum speed for which it is designed is indicated on the purchased circular disk. The number of revolutions transmitted by the engine to the shaft should be less. The engine power affects the maximum permissible saw tooth diameter. The diameter must be at least three times the thickness of the material, otherwise sawing will be difficult. It is believed that to cut materials 100 mm thick, you need a motor of at least 1 kW of power.

The transmission is made only by a V-belt - if foreign objects get under the saw, the material jams, the belt slips on the pulleys. Injuries in such cases are practically eliminated. It is important to choose the right gear ratio. We take into account two indicators: engine speed and the maximum permissible speed of the circular saw. We calculate the required pulley diameters. A pulley with a large diameter is installed on the engine, and a smaller one on the circular shaft to increase the number of revolutions.

The revolutions of the shaft with a circular saw are as many times greater than the engine revolutions as the diameter of its pulley is smaller than the diameter of the pulley on the engine.

Determining the parameters of a homemade circular saw at home

The primary task is to choose the power of the future stationary circular machine. Typically, devices with a power of up to 850 W are recommended for home use. If you are planning not to carry out repair work, but to build, for example, a bathhouse or a summer house, as a result of which you will need to cut a lot of material, then you can use a 1250 W motor. A device with a higher rating is not recommended, since such powerful circular machines require not only a solid stand-table, but also fixing the latter to the floor by fastening or concreting.

An important characteristic is the cutting depth. In home devices, it should not exceed 8 cm. In fact, this indicator is quite enough for sawing boards, plywood or wood boards.

When making a mini-circular saw or a full-scale sawing structure with your own hands, be sure to take into account the rotation speed. If you just plan to cut boards to make certain wooden elements, then you can limit yourself to a motor with a low or medium frequency. If you need perfectly smooth and clean cuts, it is better to use a high-speed motor. The optimal indicator for a home power tool is considered to be 4500 rpm.

For a circular machine, you can use a motor from a washing machine.

Be sure to take into account the height at which the start button will be located. Its location should be convenient for pressing.

Note! The control panel of a homemade circular saw must be accessible.

Kinds

Do not think that mini saws are represented by only one standard model.

In fact, you can find many different types of this instrument on sale today. It will be possible to choose the ideal option for any work. It is worth considering in detail what types of small circulars exist and how they differ from each other.

Manual

This instrument has a rather complex design and structure. As a rule, these types of tools are designed to work with fairly thin and pliable materials.

Using them, it is permissible to perform the following tasks:

- saw wood moving along the grain;

- sawing wood across the grain;

- cut various subtypes of wood (these include materials such as MDF, laminate and chipboard);

- cut metal with a thin and soft structure.

Such instruments have the following characteristic features:

- they have very modest sizes, making them easy to use and move from place to place;

- are distinguished by their low weight (this figure rarely exceeds 2 cm);

- as a rule, these models have low power;

- The saw blade size in hand saws is small;

- The cutting depth of this tool is also not very deep.

Disk

The mini circular saw also has a rather complex design. The main part of this tool is a disk designed for cutting various materials. This element has special teeth and is driven by starting an electric motor. Such tools are good because they are usually equipped with a number of additional functions that are very useful during certain work.

Such additions include the following:

- the ability to adjust the cutting depth - for this it is possible to shift the cutting half of the disk in relation to the thrust base of the device;

- removal of dust and chips - a number of tool models have a special connection required for connecting an industrial-type vacuum cleaner (this modification is especially relevant when it comes to large-scale repair work in order to prevent dust from settling on other pieces of furniture);

- protection against accidental shutdown - often to initiate a circular saw on wood you need to press two buttons in succession;

- continuous operation (without breaks) - this useful addition comes in handy if you plan to make fairly long cuts that take a lot of time.

Tabletop

Otherwise, such a circular saw is called stationary. It is multifunctional and very convenient to use. Moreover, such a machine can be made with your own hands, which is what many home craftsmen do. Of course, this unit will take up more free space, but it will also be more productive in its functions.

Rechargeable

Since modern high-capacity batteries have impressive dimensions, they hardly fit into the small body of a mini-circular. A capacious battery does not fit in this design. It is necessary to take into account the fact that the good thing about using these tools is that you don’t have to stay close to places where there are sources of electricity.

Rechargeable models are also good because their owner can stock up on an additional battery. The latter will make it possible to extend the operating time of the unit.

Manual circular as the basis of a homemade design

One of the most popular tools on the basis of which homemade saw structures are created at home is a circular saw (hand-held circular saw). This electric mechanism, using a round disk, makes straight cuts on wood materials, as well as on soft and thin metal. The tool is quite simple, it has all the basic elements that allow you to make a circular saw from a circular saw with your own hands.

The circular saw consists of the following parts:

- electric motor;

- one or two handles;

- protective casing;

A manual circular saw makes straight cuts on wood materials, as well as on soft and thin metal.

- holding platform (to allow disc alignment);

- riving knife (prevents the saw blade from getting stuck in the wood).

Manual circular saws stand out from other similar tools due to some technical features. For example, the depth and angle of cutting can be changed directly during work. Plunge-cut saws provide special capabilities. They can make isolated fragmentary cuts of the required size.

The accuracy and quality of sawing with a manual circular saw depend on the number of teeth on the disk and the angle of their sharpening. With a large number of teeth, the quality is higher, but productivity is slightly reduced.

When making a circular saw with your own hands from a hand-held circular saw, you need to pay special attention to the engine power. This is very important if you intend to perform significant amounts of work. The total weight of the saw also matters. Lightweight models are suitable for occasional sawing.

It is permissible to change the depth and angle of the cut directly during operation of the circular saw.

Advantages and disadvantages

Unfortunately, due to the high cost of a factory-made tool, which starts from 8,000 rubles, not everyone can afford to buy it. It is much cheaper and easier to make a circular saw with your own hands from a hand-held circular saw. Its manufacture does not require the use of special tools or special technical skills.

Read also: Make your own apple grater

The stationary circular saw is convenient for long-term use. The presence of a workbench reduces the load on the operator's back and reduces fatigue. In addition, if necessary, the hand-held circular saw can be quickly dismantled and used for its intended purpose.

The advantages of a stationary circular saw include:

- low cost;

- Ease of use;

- ability to work with long workpieces;

- cutting accuracy;

- versatility.

Despite all the positive qualities, a homemade circular saw has a number of disadvantages. Due to the limited diameter of the saw blade, it has a limitation in the depth of cut. In addition, such a machine is limited in terms of continuous operation, which is 15 - 20 minutes. This is due to insufficient ventilation of the tool's electric motor. This can lead to breakage of the current-collecting brushes and premature failure of the tool's electric motor.

Do-it-yourself stationary circular saw from a manual circular saw

The operational capabilities of a hand-held circular saw are significantly increased if it is converted into a stationary tool. To understand how to turn a manual circular saw into a stationary one, you should first understand the methods of rigidly attaching a power tool.

You can use metal or wood trestles as a stand. This can be either one or two products (if the sizes are small), connected to each other by boards with a thickness of at least 50 mm or bars with a similar cross-section. Next, you need to attach a tabletop to the top of the stand, which will serve as a bed.

For these purposes, it is convenient to use thick plywood (at least 10-12 mm) or two sheets of thinner material joined together, which together will give the same thickness. Panels made of particle boards or metal are also suitable. If the metal is thin, it is better to attach it to a wooden base.

The hand saw is installed from below. First, the necessary groove is made in the tabletop to extend the disk.

A tabletop needs to be attached to the top of the stand, which will act as a bed.

Note! It is necessary to fix the tool so that the saw blade is positioned strictly parallel to the cutting lines, that is, at the same distance from the sides. Otherwise, it will not be possible to correctly install additional devices and achieve high-quality cutting.

Using the above technical methods, you can make a circular saw from a grinder. But this hand-held power tool has certain differences, so a slightly different assembly scheme will be required.

Tool selection criteria

Before you start making a stationary machine for cutting wood, you should decide on the criteria for choosing a hand-held circular saw. These include:

- engine power. It must be selected depending on the planned work. A powerful saw will do an excellent job even with the hardest types of wood, but will have a lot of weight. For household use, circular saws with a power of 1 - 1.6 kW are suitable;

- cutting depth. Directly affects the performance of the tool. For infrequent household use, a saw with a cutting depth of 54 mm is suitable;

- disk rotation speed. The cleanliness of the cut depends on this criterion. The higher it is, the cleaner the cut is. It should be remembered that as the rotation speed increases, the cutting speed of the workpiece decreases. The average number of revolutions of the saw blade of a household saw is 4.5 – 5.5 min-1;

- additional functions. Important factors influencing the choice of a hand-held circular saw are the presence of a soft start system, protection against overloads and accidental start-up, as well as changes in the cutting angle.

Features of assembling a circular saw with your own hands from a grinder

Not every home workshop has a circular saw, but almost any owner who does certain household work with his own hands has a grinder. To create a stationary saw installation, you will also need a workbench or a special table; the tool will be attached from below, like a circular saw.

Attaching to the angle grinder is done using bolts.

But then the assembly process is somewhat more complicated. To make a circular grinder with your own hands, as practice shows, you need to think carefully about the option of attaching a hand tool to the frame.

This could be the following way:

- A metal band clamp is pulled on the grinder, the tie of which should be at the bottom.

- A strip of metal folded in half is attached to the holes for the sliding stop.

- Holes are made in the gearbox of the power tool. The body is first disassembled and drilling locations are marked.

- Using the holes made, an additionally manufactured axial handle is attached.

The handle can be made from a metal tube or rod. The workpiece needs to be shaped like a staple. In those places with which it will be attached to the gearbox, it is also necessary to make holes. Great and serious help for making a circular grinder with your own hands - drawings. They will allow you to correctly calculate the dimensions and number of elements, and prevent errors when calculating fastening locations. If it is difficult to complete the diagram of the future unit yourself, you can use ready-made drawings offered on the Internet.

To make a circular grinder from a grinder, you need to think carefully about the option of attaching the tool to the frame.

Drawing. The main stages of creating a jointer

Tabletop jointer - drawing

Tabletop jointing machine - drawing (part 2)

A jointing machine, its simplest version without additional functions, can be made quite easily with your own hands. The general progress of work in this case will look like this:

- first prepare all the necessary parts, tools and materials;

- We create a drawing of the future machine. Without this “document” you cannot start work. With the help of the drawing you can calculate all the nuances and prepare for them. In addition, having such a plan will greatly facilitate and simplify the task;

- Next, we transfer all the dimensions of future parts to the workpiece and manufacture them;

- A very important detail is the location for installing the rotor bearings. It is made from several pieces.

When fastening, glue and clamp are used. The recess should ideally fit the dimensions of the bearing;

- Next, we install the electric motor. To do this, as noted above, you can use a console mount, or install the unit on a skid;

- the next step will be to assemble the rotor with the bearing and install them in place. At the same time, a connection is made to the electric motor using a belt drive. Check that the rotor rotates freely in the bearing;

- Next, the work surface is assembled and installed. It will consist of two parts - the serving and the receiving. In this case, the second should be a couple of millimeters higher than the first. The working surface can be made of multi-layer plywood, and for greater strength and increased service life it can be covered with sheet iron.

After creating the system for turning the electric motor on and off, the machine is ready for use. But in order for your new tool to bring only benefit and joy to work, it is worth using it correctly and safely.

Possible options for small, DIY circular saws

Any stationary circular machine, even a homemade one, requires a fairly spacious workshop. The space should allow not only to install the unit itself, but also to place the workpieces intended for cutting in the desired position. If the task is not to cut large-sized wood, but simply, if necessary, you need to make your own slats or bars for repairing furniture, etc., it would be more rational to acquire a mini table saw.

You can make such a device yourself, using the same principles as when creating stationary machines from an angle grinder or a circular saw. Only the stand will not be a trestle, the support of which is the floor, but a frame on which a small table with a fixed hand tool is installed.

On a note! When making a circular saw of this type, it is important to take into account the overall height of the structure, that is, the plane on which the material intended for sawing will be located. Overestimating or underestimating the level will cause significant inconvenience.

A miniature machine is more functional and safer to use.

If you need to create a mini circular saw with your own hands to make very small workpieces (aircraft, ship modeling), you can assemble the tool using a PVC pipe as a body and borrowing an engine from children's toys. It is easy to make a hole for the shaft in such a pipe. You can use a glue gun as a connecting material. Such a circular machine can be powered either from the mains or from a battery. To ensure autonomous operation, it is necessary to provide a special compartment for batteries in the housing.

Machine with pendulum engine suspension

Those who can boast of the ability to work with metal can be advised to make a circular saw with a pendulum engine suspension. The main feature of the device is that the motor, shaft and cutting disc are installed in one common frame. On one side it is hinged to the frame, the second is held in place by a screw with the ability to adjust the height. By changing the length of the screw, you can adjust the height of the disk exiting the tabletop.

This system allows you to adjust the cutting height, as well as use discs of different diameters. If, instead of an adjusting screw, you use a probe placed on the tabletop, you can get a simple copying machine. The feeler gauge will allow you to adjust the cutting depth according to a certain pattern. This fairly simple modification will turn a simple circular saw into a real woodworking machine. With this device you can not only cut the board into the necessary pieces, but also make precise cuts and make various selections.

Making a carriage for a circular saw with your own hands

The functionality and quality performance of a stationary circular saw is greatly influenced by the availability of accessories. One of these is the carriage. It’s not difficult to do it at home, but trimming and sawing the material at an angle of 45° will be much easier.

You can make this device for a circular saw from a sheet of plywood as follows:

- plywood is cut out to a size slightly wider than the circular table;

You can make the carriage for the circular saw yourself.

- in the lower part, guide bars are attached to it using glue or screws, the distance between which should be equal to the width of the table;

- In a similar way, using screws or glue, thrust bars are fixed on top.

Using guides, the carriage is fed along the table onto a saw blade, which makes a through cut on the device. The height of the sides, which should be greater than the protruding saw blade, allows you to maintain the integrity and rigidity of the carriage. If the task is to make a cut at an angle of 45°, it is necessary to use an additional bar, which in this device is a removable element. The cut is made by pressing the workpiece against an angled plank.

In order for the plywood surface of the carriage to be easily cleaned of sawing waste, it must be coated with several layers of varnish.

The plywood should be slightly wider than the table of the table.

What manufacturing options are there?

There are several ways to make a circular saw at home. Among the most popular methods it is worth highlighting:

- installation of a manual circular saw on a machine made of timber;

- using a grinder with a steel disk to perform the drive function;

- installing the motor of an old washing machine on a wooden surface.

If the master plans to use a homemade product to unravel boards of considerable thickness, it is necessary to equip the machine with a high-power engine. Only such a device will be able to cope with tasks quickly enough and will not delay the master.

How to make a shaft for a circular saw with your own hands

In the general design of a circular saw, the shaft is the main element that forms the entire machine. To make it, you will need round steel grade 45. But you can only make this important part yourself if you have your own lathe or have access to it. The diameter of the workpiece must correspond to the size of the saw blades that are intended to be used.

Main standard sizes of disk mounting holes:

- 16 mm;

- 20 mm;

- 22 mm;

- 30 m;

- 32 mm;

- 50 mm.

From the indicators listed above, the size of the shaft for the circular is selected.

To make the shaft you will need steel round timber grade 45.

The most common hole diameter is 32 mm. This is the mounting socket that discs with different outer diameter sizes have. Alternatively, you can make a thinner shaft so that you can do “jewelry” work. Then an adapter will be used to use large disks. It is worth complicating the design of a home circular in this way only in cases where it will be used by a professional.

The saw blades are installed between two flanges and pressed using a nut, which is screwed onto a thread made on the edge of the working surface of the shaft.

Note! The thread must be left-handed. During the inevitable jerk when starting the circular, the nut in this position will tighten, and not vice versa.

Seats for bearings are determined taking into account the dimensions of the latter. The middle part of the shaft has the largest diameter. If the indicator is significant, additional load on the belt will be created during rotation. Drilling will help get rid of the problem, which will lighten the heavy part of the shaft.

The diameter of the workpiece must correspond to the size of the saw blades.

From a drill

This is not the best option for a miniature circular saw in terms of durability and reliability. If you use a hand drill without making additional changes to the design, then you can offer two options for a circular saw from a drill. The first option will use a chuck, without any changes - the blade of the disk will need to be mounted on the bolt and clamped in the drill chuck. The second option would be to remove the drill chuck and use the spindle to mount the saw. But be that as it may, a hand drill is intended for short-term operation; manufacturers recommend using it continuously for only 2-3 minutes, after which you take a break of at least 5-7 minutes. This tool is designed to work with drills with a maximum diameter of 10-13 mm, so using a circular saw blade with a diameter of even 125 mm on such a saw would hardly be reasonable.

What discs should you use for circular saws?

The productivity and quality of work largely depends on the correctly selected disk for a hand-made circular saw made from an angle grinder, a hand saw, or one assembled from separate mechanisms. It should be remembered that there are differences between discs for wood and metal. Even if thin, soft aluminum will be sawed, the appropriate blade must be installed. Metal cutting wheels have finer teeth. There are universal disc options that are suitable for working with both wood and metal.

There are also differences between the discs intended for longitudinal and transverse sawing of wood. Longitudinal sawing is carried out with a cutting attachment with sparse large teeth. But cross-cutting will be of better quality if discs with fine, frequent teeth are used.

As for the material and method of manufacturing disks, they can be monolithic or carbide. Monolithic ones are made from a single piece of high-carbon steel. Such bits are inexpensive, but have a significant drawback: they quickly become dull and require sharpening and re-wiring.

Circular discs can be made for wood or metal.

Carbide discs are made of tool steel with cobalt and tungsten brazing. They are more wear-resistant, but the price of such products is much higher.

The outer diameter of the disks for a homemade circular saw is limited by the dimensions of the protective casing. The standard disc thickness is 3.2 mm. There are thinner and thicker saw wheels. Thin ones are used when working with wood of valuable tree species to make a clean cut. For rougher work, thick discs are recommended.

Stationary with jointing

It is better to immediately design a stationary circular saw with a jointing drum. Without it, most of the work on its production will simply lose meaning, except perhaps for the sake of the creation process itself.

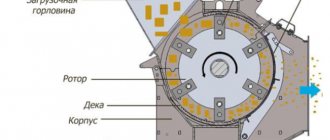

The structure of a stationary circular saw with a jointing drum is shown in the figure:

The device of a stationary circular saw with a jointing drum

When designing it, it is necessary to apply additional safety measures and ensure the quality of the machine. Firstly, during sawing, the jointing drum must be covered with a securely fastened protective cover on the pads to the jointing depth or slightly more, pos. And next. rice.:

How to adapt a jointing drum to a stationary circular saw

Loss of cutting depth will be approx. 6-8 mm (jointing depth up to 3-4 mm + 3-4 mm thickness of the lid. For jointing, a working pad of the same thickness (pos. B) is attached to the tabletop along its entire length behind the drum (along the workpiece). . overhang of the finished part behind the drum will lead to its planing onto a wedge; very flat, but due to the accumulation of errors during the construction or finishing work, it may turn out that all the processed material is damaged.

Note : by increasing the thickness of the working pad, you can adjust the jointing depth from maximum to 0.5 mm.

The motor matters

Secondly, the safety of using a homemade circular saw and the quality of sawing with it (especially finishing materials) is largely determined by the external characteristics (VnH) of the machine drive motor. ВнХ is the dependence of the torque on the shaft T on its rotation frequency N; the rotational speed (RPM) depends on the cutting resistance of the material being processed, and this, in turn, depends on the speed and feed force of the workpiece.

The VnH of a sequential excitation commutator motor (grinder, drill, hammer drill) is not monotonic (see figure).

External characteristics of a series-excited and asynchronous commutator electric motor with a squirrel-cage rotor

The maximum torque occurs at a certain rotation speed nр, slightly lower than the idle speed (without load) nхх. This is good: in the area of operating loads on the shaft ΔTр, the harder the material is, the stronger the motor turns the saw. Changing the feed force within these limits has virtually no effect on the quality of the cut, because the disk keeps the speed within the optimal range, and you can work at the highest performance.

The same thing, but without “adjusting” the saw to knots and other irregularities, is observed in a fairly wide range of overloads (ΔT region), i.e. High qualifications and a subtle tactile sense are not required from the operator - a beginner (not armless, of course) applied it once or twice, and that’s it, the work started. But, if you press hard, or something like a nail comes across, a dangerous property of the commutator motor appears in this case - a significant zero torque T0. An engine whose armature is forcibly braked will strive to turn at all costs: the workpiece can turn out and give you a kick in the teeth; the disk will fly apart.

Note : in manual circular machines, parallel-excited collector motors are used and/or with special armature winding circuits that reduce T0, but at the same time the “hump” of VnH is smoothed out. Therefore, in drills and grinders, where the “gnawing” ability of the tool with a small working stroke is important, T0 remains large. That is why it is impossible to put a saw blade larger than the standard one in the grinder - defects in work are inevitable, and the likelihood of injury increases sharply; This applies to abrasive discs to a lesser extent.

The VnH of an asynchronous electric motor with a squirrel-cage rotor is monotonous and quite rigid (in the same figure on the right). In the rotation speed range nmin – nmax that is optimal for a given disk, the feed force must be maintained very precisely, sensitively feeling the resistance of the material, i.e. Quite a high level of working skill is required. “Overfeeding” leads to a drop in both productivity and cut quality - a too slowly rotating disk tears the material. But if the saw suddenly jams, the motor will stop and begin to accelerate until the load is completely removed. If a 3-phase motor with a starting device from a single-phase network is used, then it will have to be turned off and restarted. When sawing long lengths, when the likelihood of awkwardness in work increases greatly, this quality of “asynchronous” VnH becomes valuable - a beginner/amateur can gradually learn to work without risking himself or spoiling a lot of material. Therefore, a homemade circular jointing machine should only be made with an asynchronous AC electric motor with a squirrel-cage rotor.

Motor mount

High-performance industrial circular saws, designed for long-term, round-shift operation, are equipped with large and heavy motors of 3-5 kW or more. Among other things, this reduces the sensitivity of the saw to material inhomogeneities and expands the range of permissible feed forces (see above), which, in turn, reduces the dependence of the quality of work on the qualifications and fatigue of workers. Another feature of circular saws compared to sawmills is that the belt drive from the motor to the disk turns out to be better than a chain drive, since you need to cut cleaner, but the material is of higher quality.

However, the belt tension weakens over time, so the engines of industrial circular saws are placed on supports that slide (and are fixed) in grooves (shown by arrows in position 1 of the figure).

Advantages of a pendulum motor suspension in a homemade circular saw over a sliding one

It is unrealistic to cut a long, even groove in metal without special equipment (a metal milling machine), but a 1-2 kW motor for a household circular is sufficient, and it can be placed on a pendulum suspension (item 2). Belt tension is thus ensured automatically without time-consuming adjustment work. There is more wear on the belt in a pendulum suspension, but you don’t work a full shift on your circular machine every day.

Note : assembly unit for pos. 1 pic. Above is the pendulum saw module of an industrial circular saw, which allows you to quickly install the output of the saw blade above the tabletop. But in the context of this section, this is not significant, and the output of the disk of a homemade circular saw can be changed not so quickly, but it is structurally and technically much simpler, see Fig.:

The mechanism for raising/lowering the saw blade of a homemade circular saw

The suspension hinge (shown by an arrow in position 2) can be quite rough (a steel pipe placed on a pin and filled with grease), but this does not noticeably affect the quality of the cut. You can do without a hinge on a steel sheet s(4...6) with screw support-clamps (shown by the arrow in position 2a). An additional advantage of the pendulum suspension of the motor is that the work table can be made tiltable, pos. 2b. When sawing a large amount of long timber (for example, for a construction site) by a sufficiently experienced worker, this significantly reduces his fatigue and speeds up the work.

Note: video material about building a circular saw with a jointing drum (sawing and jointing machine) on your own, see also the story:

Video: a simple homemade circular saw with a jointer

Rotation unit

The bearing assembly (rotation assembly) is the most complex and loaded part of a circular machine. We will try to make do with a minimum of expensive precision custom turning work.

Drawings of a homemade bearing assembly of a traditional design are shown in Fig.

Drawings of a bearing assembly for a homemade circular saw

Critical dimensions are highlighted in color:

- At pos. 3 D32 – for the installation size of the saw blade (see above). Tolerance –0.05 mm.

- At pos. 4 D40 – for installation of bearings (see below). Tolerance +0.03 mm. Misalignment is no more than 0.01 mm. Finish sharpening in one setting on a high-precision machine.

- At pos. 6 D17 – for bearings. Tolerance –0.03 mm. Misalignment is no more than 0.01 mm. Finish sharpening in one setting on a high-precision machine.

- The pulley (item 7) is machined to size according to the gear ratio, based on the rotation speed of the existing engine, the diameter of the pulley on its shaft and the operating speed of rotation of the saw blade (see above).

Due to more stringent requirements for the cleanliness of the cut than for a sawmill, but the same as on it, or of a comparable length, conventional ball bearings, such as, for example, for a cutting machine, wear out quite quickly in a circular saw, and the saw begins to beat. Therefore, this design uses more durable bearings No. 60203; We will continue to focus on them.

How could it be simpler?

The described design of the bearing assembly is not without serious drawbacks:

- no jointing drum;

- turning the internal diameters clean in one setting is not a task for an amateur turner or even an entry-level specialist;

- from the heat when welding the bearing race 4 to the support plate 5, the race may move, and the bearings will not fit into the sockets, and it is possible to grind them cleanly in the assembly only on a rotary or shaping machine.

Unreliable design of the housing and bearing assembly of a homemade circular saw

With a jointing drum, it looks like it can be solved: cut the frame with the slab in half, and that’s it. But adjusting the machine to verticality and eliminating the misalignment of the saw blade outside of production conditions will cost painful work with no guarantee of success. Or you will have to machine the mounting pin with high precision (for one-time use). But then, so that the setting does not soon float away, you need a strong, rigid body of the machine. Like welded UBDS-1 or UBDN-1. A homemade analogue with threaded connections (see figure on the right) will quickly become loose, and after 2-3 readjustments the bearings will also break.

Unconventional approach

What if we completely abandon the holder with the base plate? Then only the shaft will need to be sharpened with high precision. How to attach it? In wood to wood, this will further simplify and reduce the cost of the machine. Wood is an archaic material, expensive and poorly technological in mass production, but not bad for piece work. In the old days, wooden sailing battleships served for 120-150 years, with periodic upgrades. And modern 40-year-old warships are subject to renewal only if there is no ready-made full replacement.

The method of attaching the bearing assembly of a homemade circular saw in wooden cages to a plywood tabletop is shown in the figure:

Fastening the rotation unit of a homemade circular saw in wooden cages

The frames require dense, fine-grained, fairly elastic hardwood. The best is maple; further – walnut, hornbeam, oak. In this case, a durable rigid body of the machine is also not needed; a simple “bedside table”, like for a table for a manual circular saw, is enough. Modern achievements include furniture screws - confirmed ones; in fine-grained wood they fit tightly and do not come loose from vibrations. The “trick” of the design is that during the adjustment process (see below), the bearings are pressed into the wood and thereby securely fixed.

Assembly of the entire assembly is combined with adjustment:

- A groove for the saw blade is pre-cut in the tabletop and holes are drilled for the heads of the D6 confirms.

- Pioneer (installation) holes for confirmations D4.8x60 are also pre-drilled in the clip blank.

- Empty clips are “baited” so far only with the top confirmations.

- A shaft with bearings is inserted into the cages.

- A saw blade is mounted on the shaft.

- The upper confirms are tightened so that the bearings fit into the cages without play, but not tightly.

- The disk is wedged in the groove symmetrically with 4 pairs of wedges: 2 pairs on top closer to the center, 2 pairs on the bottom closer to the edge.

- By tapping the wedges, align the disc along the slot and vertically.

- The upper confirmations are tightened until the heads are recessed flush with the table top.

- The confirmations are tightened alternately on both clips in 3-4 steps using an “envelope”, i.e. with a diagonal transition.

- Leave the assembly to “settle” overnight or, better, for 2-3 days, so that the bearings are pressed into the wood.

- Take out the wedges and check to see if the disc has moved. If the confirmations were tightened carefully and correctly according to the scheme, it will not work.

- They place and tighten, also with an “envelope,” the lower confirmations.

- Let the tabletop with the bearing assembly “settle” one more time.

- Check the disk installation again. It didn’t lead, did you pull the lower ones correctly? The unit is ready for further assembly and operation.

Shaft drawings for this design are shown in Fig.:

Shaft drawings for a circular saw with a jointing drum

The blank is round timber St45 D60. The finished shaft assembly with jointing knives must (!) be balanced in the centers. During balancing, the material can be selected both from the “raw” surface of the D60 and from the areas under the knives.

Do-it-yourself parallel fence for a circular saw

The parallel stop is a mandatory device on a circular table; without it, it is almost impossible to make an even cut. You can make it yourself as follows:

- A U-shaped profile should be made from three strips of laminated chipboard; inserts should be placed and fixed inside, which will add rigidity. The result will be a square section.

- A guide channel is made from two parallel slats, which is bolted to the end of the table in a position perpendicular to the saw blade.

- An inverted T-shaped structure is then made from MDF, which is screwed to the stop and inserted into the channel.

You can make a parallel stop for a circular saw yourself.

Note! The width of the channel should be such that the side of the T-shaped element fits tightly into it.

To fix the stop of a homemade circular saw made by yourself, it is convenient to use the original slots. Threaded bolts, nuts and wooden washers are suitable as a locking mechanism; you will need a hole in the bottom plane of the stop. Tightening the bolt helps to securely press the stop to the table top. This design allows you to quickly and easily set the required cut sizes.

DIY circular table (with drawings)

This section offers a model of a universal table on which you can place a circular saw of any technical specifications and dimensions.

To make the structure you will need the following materials:

- a sheet of plywood, preferably with a laminated top covering, at least 10 mm thick and 800x800 mm in size;

- 4 laminated chipboard sheets 16 mm thick (400x784 mm);

- bars 50x50 mm;

- bolts and screws.

To make a homemade circular saw and table, you will need drawings.

Making a table for a circular table can be done in the following sequence:

- The upper part of the future table is assembled from laminated chipboard sheets, which is a box without a bottom. The sides are attached to each other using bars, the length of which is significantly greater than the height of the sheets.

- The manufactured structure is turned over, the bars-legs of the future table in the lower part are fastened with additional jumpers.

- A tabletop is cut out of plywood, in which a longitudinal hole is made using a jigsaw - a saw blade will be inserted into it.

It’s easy to find a drawing of a similar design on the Internet, which will greatly simplify production. You can modernize the version of the circular table proposed above with your own hands by replacing the bars with a metal corner or making a so-called box from boards. It’s a good idea to make a shelf at the bottom of the structure.

Original devices

The list of homemade products can be continued endlessly, but we’d rather talk in more detail about some homemade machines that can be made from any model of drill.

Drill

A drill made from a drill is not a fantasy, but a real and fairly universal machine, assembled independently. The main thing is that you need to order from Chinese engineers (if you couldn’t find it in your city) a flexible shaft from a standard medical unit. As a result, a drill appears in your arsenal, which can be used for engraving work or drill holes using special burs in small parts or structures that cannot be reached with a standard drill.

Making a crosscut from a circular saw with your own hands

Laying a wooden floor, replacing platbands, covering the facade with plank, clapboard, and creating landscape design elements require a dimensional board. The process of preparing such a board is called trimming. That is, the ends of the material are cut off in order to obtain the desired size of the workpiece and make the cuts aesthetically pleasing.

Do-it-yourself trimming makes work faster and more economical.

To make a crosscut from a manual circular saw with your own hands, you will need available materials and used tools.

The standard characteristics that a future trim should have are:

- maximum cutting length – 350 mm;

- optimal engine speed – 4500 rpm;

- light weight.

The upper part of the power tool is attached to the kingpin using a large bearing - 150 mm (it is not difficult to purchase on the market.) Ears are attached to the outside of the bearing. They are used to fasten the tool to the surface of the frame using M6 screws.

The main devices for making a circular saw with your own hands are car shock absorbers (they are convenient to use as a broach), a soft start button and additional protection that is attached to the power tool and the bed.

The upper part of the crosscut is attached to the kingpin using a bearing.

Note! Before assembling the structure, the shock absorbers must be disassembled, the oil drained and air holes made.

The advantages of a homemade miter saw include the following:

- The design is easy to disassemble, and the power tool can be used for its intended purpose.

- Low cost. Without taking into account the price of the instrument (used), the costs will be no more than 500 rubles.

Among the significant disadvantages, it is worth highlighting the high noise level. It is almost impossible to eliminate this drawback. In addition, it is necessary to make a test cut (selecting and fixing the draft) to ensure good quality of subsequent work.

From a chainsaw

To make a circular saw from a chainsaw, you will need a metal canopy that will be mounted to the body of the saw. The engine is already available, so making the unit will not be very difficult. You will also need two channels measuring 185x8000 mm. You will also need corners (55 x 100 mm) and two pieces of rails that turn with their soles up. Holes of 16 mm are drilled at the base of the sawmill, with a distance of one meter between them.

Ties are made from pipes (length - 255 mm). The structure is fastened with bolts. The racks are made separately; the sawmill body will be attached to them. It is important to ensure that all elements are not deformed. The distance between the posts should be no more than one meter. Then the sawmill is equipped with a movable carriage. It is made from a steel sheet 620x55 mm, corners are welded to the metal from below. Small bearings are mounted on the trolley. Two corners should also be welded at the top, and a chainsaw is attached to them. Then a holder is made that will work as a clamp for a beam or log.

You will need a pipe with a diameter of 45 mm. To work, you will need a hose that will be mounted at a given height, which should not be greater than the length of the pipe itself. This is how a sawmill is made. Such a unit can process timber or logs of any cross-section.

Do-it-yourself circular: safety of use

If you take into account how much a circular saw costs (from 16,000 rubles - the most modest model), and compare the price with the costs of making it yourself (this is 60-90% less), then the difference is significant. But no savings will be justified if the safety of work is not ensured.

Before starting to work on the circular saw, be sure to wear goggles and gloves.

In order to avoid traumatic situations, you should adhere to the following recommendations:

- do not use wood with metal inclusions (nails, angles, bolts, etc.) as raw materials;

- cutting boards larger than 200 cm must be done by two people;

- When using a circular saw, you should not make sudden movements;

- Before starting work, be sure to wear goggles and gloves;

- Wood waste should be removed from the surface of the circular saw, as it can cause a short circuit.

It is strictly forbidden to work on a homemade circular saw:

- if the guiding device is not made;

- no casing;

- there are no finger guards;

- the riving knife is higher than the saw blade.

To avoid hazardous situations when working with a circular saw, you should adhere to safety precautions.

A good tool allows you to enjoy your work. And the result pleases with a high level of quality. Making a tool with your own hands will allow you to obtain the desired parameters and necessary performance characteristics. You cannot limit yourself to superficial knowledge in any type of activity, especially in a technical area. You should take on the task of assembling a circular saw yourself only after thorough theoretical preparation and a full understanding of the practical part of the process.

Machine and device for sharpening drills: how to make it yourself (read more)

Design requirements

Before starting work, it will be necessary to prepare a small sketch, which should indicate not only the location of all the structural elements of the future machine, but also their main dimensions. When drawing such a sketch, you should take into account that your circular saw may consist of the following functional units:

- bed, which serves as the basis of the entire product;

- tabletops with an industrial prototype of a hand-held circular saw installed on it;

- remote control panel for turning on and off the actuator (circular saw).

The specified composition of the machine is typical for small-sized products on a wooden frame. For capital equipment manufactured on the basis of metal profiles (angles), its diagram has a slightly different form. Such a product must include the following elements:

- a base made of steel frames and brackets on which a shaft with a drive pulley is mounted in bearing pairs;

- a table top with slots for the processing blade, installed on top of a metal frame and rigidly fixed to it;

- a set of special drive electrical equipment located in the lower part of the frame and providing the required functionality of the device (it includes an electric motor, a starting device and a transformer-converter).

The main requirement for any type of frame is to ensure maximum reliability and stability of the structure. As options for the machine base, we will consider both frames made of metal profiles (corners) and load-bearing structures made of wood.

When familiarizing yourself with the requirements for the electrical equipment of a homemade machine, first of all, you should determine the drive power of the cutting tool (or autonomous saw), which for domestic conditions should not exceed 850 watts.

In addition, before preparing a sketch of the future product, the technical characteristics of the equipment used should be taken into account, such as:

- The depth of cut, which specifies the permissible thickness of wood pieces to be processed on your machine. This figure for industrial samples of woodworking equipment ranges from 5 to 8 cm, which is quite enough for cutting standard boards and thick plywood.

Additional information: In the event that you need to process wood blanks of greater thickness, it is necessary to provide a special lifting mechanism in the frame that allows you to change the position of the disk in height.

- Before manufacturing a capital machine with a separate drive, the operating speed of the electric motor rotor should be taken into account. The choice of this parameter is determined by the lumber processing modes with which you will most often have to deal. For simple cutting of wood pieces, this figure can be relatively low, but to obtain a perfectly smooth (“clean”) cut you will need a higher rotation speed.

Important! The optimal speed for homemade cutting machines is considered to be a rotation speed not exceeding 4500 rpm. At low engine speeds, the frame can be made on the basis of a reinforced wooden frame, massive enough to prevent vibrations of the mechanism.

- When drawing up a sketch, ergonomic requirements should also be taken into account, implying ease of control of the operation of the equipment, as well as safe handling. They relate to the order of the buttons on the operating panel, restricting access to the cutting blade, as well as the electrical security of the drive or individual controls.