Description of the substance

What is borax substance? Many minerals containing sodium tetraborate have been studied. Such deposits include:

- borax or sodium tetraborate tinkal decahydrate;

- kerite;

- Borax sediment is formed during the drying up of salt lakes (Searles, lakes of Turkey);

- minerals belonging to the borate class, containing calcium, sodium and similar elements other than borax.

Varieties of borax

There are two options for this material. In solid form, borax appears as a powder with small granules of a small fraction with a white color. The flux will not spread during application and can be precisely positioned in the required metal-to-metal junction areas.

Diluted borax has also been used for light metals. In some cases, liquids are very convenient, because you just need to dip a small part into the solution. In addition, the liquid form allows the use of borax even at low heating temperatures.

In some cases, it is advantageous to use a mixture of fluxes with borax included in the composition for the special characteristics of the base metal and special requirements for the connection.

Physico-chemical characteristics

- To a chemist, the mineral borax is sodium tetraborate decahydrate. The complex composition is reflected by the intricate formula: Na2B4O7x10H2O .

- According to the international classification, the mineral is classified as a borate.

- Glycerin also dissolves with warm water (the solution tastes sweet), but alcohols are powerless.

A cube of borax with an edge of 1 cm weighs 1.7 grams.

It begins to melt at 60°C, and at 320°C it dehydrates - the crystals crumble into white powder.

| Formula | Na2B4O7×10H2O |

| Color | Blue, colorless, greenish, gray, grayish white |

| Stroke color | White |

| Shine | Fatty |

| Transparency | Translucent to opaque |

| Hardness | 2—2,5 |

| Cleavage | Average of {100} and {110} |

| Density | 1.7—1.72 g/cm³ |

| singonia | Monoclinic |

The hardness of borax is one of the lowest in the mineral segment. This property is due to the chain structure of the mineral.

Composition and properties

The chemical nomenclature of soldering borax indicates that it is a crystalline hydrate of the sodium salt of tetraboric acid. If the substance contains 10 water molecules, then it is called sodium tetraborate decahydrate. In simple words, it is a salt that is surrounded by a shell containing 10 or 5 water molecules.

A temperature of 64 degrees causes decahydrates to melt and lose water in the process. Borax is dehydrated at a temperature of 380 degrees Celsius. Tetraborate is characterized by withstand heating up to a temperature of 742 degrees and melting when it increases.

Borax contains sodium chlorine, barium chlorine and, in some cases, boric acid. Flux in the form of a solution has a high ability to dissolve metal oxides, as well as fatty films and anything unnecessary that can prevent the adhesion of materials.

Thanks to the use of borax during soldering, many products are produced without defects.

Kinds

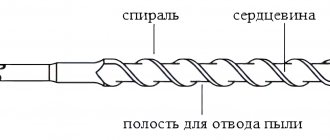

Based on appearance, welding drills are divided into 2 types.

- Solid. In powder form, flux has the form of solid fine fractions. This shape makes it easy to lay borax on a metal surface before the soldering process, while the substance does not spread. Solid borax is sold in boxes that are sealed, thereby protecting the substance from moisture and the negative influence of the environment. In the powder fraction, borax is white.

- Divorced. This type of borax is considered the most suitable for light metal and its alloy. The substance is the same powdered borax, but dissolved in a liquid. This feature of the flux makes it possible to use it at low soldering temperatures. Using diluted borax is quite simple: small metal elements are dipped into it and then soldered. This flux is popular in jewelry, as well as when working with wires and contacts.

Advantages and disadvantages of the product

Let's start with the pros:

- The drug is extremely affordable. The cost of a bottle of borax does not exceed $1, which is several times cheaper than other antiseptics and combination products.

- The drug is non-toxic, well tolerated and does not cause serious side effects.

- The product can be used in problem categories of patients: children, pregnant women, nursing mothers.

- The drug is effective, especially in gynecology. Glycerin has a softening and anti-inflammatory effect, relieving itching and burning, and boric acid helps restore the acidic protective environment of the vagina, stimulating the growth and reproduction of beneficial lactic acid bacteria.

Where is it used?

The mineral is popular in industry and everyday life. Its main mission is to be a source for obtaining boron.

Industry

Borax is used in various industries:

- Production of paper, glass, glaze, enamel.

- Component of technical fluids for mechanical engineering and the automotive industry.

- Disinfectant, preservative.

- Flux for soldering metals.

- Impregnation of textiles and ecowool cellulose insulation before painting.

Chemists use borax as a marker of the composition of metal oxides and the concentration of acid solutions.

Household sphere

The mineral powder has found application as a home sanitation product:

- Mold removal. Wet borax is applied to problem areas overnight. Wash off in the morning.

- Removing rust, scale, lime layer. A glass of powder is poured into the toilet, sink overnight, and cleaned in the morning.

- Bleaching. Before washing, add borax and baking soda (2.5-3 tsp each) to a container of water.

- Cleaning. Borax is dissolved with water (100 ml dessert spoon). Store in a tightly closed container, add to water when washing windows and floors.

- Removing gaps in pipes. A mixture of borax powder, soda (half and half), 200 g of vinegar (9%) and a liter of boiling water is poured into the pipe overnight.

- Aromatization. To get rid of mustiness and unpleasant odors, wipe the oven, refrigerator, and freezer with a borax solution.

Cockroaches and other insects are exterminated with “bait” from the yolk of a hard-boiled egg with boric acid.

Pure borax is scattered on the beds and along the baseboards to get rid of rodents.

Medicine, cosmetology

- The most popular pharmaceutical preparation from the mineral is boric acid.

- To treat fungus, doctors prescribe brown-glycerin preparations to patients.

- Borax is used in the production of shower gels, shampoos, and ointments.

- The non-food segment is in demand for a mineral obtained artificially.

The popularity of preparations made from the mineral is due to its affordable price.

The cost of a bottle of sodium tetraborate (30 ml) in pharmacies is 19-48 rubles, a kilogram of cockroach repellent is 250-300 rubles.

Scope of application of the drill

Sodium tetraborate has been actively used for the following purposes:

- as a flux during soldering and melting of metals;

- in analytical chemistry studies as a standard substance for determining the level of acid in a solution. Borax is also used to establish the characteristics of metal oxides;

- widespread use in the creation of glazes, enamel, glasses for optical instruments and decoration;

- the powder is used in pharmaceuticals and paper production;

- is a natural preservative and means for disinfection and control of parasites;

- is a component in the chemical industry to create household cleaning products;

- relevant application in the creation of cosmetic products;

- borax is used as a base for creating boron;

- the substance is a component for creating insulating building materials;

- in light industry, sodium tetraborate is applied to the product before the painting procedure.

Using a drill in everyday life

Borax can be found in most grocery stores. It is a relatively inexpensive product, making it an excellent choice for many household projects.

Use of sodium tetraborate as a medicine

The substance is very effective in controlling pests: cockroaches, ants and other household insects. The mixture is ready by mixing equal parts of powder with sugar. Sugar helps attract beetles and borax exerts its detrimental effect on the insect. It is recommended to keep the substance in hard-to-reach places, away from pets and children. Optimal places: under stoves, refrigerator and sink. Borax also works well against mice. You just have to apply the powder in the areas where the mice are located, and the borax will rid you of the pests. You can also sprinkle the solution on the carpet and vacuum it to eliminate the presence of fleas or treat the mattress to get rid of bedbugs.

Borax will get rid of rust. Mixing 1 cup of powder with 2 cups of water and 1 tablespoon of lemon juice makes an effective anti-corrosion agent. The paste-like solution is applied to the rusty items for about 15 minutes. After which the rust can be easily removed by mechanical friction.

Sodium tetraborate is a universal cleaner. Two tablespoons of borax are mixed with 2 cups of water to create an all-purpose cleaner. The solution can be applied in a spray bottle and used to clean kitchen surfaces and bathroom tiles and ceramics. Borax is great for removing very stubborn stains. Borax will help remove stubborn stains from the floor.

Borax will allow you to flush your home plumbing fixtures. Simply place ½ cup of borax into the drain with a few cups of warm water. Borax breaks down dirt that gets stuck in pipes. This will not only remove excess and unclog the drain, but also disinfect the system.

Application in forging and forge welding

Borax is actively used as a flux for forging and forge welding. The powder is a source of boron oxide, with excellent antioxidant properties. Borax can, if necessary, remove small cracks during metal processing, change the shape of a product, or when heated during artistic forging and blacksmithing of metal. The substance is classified as a high temperature flux. The processed workpiece with borax is characterized by more wear-resistant characteristics and durability.

Using borax in soldering.

During the melting of borax at a temperature of 700-900 °C, the surface of the material being processed is cleaned, and all excess inclusions are dissolved in the flux. During the processing of a material by forging, a thick layer of scale is gradually created. In some cases, the metal being processed may completely burn due to overheating of the part. But by using a thin layer of borax, this scenario can be avoided.

In industry

Industrial enterprises find the following uses for this substance:

- as a raw material for the production of boric acid;

- as an antiseptic in the production of bulk insulation materials such as “Ecowool”.

- as a means for determining the concentration of acid solutions;

- in welding production as a component of flux;

- in the mechanical engineering industry as a component of antifreeze and various lubricants;

- in glass production;

- the fabric is treated with sodium tetraborate for better dyeing;

- Borax is a component of almost all cosmetic products.

Using borax in the soldering process

In addition to household use, borax is a popular raw material for soldering. High temperature flux is produced as a finely dispersed powder. When heated above 700 degrees Celsius, the flux flows into a liquid state and becomes solder. I’ll tell you about the pros and cons of this flux in the table below.

| Pros of borax flux | Cons of solder |

| The elements being connected do not need to be heated to the same temperature. | After the borax solder cools, salt-type deposits form on the surface of the seam, which will have to be cleaned off from time to time. This is not very convenient for hard-to-reach places. |

| The quality of the roller is high even when connecting different materials. For example, metal and non-metal. | |

| The roller can be destroyed if necessary by reheating the borax to the melting point. | |

| The peak heating temperature of 700+ C will not allow copper parts to warp + the characteristics of the weld with this solder are higher than usual. | Flux absorbs moisture very well. A closed storage container doesn't even help. Too wet solder reduces the quality of the roller several times. |

| Capillary soldering itself is considered the best solution for connecting small and medium-sized parts. | |

| The powder mixture makes it possible to achieve a high level of seam strength. |

To learn how to use Borax without jambs, you need to maintain clear proportions when applying. For beginners in welding, this can be problematic, so gaining practical experience with such solder is extremely important.

Rules for soldering with technical borax:

- The base for applying boron powder must first be cleaned. The welder gets rid of various greasy stains, wax and other debris from the surface of the future seam. For this procedure I use regular sandpaper. It's quite enough.

- The soldering iron tip needs to be preheated before touching the solder.

- To form a reference seam, I advise you to heat the workpieces to the same temperature.

- The tip of the soldering iron should heat both sides of the elements being connected.

- Do not skimp on solder to form a quality connection.

- When the solder begins to flow, the soldering iron tip is temporarily removed from the joint location.

- After applying the bead, the joined elements cannot be moved until they have completely cooled. When working with transistor components, you should use “crocodiles” that will act as heat sinks, thereby reducing the risk of temperature damage to the filling.

If dry joints occur, the roller must be melted and the seam redone. After finishing work with solder, the tip of the soldering iron is cleaned. When working with copper parts, cleaning the edges of the elements being joined is especially important.

What tools and materials are used in the borax soldering process:

- soldering iron Used to heat solder + sometimes for the connections themselves. Sometimes it is more convenient to heat the elements with a gas burner;

- stand. To position the soldering iron while it is heating up or is inactive. There are a lot of variations of stands for this instrument on the Internet, so choosing one that is convenient for you will not be any problem;

- rag or sponge. Consumables needed to clean the soldering iron tip;

- fine grit sandpaper. Used for stripping joints to which solder will be applied;

- crocodiles. The clamps play an auxiliary role as radiators;

- burner. Needed when soldering pipes.

Also, to improve the quality of the seam, I advise you to use boron flux, which will contain fluoride or chloride elements. When soldering pipes, the elements being connected must be heated for at least 25 seconds.

How to make borax with your own hands?

Soldering using borax

Sodium tetraborate is widely used as a flux used in the soldering and forging process of various metals.

Borax itself is useless, but under the influence of high temperatures it turns into boron oxide, which has excellent antioxidant properties. Borax is also capable of:

- fill small cracks in the metal;

- increase wear resistance and durability of the processed part;

- help change the shape of a part during artistic metal forging.

During soldering using flux, oxides are instantly removed from the metal surface, and other substances are dissolved in it. During forging, a layer of scale constantly forms on the surface of the metal. If forging is uncontrolled, it may overheat, which will ruin the product. The use of flux allows you to avoid this.

The process of treating a forged part with flux, which prevents the formation of glow on the product Source Popgun.ru

How is soldering done?

Flux is most often used when soldering using solder - a filler metal that has a relatively low melting point. To work with all common metals: steel, copper, cast iron, etc., a flux is made based on boric acid with a 1:1 ratio. The mixture is thoroughly mixed and then the water is evaporated to obtain a white, dry powder. The use of such flux has a number of advantages:

- materials can be soldered within a wide range of soldering temperature conditions;

- it becomes possible to combine metal with non-metallic materials;

- during operation, the main materials do not melt, but only flux and solder;

- the strength and mechanical properties of the parts being soldered are improved.

Flux based on borax is sold in convenient sealed packages made of special plastic that does not allow water vapor to pass through. Source Bytlux.ru

What is it and what is it for?

Soldering borax is a high-temperature type of powdered flux that is used when joining metal products by soldering. Melting of this substance can occur under the influence of temperatures exceeding 700 degrees Celsius. Soldering borax has its own GOST, according to which it is manufactured and its characteristics are regulated.

The substance in powder form looks very similar to salt, in other words it is called sodium tetraborate. The synthesis of borax occurs naturally, and its extraction is carried out from salt lake deposits.

The use of this substance is quite wide, but most often it is used for soldering copper pipes.

The advantages of using borax include the following:

- the materials that are planned to be processed may have different temperature conditions;

- obtaining a high-quality, reliable weld not only between metals, but also between metal and non-metal surfaces;

- ease of soldering seams if necessary to separate parts;

- when soldering, the parts do not warp or deform;

- increased productivity during capillary soldering;

- obtaining smooth and durable seams even from a craftsman with little experience.

The disadvantages of sodium tetraborate are as follows:

- release of a large volume of salts, which harden on the metal at high speed;

- absorption of moisture from the environment;

- the difficulty of selecting the right amount of borax for an inexperienced welder.

What is borax: concept and distribution

In the picture below you can see a borax crystal under magnification. In nature, this substance occurs as a mineral. The scientific name of borax (borax, tincal) is sodium tetraborate. It received its historical name in Asia, from the Persian word for “brown”. This term was used to refer to a general category of fluxes that contain particles of water.

The natural inorganic compound is now found in the tombs of the pharaohs. The material was one of the basis for mummification of mummies. The second homeland of the mineral is China. There it was used for finishing ceramics, as an additive to sputtering.

Please note: the discovery of a crystalline substance dates back to 1776, which among similar compounds is one of the earliest discoveries in general.

Until 1825, Italy was the main supplier of borax in Europe. After 1850, mining of the inorganic compound began in Chile, thereby providing America with cheap raw materials until the end of the 60s of the 19th century. After the discovery of borax deposits in California (1856), this mineral began to be mined en masse in other regions of North America, thereby making borax one of the easily accessible compounds for human use.

Industrial production of the inorganic compound did not begin until late 1890, although due to a huge surge in production and minimal requests for use, the supply of borax greatly exceeded demand, causing prices to collapse. Today, this problem has disappeared, due to which boron has become one of the indispensable components in the chemical industry and household areas of mankind.

Description and external signs

Borax mineral is an aqueous sodium borate with hydroxyl. It is also popularly known as boric salt. In Asian countries it is called tincal. This substance resembles almost colorless crystals. Origin of the name: from the Arabic word bauraq - translated as “white”. The form of release of borax in pharmacies and hardware stores is a white fine-crystalline powder.

Chemical composition

The components of borax are the sodium salt of boric acid and a strong base (water, sodium). Chemical formula: Na2(B4O5)(OH)4 8H2O

The practical significance of borax is to serve for the extraction of boron.

Molecular weight of the substance: 381.37; Density: 1.7; Specific gravity: 1.69 – 1.8; Maximum birefringence: δ=0.025; IMA classes: borates.

physical characteristics

The color of borax can vary: it can be white with a gray tint, yellowish, less often with a blue or greenish tint. When exposed to light, the crystals are almost colorless. The gloss is matte resinous. The stone looks as if it has been oiled. In terms of hardness, it is a very brittle mineral. Borax is highly soluble in water and forms a slightly alkaline, sweetish solution. Melting point – 60°C; at 320°C the crystals lose water and a white powder is formed.

Borax mineral: history, composition, description and varieties

Borax is the sodium salt of boric acid. Its empirical formula is Na₂B₄O₇. The substance has a crystalline structure. It was first widely used in Central Asia, where it acquired the name “tankal”. But sodium tetraborate owes its modern name to the Persians, who nicknamed it “burah,” which meant “a mixture of flux and water.” The ancient Egyptians widely used borax during mummification. In medieval Europe, borax was used to clean metal surfaces: dishes and other household items.

By adding borax to the cat litter, it is possible to reduce the intensity of the odor emanating from it several times Source Decorobot.ru

Flaws

- After use, a deposit of salts forms, which must be removed mechanically;

- It is necessary to choose storage areas that are free of moisture, since high humidity will cause the flux to deteriorate;

- To prepare the material for use, you need to spend time and choose the right proportion, which can lead to errors.

Varieties of Borax

There are two main varieties that relate to the appearance of the material. The first option is the solid form. Borax soldering flux is supplied in the form of a powder with fine solid fractions. Thanks to this, it is easy to lay it on the metal surface before soldering in the required quantity and it will not spread at the same time. This variety is supplied in a special box that protects the material hermetically from the penetration of moisture and other foreign factors. Fractions are white.

Soldering borax in powder form

The second type, which is more often used for lighter metals and their alloys, is diluted borax. In this case, you are offered the same material, but dissolved in liquid. Due to this, it can be used at lower soldering temperatures. Using this type is also easier, since small parts are simply dipped into the liquid, after which they can be soldered. This is used both in the jewelry industry and in other places where small items are worked. Contacts, wires and other types of equipment come into good contact with dissolved flux. Despite the fact that the principle of using borax for soldering in liquid form is somewhat different from the standard one, they have almost the same effect.

There are also varieties in the form of mixtures, when other fluxes are also used. This is necessary in cases where it is impossible to achieve the desired results using one substance. Proportions and composition depend on specific goals. Most often it is combined with boric acid.

Composition and physicochemical properties

The composition of borax for soldering includes sodium chloride and barium chloride, in some cases boric acid is added to it. It is not used in its pure form for all procedures, since this would require too high a melting point. Drill soldering powder is a high-temperature flux, so its main property is resistance to high temperatures. It is worth noting that the material perfectly retains its chemical properties even at a lower concentration than what is supplied. Thus, the flux solution has a fairly high level of dissolution of the oxides of all base metals for which it is used.

It can also dissolve fatty films and other unnecessary things that will interfere with the normal soldering of the material. Brown soldering protects against many types of defects that can occur in work.

Specifications

There are two main grades of the substance, which are defined according to GOST as grade A and grade B:

Soldering of metals is carried out by first removing traces of oxides from their surface. Fluxes are used for this. They should prevent oxidation when heated and encourage good flow of molten solder.

For soldering copper products, borax solder ideally meets all requirements. The substance has been known since the Middle Ages. It was mined in the lakes of India and Tibet, then transported to Europe, where it was used for processing fabrics and leather, and producing glass.

Borax is widely used for working with metals. When manufacturing or repairing metal products, borax soldering is carried out. First of all, the method is used for parts made of copper and brass. A special type of this flux is used when repairing jewelry.

Side effects

A side effect to the drug can only appear if there is a high sensitivity to the components.

These include:

- Itching

- Weakness

- Possible skin rashes

- Convulsions

- Digestive disorders

- Dermatitis

- Failure of the menstrual cycle

- Abdominal pain

- Cardiopalmus

- Anemia

You should stop using this drug if you experience any side effects and seek immediate medical attention.

Contraindications

- Mechanical damage to the skin and mucous membrane

- Breastfeeding and pregnancy

- Hypersensitivity to individual components of the drug component

- Drug intolerance

Authenticity

Qualitative reaction. To 5 ml of a 4% solution add 0.1 ml of a 0.1% phenolphthalein solution; the solution turns red. When adding 5 ml of glycerin, the 85% solution should become colorless.

- Qualitative reaction. To 0.2 g of the substance add 1 ml of concentrated sulfuric acid, 3 ml of 96% alcohol and mix. When ignited, the mixture should burn with a green-edged flame.

- Qualitative reaction. A 4% solution should give a characteristic reaction A to sodium (General Pharmacopoeia Monograph “General reactions to authenticity”).

Disadvantages of flux

When working with borax, a characteristic deposit remains on the surface of the base metal, which must be mechanically cleaned off. Borax is susceptible to moisture and should be stored in a dry place. It is necessary to carefully prepare the flux in advance so as not to spoil the product.

Types of soldering flux

Tools and materials

The soldering technology uses a number of components.

- A soldering iron is used to heat joints that are to be soldered. Solder has a lower melting point than the metals that are being joined. Solder melts when heated with a soldering iron.

- Borax acts as a flux to prevent oxidation of the metals that are combined.

- The solder used to join copper pipes has a necessary acid base that is suitable for pipes but is corrosive to electronic connections.

- A stand on which you can hold a hot soldering iron. There are various stands. It is important to always keep the hot soldering iron in place when not in use.

- A sponge or rag that is used to clean the tip of an iron.

- Fine sandpaper used to clean connections before soldering.

- Alligator clips can be used as heat sinks if necessary.

- Burner if pipes are soldered.

Tools for soldering

Thus, the use of borax is effective in domestic conditions for cleaning surfaces and parts, and also as an antiseptic. The ingredient is often used for soldering various parts as protection against oxidation and corrosion prevention. Low cost and widespread use have allowed the substance to be used in many areas of industry and installation services.

We select, design and modernize a hand drill. Personal experience

A hand drill is an indispensable thing on a personal plot. Drill holes to install fence posts or bored piles under the foundation, make holes in the garden soil for planting plants. There is always a use for this hand tool. Users of our portal know how to make this tool yourself, and whether it is possible to somehow improve factory-made devices.

Before you buy or make your own hand drill, you need to ask yourself the following questions:

- For what purposes and work do you need it;

- What type of soil will be drilled at the site.

Sand, rocky soil, abandoned garden soil, hard clay, loam, soil with a lot of roots. Drilling a hole for installing fence posts and posts of small diameter, drilling out “heavy” soil for powerful bored piles for the foundation of a house. All these factors have a significant impact on the design of a hand drill.

Sukhanov Mikhail FORUMHOUSE user

In my opinion, the best hand drill is the one that is “tailored” for work in a specific area, taking into account the characteristics of the soil and its layers. Those. the earth drill must be made for specific tasks: installation of pillars, piles, etc.

A user of our portal offers the following mechanical design for a homemade drill. How it was made can be clearly seen in this photo.

Two knives are used to preliminary loosen the soil, which simplifies the cutting of the main blades, set at an angle, into the ground. Moreover, the main blades can be made replaceable by attaching them to bolts and nuts. Thanks to this, it is possible to drill holes of different diameters using one rod.

Although the purchased and homemade drills are similar in appearance in many ways, it is the homemade hand drills that show the best results. They are stronger and more convenient to work with, because... they are made to suit you.

Sukhanov Mikhail

My neighbor and I once conducted the following experiment: we decided to compare the performance of my homemade drill (blade diameter 25 cm) and its purchased one (blade diameter 14 cm).

The soil on the forum member’s site is like this:

- 0.7-0.8 m – “fertility”;

- 0.2-0.4 m – coarse limestone stone;

- then a layer of marl (yellow, with fine limestone chips).

During the competition, the drillers almost simultaneously went 0.8 m deep. Then the purchased tool stumbled on the marl, while, working as a homemade garden drill, Mikhail continued to drill as if nothing had happened. The neighbor had to loosen the marl with a crowbar and only then drill further.

The result of the experiment: it took Mikhail a little over 5 minutes to drill a hole under a pillar 1 meter deep, and he was not at all tired. The neighbor fell hopelessly behind in the last 0.2 m.

T.N. a universal drill, no matter how suitable for working on different soils, may turn out to be ineffective.

That is why homemade hand drill designs are so popular among users of our portal. To make one, all you need is scrap materials and basic welding skills.

The tool is made like this: take a round or square pipe, its length is selected depending on the expected depth of the hole. In the case of mechanical drilling of deep wells, the pipe can be extended by extending it with an additional rod. The diameter of the blades is selected depending on the expected diameter of the pit and the planned work.

Large-diameter saw blades from circular saws have worked well as blades. Such a disk is sawn into two parts with a grinder. The halves are welded to the pipe, and the blades must be spread to a certain angle (approximately 25-30°). This way they penetrate better into the ground. A lance or a large-diameter “killed” drill is welded to the end of the pipe. The tip is needed to center the drill at the beginning of drilling. Due to the saw teeth on the blades, such a tool cuts roots well when rotating.

The main thing when working with a hand drill is to stop in time and lift it out of the pit in order to dump the rock.

Boston FORUMHOUSE user, Moscow.

I made two earth drills for the beginning of the summer season. The first is with a diameter of 210 mm, the second is 160 mm. Circular discs were used on the blades. The rest was made from what was literally lying under our feet. I also made a collapsible extension rod. I spent 200 rubles on everything, as they say, cheap and cheerful.

If you don’t have a welding machine at hand, then such a tool can only be assembled using bolts and nuts. Also, as a drill for light soil and for drilling small-diameter holes, you can use a used ice auger (since buying a new one is an economically unjustified idea). For ease of operation of the ice device, you need to cut off the handle-turn and attach a standard T-shaped collar.

In addition to the tools described above, an interesting approach to making a homemade drill for drilling wells in the ground is from a forum member with the nickname VyacheslavK.

A conventional earth drill was used to drill to a depth of 2.5 m. The forum member cut the blades with a grinder from a piece of sheet metal 3 mm thick, onto which a paper template was previously glued.

Then a hole with a diameter of 20 mm was drilled in the resulting workpiece.

A cut was made along the radius of the circle.

Next, Vyacheslav K welded a pin into the blade, which he inserted into the pipe. The pipe is also welded to the blade.

The pin has been sharpened.

The result is a drilling device like this.

During the work, the following shortcomings were identified and eliminated:

- The blades are brought together during drilling, which significantly reduces drilling efficiency. To prevent the blades from collapsing, bracing partitions were welded between them and to the pipe.

- When drilling holes for installing a fence, the tool, if it bumped into stones or roots, was pulled to the side. To eliminate this drawback, an arcuate side of 30x10 cm was welded one blade at a time, starting from the bend of the circle.

- Low efficiency when passing through oily clay. For working with clay, the so-called was made. frame drill designed by a user of our site with the nickname KND.

This device is best suited for working with lamellar clays. It has a minimum coefficient of friction against the rock. It is easy to remove from the hole (there is no “piston effect” like an auger drill). After lifting the drill, the clay is simply shaken out of the frame.

Although such a tool is most often used when drilling homemade water wells, its design turned out to be so successful that it is worth focusing on it.

VyacheslavK did this:

From a strip of metal 5 cm wide, he cut two identical strips and made angular bevels, moving 2 cm from the end of the strip. For the strips, you can use old car springs.

Cut and sharpened knives.

I welded the knives to the drill, pointing the sharpened sides in opposite directions.

I spread the knives apart using a corner so that the distance between the ends was 25 cm.

Using a gas wrench, VyacheslavK turned the knives at an angle.

I assembled and welded the entire structure.

It is worth noting that the drill quickly broke off. Therefore, VyacheslavK sharpened the fragment, as shown in the next photo.

When making a frame drill, it should be taken into account that it is not suitable for working in loose, loose soil, because it doesn't stay in the frame.

Also interesting are the designs intended for making a widening - “heel” - during the construction of the TISE foundation.

Subarist FORUMHOUSE user

I modified the purchased drill and installed a second folding shovel on it. To make it easier to work, I made a T-handle 1 m long. Thus, I increased the force on the lever. The length of the rod is 3 meters. Now you can drill holes 2 meters deep while standing upright, rather than on all fours. I cut off the teeth from the land receiver because they are of little use.

The “improvement” did not end there. To increase the efficiency of the earth drill when drilling out the widening, Subarist bent the blades - straight ones did not cut the soil well. The forum member’s future plans include installing blades made of alloy steel, because... ordinary ones quickly become dull on stones.

Advice: when making a foundation of the TISE type, it is best to drill the base hole with a conventional drill or a special mechanical tool with a “drain pan” and two folding blades. This will save time and effort.

ValentM FORUMHOUSE user

I made an earth drill using an ordinary saucepan as a soil accumulator. With this tool I made widening at a depth of 2.5 m.

There are stoppers at the bottom of the pan that rest against the ground. When drilling the expansion, the pan stands still , this increases work efficiency, because no effort is wasted on turning the earth receiver itself. When the handle rotates along the threaded shaft, the blades open and cut the soil. After the pan is filled, the handle of the drill rotates in the opposite direction, the blades fold, and the drill rises to the surface. In 4-5 lifts, the hole with widening is completely drilled out.

It is worth considering that making such a tool is more difficult than a regular one - you will need a welding machine and a lathe.

The design turned out to be successful and in demand. Using this principle, forum members make their devices with two blades, which most often work in tandem with motor drills.

FORUMHOUSE explains in detail which hand drill to choose. The topics include advice on the global modernization of the TISE drill, and recommendations on how to independently manufacture an electric hole drill. It will also be useful to study the topic that tells how to drill an Abyssinian well. From the video you will learn why you need to examine the soil on the site.

Toxicological properties and characteristics

Warm-blooded animals and humans. Sodium tetraborate penetrates the skin and has a mild cumulative effect. Does not have a local irritant effect upon contact with the conjunctiva of the eye and skin, does not cause a sensitization effect or an embryotoxic effect. [2]

People who work with the substance often suffer from chronic eczema. When working, it is necessary to protect the respiratory system, eyes and skin from exposure to dust. [3]

Sodium tetraborate, as well as boric acid and soluble borates, are quickly and almost completely absorbed from the gastrointestinal tract. In the blood, boron is evenly distributed between red blood cells and plasma, but quickly passes into the tissues. Found in soft tissues

10% of the dose (mainly in the brain, liver and adipose tissue). The excretion of boron compounds occurs mainly through the gastrointestinal tract. [3]

Hazard classes. Insecticides based on sodium tetraborate belong to class IV of low-hazard disinfestation agents according to GOST 12.1.007. [2]

The main thing about borax with glycerin

In appearance, borax with glycerin has a transparent 5–20% solution with a slight specific odor.

Sodium tetraborate contains:

- the main substance is borax or sodium tetraborate decahydrate (20 g)

- excipient - glycerol or glycerol (80 g).

Borax with glycerin is available in glass bottles and with a nylon and tightly screwed plastic cap, 30 g each. Borax itself acts as an antiseptic, or rather eliminates various infections, and glycerin removes irritation and helps the borax penetrate skin barriers better. Using glycerin, the solution becomes thick.

Application of brass and copper powder

Practitioners often use flux that has been stored longer than expected. To solder with brass, the borax must be re-melted. The cooled powder should be placed in a jar with an airtight lid. Neglecting this procedure can ruin the work due to waste accumulated during storage.

At the beginning of soldering, the working area must be heated to a clearly visible red color. Heating should begin first at the edges, and then directly at the soldering site.

Then the heated area should be gradually sprinkled with flux, wait until it spreads in the form of a film along the edges of the part. At this point, the heated brass solder must be dipped into the molten borax so that it is covered with a hot flux film.

As experience shows, the soldering area is red in color, while the borax melt is colored bluish. You cannot keep solder in the flux for a very long time. Oxide residues may form.

Then you should warm up the work area again. The brass will take on an orange glowing appearance. You can proceed directly to soldering. If done correctly, the solder will fill all the gaps.

The soldering area will turn golden. When the process is completed, the hot zone should be sprinkled with borax powder and left to cool. Copper parts in a hot (200 ℃) state can be placed in a mixture containing equal parts acetone and water, or simply in water. It makes sense to immerse the cutters in hot sand.

A correctly made connection has a transparent film with a slight blue tint. There are no solder drops on it. If soldering is performed incorrectly, the seam becomes covered with a black porous crust.

The reason may be overheating of the working area, as a result of which slag is formed, or poor quality of borax-based flux. This is how brass and other copper-containing alloys are soldered.

Therapeutic effect

The medical potential of borax was already appreciated by Avicenna. He treated deep or poorly healing wounds with mineral powder.

Half a millennium later, in the 15th century, European healers expanded the range of possibilities of the powder:

- Inflammation of the oral cavity.

- Epilepsy (especially acute stage).

- A diuretic that dissolves stones in the kidneys and biliary tract.

Unlike most natural remedies, official medicine recognizes the healing properties of borax.

And it uses the mineral in the same segments.

Borax crystals

Plus new directions:

- Malfunctions of the nervous system.

- Skin problems: eczema, psoriasis.

- Diseases of the genitourinary system (cystitis).

- Infertility.

- Dystrophy.

The remedy is especially effective for treating children and adolescents.

Copper pipe connection

Copper pipelines are expensive. The investment can be justified with careful installation, which is often carried out by capillary soldering using borax as a flux.

It is worth noting that today, other fluxes are sold that are more convenient to use. One pipe is inserted into the second or fitting so that the gap does not exceed 0.4 mm.

Soldering time is short, 3 minutes. It is important that the parts remain stationary during operation. In order for the borax powder to stick to the surface, the copper is first heated with a torch.

For pipes with a diameter of up to 108 mm, the soldering process is carried out at low temperatures not exceeding 450°. The seam is wide (up to 50 mm), but not very strong. Wide pipes with a diameter greater than 159 mm are soldered at high temperatures. Only professionals can perform the procedure.

In both cases, the solder melt penetrates well into the capillaries of the parts, which contributes to the formation of strong connections. It is recommended to remove any remaining borax.

It must be remembered that soldering is accompanied by the formation of smoke, so you can only work in ventilated areas.

Performance in nature

Borax is a mineral of volcanic or sedimentary origin. Places of accumulation are geysers, volcanic vents, drying up areas of salt water reservoirs.

Deposits across the board:

- Tibet.

- Death Valley (Mojave Desert, USA).

- Italy.

- Argentina.

- Türkiye.

The Russian source of the mineral is the Taman hills.

Borax in nature is prism crystals, granular masses, and veins in clays.

How to make borax at home?

The cost of sodium tetraborate in hardware stores and pharmacies varies from 20 to 100 rubles. If we are talking about a one-time use, then the price is cheap, but if a person constantly needs flux or borax for other tasks, it would be more rational to get it at home. In the table below I will describe 3 popular recipes for making the substance with your own hands.

| № | Components | Packing (g) | Preparation |

| 1. | Baking soda | 50 | Pour boric acid into a glass container and add baking soda in small portions. Stir until completely dissolved. Next, we do filtration - we pass the mixture through special paper or a napkin. You should get about 100 grams of sodium tetraborate. |

| Boric acid | 70 | ||

| 2. | Water | 200 ml | Finely chop the laundry soap using a grater. To start, 1 teaspoon is enough. Pour 200 ml of water into a glass container, add boric acid and gradually add crushed laundry soap. Place the mixture in the microwave for a couple of minutes. We filter and get borax. |

| Boric acid | 5 | ||

| Laundry soap | 50 | ||

| 3. | Powdered borax | 20 | This recipe involves obtaining sodium tetraborate in liquid form. Simply mix borax powder with glycerin and leave for a day. |

| Glycerol | 80 |

Although borax itself is not a highly toxic substance, constant exposure to human skin can lead to dermatitis. If a person, due to his profession, periodically interacts with this inorganic compound, I strongly recommend using gloves, safety glasses and a respirator.

What kind of workwear should a welder have?

This concludes the analysis of the concept of what borax is. I hope that the information provided was of value to you. Share in the comments where exactly you encounter sodium tetraborate in practice. Good luck and good health to you!

Borax is a useful substance for industry and everyday life

Borax is an inorganic substance, the sodium salt of boric acid. The chemical name is sodium tetraborate. Both the anhydrous salt and its crystalline hydrates are called borax. The formula of anhydrous salt is Na2B4O7. The most commonly used is 10-aqueous crystalline hydrate Na2B4O7 10H2O.

Borax is obtained from natural raw materials, although some enterprises synthesize 10-aqueous crystalline hydrate from boric acid and soda. The minerals tinkal (ten-hydrate crystalline hydrate) and kernite (tetrahydrate crystalline hydrate) are naturally occurring sodium tetraborate. Borax is found in borate-based minerals. It is extracted from the sediments of salt lakes.

Sodium tetraborate is produced in varying degrees of purification. There are brands of technical borax and food grade borax.

Properties

Crystalline substance; The crystals are colorless, transparent, white or grayish, with a greasy sheen. Odorless, with a sweetish-alkaline taste. Easily soluble in water, glycerin; does not dissolve in alcohols. When melted, it turns into a colorless glassy material.

The aqueous solution has a pronounced alkaline reaction. Reacts with strong acids. The interaction of borax solution with metals leads to the formation of insoluble borates. This property is used to remove magnesium and calcium salts from water: their borates precipitate and are easily removed by filtration. Very interesting is the ability of borax to form colored borates (they are called “borax pearls”) when fused with metal oxides. This feature is used in analytics to assess the qualitative composition of an unknown substance.

Precautionary measures

Sodium tetraborate is classified as a substance of little danger to humans. It does not burn or explode, and its solution does not cause skin or eye irritation. It is not an allergen and does not affect the development of the fetus in pregnant women. However, if the skin is regularly exposed to borax dust, it can lead to dermatitis. Therefore, employees who constantly deal with chemicals. reagent due to the nature of their activities, must use protective equipment for the skin, eyes and respiratory organs.

In everyday life, borax should be stored out of the reach of children and animals, in hermetically sealed containers, since ingestion of a concentrated substance can lead to poisoning.

Application

- In the chemical industry for the production of boron, boric acid, borates; household and industrial SMS, cleaning products, polishes and rubs, adhesives; antifreeze; lubricants and brake fluids.

- In analytical chemistry - as an indicator of metals; for obtaining buffer solutions; standard for measuring the concentration of an acid solution.

- In the glass, ceramic, porcelain, paint and varnish industries for the production of colored glass, glazes and enamels, porcelain and earthenware products, as well as optical glass.

- At electrical, radio-electronic, metallurgical enterprises for soldering and welding of metals. Pentahydrate crystalline hydrate is in demand in jewelry as part of a flux for working with gold and silver.

- Included in electrolytes for creating anti-corrosion coatings using the electrolytic method.

- In the manufacture of building insulation "Ecowool" (as a disinfectant ingredient); for staining wood and wooden buildings.

- In medicine, aqueous and glycerin solutions of borax are used as an antiseptic external remedy for fungal diseases for treating the skin, rinsing the mouth, and douching.

- In agriculture and everyday life - an insecticide against all types of insects; included in microfertilizers.

- At tanneries - for tanning leather and dressing furs.

- In the pulp and paper, textile, rubber, pharmaceutical, food, cosmetic, soap industries, and water treatment.

- In a photo developer.

- In everyday life - to remove stubborn contaminants, for example, when cleaning plumbing; to destroy mold on surfaces; for washing wool items.

Stone care

When using borax, you must take precautions: store in a closed container in a dry, dark place, use protective gloves when working and avoid contact with skin and mucous membranes.

Previous article Mineral brookite - properties, deposits and applications Next article Mineral vanadinite - properties, significance of the stone and applications.

Sources

- https://pressadv.ru/samodelkinu/bura-formula.html

- https://stroy-podskazka.ru/pajka/bura/

- https://ArmRinok.ru/obrabotka/bura-v.html

- https://m-strana.ru/articles/bura-formula/

- https://WikiMetall.ru/spravochnik/chto-takoe-bura.html

- https://kamneteka.com/bura-svoystva-znachenie-i-primenenie/

- https://pressadv.ru/stali/bura-tehnicheskaya.html