A flexible shaft, the main purpose of which is to transmit torque over a considerable distance, is most often used to equip engravers. This type of equipment, which is essentially a miniature grinding machine, is actively used for processing small-sized parts. In particular, the engraver is used as a mini-drill; it is used to perform miniature cutting, selective grinding of small elements of products and a whole list of other works.

The flexible shaft simplifies the use of the engraver, eliminating the need to hold the tool above the work site

The most common areas where flexible shaft engravers are used are the jewelry and electronics industries. Such equipment is actively used by design specialists, employees of car repair stations and workshops involved in the repair of household appliances and electronic equipment.

An electric engraver, on which a flexible drive is installed, is especially relevant in situations where processing must be performed in hard-to-reach areas of the product. Using replaceable attachments, such equipment can be used in all stages of processing, from roughing to finishing.

Flexible engraver shaft with protective springs at the ends that protect the rubber casing from damage

Adapter Types

The angle adapter for screwdriver is divided into two types: flexible and rigid.

Features of the first type include:

- the ability to penetrate the most inaccessible places;

- unscrewing tightly seated screws;

- widespread use in everyday life;

- not suitable for tightening metal screws.

A rigid adapter differs from a flexible one in the following characteristics:

- durable cartridge;

- suitable for professional activities;

- torque: 40-50 Nm.

The structure of these types varies significantly. The flexible one has a metal body, a bit gripper on a magnet, and a flexible shaft. The rigid adapter is made of steel, there are two types of grip, magnetic and cam, there is a bearing.

Material of manufacture and shape of nozzles

The design and material of drill attachments depends on the type of technological operations in which they are used. For cleaning and roughening surfaces, various types of brush attachments are used, and for preliminary grinding, flat or flap attachments based on coarse sandpaper are used. For fine grinding and polishing, fine-grained abrasives or non-woven materials are used. In the latter case, they are often used with grinding and polishing pastes and aerosols. When grinding requires the removal of a thick layer of material, including unevenly, various types of cutters made of hard abrasives based on aluminum and silicon compounds are used.

Disc and fan nozzles

Flap wheels are also used as attachments for drills. They consist of many identical strips of sanding paper, fixed at one end to the axis of rotation, resulting in the formation of a dense circular brush of abrasive lamellas. Due to their external similarity, such attachments are commonly called fan attachments.

End bits

Abrasive end attachments for drills are one of the types of cutters - a metalworking tool that is used for manual grinding of profile surfaces, widening holes and removing excess metal in hard-to-reach places. This cutter is a cylindrical shank with an abrasive head pressed onto the front end of it. And the name “end” is due to the fact that processing with such a tool is most often performed in a perpendicular direction. End attachments are available with a wide variety of heads: round, conical, cylindrical, parabolic, etc. Therefore, you can always choose a cutter whose geometry best matches the profile being processed. The material used for abrasive heads is various types of high-hardness sandstone. In a fixed drill, cylindrical cutters can be used to sharpen metalworking tools.

How to do it yourself?

You can make such a product yourself, using a cable as a base. It can be from the clutch, gas or speedometer. You can buy braided wire or take one you already have - it’s almost impossible to make it yourself. It is threaded inside the cable.

One end of the future core is connected to the shank, for which a nut and welding are used. The second end is fitted with a screwdriver cartridge.

When using a homemade flexible shaft, it is important to hold on not to the cartridge, but to the protective shell, that is, the cable

The choice of the finished product should be approached with great responsibility. Work performed using a flexible shaft is complex and time-consuming. A malfunction of one mechanism will disrupt the operation of all others.

When purchasing, you need to pay attention to the manufacturer of the product. A tested and correctly made device will ensure high quality of work performed.

A hasty purchase will result in double expenses. In addition, if the work needs to be done urgently, deadlines will be missed.

In the next video you will find an overview of the flexible shaft for a screwdriver.

Shafts for lawn mowers

Mechanical scythes with electric and gasoline drives use both flexible and rigid shafts.

Powerful brush cutters, capable of cutting tall, hard and dense grass and even small bushes, use all-metal rigid drives. Such devices are designed for long-term operation and have high torque. They are also large in size and weight and are worn on shoulder straps. The working tool is thick, rigid fishing line or powerful steel knives - two, three or four - bladed.

The flexible drive is used in lightweight, low-power and small-sized trimmers designed for mowing corners after a lawn mower or trimming grass on small lawns. These trimmers are held with one hand, and the flexible shaft is used to mow in the most comfortable position. The cutting element of such devices is a fishing line of small or medium thickness or a lightweight two-bladed knife. If the device is overloaded, the flexible shaft may become twisted. In this case, the rupture usually occurs near the shaft-to-engine attachment point. If you cannot buy a “original shaft”, then you need to select a suitable length from drives in the direction of the braid. Such drives can only rotate in one direction.

Before starting seasonal work and after changing the drive, remove any remaining old lubricant, rinse with gasoline or other solvent, and fill the cavity in the handle with new lubricant. The type of lubricant is specified in the user manual.

Why do you need a flexible shaft and where is it used?

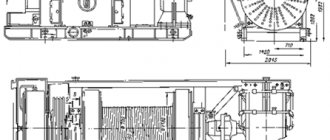

The flexible drive for the drill consists of two main parts: a flexible cable with armored braiding and a soft shell. On the one hand, it is equipped with a connection unit for an engine or a manual drive, on the other, it has a chuck for attaching a tool.

Using a flexible shaft is very convenient when you need to tighten or unscrew fasteners in narrow places with difficult access, where you cannot insert a screwdriver in the working position

Flexible shafts are also used to drive hand tools for fine and precise work. Placing a heavy, high-speed electric motor in the tool itself would lead to rapid operator fatigue and loss of precision in operations. An example is a dentist's or engraver's drill.

As a result, the user gets the opportunity to work for a long time with a comfortable, light and small-sized device, and the level of vibration from the electric motor transmitted to the hand is reduced.

Flexible shaft for screwdriver

A feature of the use of a flexible shaft is the limitation of the maximum torque that it is capable of transmitting. If this limit is exceeded, the cable becomes twisted and the shaft fails.

Tips for use

- Before you start using a screwdriver, you should choose the right attachment. It must correspond to the type of work and be suitable in diameter to the head of the fasteners.

- To insert a bit into a tool equipped with a quick-release chuck, it should be pushed between the “cams”, carefully turning the sleeve in a clockwise direction. If the screwdriver design has a key chuck, then the bit is installed in a special socket and turned with a key until it is completely locked in a clockwise direction. After the selected bit is set, the device can be connected to the network and immediate work can begin.

- To reduce or, conversely, increase the speed of rotation of the nozzle, you need to weaken or strengthen the pressure on the start button.

- When the fastener is tightened, the limit sensor will automatically operate and the device will stop operating.

- When unscrewing a screw, the bit must be placed in the slot, and the rotation of the bit must first be adjusted to work in the opposite direction.

- If during operation it is necessary to remove or change the nozzle, you must first turn on the reverse mode. When the bit has rotated in the opposite direction, the ring holding it is squeezed with your hand, and the nozzle is easily removed and replaced with another one.

Operations performed using an engraver

If we talk about buying an assistant for delicate work, then you should choose a reliable tool that itself costs a decent amount, even if it comes with a limited number of attachments. Additional accessories can be purchased later:

- the use of grinding and polishing wheels helps to achieve a flawless smooth and shiny surface;

- brushes are used to remove rust from the material and grind seams that are difficult to reach with standard tools;

- an attachment in the form of a cutting wheel will allow you to obtain miniature pieces of workpieces and smooth out their torn edges;

- a set of thin drills is useful when forming the smallest holes;

- cutters will help to process hard-to-reach surfaces; abrasive devices are also used for this;

- A compact tool with the help of feather-shaped attachments will make it possible to easily perform openwork in miniature writing and make minor restoration repairs, allowing you to make elegant souvenirs.

To make operations easier, various additional items are sold:

- rubber pads will allow you to better hold the device during operations;

- so that you can pay more attention to the work, rather than holding the button in the working position, a mechanism for fixing the button is provided;

- a flexible shaft for the engraver will allow you to transfer torque to the nozzle;

- To make it easy and convenient to change attachments, the design has a spindle lock button.

The work of an engraver is akin to that of a jeweler, of course, not always requiring miniature precision. But the criterion for the quality of work has always been the use of high-quality and durable tools. An engraver belongs to one type of tool, the direction of activity changes with the use of different attachments. The category of engravers includes both a drill in a dental office and a manicure machine in a hairdresser. Engravers of inscriptions and drawings on the surface of natural granite and marble also use this compact and affordable device to create monuments and crafts.

Grinding and polishing

A huge number of attachments intended for polishing, stripping, and grinding the surface should be placed in a separate group. With their help, you can not only remove paint or unevenness from metal or wood, but even remove a few millimeters of the material, increase its strength characteristics, and much more! Let's look at some of them.

- Grinding attachment for drill. Intended for removing rust on metal, eliminating visible product defects, sharpening steel cuts and many other functions. Drill attachments for grinding are rods on which abrasive attachments are located. When the chuck rotates, it accelerates to the same speed and is used as a grinding wheel. The abrasive can have different grain sizes.

- Drill attachment for sanding wood. A similar item as for metal processing, only instead of an abrasive, a polyurethane, rubber, mineral (etc.) circle is installed, with which you can make the surface extremely smooth and without chips or needles.

- Drill attachment for polishing. This is a specific tool, the base of which is made of rubber and foam rubber; an emery wheel can be attached to them. This design ensures maximum processing quality. No worse than a polishing machine. The only drawback is that the drill is much heavier, so holding it will be a little awkward.

- Grinding "sun". Another unusual nozzle. It is a circle from which strips of sandpaper emerge like rays. When the chuck rotates, the paper blades accelerate to high speed and polish any metal in a few seconds! The attachment is short-lived, lasts only a couple of hours, but is very effective!

We reviewed the most useful attachments. Now the choice is yours: use these devices or buy expensive devices.

Selection instructions

The selection of a nozzle includes a determination with several parameters:

1. The maximum size of hardware that this model can twist. Depends on the torque that the cartridge is able to transmit. There is a table that will help with the choice (the data describes the possibilities of working with medium-strength steel)

| Hardware diameter, mm | Torque, Nm |

| 8 | 12 |

| 12 | 20 |

| 16 | 30 |

| 21 | 60 |

| 50 | 180 |

2. Method of connecting the working bit to the chuck. Magnetic gripper and three-jaw collet chuck. The first option is more practical, but less reliable. The second provides the most durable grip.

There are different companies on the market, with significant differences in price and quality. Inexpensive, accessible attachments from China and Taiwan are designed for the picky user. At rotation speeds greater than 300 rpm. they begin to vibrate and heat up. Magnetic fasteners are only suitable for single-sided bits. After a short period of use, the nozzles begin to run out radially, which negatively affects their performance.

AEG and Dewalt produce more reliable bits with acceptable torque values and a strong connection for the bit. They are designed to operate at 400-600 rpm.

Professional equipment from the USA from Milwaukee is aimed at the fastidious consumer. Huge rotation speed of 1600-1800 rpm, combined with the ability to drill.

An angled screwdriver attachment helps make repair work, furniture assembly, hanging pictures on the wall, and other everyday tasks easier. The main thing is to correctly determine what is required from the tool. Then choose the right model without overpaying for unnecessary features and follow the instructions.

Design

This adapter has special requirements regarding bending rigidity. In the center of the structure there is a special cable or wire rod. They are made from materials that can withstand torsional loads. It is based on a metal core onto which the wire is wound. There can be several layers.

The safety of the tool is ensured by a rubber shell, which also provides additional protection for the core from damage and retains lubricant inside. In relation to the rotating rod, this shell remains motionless. On one side of the adapter there is a cartridge through which you can change attachments. On the other side there is a union nut or fastening fittings, through which fixation occurs with a screwdriver.

Design Features

The main design feature and at the same time the main advantage in application is the ability to bend it anywhere in any direction. This is achieved by using the following components:

- flexible and durable steel braided cable that transmits torque;

- armor braid or spiral-wound spring wire that acts as a flexible drive housing.

The outside of the wire is covered with a corrugated plastic sheath, inside of which there is a grease. It reduces friction, prevents abrasion of the core cable and protects it from moisture and dust.

The design of the flexible drill drive also includes bearings to which the cable is attached. They keep it spinning. At one end the cable is fixed in a socket, at the other it is provided with a mount for a tool.

Extension shaft with collet clamp

Such a drive is intended for light and delicate work; you should not count on using it to unscrew a soured bolt or screw in a 130 mm self-tapping screw at full speed; you must remember that the torque transmitted by the flexible shaft is limited.

How to choose an adapter?

Battery-powered screwdrivers are the most common device in construction. Its main “advantage” is mobility. Depending on the screwdriver model, the battery receives voltage from 14 to 21 volts. The “output” is from 12 to 18 volts

When choosing an angled adapter for a screwdriver for an 18-volt socket head, pay attention to the following recommendations:

- nozzles (steel P6 and P12) are suitable for working with metal screws;

- available models, as a rule, use a trib made of modern plastic;

- the adapter is light in weight, but the torque is limited to 10 nm;

- a steel gearbox is capable of increasing torque up to 50 nm;

- the larger the size of the bit extension, the higher the performance of the screwdriver;

- the possibility of “reverse” expands the functionality of the device (we not only tighten, but also unscrew the screws).

When selecting an adapter, we look at the maximum screw size and adapter model, as well as the method of connecting the bit to the chuck. The magnetic grip is practical, but the three-jaw chuck will provide maximum grip strength.

Today, the modern market is saturated with different models of adapters for screwdrivers; they differ in quality and price. In most cases, inexpensive Chinese nozzles with a rotation speed of 300 rpm quickly heat up and vibrate. Magnetic mounts are suitable for single-sided bits.

The most common attachments and their descriptions

There are several hundred different attachments and they all differ in some way from one another. It is simply impossible to cover the entire range of products, so let’s start with the most popular models that can replace your expensive tools. With their help, you can perform basic construction and finishing work, process many surfaces and materials

We do not take into account the drill and “shovel”, only additional accessories. Let's take a closer look

- Crowns. Unique attachments for making holes in wood. An indispensable item in furniture making. They have different diameters and heights. As a result of the work, you get perfectly even holes in any wood. The cost of such crowns ranges from 40 to 700 rubles per piece (depending on the manufacturer, steel grade, height and other parameters).

- Screwdriver attachment. There is nothing easier than turning an electric drill into a regular screwdriver. It is enough to buy inexpensive cross-shaped and straight bits and you will have 2 types of screwdrivers at once. More precisely, 3 types, since there is also an impact function (perforation function on a drill).

- Metal brush-circle. Used for metal work (mainly), it consists of metal bristles that are located around the shaft, and it, in turn, is attached to the chuck. This shape is made for maximum balance of the nozzle. When you turn on the device, the brush has a very high speed and removes all rust and roughness in seconds!

- Whisk. To mix construction mixtures, a specific nozzle is used in the form of a long screw and a large holder, which is inserted into the tool chuck. With the help of such a thing, you can mix excellent adhesive for laying tiles, mortar for laying bricks, and anything else you want in a few minutes. Yes, at least mix the paint with solvent! The quality of the mixture is much better than in the case of manual preparation of the mixture.

These attachments are familiar to almost every builder and have gained immense popularity not only in the construction industry, but also in many household tasks.

Job

Externally, a flexible shaft is almost no different from a thick cable, only its surface is often corrugated. Tight hinge joints are installed on the flexible shaft, which remain motionless during operation. You can notice how when you turn on the screwdriver, only the tips begin to move.

The user can hold the adapter in his hand and tighten or unscrew the screws without fear of damaging his palm. Some models have a limit when using self-tapping screws, and it reaches 4*70 mm. If this indicator is, for example, 4 * 100 mm, then after crossing 80 mm into the beam, the flexible shaft simply curls into a loop and cannot complete the task. If you try to continue working, the cable inside simply breaks off near the nozzle. The maximum load is 6 Nm.

Information for fishermen

The angle adapter for a screwdriver is designed not only for tightening screws and self-tapping screws, but is also widely used by fishermen. An ice ax adapter for a screwdriver helps in drilling holes.

Using an attachment that allows you to rotate the ice ax with a screwdriver gives the fishing enthusiast the following advantages:

- simple ice drilling;

- a sufficient number of holes in a short period of time;

- when the screwdriver is discharged, the ice ax can be operated manually;

- slight noise;

- The adapter for an ice ax to a screwdriver is compact and convenient.

The main purpose of the device is to transfer rotations from an electrical device to an ice ax. Most modern adapters are equipped with a special handle for securely holding the tool. Adapters have different designs, the simplest one is a sleeve made of metal. With a more complicated design, the adapter is attached at one end to the auger part of the drill, and at the other to the chuck.

Installing an adapter for an ice ax under a screwdriver is not difficult:

- unscrew the bolt that connects both parts of the drill;

- We mount an adapter in place of the “top” of the drill;

- The hex shank is fixed into the screwdriver chuck.

Some disadvantages of adapters for ice axes for screwdrivers are still present. For long and productive operation of the tool, a powerful charge is required. As a rule, 18-volt screwdrivers with a torque of up to 70 nm are used to drill ice. Unfortunately, not all batteries work properly at low temperatures. It is necessary to take care of additional batteries, which should be kept warm. Fishermen need a more powerful tool, which costs a lot.

The way out of the situation is to use an adapter with a gearbox (a set of gears located in the crankcase is designed to adjust the speed of rotation of the shafts). This element will allow you to use an inexpensive screwdriver for the drilling process. The gearbox will take on part of the load from the chuck and the tool mechanism, and will also help save battery power on the device.

To learn how to make an ice drill adapter for a screwdriver, see the following video.

Let's block ads! (Why?)

Rules for working with an engraver equipped with a flexible shaft

There are a number of rules that should be followed when using a flexible shaft engraver to process various materials.

What to do before you start

Before starting work, select nozzles. All of them should be at hand, so as not to waste time searching for them later. While the device is turned off, it is better to hang it on a special hook, which comes complete with most modern models.

You can prevent the chips formed during processing from sticking to the surface of the tool if you first coat it with a layer of paraffin. It should be kept in mind: if the design of the tool does not provide for forced ventilation, you can work with it for no more than 15–25 minutes, and then you need to give it time to cool naturally. By doing this, you will protect your engraver from premature failure.

When holding the engraver with your hands, you should try not to cover the ventilation slots with your palms

Changing mode

It is necessary to change the speed at which the tool of an engraver equipped with a flexible shaft rotates both when changing the operations being performed and when switching to processing another material. At low speeds, softer materials, such as plastic, are processed. If such materials are processed at high speeds, this can lead to intense heating of the tool and melting of the edges of the workpiece. At medium speeds they process metal products, at high speeds – from hard natural stone.

How to properly care for your engraver

Like any other technical device, an engraver equipped with a flexible drive shaft requires appropriate care. If performed correctly and regularly, such maintenance will not only allow you to use the device at its maximum capacity, but will also significantly extend its trouble-free operation.

During the processing performed with the help of an engraver, its fan blades are actively clogged with dust and small particles of waste material. For this type of fan to work effectively, it must be cleaned regularly using a soft cloth soaked in soapy water. Under no circumstances should you use various solvents and aggressive detergents for these purposes, which can lead to premature damage to the fan blades.

To clean and lubricate the insides, the tool must be disassembled. This infrequent procedure requires certain repair skills

The technical condition of the attachments used with the engraver must also be checked regularly. Worn attachments should be immediately replaced with new ones, as they can cause increased vibration of the device, which will ultimately lead to its premature failure.

It is very important to pay constant attention to the technical condition of the flexible drive shaft of the engraver. The protective shell of the shaft, which is made of polymer materials, should not have serious mechanical damage that could lead to premature failure of the shaft. After each use of the engraver, it is advisable to clean its flexible drive shaft from dust and other contaminants, wipe and, if necessary, lubricate the tips with which it is connected to the electric motor and the working attachment.

After each use of the engraver, it is advisable to clean its flexible drive shaft from dust and other contaminants, wipe and, if necessary, lubricate the tips with which it is connected to the electric motor and the working attachment.

Liquid oil is used to lubricate the internal cable.

During operation, care must be taken to ensure that the flexible shaft does not bend too much. Both during storage and during operation, it is necessary to protect the flexible shaft from mechanical damage.

Equipment selection criteria

When choosing an engraver, you should focus on a number of characteristics.

Based on the power level of the device, on which its performance directly depends, one can indirectly judge the operating life of the drive motor. The power of the engraver, which for serial models can be in the range of 35–300 W, should be selected based on the tasks for which it is planned to use such equipment. In addition, you need to consider how long it will work between turning on and off. The duration of the operating process depends on the hardness of the material from which the product being processed is made. The longer the engraver is used at one time, the more power it should have.

Low-power compact engraver is convenient for simple work without a flexible drive

The speed at which the motor shaft and the flexible drive shaft attached to it rotate is also selected depending on the hardness of the materials to be processed by the engraver. Models offered on the modern market can provide tool rotation speeds in the range of 10–35 thousand rpm. Low-speed models can be purchased if they will be used primarily for finishing grinding and polishing. When performing such operations, a small load is placed on the tool, so the engraver itself does not overheat, and therefore does not fail.

If you need a more universal device with a flexible shaft, it is better to give preference to engravers that provide the ability to adjust the rotation speed of the tool.

The speed controller significantly increases the functionality of the engraver

The weight and dimensions of the engraver influence how convenient and easy it will be to manipulate such a device during processing with its help. Engravers that have significant dimensions and weight are much more difficult to work with, but such devices, as a rule, have higher power and productivity. The weight of an engraver with a flexible drive shaft can be in the range of 0.5–8.5 kg. When choosing such a device, first of all take into account the required power and functionality, and only then pay attention to the weight and dimensions.

Since an engraver works by constantly holding such a device in his hands, its ergonomics, which characterizes the ease of working with the equipment, is an important factor when choosing. When assessing the ergonomics of a device, you should pay attention not only to its design, but also to the build quality, manufacturing materials, button placement and comfortable handle design.

Before purchasing a tool, you should hold the engraver in your hands and try out the buttons and latches.

These parameters are not indicated in the equipment passport. It is advisable to pay attention to them if the engraver will be used quite often. To evaluate how much noise and vibration the device makes during operation, you just need to turn it on and evaluate these parameters. As a rule, medium-power engravers make more noise, and in more high-speed equipment this problem is provided for by the manufacturers and is eliminated by including special elements in the design. You can only estimate how hot an engraver equipped with a flexible drive shaft gets during operation.

Bracket for receiving drilling machine

The multifunctional bracket will help you convert a standard hand drill (corded, with battery) into a stationary drilling machine. The body is made of heavy-duty aluminum alloy. Massive, allows you to securely install the drill for subsequent drilling. The fasteners are designed in such a way that they are suitable for all modern power tools.

The sole is equipped with a vice, which allows you to fix the workpieces in the desired position and avoid their displacement while drilling holes. The adjustable bracket allows you to set the desired height, taking into account the size of the tool itself. For convenient operation, there is a handle with a rubber pad that smoothly lowers the drill.

Multifunctional bracket for drill and screwdriver

| Price | 2,077.21 - 2,345.32 rub. |

| Rating | 4,6 |

| Reviews | 115 |

| Orders | 188 |

| Delivery to Russia | Free |

Purpose

A flexible shaft for a drill is a special attachment capable of transmitting torque from the electric motor of a drill to a tool that is not aligned with it. Thus, it becomes possible to make the tip with the drill, located in a completely different plane with respect to the axis of the electric motor, rotate, and also change its position at the first need. Thanks to the design features, the shaft easily bends in the desired direction and allows you to perform work in hard-to-reach places where it is technically impossible to get to with a standard drill.

Externally, the flexible shaft is an elongated bendable attachment, one end of which is fixed to the drill using a tip, and the second is equipped with a collet clamp designed for fixing a cutter, bur or drill. Thanks to the flexible shaft, there is no need to hold a heavy drill, which allows you to perform rather delicate and painstaking work. For example, using this device you can drill holes with a diameter of 1 mm, clean a part in a hard-to-reach place and tighten a screw where a drill or screwdriver not equipped with additional equipment cannot be reached.

Using a flexible shaft, you can turn parts made of various materials, engrave any surfaces, or use it as a grinding machine. Moreover, engraving using a shaft is especially convenient. This is explained by the small thickness of the working tip into which the bur is installed, and the ability to wrap your fingers around it like a ballpoint pen.

How does the engraver work and how does it work?

The engraver, which allows you to process parts with high precision and productivity, works on the principle of a conventional drill, and in appearance it is very similar to a large automatic pen. The main structural elements of such a device are:

- engine;

- a flexible drive shaft that transmits torque from the engine to the working attachment;

- gearbox;

- a fan used to cool the spindle;

- the spindle itself with a protruding working part;

- device body with special openings for the exit of heated air;

- a nut designed to fix the used nozzles;

- device power regulator;

- lock button;

- power switch;

- hook for hanging the switched off device.

Engraver device

Rotation from the engine is transmitted to the axis of the flexible shaft, the reverse side of which is connected to the working nozzle. The mounting locations of the nozzles are unified, so there are no problems with choosing the required tool and replacing it.