Notes

- GOST 13940-86 Flat external concentric spring thrust rings and grooves for them. Design and dimensions. Developer - USSR State Committee for Standards

- GOST 13942-86 Flat external eccentric spring thrust rings and grooves for them. Design and dimensions. Developer - USSR State Committee for Standards

- GOST 13941-86 Flat internal concentric spring thrust rings and grooves for them. Design and dimensions. Developer - USSR State Committee for Standards

- GOST 13943-86 Flat internal eccentric spring thrust rings and grooves for them. Design and dimensions. Developer - USSR State Committee for Standards

Domestic

These types of rings are used to secure parts within each assembly. They are needed in a technical device to prevent the movement of rotating parts by means of firm fixation. The type in question is produced according to the following technical documentation.

GOST 13941

This GOST is characterized by a type of ring that has an identical circumference width. This type is used to create fixation with an emphasis. Also used in bearings, levers, bushings. The type in question is made from high-strength steel.

Source

Retaining ring pullers for removal and installation

Ring locking fasteners are widely used in the design and manufacture of various mechanisms.

They limit or block the axial movement of shafts, rods and bearings. The ring is made of elastic spring steel. It has a narrow cut, next to which it expands into rounded areas. In the center of these areas there are holes for the jaws of the circlip remover. A narrow groove is machined into the body of the part, the holder, or the shaft itself; the ring is inserted into it in a compressed state, when the pads are brought together by the puller jaws inserted into the holes and there is practically no gap. Due to the elastic deformation of the ring, its circumference decreases, and it fits freely into the groove. After the jaws are unclenched, the fastening, under the action of elastic forces, returns to its original shape and is tightly fixed into the groove, clamping the locking ring. This makes axial movement of the fastened part impossible; when axial forces are applied to it, the ring locking fastening, resting against the groove, stops the movement. Rings can be external, put on the cylindrical part from the outside, and internal, inserted into a groove milled or machined in the inner surface of a cylindrical hole, blind or through. The pullers designed for such rings also differ. External ones have smaller dimensions, and for internal ones, circlip pliers with elongated jaws are used

If the external ring fastening can still be installed and removed using improvised means, then for the internal one, and even located in a certain recess, a puller is the only way to accurately install and dismantle the rings without the risk of injuring your fingers or breaking the part.

In everyday life, retaining ring pullers are often called pincers, round nose pliers or pliers due to their external similarity. Technically this is incorrect, since by type of instrument they are classified as forceps.

Pullers are precision tools and must withstand large short-term loads. Therefore, they are made from high-strength tool steel. Often, to save weight and reduce prices, only jaws that experience maximum loads are made from high-strength alloys. Manufacturers offer a wide selection of pullers for a wide variety of ring sizes. Some include sets of several pullers for the most popular sizes, while others have gone the route of producing universal pullers. The kit of such a device includes several pairs of replaceable jaws, which can be quickly rearranged as needed.

If a tool is purchased for one-time work, there is no point in chasing the brand; cheap Chinese products will remove one or two fasteners no worse than famous ones. But if the equipment is purchased for regular use, for example, in a car service, then, of course, you should choose products from a well-known brand. Such manufacturers use the most advanced technologies and engineering solutions; their products are equipped with additional functions that make work easier and increase safety.

They use screw joints, which ensure exceptionally smooth and even movement of the handles. The special shape of the working surfaces prevents the ring from slipping off. The limit screw allows you to adjust the range of travel of the jaws, preventing excessive stretching or compression of the ring material, which could lead to its breakage. The detachable locking mechanism allows you to fix the locking fastener in an extended state, saves the worker’s energy and allows you to move the ring to the seat more accurately and quickly. Ergonomic handles do not injure hands and reduce worker fatigue, so he can work effectively for an entire shift.

And where is the savings?!

However, with each subsequent repair to replace 3 crosspieces using the punching method and the necessary balancing, the client is forced to pay again 6,600 rubles for the repair. excluding the cost of crosspieces, and when replacing crosspieces in units converted to retaining rings, only 1800 rubles, since replacing one crosspiece costs 600 rubles. and if replaced correctly, balancing is not required.

It should also be noted that replacing crosspieces using the core method can be done once or maximum twice, then there is no room left for cores, and replacing crosspieces in assemblies for locking rings can be done repeatedly, as necessary, and without balancing!

Each client decides for himself what is more profitable for him - we only explain and help make the right choice!

What it is?

The best way to explain what a lock nut is is to compare it with conventional examples. “Classic” when interacting with a bolt guarantees a completely reliable connection. But this persists only until stable intense vibrations appear. After some time, they break the mechanical adhesion, and weakening and unscrewing begin. Theoretically, the stopper can be provided using locknuts and lock washers.

That is why locking (self-locking) nuts are in very wide demand, and their importance only grows over the years. There are quite a few types of such fasteners. The production of lock nuts in Russia is regulated by GOST standards.

Thus, hexagonal steel nuts with automatic locking must comply with GOST R 50271-92. Products without galvanic coating are designed for temperatures from -50 to 300 degrees. If galvanized, the maximum permissible heating is 230 degrees. If the nut has inserts made of non-metallic materials, the critical temperature level is 120 degrees. The standard normalizes:

- test load voltage;

- Vickers hardness level;

- Rockwell hardness level;

- the amount of torque.

Self-locking nuts can maintain the prevailing torque even after repeated tightening and unscrewing. The chemical compositions of the steels used are also standardized. The nut inserts responsible for the predominant torque cannot be made of steel alloys - completely different materials are needed for this purpose. Fasteners made of free-cut steel also comply with the standard (if its use does not violate the supply agreement). The highest sulfur content in nut steel should be 0.24%.

The regulation strictly prohibits the use of hydrogen embrittlement material

This is especially important when applying special coatings

The standard strictly defines temperature requirements for operation - stable use at air temperatures from + 10 to + 35 degrees. If necessary, additional research of these properties can be carried out through full-scale testing. The standard covers self-locking nuts made of solid metal or non-metallic elements that have:

- triangular cutting ISO 68-1;

- combinations of diameters and pitches prescribed in ISO 261 and ISO 262;

- large rifling spacing (M3 - M39);

- small gap of rifling (M8x1 - M39x3).

Retaining rings and their purpose

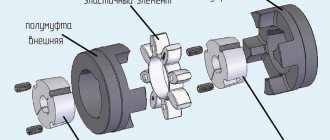

To limit the movement of a bearing, axle, shaft or other parts, many mechanisms use retaining rings (also called split washers). These parts are similar to lock washers, but their main difference is the presence of a through cut. High-strength spring steel is used to manufacture the split washer. Structurally, this part looks like a washer with a slot. Near the slot there are two areas with holes, which are called ears. It is through these lugs that parts are removed and installed.

The operating principle of such devices is quite simple - when the ring is compressed or unclenched, which is done by applying a special tool to the ears of the part, the circumference changes. The split washer, in a compressed or uncompressed state, is inserted into the groove and then released. In this case, it is compressed or expanded, thereby encircling the shaft, fixing the bearing and excluding its axial movement.

This is interesting!

Retaining rings have found their application in many areas of production. In everyday life, such parts are also found, for example, on bicycles, motorcycles, door handles, and in the design of various household appliances and tools.

Internal retaining rings DIN 472, SEG W

In some cases, in addition to serving as a part-holding function, circlips of varying thickness also determine the amount of play.

Retaining rings are easy to install and take up little space. Their use eliminates the need to make shafts with steps, shoulders or threads for nuts. They can withstand significant axial loads.

The disadvantage of fastening with retaining rings is that the parts are weakened by the annular grooves. This disadvantage is especially noticeable in shafts. For rings mounted on shafts, the fit tension is weakened by centrifugal forces. At very high rotation speeds, it is necessary to secure the rings from leaving the grooves. According to the type of installation, lock rings of axial and radial assembly are distinguished. According to the manufacturing method, retaining rings are divided into turned, wire and stamped.

Types of circlip pullers

Thus, based on the information from the previous paragraph, two types of circlip pullers can be distinguished:

- External circlip pullers (usually designated by the English abbreviation EX, from the word external). When the puller handles are compressed, the puller jaws will unclench, and accordingly the ring will stretch and increase in diameter. Such pullers are most often used to remove retaining rings on car axle shafts.

- Internal retaining ring pullers (usually designated by the English abbreviation IN, from the word internal). When the puller handles are compressed, the puller jaws will also shrink, and accordingly the ring will shrink and decrease in diameter. These pullers are most often used to remove retaining rings on vehicle wheel bearings.

The above two types of pullers are fundamental; we will talk about the characteristics of pullers in more detail below.

Inserting a piston into the inner diameter of a cylinder

If the sealing surface of the cylinder block was not subjected to finishing during repair, then thoroughly clean it of gasket residues. Thoroughly clean all threaded holes of any dirt, oil or coolant that may still be there. Do all the cleaning work before inserting the pistons into the cylinder bores. Wet all surfaces in the piston with fresh engine oil.

Don't forget the piston pin and connecting rod bearing! When installing, pay attention to the direction of the piston (markings for installation on the piston bottom, valve pockets). Clean the inner bore of the cylinder again with a rag and also moisten it with engine oil.

Check your piston ring tension band for damage or dents, repair them and replace the tool if necessary. When installing the piston, make sure that the tension band or tapered mounting sleeve lies flat on the sealing surface of the cylinder head,

When installing the piston there should not be strong pressure. If the piston does not want to slide inside the cylinder, be sure to check the piston ring tension band. Do not twist the opening of the tape so that it is in the same place as the butt ends of the rings.

Do not install pistons into the engine without the installation tool (risk of injury, risk of ring damage). If a hammer handle is used for installation, only the weight of the hammer itself can act on the piston bottom. Never use a hammer to force the piston into the cylinder diameter! If the piston rings do not break during installation, they can still bend, and because of this they will not perform their task well enough.

Forced installation not only damages the rings, but can also damage the piston.

This is especially important for gasoline engine pistons. Their fire or working belts are very thin, and when hit, the rings easily break or break completely.

The result: loss of power and quick (and expensive) repairs.

Avoid allowing dirt and sand to enter the cylinder bore after the pistons have been installed. Place a clean cloth over/in the openings if necessary to prevent contamination. Especially when work takes place in a dusty environment and/or outdoors.

Overview of types and sizes

In one of the options, the “pull” method is used. The thread has some positive tolerance. When a part is twisted, intense friction is created between the turns. This is what secures the fastener to the bolt rod; the connection will not lose stability even with strong vibration.

Some versions come with a nylon ring. Typically their size ranges from M4 to M16. Fasteners with an insert can have a durable or particularly durable design. Most often it is intended to be used in conjunction with a bolt (screw). In some cases, additional equipment with a washer is practiced; its role is to reduce the risk of the connection unwinding.

Sometimes a self-locking nut has a flange - this can be easily recognized by its hexagonal shape. There are also versions with a collar, which additionally helps in stopping. As for the sizes, everything is simple and strict:

- M6 - height from 4.7 to 5 mm, grip height for the key - not less than 3.7 mm;

- M8 - with a rifling pitch of 1 or 1.25 mm (the second option is standard, other dimensions are indicated in the order and in the markings);

- M10 - standard height from 0.764 to 0.8 cm, with the lowest key grip level 0.611 cm.

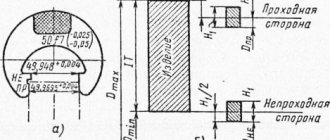

Dimensions of external circlips DIN 471 (heavy), SEG Z (mm)

d1 - shaft diameter s - ring thickness d3 - inner ring diameter a - eyelet width b - max. ring width d5 - hole diameter m - groove width n - protrusion height d4 - circle diameter

| d1 | s | d3 | A | b | d5 | d2 | m | n | d4 |

| 15 | 1,5 | 13,8 | 4,8 | 2,4 | 2 | 14,3 | 1,6 | 1,1 | 25,1 |

| 16 | 1,5 | 14,7 | 5 | 2,5 | 2 | 15,2 | 1,6 | 1,2 | 26,5 |

| 20 | 1,75 | 18,5 | 5,5 | 3 | 2 | 19 | 1,85 | 1,5 | 31,6 |

| 25 | 2 | 23,2 | 6,4 | 3,4 | 2 | 23,9 | 2,15 | 1,7 | 38,5 |

| 30 | 2 | 27,9 | 6,5 | 4,1 | 2 | 28,6 | 2,15 | 2,1 | 43,7 |

| 35 | 2,5 | 32,2 | 6,7 | 4,2 | 2,5 | 33 | 2,65 | 3 | 49,1 |

| 40 | 2,5 | 36,5 | 7 | 4,4 | 2,5 | 37,5 | 2,65 | 3,8 | 54,7 |

| 45 | 2,5 | 41,5 | 7,5 | 4,7 | 2,5 | 42,5 | 2,65 | 3,8 | 60,8 |

| 50 | 3 | 45,8 | 8 | 5,1 | 2,5 | 47 | 3,15 | 4,5 | 66,8 |

| 55 | 3 | 50,8 | 8,5 | 5,4 | 2,5 | 52 | 3,15 | 4,5 | 72,9 |

| 60 | 3 | 55,8 | 9 | 5,8 | 2,5 | 57 | 3,15 | 4,5 | 78,9 |

| d1 | s | d3 | A | b | d5 | d2 | m | n | d4 |

Circlip Pliers

Retaining rings are a fairly common type of fastener used in the automotive industry and other areas of light and heavy industry.

They are usually designed to secure parts to shafts or holes of other parts. They are distinguished into external and internal, in accordance with the method of fastening.

For example, external ones are installed directly on the shaft, and internal ones - on holes.

This is not entirely correct from the point of view of terminology, since the device is a forceps. Currently, manufacturers offer a wide range of such tools; we will analyze the pros and cons of each type and tell you about the most interesting models.

We hope this information will help you choose and buy a circlip puller that will be most convenient for solving your problems.

Design and features of retaining ring pullers

So, lock ring pullers are a type of pliers tool. They have a classic design - two handles with jaws are connected to each other using a hinge joint. Their key difference is the execution of the working profile.

The jaws of the tool are tips that are inserted into the grooves of the rings. Moreover, they may differ from each other in certain design features. The most common types are:

- Retaining ring pullers are of the so-called “Japanese type”, which are characterized by extremely high strength. The jaws of the tool have a pointed shape with notches. Objectively about the disadvantages of this type: in rare cases, the tips may not be securely fixed in the groove.

- The “European type” has a special chamfer at the end of the working part, due to which a decent fixation of the ring is achieved. The main disadvantage of the Eurotype is that this design significantly weakens the tip, which leads to less durability of the tool.

- There are also circlip pullers with pressed-in carbide steel tips. Such devices do not have the disadvantages described above, however, their price is significantly higher than the cost of the two previous types.

Classification of retaining ring pullers and their characteristics

Key features of the circlip pliers include:

- Jaw grip range.

- Length of handles. Determines the force that the tool can transmit. The longer the handles are, the more force the pliers can exert on the rings.

- Material of manufacture. Directly affects the strength characteristics of the device. We recommend pliers made from reinforced alloys such as chrome vanadium.

As for classification, all snap ring pliers are divided into two types: compression and release. The shape of the tip also matters - it can be straight or curved. Thus, all pullers can be classified into four types:

- Direct compression (for internal).

- Direct release (for external ones).

- Curved for internal ones.

- Curved for external ones.

Sets and universal circlip pullers with replaceable jaws

To achieve the greatest efficiency and for comfortable work with different types of rings, it is best to buy a set of circlip pullers or a universal device with replaceable jaws:

- Sets.

In this case, the user receives four pairs of pliers with different types of tips (curved and straight) for both outer and inner rings. - Universal devices.

Various jaws can be installed on the handles of such pullers - straight or curved, working for compression or expansion.

We recommend paying attention to the most advanced and functional models, such as the universal circlip puller Licota ATB-0100. They have unique advantages, including:

- Switching the compression mode to the release mode is carried out using a special lever, thereby increasing the operating speed.

- The kit includes interchangeable jaws to allow the puller to remove and install different sizes of circlips.

- The tips of the pliers can be adjusted and fixed in any position from 0 to 180 degrees, due to which the device can be used in the most inconvenient and difficult to reach places.

Removing the retaining rings

Removing locking split washers is carried out using two main methods:

- With partial disassembly of the main mechanism. In this case, the assembly containing the ring is dismantled. It is fixed in a vice or other clamping device on the workbench, and the part can be removed in the comfortable conditions of a warm and well-lit workshop.

- No partial disassembly. The unit to be repaired is not dismantled; its disassembly and replacement of parts occurs in less convenient conditions, conceived in the open air.

In both cases, it is better to remove the locking part using special pullers that match the type and size of the locking fastener.

Read also: DIY channel sheet bender

If for some reason they are not at hand, craftsmen adapt one or another universal tool or modify it by making a puller with their own hands. This approach may be justified if you urgently need to remove one or two rings. For large volumes of work, factory-made pullers demonstrate their superiority in a number of ways:

- strength;

- reliability;

- convenience and speed of work;

- safety.

Experienced craftsmen have formulated a number of recommendations on how to remove the lock washer from the front suspension wheel bearing:

- The rack is removed from the car and clamped in a vice.

- The hub is knocked out with a hammer.

- Lightly tapping the side of the inner retaining ring with a small hammer loosens its contact with the groove.

- Next, using a suitable type and size ring remover, you need to remove the ring mount. In the absence of a standard tool, some craftsmen manage to remove the stopper with two thin screwdrivers.

- After pressing out and replacing the bearing, you need to check its position: the front end must be at the level of the far wall of the groove for installing the locking part.

- The ring is compressed with a puller and brought to the groove. After alignment along the entire perimeter, the handles are gradually loosened and the part falls into place.

Recommendations on how to remove the rear wheel bearing and its retaining ring are as follows:

Remove the wheel and brake drum. Using a flat-head screwdriver, carefully pry up and remove the oil seal. Remove the ring from the inner diameter with a puller of suitable size and type. Remove the inner race of the bearing. Knock out the outer ring by lightly tapping it on the beard and remove it.

After lubricating or replacing the bearing, reassemble the assembly in the reverse order.

Don't save 1000 rubles, but save 5000 rubles!

The cardan shaft crosspieces of modern passenger cars and commercial vehicles are installed using the punching method. As the crosspieces are used, they become damaged and need to be replaced.

Replacement of crosspieces is carried out in two ways - by punching or altering the units for retaining rings.

carries out the replacement of crosspieces, both by core and by alteration for locking rings.

The advantage of converting it to a stopper is undeniable and is proven by simply counting the money spent on repairs.

DIY tool for removing circlips

Many people have probably had occasions when they needed to unscrew a screw with a non-standard head, remove/put on a part in a hard-to-reach place, etc. and so on. In general, the review is devoted to just such a specific tool, the need for which arises no more than once a year, but when it is needed, it is better if it is there. For those interested, take a look under the “cut”

Once I needed to replace the mowing reel for the trimmer - the old one “died”. Well, of course, I have a screwdriver and hands. I unscrewed what was unscrewed, took off what was removed... And here’s the ambush.

In the depths of the Siberian shaft there is a retaining ring, the removal of which takes quite a long time without a special tool.

With the help of 2 nails, a flat-head screwdriver, I took off this ring about the 20th time (it’s much easier to put it on), but when I came across “or” this product, I decided to buy it, fortunately the price was not high, and the Welcomeback_User_Coupon_Oct_R1_2_1 coupon for $2 came in handy.

After 3 days, the seller provided me with a tracking number, and after 16 days I received a parcel.

The pliers are packaged in a blister, on the back of which there is an instruction manual.

The kit includes additional attachments at 45° and 90° for various “situations”. The pliers are universal - they work both for expanding (to remove the locking ring from the shaft) and for compressing (if it sits inside the tube).

Simply press the central spring-loaded pin, pull out the “lock”, pull it out, and then put the attachment on the other side of the pliers onto the pins and lock it again. Voila! In this way, the principle “there is no extra tool in the house” is observed, and the next time you replace the coil, when it falls apart again, 20 minutes of time and a lot of nerves will be saved.

Well, of course, I didn’t buy these pliers just to repair the trimmer; there are rings in many tools that sooner or later will have to be disassembled/lubricated/repaired.

Retaining rings are widely used in the designs of a wide variety of mechanisms to secure a shaft, rod, axis of rotation or bearing. They are used in water valves and gearboxes, in ship gearboxes and in space stations. If it is necessary to replace or repair a mechanism assembly, the ring must be removed. For this purpose, special tools are used - ring removers.

What is a snap ring

Due to the similar name and shape of the ring, many people confuse a locking ring with a lock washer. Despite the similarity in name and appearance, they have fundamentally different functions.

A lock washer secures a threaded connection by preventing rotation of the nut or bolt head.

A locking ring prevents axial movement of a bearing, shaft, axis of rotation or other structural element.

On the mechanism parts that need to be secured against axial movement, a narrow shaft is machined or milled, slightly wider than the height of the ring. The ring, in a compressed or stretched state, is inserted into the groove and released. The part is compressed, enveloping the shaft, or expanded, fixing the bearing in the hole.

To remove the fastener, you also need to unclench or close the ears.

Ring locking fasteners are widely used in all branches of mechanical engineering, from watchmaking to mining equipment, from paper machines to bicycles, from household appliances to spacecraft.

Types of retaining rings

There are two main types of locking ring connections:

- Internal. Serve to fix parts inside holes. Used for fastening bearings. The ears protrude inward. To install them, you need to compress them so that the length of the outer circumference decreases, insert the part into the inner groove and release the ears. The part will straighten and partially fall into the groove, and partially protrude from it. This protruding part will not allow the bearing resting against it to move in the axial direction. To remove the mount, the ears need to be spread apart.

- External. Used for fastening parts on shafts, axles, rods. They are put on the shaft from the outside, the ears protrude on the outer side of the product, the cut between them is minimal. For installation, the ears are moved apart, the length of the inner circumference of the product increases, and it can be put on a shaft or axle, placed in a machined groove. After this, the ears are released, the part is compressed under the influence of elastic forces, fits tightly into the groove, leaving an annular rim on the outside. It will not allow the part to move in the axial direction. To remove such a part, the ears are brought together.

Groove for internal retaining rings

Mounting bearings on shafts and in housing holes

The simplest way to fasten bearings on shafts and in housing holes is interference fastening, when fixation of the bearing is achieved using friction forces between the bearing race and the surface of the shaft (hole).

But, in the case of using radial bearings, this method is applicable only if high installation accuracy is observed and only with low loads on the bearing assembly. It is not always possible to install the bearing accurately - there is some misalignment between the axis of rotation of the bearing and the axis of the shaft (hole), which increases the load on the bearing. Axial loads on the bearing are also often present. In such cases, as well as simply in the presence of high loads on the bearing, the use of additional locking elements is required to hold the bearing in its final position. For these purposes, various fasteners are used:

Let us next consider the main methods of installing and securing bearings using additional fasteners.

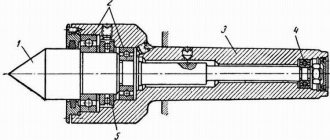

Securing the bearing to the shaft with a lock nut

This is the most common way of fixing a bearing on a shaft using auxiliary fasteners. It is used both for end mounting of the bearing on the shaft and for intermediate mounting. When mounted on a shaft, the inner race of the bearing must rest either on the shoulders or flange on the shaft (left diagram in the figure), or on the intermediate sleeve (right diagram in the figure). To tighten and fix the final position of the bearing, a fastening pair is used: Round splined nut GOST 11871-88 (item 2 in the figure) + Multi-jaw lock washer GOST 11872-89 (item 1 in the figure).

One of the legs of the washer, which prevents the washer from turning on the shaft (i.e., the inner one), is inserted into the manufactured groove on the shaft; After tightening the nut, one of the outer tabs is bent into the matching groove of the nut.

There are two main methods of fixing a multi-claw lock washer on the shaft. In the first method, the fixing inner tab is bent “away from the nut”, in the second - “under the nut”. In the second case, the groove on the shaft should be deeper, so in practice, the first method is usually preferred. Sometimes, if the thickness of the shaft walls allows, the groove is made so deep that the locking inner tab of a multi-claw washer can be inserted into it without bending. This increases the reliability of the connection.

The groove can be replaced with a through slot in the shaft. With this method of fixation, the shaft is greatly weakened. This method is applicable only for the final installation of a bearing on a shaft, while the previous methods are also used for intermediate installation of bearings (for example, on stepped shafts).

Securing the bearing with a thrust retaining ring

A very technologically advanced, convenient and inexpensive way to save space and speed up installation and dismantling is the use of thrust spring retaining rings to secure rolling bearings on shafts and in holes in the housing. Rings made of spring steel allow the bearing assembly to be assembled and disassembled repeatedly.

Also, along with eccentric ones, concentric spring retaining rings are used to secure bearings: for shafts - external thrust retaining rings in accordance with GOST 13940-86 , for holes in the housing - internal thrust retaining rings in accordance with GOST 13941-86 .

In the case when large axial loads act on the bearing assembly, thrust concentric rings in accordance with GOST 13940-86 and GOST 13941-86 can be additionally used in combination with eccentric rings. In this case, the persistent concentric ring absorbs part of the bending moment from axial loads and unloads the eccentric retaining ring, which is responsible for the integrity of the bearing assembly.

In the case of using retaining rings to secure bearings, when designing a bearing assembly, it is necessary to take into account and control the maximum permissible axial load of the retaining ring in order to avoid its destruction during operation.

Fastening the bearing with an end cap and an end washer

When installing bearings at the end of the shaft, you can use end washers in accordance with GOST 14734-69 or special ones. These end washers are secured with one or more bolts or screws that prevent the washer from rotating relative to the shaft. An example of such a scheme with end washers is shown in the following figure:

Read also: Steel 12x17 characteristics application

If it is necessary to fix the outer race of the bearing, use end caps, also with bolts.

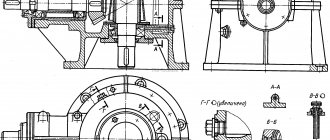

Mounting the bearing using a tapered withdrawal sleeve or adapter sleeve

The use of large size and weight bearings in machines and mechanisms makes their installation and dismantling very difficult. In such cases, the use of bearings with a tapered inner race is recommended. Bearings with a tapered bore are also used for heavily loaded bearings. Such bearings are easy to install/dismount and are very “hardy” in operation, but have a significant drawback: large axial loads directed along the axis from the smaller cone to the larger one can lead to jamming of the bearing, and even destruction.

When installing a tapered bearing directly on a shaft, good centering is achieved, but for this the shaft must have a conical section made with high precision machining, which leads to an increase in the cost of the shaft. In addition, over time, due to dynamic loads, in an emergency, or from repeated installation/disassembly of the bearing, the conical section of the shaft loses the necessary accuracy - it “licks off” - and the expensive shaft has to be replaced. An excellent solution from the point of view of economy, in this case, is the technical solution using conical coupling and adapter bushings, which have a conical outer surface and a cylindrical inner surface - adapter bushings, which allow fixing tapered bearings on a smooth, and even roughly machined, cylindrical shaft. The tightening and adapter sleeves have a longitudinal cut along the axis, allowing them to expand and contract in diameter. They greatly simplify the installation of bearings with a tapered bore on cylindrical stepped shafts. The disadvantage of using bushings is the deterioration of shaft alignment, since another seating surface is added.

Bearings with a tapered inner race, when installed directly on the shaft, are fixed, like bearings with a cylindrical race, using a fastening pair: Round splined nut GOST 11871-88 (item 2 in the figure) + Multi-jaw lock washer GOST 11872-89 (item 1 on the image).

Installation of a bearing using a conical withdrawal sleeve occurs as follows: the sleeve is pressed into the conical hole of the bearing and the resulting structure is placed on the shaft. In this case, the bearing rests against a step or stationary part on the shaft.

An example of installing a bearing with a tapered bore using a tapered withdrawal sleeve on a cylindrical shaft is shown in the figure:

The adapter sleeve, unlike the withdrawal sleeve, has a cone on the outer surface, directed in the other direction (if the withdrawal sleeve has a larger cone diameter located at the nut end, then the adapter sleeve has a larger cone diameter located at the free end of the sleeve). The use of an adapter sleeve allows the bearing to be positioned on any section of a cylindrical shaft without any additional steps, supports or fixed parts - solely due to the frictional force between the shaft, sleeve and bearing.

Fixation of the adapter sleeve is carried out with the same fastening pair as for the withdrawal sleeve: Round splined nut GOST 8530-90 (item 2 in the figure) + Multi-jaw lock washer GOST 8530-90 (item 1 in the figure). The diagram for installing a bearing using an adapter sleeve on a smooth shaft is shown in the figure:

When installing an adapter sleeve on a stepped cylindrical shaft, to increase reliability, it is recommended to use an additional spacer sleeve:

DIN 472 Inner retaining ring

for hole, spring-thrust eccentric. Hole diameter from 8 to 300 mm.

- Spring steel

- Coated steel: galvanized

- Stainless steel: 1.4034, 1.4122, 1.4310, 1.4568

Size chart of internal circlips DIN 472 for bores (normal type) in mm

| d1 | s | d3 | A | b | d5 | d2 | m | n | d4 |

| 8 | 0.8 | 8.7 | 2.4 | 1.1 | 1 | 8.4 | 0.9 | 0.6 | 3 |

| 9 | 0.8 | 9.8 | 2.5 | 1.3 | 1 | 9.4 | 0.9 | 0.6 | 3.3 |

| 10 | 1 | 10.8 | 3.2 | 1.4 | 1.2 | 10.4 | 1.1 | 0.6 | 3.7 |

| 11 | 1 | 11.8 | 3.3 | 1.5 | 1.2 | 11.4 | 1.1 | 0.6 | 4.1 |

| 12 | 1 | 13 | 3.4 | 1.7 | 1.5 | 12.5 | 1.1 | 0.8 | 4.9 |

| 13 | 1 | 14.1 | 3.6 | 1.8 | 1.5 | 13.6 | 1.1 | 0.9 | 5.4 |

| 14 | 1 | 15.1 | 3.7 | 1.9 | 1.7 | 14.6 | 1.1 | 0.9 | 6.2 |

| 15 | 1 | 16.2 | 3.7 | 2 | 1.7 | 15.7 | 1.1 | 1.1 | 7.2 |

| 16 | 1 | 17.3 | 3.8 | 2 | 1.7 | 16.8 | 1.1 | 1.2 | 8 |

| 17 | 1 | 18.3 | 3.9 | 2.1 | 1.7 | 17.8 | 1.1 | 1.2 | 8.8 |

| 18 | 1 | 19.5 | 4.1 | 2.2 | 2 | 19 | 1.1 | 1.5 | 9.4 |

| 19 | 1 | 20.5 | 4.1 | 2.2 | 2 | 20 | 1.1 | 1.5 | 10.4 |

| 20 | 1 | 21.5 | 4.2 | 2.3 | 2 | 21 | 1.1 | 1.5 | 11.2 |

| d1 | s | d3 | A | b | d5 | d2 | m | n | d4 |

| 21 | 1 | 22.5 | 4.2 | 2.4 | 2 | 22 | 1.1 | 1.5 | 12.2 |

| 22 | 1 | 23.5 | 4.2 | 2.5 | 2 | 23 | 1.1 | 1.5 | 13.2 |

| 24 | 1.2 | 25.9 | 4.4 | 2.6 | 2 | 25.2 | 1.3 | 1.8 | 14.8 |

| 25 | 1.2 | 26.9 | 4.5 | 2.7 | 2 | 26.2 | 1.3 | 1.8 | 15.5 |

| 26 | 1.2 | 27.9 | 4.7 | 2.8 | 2 | 27.2 | 1.3 | 1.8 | 16.1 |

| 28 | 1.2 | 30.1 | 4.8 | 2.9 | 2 | 29.4 | 1.3 | 2.1 | 17.9 |

| 30 | 1.2 | 32.1 | 4.8 | 3 | 2 | 31.4 | 1.3 | 2.1 | 19.9 |

| 31 | 1.2 | 33.4 | 5.2 | 3.2 | 2.5 | 32.7 | 1.3 | 2.6 | 20 |

| 32 | 1.2 | 34.4 | 5.4 | 3.2 | 2.5 | 33.7 | 1.3 | 2.6 | 20.6 |

| 34 | 1.5 | 35.5 | 5.4 | 3.3 | 2.5 | 35.7 | 1.6 | 2.6 | 22.6 |

| 35 | 1.5 | 37.8 | 5.4 | 3.4 | 2.5 | 37 | 1.6 | 3 | 23.6 |

| 36 | 1.5 | 38.8 | 5.4 | 3.5 | 2.5 | 38 | 1.6 | 3 | 24.6 |

| 37 | 1.5 | 39.8 | 5.5 | 3.6 | 2.5 | 39 | 1.6 | 3 | 25.4 |

| 38 | 1.5 | 40.8 | 5.5 | 3.7 | 2.5 | 40 | 1.6 | 3 | 26.4 |

| 40 | 1.75 | 43.5 | 5.8 | 3.9 | 2.5 | 42.5 | 1.85 | 3.8 | 27.8 |

| 42 | 1.75 | 45.5 | 5.9 | 4.1 | 2.5 | 44.5 | 1.85 | 3.8 | 29.6 |

| 45 | 1.75 | 48.5 | 6.2 | 4.3 | 2.5 | 47.5 | 1.85 | 3.8 | 32 |

| 47 | 1.75 | 50.5 | 6.4 | 4.4 | 2.5 | 49.5 | 1.85 | 3.8 | 33.5 |

| 48 | 1.75 | 51.5 | 6.4 | 4.5 | 2.5 | 50.5 | 1.85 | 3.8 | 34.5 |

| 50 | 2 | 54.2 | 6.5 | 4.6 | 2.5 | 53 | 2.15 | 4.5 | 36.3 |

| d1 | s | d3 | A | b | d5 | d2 | m | n | d4 |

| 52 | 2 | 56.2 | 6.7 | 4.7 | 2.5 | 55 | 2.15 | 4.5 | 37.9 |

| 55 | 2 | 59.2 | 6.8 | 5 | 2.5 | 58 | 2.15 | 4.5 | 40.7 |

| 56 | 2 | 60.2 | 6.8 | 5.1 | 2.5 | 59 | 2.15 | 4.5 | 41.7 |

| 58 | 2 | 62.2 | 6.9 | 5.2 | 2.5 | 61 | 2.15 | 4.5 | 43.5 |

| 60 | 2 | 64.2 | 7.3 | 5.4 | 2.5 | 63 | 2.15 | 4.5 | 44.7 |

| 62 | 2 | 66.2 | 7.3 | 5.5 | 2.5 | 59 | 2.15 | 4.5 | 46.7 |

| 63 | 2 | 67.2 | 7.3 | 5.6 | 2.5 | 66 | 2.15 | 4.5 | 47.7 |

| 65 | 2.5 | 69.2 | 7.6 | 5.8 | 3 | 68 | 2.65 | 4.5 | 49 |

| 68 | 2.5 | 72.5 | 7.8 | 6.1 | 3 | 71 | 2.65 | 4.5 | 51.6 |

| 70 | 2.5 | 74.5 | 7.8 | 6.2 | 3 | 73 | 2.65 | 4.5 | 53.6 |

| 72 | 2.5 | 76.5 | 7.8 | 6.4 | 3 | 75 | 2.65 | 4.5 | 55.6 |

| 75 | 2.5 | 79.5 | 7.8 | 6.6 | 3 | 78 | 2.65 | 4.5 | 58.6 |

| 78 | 2.5 | 82.5 | 8.5 | 6.8 | 3 | 81 | 2.65 | 4.5 | 60.1 |

| 80 | 2.5 | 82.5 | 8.5 | 7 | 3 | 83.5 | 2.65 | 5.3 | 62.1 |

| 82 | 2.5 | 87.5 | 8.5 | 7 | 3 | 85.5 | 2.65 | 5.3 | 64.1 |

| 85 | 3 | 90.5 | 8.6 | 7.2 | 3.5 | 88.5 | 3.15 | 5.3 | 66.9 |

| 88 | 3 | 93.5 | 8.6 | 7.4 | 3.5 | 91.5 | 3.15 | 5.3 | 69.9 |

| 90 | 3 | 95.5 | 8.6 | 7.6 | 3.5 | 93.5 | 3.15 | 5.3 | 71.9 |

| 92 | 3 | 97.5 | 8.7 | 7.8 | 3.5 | 95.5 | 3.15 | 5.3 | 73.7 |

| 95 | 3 | 100.5 | 8.8 | 8.1 | 3.5 | 98.5 | 3.15 | 5.3 | 76.5 |

| 98 | 3 | 103.5 | 9 | 8.3 | 3.5 | 101.5 | 3.15 | 5.3 | 79 |

| 100 | 3 | 105.5 | 9.2 | 8.4 | 3.5 | 103.5 | 3.15 | 5.3 | 80.6 |

| d1 | s | d3 | A | b | d5 | d2 | m | n | d4 |

| 102 | 4 | 108 | 9.5 | 8.5 | 3.5 | 106 | 4.15 | 6 | 82 |

| 105 | 4 | 112 | 9.5 | 8.7 | 3.5 | 109 | 4.15 | 6 | 85 |

| 108 | 4 | 115 | 9.5 | 8.9 | 3.5 | 112 | 4.15 | 6 | 88 |

| 110 | 4 | 117 | 10.4 | 9 | 3.5 | 114 | 4.15 | 6 | 88.2 |

| 112 | 4 | 119 | 10.5 | 9.1 | 3.5 | 116 | 4.15 | 6 | 90 |

| 115 | 4 | 122 | 10.5 | 9.3 | 3.5 | 119 | 4.15 | 6 | 93 |

| 120 | 4 | 127 | 11 | 9.7 | 3.5 | 124 | 4.15 | 6 | 96.9 |

| 125 | 4 | 132 | 11 | 10 | 4 | 129 | 4.15 | 6 | 101.9 |

| 130 | 4 | 137 | 11 | 10.2 | 4 | 134 | 4.15 | 6 | 106.9 |

| 135 | 4 | 142 | 11.2 | 10.5 | 4 | 139 | 4.15 | 6 | 111.5 |

| 140 | 4 | 147 | 11.2 | 10.7 | 4 | 144 | 4.15 | 6 | 116.5 |

| 145 | 4 | 152 | 11.4 | 10.9 | 4 | 149 | 4.15 | 6 | 121 |

| 150 | 4 | 158 | 12 | 11.2 | 4 | 155 | 4.15 | 7.5 | 124.8 |

| 155 | 4 | 164 | 12 | 11.4 | 4 | 160 | 4.15 | 7.5 | 129.8 |

| 160 | 4 | 169 | 13 | 11.6 | 4 | 165 | 4.15 | 7.5 | 132.7 |

| 165 | 4 | 174.5 | 13 | 11.8 | 4 | 170 | 4.15 | 7.5 | 137.7 |

| 170 | 4 | 179.5 | 13.5 | 12.2 | 4 | 175 | 4.15 | 7.5 | 141.6 |

| 175 | 4 | 184.5 | 13.5 | 12.7 | 4 | 180 | 4.15 | 7.5 | 146.6 |

| 180 | 4 | 189.5 | 14.2 | 13.2 | 4 | 185 | 4.15 | 7.5 | 150.2 |

| 185 | 4 | 194.5 | 14.2 | 13.7 | 4 | 190 | 4.15 | 7.5 | 155.2 |

| d1 | s | d3 | A | b | d5 | d2 | m | n | d4 |

| 190 | 4 | 199.5 | 14.2 | 13.8 | 4 | 195 | 4.15 | 7.5 | 160.2 |

| 195 | 4 | 204.5 | 14.2 | 13.8 | 4 | 200 | 4.15 | 7.5 | 165.2 |

| 200 | 4 | 209.5 | 14.2 | 14 | 4 | 205 | 4.15 | 7.5 | 170.2 |

| 210 | 5 | 222 | 14.2 | 14 | 4 | 216 | 5.15 | 9 | 180.2 |

| 220 | 5 | 232 | 14.2 | 14 | 4 | 226 | 5.15 | 9 | 190.2 |

| 230 | 5 | 242 | 14.2 | 14 | 4 | 236 | 5.15 | 9 | 200.2 |

| 240 | 5 | 252 | 14.2 | 14 | 4 | 246 | 5.15 | 9 | 210.2 |

| 250 | 5 | 262 | 14.2 | 14 | 4 | 256 | 5.15 | 9 | 220.2 |

| 260 | 5 | 275 | 16.2 | 16 | 5 | 268 | 5.15 | 12 | 226 |

| 270 | 5 | 285 | 16.2 | 16 | 5 | 278 | 5.15 | 12 | 236 |

| 280 | 5 | 295 | 16.2 | 16 | 5 | 288 | 5.15 | 12 | 246 |

| 290 | 5 | 305 | 16.2 | 16 | 5 | 298 | 5.15 | 12 | 256 |

| 300 | 5 | 315 | 16.2 | 16 | 5 | 308 | 5.15 | 12 | 266 |

| d1 | s | d3 | A | b | d5 | d2 | m | n | d4 |

Read also: Types of mandrels for a milling machine

Designations: d1 – hole diameter s – ring thickness d3 – outer diameter of the ring a – eyelet width b – max. ring width d5 – hole diameter m – groove width n – edge height d4 – circle diameter

Analogue DIN 472:

GOST 13943-86 – spring thrust flat internal eccentric rings of accuracy classes A, B and C and grooves for them, intended for securing rolling bearings and other parts against axial displacement in holes with a diameter of 8 to 320 mm.

You can order and buy internal retaining rings DIN 472 in bulk at negotiated prices.

192007, St. Petersburg, st. Kurskaya, 27

Trading House Neva sells wholesale fasteners of DIN and GOST standards, galvanized hardware and high-strength fasteners. Deliveries of construction fasteners are carried out to all regions of Russia.

Retaining rings are a type of special fasteners. With their help, it is possible to fix various parts, for example, rolling bearings in various mechanisms. Despite the fact that these products are called rings, their contour is not closed. However, due to the round shape of the locking rings

have a fairly high level of adherence to the working surface along the entire perimeter. Based on the structural form, these products are divided into the following types:

- Internal retaining rings

- Outer retaining rings

Actually, the internal retaining rings

are installed directly in the bore of the mechanisms, and

external retaining rings

, in turn, are designed for installation on shafts. They are installed in special grooves, which are often also called grooves or grooves. In this case, they are installed in such a way that a certain part of the body protrudes outward. It is this protruding element that functions as a shoulder, taking the load and allowing the part to be held in place.

It is noteworthy that the retaining rings

may have different design options.

For example, there are both eccentric locking rings

and

concentric locking rings

. The difference between them is that eccentric ones have an uneven section thickness, which increases significantly near the edges. In this case, a special hole is made in the extension itself. Because of this appearance, they somewhat visually resemble ears, which is why they are often called ears.

Read also: Equipment for mini-businesses at home

Here are the retaining rings

they no longer have concentric ears. The width of this type of section will be uniform around the entire perimeter. However, eccentric products will be able to withstand higher axial loads due to their design. However, both retaining rings generally remain very well balanced during rotation and are able to withstand severe mechanical stress, as well as aggressive substances. The material they are made of helps them achieve these features in many ways:

- Structural spring steel 65G

- Structural spring steel 60S2A

- Heat-resistant corrosion-resistant steel 40Х13

In some cases, the manufacturing material may be substitutes for these steel grades. Sometimes production is carried out from completely different alloys, most suitable for operating conditions. Typically, retaining rings

They are specially coated with cadmium or zinc to protect their surface from corrosive elements. The blank for the production of retaining rings can be steel strip or wire, and production occurs either by stamping or laser cutting.

In the case where wire is used, retaining rings

will have a round cross section. But products made from steel tape will already have a rectangular cross-section. These and other characteristics are regulated by special manufacturing standards. Each of them prescribes different design features, but all of them have the same requirements for surface quality. In particular, it must be free of any visual defects, such as cracks, chips, burrs, unevenness and other defects.

Retaining ring table

Types of retaining rings

Spring thrust flat eccentric internal

Spring thrust flat concentric internal