Wood carving has an ancient history. And although few examples of such products have survived, they exist, for example, ancient Egyptian wooden sarcophagi. In those days, craftsmen used mechanical tools. Nowadays, this ancient art has received a second life, and modern power tools for wood carving have significantly expanded the capabilities of the ancient craft.

In this article, we will consider in detail the types of electric tools, the purpose of the devices, the best manufacturers and the cost of the devices.

Electric chisel

The classic hand chisel was recently replaced by an electric analogue. The wooden handle was replaced with a plastic case in which the electric drive is hidden. The device has a power button, an indicator of operating and locking modes, as well as a nozzle lock.

Very often, an electric chisel is called an electric scraper or an electric chisel. It combines many functions and allows you to perform a large number of jobs:

- removing old coating, traces of technical fluids or adhesive base from the surface;

- performing, including the most miniature, wood carvings;

- complete or partial removal of the thin top layer from the material being processed.

The main advantage of this tool is its versatility. Thanks to the power control system, both rough processing of the material and fine finishing, including wood carving, are performed. The downside is that during work you need rest periods to cool down. Working surfaces require regular sharpening.

Electric chisels perform both rough processing of material and fine finishing, including wood carving.

When choosing a chisel, decide what and how often it will be used. If from time to time, a device with a minimum number of functions is sufficient. For frequent professional activities, a powerful, multifunctional device with a large number of attachments is suitable.

For small jobs, a miniature device is suitable; for large, large-scale jobs, the tool must match.

But in all cases, when choosing, they focus on:

- The body must be light and strong, without loose parts.

- The tool should fit comfortably in your hand.

- The presence of a lock button and a regulator of operating modes is mandatory.

- The attachments should be held tightly in the retainer and can be easily removed.

- Nozzles must be made of durable steel.

The manufacturer also plays an important role in choosing an electric chisel. Below are the main companies and the characteristics of their tools.

- Makita TM 3000С

Electric chisels have a proprietary set of attachments that allow you to perform a wide range of work. The tool is easy to use. There are practically no vibrations in the body. Has 12 fixed positions for interchangeable attachments. It has a power of 320 W, engine rotation speed is from 6000 to 20000 rpm. The package includes a chip remover with a vacuum cleaner.

Prices fluctuate around 13,000 rubles.

- Bosch Pmf 190 e set – 7489

It is characterized by the accuracy of the work performed, minimal noise and vibration. Ideal for household chores. Convenient, lockable start button. The attachment of the attachments at different angles to the device is reliable and does not allow slipping. Power 190 W, motor rotation speed from 15,000 to 21,000 rpm. Includes 2 segmented and 3 immersion elements, a set of sandpapers, a mounting screw and a key.

The cost is around 8000 rubles.

- Skil Masters 1490 NA – 4850

Designed for finishing wood, plastic, metal and drywall. Allows you to sand difficult areas. Has a speed control function. It is characterized by low weight and a comfortable key. Power 220 W, engine rotation speed from 12,000 to 19,000 rpm. It has a set of replaceable attachments, a sanding pad, a set of sandpapers, and a key.

Price 4500 – 5000 rub.

Features and Specifications

Electric chisels produced by modern manufacturers, including equipment from Bosch, as well as the electric scraper model Skil 7720, have a similar design, which includes the following components:

- body made of durable plastic and equipped with a comfortable handle;

- electric tool power button and speed control;

- a signal element indicating the blocking of the equipment as well as the selected speed of its operation;

- a special socket that ensures quick change and reliable fixation of the working tool.

Components of the Bosch PMF 190E multicutter

It is no coincidence that the electric chisel also has another name - multi-cutter, because the standard set of such a device includes several different types of working tools. So, for example, the set of the popular electric multi-tool model Skil 7720 has:

- steel knives 60 mm wide - 5 pieces;

- wide (60 mm) spatulas, also made of steel - 3 pieces;

- flat-type steel cutters with a blade width of 15 mm - 2 pieces;

- universal steel scraper blades 35 mm wide - 5 pieces.

Having such a rich set of working tools, any specialist or home craftsman can use an electric chisel to effectively solve a wide variety of tasks.

Multifunctional tool Skil 7720 with a set of various attachments

As an example, you can also consider the characteristics of the electrical equipment of the popular Skil 7720 model, which make it possible to understand how wide the technical capabilities a device of this type has:

- power consumed by the device - 250 W;

- platform working stroke - 2.2 mm;

- 3 operating speeds with oscillation frequency respectively: 6500/8500/9500 kol/min;

- acoustic pressure value - 81 dB;

- acoustic power value - 92 dB;

- the level of vibration created by the device is 12.7 m/s2.

- tool weight - 1.2 kg.

The convenience and efficiency of using the electric multi-cutter model Skil 7720 is also ensured by the fact that it is equipped with a special device that allows you to quickly and without the use of additional devices replace the working tool. The electric chisel of this model has the option of additional feed of the tool forward, which also makes the use of this device more convenient and efficient.

Electric chisel device

Jigsaw

Universal device. Used for wood carving and straight cuts. Suitable for working with plastic, metal, plasterboard and wood. The versatility of a jigsaw is its main advantage; unlike mechanical tools, it does not require frequent replacement of saw blades and allows you to increase the speed of work. The disadvantages include the thick canvas compared to a hand-held device, which does not allow the creation of miniature patterns.

Jigsaws are divided into two large groups - household and professional. The first ones are suitable for small household work and rare finishing works. The latter are intended for large-scale, voluminous work.

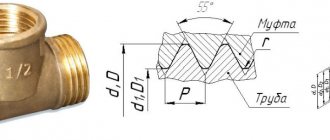

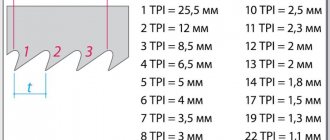

Different materials require saw blades with different characteristics.

Choosing the right file will improve quality and speed up work

On wood

- fast cutting – elongated blade, with large and widely spaced teeth;

- clean cut – average spread and tooth size;

- figured cut - a narrow blade with small teeth that are beveled towards the back.

For metal

Saw blade made of durable metal with wavy teeth.

For polymer materials

Saw attachment with exceptionally fine teeth.

There is a large selection of jigsaws on the market; the most popular are models from three companies:

- Makita. The company's best-selling model is 4350ST.

Tool power 720 W, suitable for working with material up to 135 mm thick. It has a pendulum stroke and can be connected to a vacuum cleaner. There is a keyless replacement of nozzles. The tool is well assembled, has a low noise level, and has the ability to perform work at different angles.

The price is around 10,000 rubles.

- Bosch GST 850 BE

Power 600 W. It has a pendulum stroke and quick-release fastening of the saw blade. Cutting depth up to 85 mm. The handle is staple-shaped. Built-in sawdust blower. The advantages are low noise level, speed adjustment by changing the force of pressing the button, smooth cutting line. Connecting to a vacuum cleaner will get rid of dust. Cons: no cutting light, no storage case included.

The price is around 10,000 rubles.

- DeWALT DW 333K

Power – 701 W. Cutting depth of wood up to 130 mm, metal up to 30 mm. Has a four-stage pendulum stroke. The frequency of the blade movement is 3100 movements per minute. Characterized by fast and accurate cutting, convenient speed adjustment. The sole is adjustable up to 45 degrees in two directions. The downsides are weak sawdust blowing and lack of lighting.

Tool classification

Electric chisels are grouped according to the type of attachments intended for different types of work.

Among them are the following options:

- Flat is the most common type, equipped with a blade 6-30 mm wide. The blade is sharpened at an angle of 15-25°. Used for final finishing of workpieces.

- Round – suitable for forming simple recesses and processing parts.

- Oblique – a nozzle with a blade beveled at an angle of 45°. Such equipment is used when creating longitudinal recesses and initial finishing of elements.

- Angular - V-shaped equipment with two blades for cutting recesses of the corresponding tuyere.

- Semicircular – a nozzle for creating ornaments of varying complexity.

- Cranberry - available in models with straight, inclined or rounded blades.

- Caesars are a semicircular nozzle with a narrowed base. It is intended for the formation of thin recesses and ornamental details.

Plane

Indispensable for leveling the surface, removing knots and irregularities. Used for tongue-and-groove and quarter cutting. Often used as a planing device. When using an additional ruler and square, it is used to level the workpiece and give it a square shape.

The advantages of using planes include:

- ease of use - no physical strength required;

- high productivity;

- used as a rimming or jointing tool.

Minuses:

- not used for treating floor coverings;

- traumatic;

- After using a power tool, manual processing with a mechanical device is necessary.

You will find useful tips on choosing a plane in this video:

The choice of electric planer is determined by the scale of the work. Accordingly, a suitable optional tool is selected. And in order not to make a mistake with your choice, you must adhere to the basic rules:

- Power tools for woodworking are purchased in specialized stores, from sellers who have the appropriate certificates. A quality device should have a warranty of at least two years.

- When purchasing, both the tool and its equipment are carefully checked.

Below are the models of electric planers, their characteristics and prices.

- Metabo ho 26-82

Designed for processing and chamfering wood, suitable for cutting quarters. The handle is equipped with a non-slip nozzle. Aluminum casting sole.

The price varies around 8500 to 9500 rubles.

- Makita KP0800

Equipped with a powerful motor, which allows you to work with hard wood. It is lightweight and has a convenient blade replacement system.

Price from 8000 to 9000 rubles.

- Hitachi P 20ST

Suitable for wood processing. Easy. Equipped with a lightweight non-slip handle. There is a button for fixing the start mode.

The price is around 5000 rubles.

Selection rules

Would an electric chisel be useful for your work?

Of course! Not really

The device blade can be made of stamped, die-cut or forged metal.

Stamped cutters have extended side edges. Forged products have a feather that is slightly narrowed in relation to the edge. They can be used on hardwood. Cutting varieties have the thinnest feather of the presented types of tools and are convenient for manipulating soft types of wood.

A high-quality chisel has the following important qualities:

- high overall strength;

- reliable and strong handle;

- resistant sharpening.

The metal of the blade and blade must have a hard and viscous structure. The best models are made of chrome vanadium alloy steel (possible markings: “ХВГ”, C-105-W/2, “chrome vanadium”, CrV).

Budget options are made from carbon steel (“2U-7”, drop forged, “U-8”). The structure of this material is quite fragile and the product does not last long.

Units labeled “chrome vanadium” may be counterfeit. It is worth doubting the quality of the product given the low cost of such a model and the lack of information about the manufacturer.

Circular Saw

The electric circular saw is a universal tool; it allows you to work with wood, laminate, and metal. Replaceable saw blades allow you to work with almost any material. The main disadvantage of the tool is the risk of injury and high cost.

Pros:

- ability to perform any type of cut. The exception is figured cutting;

- the weight in the structure is distributed evenly, this reduces physical stress during work and increases work efficiency;

- the design of the tool ensures precision work.

An important parameter when choosing a circular saw is comfort during use. Before purchasing, you need to hold it in your hands for a couple of minutes and, if possible, make a cut.

When purchasing, it is important to pay attention to the complexity of setting cutting parameters.

It is important to choose tools from well-known companies that have specialized service centers.

The most popular models are:

- Makita HS 7601

The device has a power of 1200 W and a rotation speed of 5200 rpm. Suitable for working with wood, plastic, plasterboard, metal. Has a low noise level. It is possible to connect a construction vacuum cleaner. The downsides are the lack of a dive indicator and the soft rip fence.

Price from 7,000 to 10,500 rubles.

- Hammer CRP 1500 D

Power 1500 W. Equipped with a laser, has a mode lock button. Can be connected to a vacuum cleaner. Powered by battery. Suitable for cutting wood. If you have a specialized disc, it is suitable for metal and plastic. It can be used outdoors for cutting down trees. The disadvantages are the large mass and inconvenient fixation of the depth of cut.

Price 5,000 – 6,000 rubles.

- DeWalt DWE560/

Power 1350 W. Rotation speed 5500 rpm. Has a low noise level. Allows you to make the most accurate cuts. It is possible to connect to a vacuum cleaner. The downside is a weak rip fence.

Price 7300 – 10800 rubles.

Sander

This is a tool that allows you to process the surfaces of wood, metal elements and stone. Indispensable for grinding and polishing. Used in professional and household work.

The choice of an electric grinder depends on the work for which it is chosen. A consultant from the store will help you decide on the type of tool.

When choosing, focus on:

- ease of use – weight, comfort of the handle, cord length;

- quality of materials;

- power - the higher, the greater the productivity;

- additional functions.

Popular sanders are:

- Bosch PBS 75AE

Belt type grinding tool. Power – 750 W. The belt rotation speed is 350 m per second. Working surface – 76*165 mm. Has a dust bag. Provides quick belt replacement and a large sanding area. The downside is that there is no way to properly process the corners.

The cost fluctuates around 9,000 rubles.

- Ryobi ROS300A

Orbital type model with a power of 300W. Has a built-in ventilation system. The machine is durable and equipped with a shockproof housing. The device is compact and light weight. The controls are smooth. Equipped with light indication. The downside is an inconvenient dust bag.

Price – 3500 – 5000 rub.

- Bosch PEX 300AE

Orbital sander with a power of 270 W. Number of revolutions – 12000. Copes perfectly with a large area of the processed surface. Leaves little dust. Built-in vibration control system. The presence of micro Velcro makes it easy to change the sandpaper. The downside is the high noise level. Headphones are required during operation.

The cost is about 5000 rubles.

Surface grinder

Unlike a sander, it is a vibrating tool with a flat sanding platform. Consumables for performing surface treatment are attached to it. These tools are designed for large-volume work, without a lot of time. Abrasive consumables are attached to the working surface using Velcro. The machines are comfortable to use as they are light in weight – maximum 3 kg. Motor power starts at 110 W and reaches 600 W. The shaft rotation speed reaches 25,000 rpm. The level of vibration of the sole depends on the speed of rotation.

The choice of machine depends on the upcoming actions - for fine work, a tool with a displacement amplitude of 1.5-2.5 mm is suitable. For coarse – up to 5 mm.

Used for work in workshops, for surface restoration. Allows you to level the surface, remove dirt and oil traces from materials. Prepare walls and floors for painting or covering.

Below are examples of popular surface grinding tools.

- Interskol PShM-115/300E

Surface grinder with a power of 300W. Suitable for household work. Equipped with a dust collection system and a speed control system. Has a reliable wear-resistant sole. Equipped with a rubberized comfortable handle. The downside is the noise level.

Price – 2000 – 2500 rub.

- Makita BO3700

Power 180 W. Platform oscillation – 20,000 per minute. Has a dust collector and vibration damping system. It has a low noise level and can work with any sandpaper. The downside is a lot of dust after work.

Cost from 3500 to 5000 rubles.

- Hammer PSM 300

Power 300 W. Platform oscillation – 12000 per minute. Equipped with a speed control system and a power button lock. Has an additional handle. Spare brushes and sheets included. Made from quality materials. Suitable for frequent use. The downside is that it sometimes overheats during operation.

Price – 2000 – 3000 rubles.

Three factors that determine the choice among different brands

Chisel blade

A short excursion into metal science. Hard steels (high alloy tool steels or high speed steels) stay sharp longer (and cost more) than softer alloys (carbon steel). But mild steel is easier to sharpen. Almost all of the chisels tested had Ol carbon tool steel blades, and among them, the Kirschen, Pfeil, Stanley Sweetheart, Ashley lies and Veritas stayed sharp the longest. Both sets of chisels with A2 high-speed steel blades (Blue Spruce and Lie-Nielsen) maintained an edge nearly three times longer than the best carbon steel examples, which may justify the high price. However, the new PM-V11 alloy, from which the blades of one of the Veritas sets are made, refutes the traditional rule for hand tools: “tight steel, tight sharpening.” These chisels stayed sharp even a little longer than their HSS competitors, and we were surprised by their sharpening speed, which was average compared to A2 and Ol steels.

You can increase the edge life of chisels made from hard but brittle steel, such as A2 or PM-V11, by increasing the secondary bevel angle to 30° instead of the usual 25°.

The width of the chisel blade usually doesn't matter much unless you have to trim sockets - to trim the ends of a 6mm socket, you need to have a 6mm wide chisel. All the sets we tested consisted of 6, 12 and 18mm wide chisels, and some also included 10mm wide blades. Chisels of this width are suitable for most carpentry tasks, however, sometimes it is good to have an additional 3mm blade, as well as a chisel 25mm wide or larger for trimming wide tenons or long sockets.

A thick blade with narrow chamfers limits the capabilities of the chisel

Both chisels are 12mm wide, but the thick edges of the Lee Valley blade (left) make it difficult to clear the corners of the dovetail lugs. The wide beveled blade of the Ashley lies chisel (right) is more suitable for working in tight spaces.

The flat edge of the blade, opposite the bevel, guides the cutting edge and gives stability to the tool for better control, which is why we appreciate sets of chisels that are sold with perfectly flat backs - Lie-Nielsen, Blue Spruce, Pfeil and both Veritas sets. As for other sets, it took several minutes, and sometimes even an hour, to level the backs using various manual and mechanical devices.

Chisel handle

Good chisels can last for decades, so take your time when choosing a tool that suits your hand. If possible, test it before purchasing. If you have large hands or problems with the wrist joints, it is better to choose chisels with large diameter handles, such as Stanley Bailey, Narex, Irwin Marples, Pfeil, Kirschen and Robert Sorby Sheaf River. For those with small hands, chisels from Blue Spruce, Lie-Nielsen, Stanley Sweetheart, Traditional Woodworker and Veritas are better suited. (In about half of the sets, narrow chisels have slightly thinner and shorter handles than wide blades, giving more control during delicate work.) The shape of the handle, and the way you hold it for different tasks, is just as important as its sizes. A variety of handle shapes are shown in the photographs.

Enjoy convenience in different operations

| When chiseling sockets and tenons, we hold the handle tightly in our fist, providing maximum control. First of all, try holding the chisel this way. |

| And when doing light trimming with a chisel, for example, in the corners of the eyes, when there is no need for a mallet, one hand usually guides the blade, while the other pushes the handle. Would a chisel be convenient for you for this type of work? |

Also find out the features of attaching the blade to the handle. Shown here are the two most common methods - with the so-called “skirt” and the shank. The two sets we tested had skirt mounts (Lie-Nielsen and Stanley Sweetheart). Such handles sit tightly in conical recesses; if they become loose, they can be easily corrected with a light blow of a mallet, and this method is preferable if the chisel works as a lever. But they are more difficult to make, so be prepared to pay more. Chisels with a shank are cheaper and, as a rule, their handles are more comfortable, but with this method of attachment the handle can easily break, since the shank acts like a wedge inside it. The metal collar helps prevent splintering, but does not guarantee it. For basic work in the workshop, it is advisable to purchase inexpensive chisels such as the Stanley Fat Max. Their plastic handles with a metal butt pad can easily withstand a hammer blow, and their short blades dull relatively quickly. These tools will be useful on construction sites, as well as when making DIY crafts and scraping off dried glue or paint.

Carpenter's chisels (above and in the center) have a blade that is simply attached, so you can work with them using hand force or light blows with a mallet, however, a hammer can split the handle. The shank of an inexpensive carpenter's chisel (below) usually extends through the handle and ends in a metal butt plate that can withstand hammer and mallet blows.

While none of the plastic handles cracked in testing, we preferred chisels with wood handles (mostly out of aesthetic preference), especially those made from hard, dense woods like maple, bubingo, elm, hornbeam, boxwood, or ash. Handles made from softer beechwood (Bailey and Narex) usually have metal rings to prevent splintering when struck with a mallet.

Chisel price

You can buy chisels individually when you need them. But often a set of several chisels of the most popular sizes is cheaper than buying the same chisels one at a time. We divided the seventeen sets we tested into three price groups: less than $90, from $130 to $230, and more than $275. They all cope with basic tasks in the same way. But be prepared for the fact that cheap chisels will have to be sharpened and adjusted more often than more expensive ones made from high-quality steel.

Testing of chisels is in full swing

Safety rules when working with power tools

Tools require attention and compliance with safety regulations:

- Before starting work, check the serviceability of the tool, the integrity of the electrical wiring elements, and the reliability of fastening the elements:

- check the surface for the presence of foreign objects - nails, staples;

- Work with power tools should be performed in a comfortable position. The instrument is held with both hands;

- replaceable elements are used only those recommended by the manufacturer;

- When working, use protective glasses and gloves.

This video clearly shows why you need to know and follow safety precautions.

Security measures

As with any electromechanical equipment, safety precautions must be strictly followed when using an electrically powered chisel. The main rules are that it is necessary to protect your hands with work gloves, as well as your eyes, for which work glasses are used. The first thing you need to do when starting to work with an electric chisel is to fix the working tool in a special socket, which is done in the following sequence:

- using a special locking switch located on the device body, you need to unlock the socket;

- the tool required in this situation is inserted into the unlocked socket, with its cutting edge pointing down;

- After installation, the socket is blocked, for which the locking switch is pulled forward.

After each processing cycle and removal of the working tool from the socket, its rod and the electric scraper itself must be thoroughly cleaned.

Cleaning the collet

To turn on the electric chisel, there is a special toggle switch on its body, with which the device is turned off. Only after turning on the device can you select the required processing speed, for which a special switch is also used on the equipment body. Work using any chisel with an electric drive, both equipment from Bosch and other manufacturers, and the Skil 7720 MA model, is performed in three speed modes:

- with low moving speed - processing that requires high precision; at medium speed;

- at high speed when processing must be completed in a minimum period of time.

There are no specific recommendations for choosing the speed of movement of the working tool; each master decides for himself what speed to choose, taking into account the characteristics of the surface being processed.

It is better to cut a groove in wood with a bimetallic segment saw blade at maximum vibration frequency

The algorithm for using an electric chisel is as follows.

- The switched on device is brought to the surface to be treated and installed at a slight angle to it.

- By applying slight pressure on the surface being treated with the working part, they begin to move it along it in the direction “away from you”.

When performing processing, you should not press the tool too hard on the surface being treated: this can lead to damage. The processing process using an electric chisel is well demonstrated in videos that are easy to find on the Internet.

Most models of scrapers or chisels equipped with an electric drive are intended for home use, so they are not designed for prolonged and intense loads, which can quickly damage the equipment. Therefore, when working with an electric chisel, you should not overload it; you need to periodically, after each processing cycle, give it time to cool. In addition, to ensure processing efficiency, you should regularly sharpen the working tool installed in the electric chisel.

Instrument care

To ensure that the power tool is always in working order and in good working order, it is necessary to care for it and perform the following actions:

- Regularly sharpen and change removable working parts.

- The tool is stored in a protective container in a dry place - this will prevent rust from appearing on the elements.

- Regularly inspect the instrument to ensure its integrity.

- It is important to regularly lubricate the tool mechanisms with specialized oil.

- If necessary, seal the device with sealing paste.

- Cleaning internal cavities from dirt.

Wood carving is impossible without the use of hand tools; read about what you may need in your work in the article: “Basic tools for wood carving.”