Any, even a very compact drill, has certain overall dimensions. This limits its use: it is not always possible to “crawl” into a secluded corner. The power tool market offers portable options called “Dremels”, named after the manufacturer.

With the help of such a device you can penetrate into places with limited access, however, it also has disadvantages:

- Still, the Dremel is not compact enough, the dimensions of the electric motor do not allow the tool to be reduced;

- small size means little power.

In addition, in addition to banal drilling, using a drill (of any size) you can perform other methods of processing the material: grinding, engraving, giving the workpiece complex shapes (turning). To do this, you need to hold the working tip with your fingers, like a fountain pen. Of course, even a very compact instrument cannot be used in this way.

Again, with the exception of compact engravers.

How to get out of this situation? Tool manufacturers offer the use of flexible shafts for power transmission.

Flexible shaft KWB, 950 mm, BZP 0.5-6 mm, 3000 rpm

We deliver goods directly from partners from all over Russia. These products are not presented in stores and are only available for ordering on the website.

Art. 12565076 In the shopping list In the shopping list In comparison In comparison

Features of work using corner adapters

Naturally, when carrying out work using angle attachments, it is necessary to comply with safety regulations. In addition, during work it is advisable to apply the following practical tips:

- The bit or drill must be securely fastened in the adapter, just as the adapter itself must be securely fastened in the main tool;

- If the adapter is installed on a drill, it is preferable to hold it with both hands;

- Regardless of the device used for corner work (drill or screwdriver), you should not put excessive pressure on it;

- It is prohibited to change the operating mode until the rotation of the device has completely stopped;

- The operator must use personal protective equipment during operation;

- Immediately after completing the work, it is forbidden to touch the nozzle, because it will be extremely hot.

Description

The 950 mm flexible shaft is a design that makes it possible to drill in places that are difficult for a drill to reach. The principle of operation is based on the fact that torque is transmitted between two axes, and the soft hose allows convenient placement of the tool. Also suitable for cleaning water and sewer pipes, installation in jewelry automated tools, grinding, etc.

- versatility of use;

- high efficiency of torque transmission;

- durability.

You can buy a flexible shaft in our specialized stores at an attractive price. Leroy Merlin works to ensure that there are more cozy homes in our country!

Choosing the cost of the device and manufacturer

The list of well-known manufacturers who are responsible to the consumer for all their products looks like this: Bosch, Bort, Stayer, Gardenlux, Makita, FIT, Dremel, Prorab, Sturm, DeWalt, Vityaz. As for the differences in prices, there is a wide range. Simple, low-functional devices are purchased for the equivalent of 15–20 dollars, and for high-power devices with a varied number of processes you will have to pay about 1 thousand dollars.

For some novice professionals and hobbyists, the cost of the device and brand recognition play a purely symbolic meaning; it is much more important if the device exactly matches the job for which it will be purchased. It is this requirement that allows you to buy high-quality devices at a low cost from our domestic manufacturers.

Flexible shaft KWB, 950 mm, BZP 0.5-6 mm, 3000 rpm in Moscow

Flexible shaft KWB, 950 mm, BZP 0.5-6 mm, 3000 rpm and other products in this category are available in the catalog of the Leroy Merlin online store in Moscow at low prices. Read the detailed characteristics and description, as well as reviews of this product, to make the right choice and order the product online.

Buy products such as flexible shaft KWB, 950 mm, BZP 0.5-6 mm, 3000 rpm, in the Leroy Merlin online store, having first checked their availability. You can receive the goods in Moscow in a way convenient for you; to do this, read the information about delivery and pickup.

You can always place an order and pay for it online on the official website of Leroy Merlin in Russia. For residents of the Moscow region, we not only have low prices for such goods as “Flexible shaft KWB, 950 mm, BZP 0.5-6 mm, 3000 rpm”, but also fast delivery to cities such as Moscow, Balashikha, Podolsk, Khimki, Korolev, Mytishchi, Lyubertsy, Krasnogorsk, Elektrostal, Kolomna, Odintsovo, Domodedovo, Serpukhov, Shchelkovo, Orekhovo-Zuevo, Ramenskoye, Dolgoprudny, Pushkino, Reutov, Sergiev Posad, Voskresensk, Lobnya, Ivanteevka, Dubna, Egoryevsk, Chekhov, Dmitrov , Vidnoye, Stupino, Pavlovsky Posad, Naro-Fominsk, Fryazino, Lytkarino, Dzerzhinsky, Solnechnogorsk, Istra and Zhukovsky.

Source

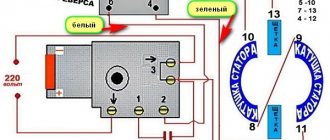

Vibrator device

The vibrator consists of three components:

- directly from the vibrator itself;

- drive to the executive body - vibrating beater;

- drive mechanism. This device can be any engine: pneumatic, electric or internal combustion engine.

Flexible drive device

The connection between the motor and the actuator is a flexible drive. Drives can be of various designs: flexible, metal, short, long, closed type, rigid mounting and are selected for a specific type of work. The outer diameter of the flexible drive can be in a wide range from 15 to 35 mm, length from 0.5 to 15 m. The most universal is a flexible shaft with a length of 2.5-3 m.

The drive consists of an outer hollow shell with an internal passage hole for a flexible steel cable or coiled spring. One end of the steel cable is connected to the motor shaft, the other end is connected to the “beater” drive. The connection is made with a classic hexagon or clamp clamp.

Tip (vibrator) device

The vibrator is used to create high-frequency mechanical waves and transmit them into the concrete solution. The designs of the tip are varied, but the purpose is the same - to create high-frequency vibration in the tip and transmit vibrations to the building mixture.

An eccentric shaft is used to create vibration. Eccentricity creates an additional load at the end or middle of the rod attached to one side. The rod itself is located inside a hard shell, usually metal and made of pipe. The rotation of the eccentric shaft is ensured by bearings, the outer races of which are installed in guides, which serve as the housing, and the inner races are installed in the eccentric rod.

The body of the “beater” is hermetically sealed at one end; the end of a flexible shaft, which connects to a vibrating rod, is connected to the second. As the eccentric of the rod unwinds, it begins to vibrate. Vibration is transmitted through the bearings to the handpiece body. The oscillation frequency depends on the drive speed and the diameter of the shaft on which the eccentric is located. The larger the shaft diameter, the greater the amplitude and the lower the oscillation frequency.

External sealing devices

In addition to deep compactors for concrete mortar, the industry produces external ones. External fixtures are used for the manufacture of small, narrow or deep products, for example, monolithic walls or columns. In such devices, the principle of transmitting mechanical waves into the solution is transmitted through the shells of the formwork in which the mixture is located. Small parts of the same shape or the same size are placed on a single-multi-level pedestal, vibrations are transmitted through a common vibrating table driven by a single mover. External vibrators are also widely used to help unload solution from large containers: car bodies or concrete mixers and accelerate the movement of the mixture in trays.

The design of such devices is simple, usually it is a single or three-phase motor with elongated shafts on which unbalanced bushings are mounted. When the shaft rotates, these bushings create vibration, which is transmitted through a rigid mount through the table to the products.

To further increase the vibration power, the extreme ends of the unbalanced bushings can touch the base of the table pedestal, creating additional shock amplitude. In addition to those described above, there are molding and compression molding machines for working with concrete mixtures.

General characteristics of vibrating devices for compacting concrete solutions

| Parameter | Meaning | Note |

| type of drive | Electric | The most common vibrators, since the power of the electric motor can vary from 7 kW to 100 kW. Modern battery power sources make the electric drive operational in stationary conditions and suitable for any conditions. Electric vibrators are lightweight, cheap and versatile. |

| ICE | Use with high-performance stationary or professional devices. | |

| Pneumatic drive | The use of stationary compressor units is due to large production plants of reinforced concrete products. | |

| Performance | Household | The so-called domestic or household is used in home construction for the construction of light one-time work on the construction of foundations, pouring in formwork or laying floors in apartments. |

| Professional | Reliable equipment with a power of more than 2 kW and above. Made for constant work with concrete mixtures of any fraction. | |

| Vibration | Low frequency | Low frequency (up to 4) thousand vibrations/min. and the large amplitude determines the use of large filler fractions with concrete. |

| Mid frequency | The most widely used option (10 thousand vibrations/min.) It is used with concrete with an average filler fraction and degree of mobility. | |

| High frequency | Vibration frequency more than 10 thousand vibrations/min. The optimal choice for working with thick mixtures of fine fillers. | |

| Weight | up to 10 kg | In this case, the weight of the device cannot be equated to its power, since the main mass is taken by the flexible drive of the mace. The weight of the actuator depends on the diameter and length. The minimum weight of the vibrator is 7 kg. Industrial stationary ones can weigh up to 200 kg. |

| 10-25 kg | ||

| more than 25 kg |

Dynamic concrete vibrator

“Dynamic” is a well-known brand of Chinese companies producing tools, including construction and hand tools. The official name is Dynamic Construction Machinery Co., Ltd. A flexible drive with a mace produced by this company can be purchased separately. One of the popular ones is the EN brand model. The diameter of the mace is available from 25 to 58 mm, the length of the flexible drive is from 2.5 to 9 m. This product can also be used as an internal vibrator for concrete for attaching to a drill, or you can select an individual working motor for it, depending on the volume of work.

Concrete vibrator model ZPND

Produced by the same company, the differences are that the ZPND model is more focused on professional work, has a more powerful fastening tip and a wide range of club diameters.

Overview of autonomous drives based on internal combustion engines

Grost VGB 4000 W.

The drive is based on a four-stroke gasoline engine with a power of 4000 W. (China) Autonomous sources manufactured on the basis of internal combustion engines, in addition to the main drive for the flexible shaft of the concrete compactor, have additional features

and devices for connecting additional devices, for example, a current generator, universal couplings for connecting other machines, with standard shafts.

In addition to its main purpose, the Grost VGB 4000 W internal combustion engine can be used as an additional source of electricity with a power of up to 4 kW. The versatility of the engine makes it indispensable in facilities that do not have a constant power supply.

CHAMPION CVG424

This is another universal drive from the Chinese company, having the same power as the one described above, but cheaper. The model is 4 kg heavier due to the stand, as it is made of thick-walled metal sheet. Has a smaller fuel tank capacity. Engine characteristics are presented in the table

Basic characteristics of autonomous vibrator drive models | ||

| Parameter | Meaning | |

| Model | Grost VGB 4000 W | CHAMPION CVG424 |

| type of drive | Flexible vibrator | Flexible vibrator |

| Power | 4100 W | 4000 W |

| Nutrition | petrol | petrol |

| Max. rev. | 4000 rpm | 3600 rpm |

| Flexible shaft length | Not included | Not included |

| Recommended vibrating tip diameter | 28,32,38, 50 mm | 28,32,38,45,50,60,70 mm |

| Dimensions | 550x410x430 mm | 550x410x430 mm |

| Weight | 21.2 kg | 23.6 kg |

| Price | 17,000 rub. | 13000 rub. |

Industrial devices for compacting concrete are expensive, and their purchase is advisable for large volumes of work. If working with concrete is intermittent, and your home workshop has a drill with a power of 1 kW or more, then it makes sense to make an internal vibrator for concrete with a drill attachment yourself.

Making a "beater"

A “beater” is a working element that creates vibration to transmit it into the working concrete mixture.

Vibrations are created by an eccentric rod that rotates in bearings. To make the rod, you will need a 12-20mm steel rod (depending on the internal diameter of the selected pipe for the housing). By turning the eccentric on a lathe, or by welding an additional weight on the side of the rod. Before making the eccentric itself, it is necessary to select the bearings in which it will rotate. On the shaft itself it is necessary to prepare seats for the bearing. The length of the shaft is calculated depending on the diameter and length of the rod. The more powerful the drill, the longer or larger in diameter the eccentric.

Selecting a bearing

The type of load on the bearing is rotation with variable radial load. The radial load is transferred from the rod to the body. Additional load is carried by the bearing at the end of the shaft, which is under radial contact load.

Types of bearings that accept radial load

a-c) single-row radial ball bearings, respectively, types 0000, 60000 and 80000 (without, with one, two protective washers);

a-c) radial roller bearings with short cylindrical rollers, respectively, types 2000, 32000, 42000, 52000, 92000, 62000;

e-f) single-row angular contact ball bearings type 36000; angular contact rollers with conical rollers, single row, type 7000.

Having analyzed a number of standard bearings, we can conclude that the most budget option is to choose the radial single-row type 0000. These bearings have the simplest design, but they also have the lowest degree of protection. If the responsible master is used to doing everything as needed, it becomes clear that this option is not optimal. If you choose a single-row radial ball bearing, then it is best to take the option with two protective washers; it is protected from dirt getting into the balls and does not require lubrication because it is included during manufacture.

Even better, variable radial loads can be withstood radially - roller bearings have load distribution over the entire area of the roller, and accordingly, the load concentration is distributed over the entire area of the cages. Considering the operating conditions of the bearing at the end of the shaft, which is not only under radial load, but must also withstand the weight of the entire structure, a thrust roller bearing with short rollers, or radial thrust roller bearings with a tapered roller type 7000 (e) are best suited. on the image.

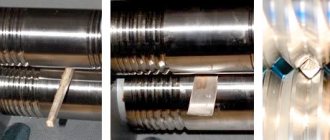

Bearing seating

In order to correctly install the bearing, it is necessary to prepare the appropriate place on the shaft for landing the bearing races; for the external one, you need to make an axle box, the outer diameter of which must correspond to the inner diameter of the “beater” pipe. The inner race is pressed onto the shaft. First of all, the seating surface must be smooth and parallel and made to an accuracy class of at least 5. The end bearing shank must have a thread with a bearing fixing nut.

The bearing can be seated on the prepared shaft surface either hot or cold. When shrink-fitting, the inner diameter of the bearing should be approximately 0.07 mm smaller than the shaft diameter, and before landing, it should be heated in oil to a temperature of 80°C.

Cold fit - the diameter of the seating surface of the race must exactly match the bearing. In this case, it is allowed to place the clips on a special glue. The permitted tolerances for bearing fit on the shaft can be seen in the figure.

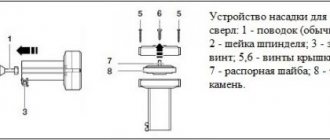

Attaching the vibrator to the drill

The design of fastening an in-depth vibrator for concrete when attached to a drill can be imagined by looking at the figure. The mount consists of a clamp attached to the protruding part of the spindle. Stretches are welded to it, which hold the protective pipe and the entire structure. And although this is not the best option, the principle itself is simple and clear.