In construction terminology, dowels mean rounded rods or bars designed for fastening building parts by installing them in specially prepared holes. The main purpose of dowel connections is to counteract shear forces due to the elasticity of the dowel body.

A wooden dowel for timber is called a dowel or a wooden nail; dowel (dowel) connections are used in the construction of log houses for residential buildings, bathhouses and outbuildings, and are used in the installation of various wooden structures. The technology has a long history; similar fastenings were discovered in buildings of the 16th century on the territory of modern Austria and during excavations in Veliky Novgorod.

What is a concrete dowel?

Such screws are most often used for fastening heavy structures - frames, door jambs, cabinets, shelves, fences, heating radiators and other communications. The screw is held tightly due to the uneven two-start thread and notches along its entire length. This shape ensures reliable fixation even in a concrete wall. On the head of the screw there are notches for countersinking.

The dowel for concrete looks like an elongated self-tapping screw with a thread in the center. On one side there is a head with a hexagonal groove, on the other side there is a sharp end. They are made from carbon steel with a protective galvanized or anodized coating, which provides protection against corrosion and other influences. For screwing, TORX T30 bits are used.

The fasteners can be reused, which is a great advantage for temporary structures. They are chosen for their low price, resistance to moisture and stress, and reliable fixation of objects, regardless of the material.

Advantages and disadvantages of dowel joints

The advantages of using wooden dowel connections have been tested for centuries, these include:

- Dowels for timber are resistant to deformation, retain elasticity for a long time, and withstand significant bending loads;

- Fastenings counteract the negative consequences of shrinkage, eliminate the causes of the formation of cracks, crevices and gaps between the crowns;

- The timber and dowels react equally to ambient humidity and climate changes, which avoids wall deformation;

- The use of wooden fasteners allows you to build a house without the use of construction equipment and special tools.

The disadvantages include: additional labor costs due to the need to drill installation holes; when selecting materials and carrying out work, certain rules must be followed.

Benefits of use

The main advantage, compared to other concrete screws, is that it is used without a dowel. Before screwing anything to a concrete wall, beam or partition, you need to drill a hole with a diameter of 6 mm, then screw the dowel into it. The density of concrete does not matter. The screw can be used for dense or cellular concrete. You can screw self-tapping screws into walls made of some types of cellular materials without pre-drilling.

Types of dowels for concrete

Head shape

- Secret . A flat head that allows you to tighten the screw deep into the structure without leaving a bulge on the surface. The head has cross-shaped slots. There are notches for countersinking.

- Rectangular . They are shaped like a hook. May be rounded.

- Hexagonal . The thread is located inside with a cross-shaped slot. For these types, open-end and ring wrenches are used.

- Hairpin . There is a nut threaded fitting.

The type of head affects the way the dowel is screwed into a concrete wall. A screw with a hook or a pin can only be mounted with a pre-drilled hole. Other types can be screwed directly into the wall.

Coverage type

- Blacked out . Black self-tapping screws with oxidized coating. For use only in rooms with normal humidity. It is not used on the street or in basements.

- Copper-plated . Yellow color. Sensitive to various influences. Used only for indoor work.

- Galvanized . Silver color. Can be used indoors and outdoors. They do not collapse or deform.

The dowel is used where other fastening is impossible: the base is too fragile, or installation causes certain difficulties.

The main sizes of screws that can be bought in stores

The diameter of the dowel always remains the same - 75 mm. The length of the working part varies - from 52 to 202 mm in increments of 20 mm, except for the 30 mm gap between 150 and 180 mm. Pins are sold in boxes of 20, 100 and 200 pieces. On some construction sites you can order from 1000 pieces. There is no price difference between screws with different coatings. The cost depends only on the length of the working part.

How to make a dowel with your own hands

DIY Nagel

It is advisable to buy a complete set of dowels for building a house; if a few pieces are not enough, you can make dowels yourself. If your household does not have a lathe, you can use a shovel handle. The diameter of the handle is 39-40 mm - this is a lot for a dowel; the excess must be removed with an ax and a plane. A chamfer is removed from the seating edge to form a cone 7-10 mm high, and the surface is cleaned of unevenness using sandpaper. Rectangular dowels for timber are cut from scrap boards using a circular saw or jigsaw, on the seating side the edges of the ribs are cut at an angle of 45-60 degrees, the surface is subjected to finishing (grinding).

Drill for a dowel for concrete: is it necessary?

Before screwing the mount into the concrete wall, you must drill a hole. To do this, use a drill with a diameter of 6 mm. The width and length of the hole should be 15-20% smaller than the dowel itself. If you use an electric drill in drilling mode, then a universal or special concrete drill will do.

When using an impact drill or hammer drill, a drill is used that has grooves located on a cylindrical surface. For expanded clay concrete, foam or aerated concrete, there is no need to drill a preliminary hole. This is done in order to create full contact between the screw and the concrete.

Blitz tips

There is a set of installation tricks that will allow you to build your dream home that will last for many years:

- Chess order. The condition is not mandatory, but highly recommended by carpenters of all stripes;

- To avoid sagging, it is necessary to use round-shaped wooden dowels. Square products are mainly promoted by manufacturers as they are easier to manufacture;

- When clogging, you can and should reduce friction. To do this, it is enough to use a soap solution;

- It is recommended to use birch fasteners. This guarantees the reliability of the structure, gives a certain charm, and does not increase the cost of construction;

- Similar humidity between the tenon and the beam is a fundamental condition for the durability of the structure. You need to pay close attention to this;

- Feel free to use additional fasteners. Science does not stand still; modern devices can make the task much easier.

How to screw a dowel into concrete

- Before installing the structure, it is necessary to calculate the load. This is quite easy to do, since the diameter of the screws is standard. Lightweight items such as wall shelves can be mounted on 72mm long dowels. For heavy and bulky objects, the screw is selected individually.

- Before drilling, it is necessary to clean the wall surface. Future fastenings are marked on the surface. Before marking, you need to make sure that it does not fall into the passage of fittings or wiring. There should be no more than 60 centimeters between the fastening points; when installing windows, the step should be no more than 70 centimeters. 5-6 centimeters retreat from the edge of the wall.

The depth of the drilled hole should be slightly greater than the length of the dowel. If the hole is not deep enough, a metal pin can be used to achieve the desired depth. During installation, deviations from the drilling axis are unacceptable; the drill must be held strictly perpendicular to the wall. The hole is cleaned of dust using a cleaning rod or a construction vacuum cleaner.- In the absence of a tool, simply use a drill to drill a preliminary hole. He is driven into the wall with a hammer. After several blows, turn and hammer again until a hole of the required size is obtained.

- When screwing the dowel into concrete, it is not recommended to use a screwdriver. Since the screw itself is quite fragile, it may not withstand excessive tightening and the heat generated during operation of the power tool. For installation use a simple screwdriver. If you have problems with screwing, it is better to take a hammer. When screwing a screw into a wall made of porous concrete, the installation must be done carefully.

How far apart are the dowels?

The distance from the edge of the beam must be at least 300 mm, the distance

between the attachment points is from one and a half to two meters.

Interesting materials:

How to quickly remove guides in Photoshop? How to quickly remove line breaks? How to quickly remove subscriptions on Instagram? How to quickly remove your likes on Instagram? How to quickly remove the background in Photoshop? How to remove the second system from the bootloader? How can you remove a person from your important friends on VK? How can I remove my voice on VK? How can I remove instant glue from my hands? How can I remove a password on my computer?

Is it possible to fasten heavy structures

Concrete dowels are used when working with structures made of different materials. It is used for metal, plastic or wooden products. It is also used to attach aluminum and plastic windows to concrete walls and beams. The notches on the working surface of the screw prevent any unscrewing.

Dowels are used to secure aluminum profiles, door frames, roofs, stairs, awnings, fences, and fireproof doors. When choosing the length of the working part, it should be taken into account that a screw measuring 7.5x72 mm can withstand a structure of 10 kilograms. To secure a structure weighing more than 100 kilograms, it is necessary to use a dowel of at least 152 mm. The load-bearing capacity of the self-tapping screw depends on the length of the working part. The material from which it is made allows it to be used in home renovation, construction and industry.

For concrete, the dowel is the most reliable fastening. Its low price and ease of use will be an excellent assistant in construction and repair. A minimum of tools for installation and various types of screws will simplify repairs and make the fastening reliable and strong.

Any calculations will show that during repair, construction or reconstruction, the share of fasteners, compared to other materials, accounts for negligibly small costs. However, if we make the wrong choice or use these components incorrectly, we risk the reliability and functionality of the entire facility.

Therefore, there is an unwritten rule: “you cannot save on fasteners and consumables.” But what’s interesting is that sometimes the most accessible and inexpensive solution can be the most successful. This happened with dowels - special parts for assembling log houses, which can be made of wood, polymers or metal. Let’s try to figure out which option is better and why.

Structure and purpose

A dowel for concrete is a special screw (self-tapping screw) in the form of a metal rod with a sharp tip and unevenly cut threads. Hardware is available with heads of different shapes, but more often it has a hidden design with notches on the inside. This is a countersink that ensures maximum adherence of the fastening element to the product fixed on a base with a solid structure.

Typically, the dowel is tightened with a tool with a cross bit or a bat, the shape of which has the shape of a six-pointed star. It depends on the slot on the head of the fastener. Experts call the hex star version TORX.

A special screw is a fastener for working not only with concrete, but also with natural stone, hollow and solid brick. If the diameter is selected correctly and installation rules are followed, the dowel can even be used for fastening in porous substrates. Reliability of fixation is ensured by frequent threads with variable heights. The following are attached using hardware:

- door frames;

- window frames;

- radiators;

- hangers; chandeliers;

- curtain rods;

- shelves;

- cabinets and other various hanging interior elements.

Dowels with anti-corrosion coating are used outdoors and indoors. With their help, wooden, plastic, and aluminum structures are fixed. Specialty screws are popular because of their reusability. Therefore, they are used for fastening temporary products. These are ladders, handrails, scaffolding.

Problems that can be solved with dowels

It has always been believed that traditional wooden architecture in Rus' managed “without a single nail.” But even hereditary aerobatic masters use something. This is a dowel.

To be more precise, dowels, also called “dowels,” are not exactly fasteners in the traditional sense. The thing is that a dowel works differently than, for example, a nail, screw or pin.

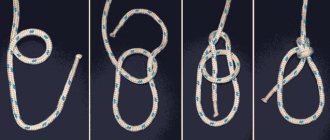

To install it, holes are drilled every 1.5-2 meters in each element of the assembled wooden wall, with a diameter comparable to the cross-section of the dowels (so that the dowel fits in without excessive effort). Drilling is carried out strictly vertically and strictly along the axis of the wall.

What is a wooden dowel?

Pins, which can be purchased at numerous retail outlets in our country, are in most cases wooden. These are whips from one to one and a half meters long, with a circular cross-section. In some cases, builders use an edged block as a dowel, but it, resting against the walls of the socket only with its edges, can become very loose over time. In addition, its total cross-sectional area (and therefore strength) will be significantly less than if a round dowel were driven into the same hole.

The diameter of standard dowels is either 30 or 25 mm. The choice is made depending on the size of the wall materials used. The defining threshold is considered to be 150 mm. If the diameter of the log is less than this value, then it is worth ordering a dowel with a cross-section of 25 mm, and if it is larger, then dowels of 30 mm are better suited.

If we talk about the types of wood used, then the best option is expected to be expensive oak or beech, since their wood is the most resistant to mechanical stress. In turn, spruce, pine and aspen are at the other pole - products made from them are inexpensive, but will be too soft to be used for these purposes. The golden mean is birch. Turned birch dowels, even if there are knots, can cope well with the tasks.

The advantages of birch dowels include favorable price and availability. If they have the same moisture content as the material of the crowns, they will work as a single whole, and if they change in size, then the same. In addition, unlike metals, wood has low thermal conductivity, which is why this embedded part will never become a bridge of cold, begin to rust, or become covered with condensation...

Types of dowels

There are many types of fasteners, but they are conventionally divided into groups according to material and shape. Let's consider this issue in more detail.

Material of manufacture

Two types are actively used:

- Wood. Most experts strongly recommend using a wooden tenon when constructing wooden structures. The main advantages when choosing such fasteners are given:

- Even drying. The beam and dowel should be approximately the same humidity. This will allow the shrinkage process to go through with virtually no visible changes;

- Not affected by temperature changes . The tree practically does not change its linear dimensions at different temperatures, so the fastening element will always be in place;

- No rust . Metal rusts over time, which leads to rotting of wooden surfaces in contact with it;

- There is no condensation. With a sharp change in temperature, moisture forms on steel, which is completely useless inside a load-bearing wall.

- The dowel fuses with the wall. After a certain time, the house will become monolithic, the wooden surfaces will be soldered together.

- Metal. This option also applies to a budget fastening method; waste materials (pipes, fittings) are often used. Although experts prefer the previous method, The metal dowel has its advantages:

- The top layers of wood are protected from torsion;

- Durability of the structure.

Form

There are also several main forms:

- Round section. Taking into account the fact that the holes for fastening in the log are made with a drill, the round dowel will provide the maximum contact area, guaranteeing the reliability and durability of the structure;

- Square. It is easier to make such an element; it also costs less. But that's where the positives end. When entering the hole, the edges of the tenon are deformed, and the total contact area remains minimal. Building a house this way is dangerous;

- Narrow rectangle . The easiest option to manufacture. A board of a certain thickness is taken and cut into rectangles. The only advantage is the very small thickness. Suitable for narrow timber, but installation is extremely difficult.

Metal dowels and fasteners for assembling log houses

A dowel made of metal, by definition, will be stronger than a wooden dowel of the same cross-section, but not everything is so simple. This statement will be true only if a complete analogue in cross-sectional size is used. For example, you can often see how builders use 10-12 mm steel reinforcement, moreover, with corrugation, which is hammered into narrow holes with enormous resistance with sledgehammers. As a result, due to the ribs embedded in the wood, the crowns cannot sit freely and hang on the metal - cracks appear, the walls of the house begin to be blown by all the winds.

Due to the small cross-section of steel dowels and the plasticity of ordinary black steel, logs bend and wedge even smooth metal dowels during shrinkage. Therefore, powerful nails are also not the best option, although they are used quite often.

This problem would not have arisen if smooth rods with a cross-section of 20 mm or more, or pipes with a cross-section of 25-30 mm, had been used. But the cost of such metal dowels would be simply prohibitive.

There is a technology where, instead of dowels (in the usual sense), threaded rods perform a similar function. Meter pins are fixed at one end in the foundation, then crowns are put on them. As the walls are assembled, the studs are extended using couplings. Using nuts and washers, craftsmen are able to tightly connect piece wall material, including tightening the fasteners as they shrink.