In ceramic tiles, which are actively used for finishing the surfaces of walls and floors, it is often necessary to drill round holes of large diameter, which are indispensable when laying communications, as well as when installing electrical sockets, fastening and decorative elements. A tool with which such holes can be made as accurately as possible is a ballerina.

Skillful use of the “ballerina” guarantees an accurate hole with neat edges

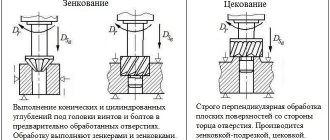

What is a ballerina

The cutting tool, commonly called a ballerina, also has a more professional name - “circular adjustable drill with cutters.” The drill is located in the central part of the tool and is used to center the hole. The radius of the circle that the cutters will describe is measured from the center line of this drill.

To equip ballerinas, drills of the first or auger type are used, since a conical tool does not cope well with ceramic materials and can slide off their surface. The result of such slipping can be damage to both the tool itself and the surface of the tile.

Ballerina on tiles differs from a nozzle designed for drilling holes in wood materials

Recommendations for using a ballerina

Before using this tool, please read the instructions and operating instructions carefully.

- Particular attention must be paid to the selection of drills to create a recess at the central point.

- If the shape and type of drill are unsuitable, the tile will simply crack, making it completely unsuitable for further use.

- The drill should be of small diameter to avoid cracking the material during drilling.

You also need to pay special attention to the fastening of the cutters in the ballerina; if the working surfaces are not securely fastened, they may fly off during work, which will lead to damage to the material.

In addition, there is a danger of injury to the master’s hands. Therefore, it is necessary to comply with all safety requirements, wear a protective mask and gloves, and respiratory protection to avoid injury.

Circular drill device

A ballerina drill for wood is made from carbon, tool, and alloy steels, which are not suitable for processing hard materials: metal, tile, porcelain stoneware. But they cut drywall and plastic easily.

The two-incisor ballerina looks like an ordinary compass. But the design is much more complex. The bracket and cylindrical shank are manufactured in one piece. There are two holes in the bracket. A centering drill is installed in one. A rod is installed in the second. Both are secured with screws.

To set the required diameter, the cutters move along the rod. It has a vernier scale on it. The tool holders are also secured with screws. The incisors are shaped like a knife. The oblique edge of the cutter should be directed in the direction of rotation, clockwise.

If the drill becomes dull during operation, it can be easily replaced. If the cutters are dull, then, having the skills to work on a sharpening machine, you can refill them. The shank of the structure is fixed in the chuck of an electric drill. It is worth remembering that the small power of a power tool may not be enough to work with a ballerina, unlike metal drills.

Rules for drilling ceramic tiles

First of all, you need to choose the right drilling tool. The most ordinary drill (neither an impact drill nor a high-speed drill) is suitable for this, since working with tiles must be extremely delicate. To make holes in the tiles, you can use the following list of tools:

- electric drill. It is allowed to work at minimum speed;

- a cordless screwdriver whose maximum speed does not exceed 1000 rpm;

- low-speed screwdriver that runs on mains power.

To drill ceramic tiles, special drills must be selected. They differ from those used for working with wood, concrete and metal surfaces. The principle of drilling ceramics is the use of abrasives. For example, diamond or pobedite drills, which come in arrow-shaped or crown-shaped, are suitable. Also, for drilling tiles, so-called “ballerinas” are well used - special devices that allow you to adjust the diameter.

After preparing the necessary tools, you can smoothly move on to the work process. It is worth noting that according to technology, certain points must be observed:

Overheating of either the tool or the working surface of the tile is not allowed. This can cause the top layers to crack, splitting the tile completely. To cool the material, it is necessary to use water, periodically watering it in between drilling. It is necessary to adhere to the optimal pressing force on the power tool. Don't press too lightly or too hard. Because with weak pressure it will be quite difficult to drill a hole, and with strong pressure there is a possibility of breaking the tile. Reverse movement of the drill is not allowed when performing this type of work. Its rotation should be slow and carried out exclusively clockwise

Otherwise, there is a possibility of cracks appearing. When drilling holes in tile joints, special care must be taken. The drill should be positioned strictly in the center of the seam

There is no protective layer along the edges of the tiles, so chipping may occur even with careful work.

According to some craftsmen, the area where the hole will be should first be pierced or a layer of glaze on the ceramic should be removed at the place where it is drilled. However, modern specialists no longer apply this practice. This was done several decades ago, since there were no modern drills that would allow the procedure to be performed without chipping the surface.

Types by number of incisors

The design of a ballerina is influenced by the number of incisors with which it is equipped (their number can vary from one to three).

- The design of ballerinas equipped with one cutter has a special adjustable bracket with a tightening screw. To start working with such a tool, use a bracket to move the cutter to the required distance from the axis of the central drill, and then fix its position using a tightening screw.

- The cutting tools of two-cut ballerinas are also located on a bracket, which is motionless. Adjustment of the position of the cutters relative to the axis of the central drill is ensured by movable holders on which clamping screws are installed for fixing the cutting tool. The position of each of the incisors of such a ballerina is set separately, and, of course, their distance from the axis of the central drill must be the same.

- The three-incisor ballerina for tiles and ceramic tiles has the most complex design. The basis of such a tool is a round disk-type platform, in special grooves in which the cutters move. A special scale applied to the body of the device platform in the area of its grooves allows you to accurately set the position of the cutters and, accordingly, obtain holes of the required diameter. The movement of all three cutters of such a device is synchronized, which allows you to quickly, easily, and most importantly, accurately set the position of each tool relative to the axis of the central drill.

The protective basket on some instrument models protects against flying fragments

Modern models of one- and two-incisor ballerinas are also equipped with a scale for determining the exact position of the incisors relative to the axis of the central drill. It should be borne in mind that the accuracy of the holes obtained by a ballerina with such a scale is much higher than when using a simpler tool.

It is necessary to choose a ballerina of a more complex design in cases where it is necessary to drill a large number of holes in ceramic or tiles. A tool equipped with multiple cutters not only improves the productivity of the drilling process, but also creates holes with higher accuracy.

How to drill a small hole

To cut small holes, you need to mark the tile and select a drill bit. The most convenient option would be a drill with a diamond coating , but such devices are not cheap. A spear-shaped drill with a Pobedit tip can be a replacement. Its feature is an arrow-shaped tip , thanks to which the drill does not slip on the smooth surface of the tile. A sharp cutting edge reduces the contact area, so less pressure on the drill is required, which means there is little risk of cracking. As a last resort, it is permissible to use a well-sharpened ordinary concrete drill , but working with it requires precision and accuracy.

Before starting work, stick a piece of masking tape in the area of the future hole - this will help fix the drill and prevent slipping.

At the beginning of the process, while the drill is passing the surface layer of the tile, the drill should operate at the lowest speed . When the drill penetrates the thickness of the tile, the speed can be increased. strictly forbidden to use the shock mode - this will immediately lead to the formation of cracks. If, after drilling the tile, it is also necessary to drill into the concrete wall on which it is attached, then the drill must be changed to a drill for concrete and continue drilling with it. Here it is already allowed to turn on the drill at high speeds and use the impact mode.

Types of ballerinas

To work with materials of different densities and structures - soft and hard wood, plastic, plasterboard, concrete, stone, brick, porcelain stoneware - drills made from various grades of steel and having special designs are used.

For woodworking

You can drill a large diameter hole in a wooden surface using a 200 mm wood ballerina.

Before you start drilling in a wooden surface (especially laminated or veneered), you need to make a shallow hole with an awl. This will allow you to accurately comply with the specified dimensions. Drill at low or medium speeds (1000-1200 rpm) to avoid chipping at the exit (if necessary, drill a through hole).

To work with hard wood, use wood ballerina 40 (300). In some cases (hardwoods) a wood ballerina with a diameter of 30 200 mm mk is used (category Strong -stk, 057)

How to prepare to drill out tiles

What can make working with the material more difficult? Let's remember how it's done.

Material characteristics

The innovative specifics of the process involve firing at high temperatures.

Also, the material has a high density and has a particularly hard (especially if there is glazing) surface, while it is characterized by specific fragility.

The material does not have plasticity, and due to this, if not handled very carefully, drilling and cutting, it can crack, form chips and even fall apart. Moreover, the hard surface has an abrasive effect on cutting tools, rendering drills unusable and dull in a short time

Moreover, the hard surface has an abrasive effect on cutting tools, rendering drills unusable and dull in a short time.

Rules for drilling tiles

Because of this, it is very important to follow a number of specific rules:

- tiles do not like vibration influences,

- tiles are afraid of heavy loads,

- tiles do not like excessively revving modes of drilling tools.

It follows that you need to use special drills made of heavy-duty materials that can easily overcome solid structures. They must also contain a specific sharpening and configuration.

Preparing the tools

What you need to drill out tiles from tiles

without loss?

A good screwdriver with a fairly powerful power source. Sometimes such a tool is completely sufficient. Electric drill with speed control option.

The simplest, already forgotten by some, hand drill. In most cases, it is completely sufficient for making small and not very deep holes. Moreover, there will definitely be no problems with adjusting the rotation speed. In most cases, even a regular brace is used.

Special devices - jigs: they can be used to make the process easier for drilling straight holes. Using suction cups, they are fixed to the surface, preventing the drill, especially at the beginning of work, from moving to the side.

Specialized superchargers. At low pressure, they supply water to the workplace, which cools the hot tool.

Drill

Special spear-shaped (feather) drills designed specifically for tiles. They are convenient for making holes of medium and small diameter (for dowel fasteners).

For good clamping in the tool chuck, the tool is equipped with a cylindrical shank. Drills with a hexagon are produced to suit the size of standard bits - they are used when working with a screwdriver.

In an ordinary tile, such a drill can make on average no more than thirty holes before it fails. If you have to work with ceramic granite, then this figure is reduced to two or three pieces.

Core drills with corundum or diamond coating, which are included in the category of professional tools: they work perfectly not only with tiles, but also with ceramic granite.

Such drills are like a hollow tube, thus significantly facilitating the work process. Waste is removed through the cavity without interference. In most cases they are made to make very large holes.

Ballerina drill. Can be used for one-time work when it is necessary to make a hole of significant diameter. It has a low price and easily copes with the established task.

Drills with heavy-duty carbide tips. This option is not one of the most successful, since difficulties may arise when passing the mechanism through the top, very strong tile layer. They are more suitable for deepening holes that have already been made by other nozzles.

Carbide very durable drills with acute angled one-sided sharpening. They pass through the hardest layer located on the outside of the tile perfectly. Products of this type, made by a good manufacturer, will last a very long time.

Resembling the ones just mentioned, tungsten carbide coated drills. They are used not only for drilling ceramics; they can also be used on hard materials of natural origin, such as granite and marble. They are mainly sold in sets of different diameters and are used more often by specialists.

How to choose the right one

When purchasing a drill, be sure to evaluate the configuration of the ballerina. Three-cut drills are considered the most reliable and in demand.

They have good mounting screws that firmly secure the working cutters. The length of the working cutters should be 4-5 mm less than the length of the centering cutter.

Some models use standard clamps to secure the incisors. They require a Phillips screwdriver and are much less reliable than models with hex screws.

- For drilling tiles, it is better to choose a ballerina with two incisors. With its help, you can make a hole with a diameter of up to 160 mm, whereas when working with a single-cut tool, the maximum diameter will be only 120 mm.

- A double-sided wood ballerina will allow you to make a hole with a diameter of up to 300 mm. And for working with thin (less than 5 mm) sheets of wood, a special drill is included in the kit.

- To work with hard surfaces (metal, porcelain stoneware, stone), use a one-sided ballerina. Before drilling begins, its central axis is securely clamped in the drill chuck.

On the brackets of branded ballerina models there is a ruler with clearly visible divisions. As a rule, the movement of the cutters is carried out synchronously. You should also pay attention to the width of the incisor run (it can be up to 150 mm). This parameter determines the radius of the future hole. Usually, the quality of the working surface (wood, metal, tile) is taken into account when choosing the permissible width of the cutters.

Some models are equipped with a protective plastic grid that holds large sawdust.

Design and principle of operation of the ballerina drill

The design of the tool is simple and reliable. It includes:

- Bracket. A centering drill, a crossbar, and an end cap for fixing in a drill or brace are attached to it.

- Centering twist drill. Marks the center of the circle for cutting, provides support for cutting elements.

- Crossbar. Support for moving cutting elements. It is graduated to set the diameter of the recess.

- Sliding cutters. By moving them along the divisions on the rod, the required hole size is set.

The device of a ballerina on wood and on tiles

The cutters are attached to the transverse rod with hexagonal screws. Some ballerina drill models use clamps for a Phillips screwdriver, but they are inferior in terms of convenience and reliability of fixation. Before starting work, the cutters are installed in the desired position, at an equal distance from the center, using markings on the rod or measurements with a caliper. After installation, the cutters are securely fixed in a strictly vertical position.

To start work, a centering drill drills in the center of the future opening, fixing the tool. The cutting elements are installed to the required size. They slide apart along the guide rod and are securely fastened. Using a drill or a brace, the ballerina begins to rotate, and the incisors moving around the circumference cut a recess along the contour of the future recess. The drilling speed depends on the material being processed and the rotation speed.

Using a ballerina drill

Method of drilling holes with a ballerina

Please note: Before starting drilling, when the intended hole is marked, mark the drilling center mechanically. For this, a regular drill is used. The ballerina may slip on the tile (at the first touch) and scratch the tile.

The use of hammer drills is prohibited. If you have a multi-mode drill, the hammer function should be disabled. It is recommended to immerse the workpiece in water in advance. There will be no harm to the tile, and there will be much less chipping and dust.

In principle, there are two ways of drilling: before laying the tiles, and on the finished tiled surface.

Drilling individual tiles

The workpiece is placed on a flat surface. The thickness of the backing should allow the center drill to deepen 4-8 mm relative to the main cutting element.

You can hold the tiles with your hands, although it would be better to secure them with clamps. You must be prepared for the fact that after the ballerina passes through, the cut out circle will rotate freely. For control, it is recommended to periodically stop the process and check the depth of the cut.

Drilling a hole in the tile with a ballerina with a basket - expert advice

Communities › Kulibin Club › Blog › Ballerina for metal - a new cutter with carbide. Is it worth it?

Recently I made a “ballerina” for metal from pieces of iron found in the garage - an old broken lathe, a broken 6 mm drill, a core from a bent valve and a blank with a diameter of 26 mm. I posted a report in the DIY community - here is the link.

There are two solutions: the first is to lower the speed of the drilling machine and avoid overheating of the cutter, the second is to improve the wear resistance of the cutter.

The first path requires the purchase of a frequency drive - the speed is already set to a minimum. But for now there is no extra money for a frequency drive, and I chose the second path - I decided to make a new cutter with carbide tipping. Well, then compare both incisors...

For the holder of the new cutter, I found an old bent valve from my C8 (there are still 7 of them left))) and a broken carbide plate from a cutting cutter. You can buy records - 50 rubles per piece, but I had them)).

I decided to solder using an electrolysis gas welding machine “League” - a good friend presented it to me a couple of years ago. And he stood idle, but here it seemed appropriate.

I looked into the issue of soldering plates - what I liked the most was the “recipe” from Uncle Maxim (it’s on the chip maker and on YouTube - cool guy)).

For soldering, he uses a mixture of borax (as a flux) and brass filings. No sooner said than done. I sharpened some sawdust from some old plumbing part, mixed it with borax and started soldering.

Before soldering, the surface was “rubbed” with a file - the surface after the grinder is not suitable for soldering (as Uncle Maxim said)).

We heat it, pour in the resulting powder, heat it again and voila.

Let it cool and sharpen. The result is this first option (the camera focuses only on the background of the hands, sorry):

I tried to drill, but the cutting speed is much lower than that of a cutter from a drill.

I tried several more different sharpening methods. Here is the most progressive one:

But he also disappointed me. Better than the previous ones, but it still drills slowly and sadly... What’s strange is that the sharpening profile is identical, the edge width is even smaller, and it’s really sharp.

In general, during the next attempt I freaked out and pressed the incisor harder. You understand what happened)). It bit into the metal, the machine jammed, the cutter was bent...

I straightened the cutter. The most interesting thing is that my soldering withstood all this - it was soldered well. And she didn't get dull

But she didn’t cut it well...

In general, the question is: who knows why a cutter made from a drill, made from high-speed steel (don’t talk about the name)) actually cuts faster than carbide and what to do about it? How to make carbide cut well?

Here is a short video demonstrating the sharpening and operation of a drill cutter, filmed in one shot, as well as the manufacture and testing of a new carbide-tipped cutter:

In general, if anyone knows the secret, don’t be shy about sharing it))

Design Features

The design of any ballerina includes the following elements:

- a rod with which such a device is fixed in the chuck of an electric drill;

- feather-type centering drill;

- adjustable bracket on which the cutting tool is fixed;

- a cutter, the working part of which is coated with diamond sputtering or a carbide plate is brazed.

Ballerina device

When choosing a ballerina to perform work on tiles or ceramic tiles, you should not save money. A high-quality tool, the price of which is significantly higher than that of simpler models, will not only allow you to get the job done efficiently, but will also not ruin the tiles, which may cost even more than the ballerina used to drill them.

Elementary technology: drilling tiles in the bathroom

In order to hang a shelf, hooks, install electrical equipment and for any other purposes, you may need to make a hole in a solid tile and it can be successfully drilled if you strictly follow all the tips and act according to the technological process. In fact, the operation algorithm is simple: you need to drill a hole that penetrates the wall, insert a dowel into it, and then screw in a screw or self-tapping screw. But first you should find out how to drill tiles in the bathroom, since the success of the entire enterprise may depend on this.

Advantages and Disadvantages of Tools

Before you start working directly, it doesn’t hurt to think about how to drill ceramic tiles in the bathroom, that is, to finally decide on the equipment. Today on the market there is a wide selection of a wide variety of drills, hammer drills, hand rotators and who knows what else. Among this variety, you should choose only the most suitable one.

The most suitable tool for drilling tiles is an electric drill, which has variable speed. It will be much more convenient and faster to work with it, and low speeds will eliminate or at least minimize the risk of cracking of the glazed ceramic surface. A high-quality drill is not cheap, but it is an indispensable assistant for the home craftsman, so you should not waste money on equipment from well-known manufacturers.

A battery-powered screwdriver is the second profitable and convenient tool that is suitable for drilling tiles in the bathroom without any problems. It also has one more advantageous property - it can be used even where the equipment cannot be connected to the network.

Rotary hammers from well-known companies also have enviable multifunctionality, so you can use such a tool when drilling holes in tiles. True, the price of such equipment is even higher than that of a drill if we are talking about professional models.

The most tedious and time-consuming process is drilling ceramics using a hand drill. However, if you only need to make a few small holes, you can try to do it this way.

Selecting consumables and components

Low-speed drills, screwdrivers or hammer drills are mainly used for drilling holes in ceramic tiles.

But choosing the right tool is only half the battle, since it is important to understand which drill to use to drill tiles in the bathroom so as not to damage the glazed surface. Moreover, you must take into account that drills for brick or concrete can be immediately put aside; their use does not bode well, the tile will simply crack and will have to be replaced. There are three most suitable consumable options that will best suit your purposes:

There are three most suitable consumable options that will best suit your purposes:

The best drills for drilling dense and slippery ceramics are diamond-coated drills, which makes their tips look like sparklers. These are quite expensive components, because their production uses chips of natural diamonds and it is impractical to purchase such drills for making one or two holes. If you are faced with major repairs, construction or finishing, this is your professional occupation, then you simply must have it in your “arsenal”. The second place is rightfully occupied by spear-shaped drill bits for drills with pobedite tips. They are designed in such a way as not to split the tiles, and the special sharpening does not allow them to slip off when starting work. Due to this shape, the adhesion of arrow-shaped drills to the surface improves, and the risk of cracks and chips is reduced

The price of such drills is much lower than diamond ones, but they cannot be called cheap either.

When figuring out how to drill tiles in the bathroom, you can pay attention to drills made of refractory, durable metals, which are designed for processing metal surfaces, if nothing else is at hand. The cost of such a drill bit for a drill is quite affordable for everyone, however, you will have to work at your own peril and risk

It won’t hurt if such equipment is new, perfectly sharpened, and also has a pobedite coating or tip.

Thus, it will not be at all difficult to decide on drills and all that remains is to figure out how to drill the tiles in the bathroom step by step so that they do not burst or become cracked, which will add more work to you in replacing them.

Making a ballerina cutter

A ballerina drill significantly saves time when processing (milling) the contours of a cut hole. Processing is carried out automatically using power tools (drill, hammer drill).

Therefore, the physical effort expended when working with a ballerina is also insignificant. Given these advantages, home craftsmen want to have such a tool in their workshop. Moreover, making a ballerina with your own hands is not at all difficult for a competent craftsman.

For this you will need materials:

- Working (metal) plate with dimensions 200x25x4-6 mm.

- Bolts: M8 grade - 2 pieces (in addition to them you need to take 2 nuts and 4 washers) and M10 grade - 1 piece (in addition to them you need to take 2 nuts and 1 washer).

To work you will need tools:

- To mark the work surface: a marker and a ruler with centimeter divisions.

- Painting tape.

- Stationary machine or power tools (hammer, drill).

- Vise.

- File.

- Kern.

- Grinder equipped with grinding and cutting discs.

- Drills for metal with a diameter from 9 mm to 10.5 mm.

- Keys: open-end and adjustable.

- Screw clamps.

Step-by-step instructions on how to make it yourself

- Marking and processing of the work plate.

- Creation and processing of working grooves.

- Manufacturing of cutters.

- Connection of cutters to the working plate.

- Marking (gradation) of the finished drill.

- At the first stage, we cut a 20 cm long strip from the metal sheet. This will be the basis of the tool being created.

- Using a drill with a diameter of 10.5 mm, we drill a through hole on the machine in the pre-punched center of the work plate.

- Stepping back 1 cm from the drilled hole to the edges of the working plate (at the same level as the central hole), we make marks (punch) on the plate for future drilling.

- The distance between the marks must exceed the diameter of the holes that will subsequently be drilled. This precaution will help preserve the drill.

- Using a grinder cutting disc, you need to create two oblong grooves by combining the existing holes. The working plate is in a vice during this operation.

- Using a file (square or flat), we process the resulting holes. The free movement of the incisors will depend on the thoroughness of this operation (we remove irregularities, hangnails, and tubercles).

- Pressing the work plate tightly against the table (we use clamps or a vice), we smooth out all the irregularities and sharp corners with a grinding disc. We insert an M10 bolt into the central hole and screw one of the nuts onto it from the reverse side.

- We put the second nut (lock nut) on it and press it tightly using an open-end (or adjustable) wrench. To make the cutters, we wrap the upper parts of the M8 bolts with masking tape. We fix the bolt heads in a vice.

- Using a grinder's grinding disc, we cut off the thread, processing the bolt on both sides until a metal handle 4-5 mm thick is formed.

- The pointed ends of the bolt, shaped like a one-sided hook, will serve as the working cutters of the drill. The resulting cutters must be inserted into the grooves, having previously been laid with washers on both sides.

- This will increase the area of their contact with the working plate.

- The rod of the future tool and the cutters should be located in opposite directions. The thread sections remaining on the side surfaces of the bolts will allow you to screw on the nuts and secure the cutters tightly.

- Using a ruler and a marker, we mark the entire plane of the working plate, making marks every 0.5 cm. Later on these marks it is necessary to make notches that will be clearly visible during operation.

How can you make a hole?

To make a hole in a tile use:

- Drill:

- Spear-shaped;

- Tubular;

- Spiral with pobeditovy cutter;

- Diamond-coated crowns;

- Ballerina;

- Cutting disc with grinder;

- Diamond-coated string;

Depending on the amount of work and the type of tile, one or another device is used. Among them there are universal and highly specialized.

- Drill.

Spear drills have 2 or 4 edges. The second option is less common. The edges are formed by soldering, which are made of pobedite alloy. Spear drills are intended only for drilling tiles. Some manufacturers produce models for porcelain stoneware, but practice has shown their poor functionality.

If you drill wet, you can double the life of cheap drills.

Expensive models from Bosch or KWB cost an order of magnitude more, 600-700 rubles. Of course, if handled carelessly, they can also break, but careful use is guaranteed to make more than one hundred holes.

Tubular drills represent a qualitatively different level of consumables. In appearance, it is a high-alloy steel tube with diamond coating on the working end. They are already able to cope with porcelain stoneware and Metlakh tiles. Almost always, the manufacturer recommends using them for wet drilling.

The cheapest models of the domestic brand “Praktika” cost 150-170 rubles. Expensive ones, from Bosch or MESSER, will cost 2.5-3 thousand. Moreover, in expensive models, the dry drilling function is implemented. This option is made possible thanks to vacuum deposition of abrasive material and the integration of a miniature coolant container.

Twist drills with a Pobedit cutter occupy a special position. They are rather an upgrade of conventional models, but their intended purpose is deep holes in durable material. This is confirmed by the spiral grooves, which remove dust very well when working with thick tiles.

- Diamond-coated crowns.

Structurally, they can be thought of as tubular drills of large diameter. But these are more complex devices. Depending on the diameter and model, they can have from 8 to 36 teeth, or without them. Some of them do not even have segmenting slots, that is, this is a real large-diameter tubular drill.

All models must have a centering drill in the center.

There is no clear division of them according to any characteristics into tubular drills and crowns. Some manufacturers produce drill bits without a shank with a diameter of 8 mm, while other companies offer tubular drills with a shank, ø20 mm.

But in any case, for large-diameter holes, diamond-coated crowns are used.

The cheapest models cost 180 rubles, the most expensive from RUBI, 11-12 thousand.

- Ballerina.

A convenient device in the form of an h-shaped compass, with the possibility of adjustment. The central leg is an analogue of a spear-shaped drill. A cutter, most often made of a tungsten carbide alloy.

Almost all of them can drill a hole from 20 to 90 mm. Some models are equipped with a protective screen. Price from 350 to 1000 rubles.

The ballerina is attracted by the possibility of adjustment, and an inexperienced buyer is attracted by this feature. But they are extremely inconvenient to use! The reason becomes clear if you imagine the ballerina not as a device for work, but as an eccentric. When drilling, even at low speeds, the vibration is so strong that it takes considerable effort to hold the drill in one position.

- Cutting disc with grinder.

This option can be considered indirect, because the holes are made not by drilling, but by sequentially cutting closely spaced slits. The method is labor-intensive, the edges are uneven. But it is possible to make a cutout in the form of any figure of the correct shape: a square or a triangle.

The disc is required to have a smooth edge and diamond coating.

It doesn’t make sense to buy it specifically, and more often this option is used if the work takes place in emergency mode.

- Diamond coated string.

This is an ideal device for cutting holes of any geometric shape, in all tiles without exception. It is a string with ears on which an abrasive coating is applied. The material can be different, from tool steel to tungsten. It cuts any tile like butter. The only negative is that mechanization is impossible; all work must be done manually.

Price from 200 to 600 rubles. If you don't break it on purpose, it will last for several years.

Precautionary measures

- All parts of clothing (work apron, robe, shirt cuffs) must be secured (tied, buttoned).

- To prevent metal shavings and dust from getting into your eyes, you must wear work glasses.

- It is advisable to tuck long hair under a cap (beret, bandana).

- Rotating parts of drills and power tools (machine) must be securely fastened.

- It is advisable to use a ballerina equipped with a protective grille.

The working surface should be less hard than the steel from which the drill is made. Bring the already rotating drill to the surface. These tips will help extend the life of your tool.

Advantages and disadvantages of use

To drill large-diameter holes in ceramic or tiles, you can use not only a ballerina, but also a number of other devices, which include a core-type tool, a chain saw or a diamond string mounted on a hacksaw. When choosing any of these tools, you should first evaluate the effectiveness of its use.

The main advantage of a ballerina over crowns is the adjustable diameter of the cut hole.

Let's look at the disadvantages of using a ballerina to drill holes.

- When using such a tool for drilling work on tiles, a large number of fragments are formed that can harm the worker. Meanwhile, you can successfully solve this problem if you stick ordinary tape on the surface of the tile that is being drilled, or use a tool with a protective grill for drilling. The cost of the latter is not much higher than the price of conventional models, but it significantly increases the safety of the person who works with it.

- The edge of the hole, which is drilled using a ballerina, is not very neat. This problem is also solved: the tool can be moistened with water or machine oil, and drilling can be performed as carefully as possible and without unnecessary haste.

The most significant advantage of ballerinas is that their use allows you to create holes in a wide range of diameters in ceramic or tiles. Thus, on the modern market there is a tool with which you can make holes whose radius is in the range of 20–90 and 40–130 mm. Accordingly, to determine the diameter of such holes, these values must be multiplied by two. If the main working elements of the ballerina (drill and cutters) are made of high-quality materials, it copes with all its functions quite successfully.

When purchasing a ballerina of any design, you should pay attention to the rigidity of the connection between the rod and the central rod

What drills to use

The central stabilizer can be replaced, this is due to the different characteristics of the materials for which it can be used. It is worth noting that conical drills are not allowed for use on tiles.

This is due to the fact that, due to the peculiarities of their design, they can slide off the intended, pre-deepened point and scratch the front surface of the tile.

For this reason, it is recommended to use auger or type 1 drills for these purposes. They are ideal for these tasks

It is worth noting that it is not always necessary to drill with a ballerina until the inner circle is completely separated from the tile, thus forming a hole

- Some tiles have an extra layer at the back that is not tile, a hard material designed to improve the tile's adhesion to the stucco wall surface.

- In such cases, it is enough to drill with a ballerina to a depth of no more than 2/3 of the total thickness. After this, you can carefully knock out the resulting circle. The disadvantage of this method is that on the reverse side, when knocking out, chips form on the material.

However, you shouldn’t worry about this, because the back side of the tile will be attached to the wall using a primer, so the chips will be hidden from view. In addition, they will not affect the quality of adhesion between the surface of the slab and the wall, because the vast majority of the area's materials remain intact.

Adjustable tool overview

Ballerina – adjustable drill. One of its structural elements is a bracket with a scale printed on it. With its help, you can independently set the required diameter. And in a three-cut drill, the cutting elements move synchronously along special grooves.

Before starting work (drilling), it is necessary to set both cutters at the same distance from the central hole.

Sources

- https://met-all.org/oborudovanie/prochee/sverlo-balerinka-po-kafelyu-plitke.html

- https://tokar.guru/instrumenty/balerinka-po-derevu-kafelyu-metallu.html

- https://instruments24.ru/universal/balerinka.html

- https://obplitke.ru/bytovye-voprosy/instrumenty/balerinka-po-kafelyu

Types of crowns for tiles

Diamond crowns

Very often it becomes necessary to drill a hole in a large diameter tile; crowns are used for this.

Characteristics of diamond-coated crowns:

- Crowns exist in different diameters, from 10 mm to 70 cm, and there are even larger ones.

- It is better to drill with such crowns in a stationary machine with water cooling.

- Crowns for working with porcelain stoneware and ceramic tiles are the same and look the same in appearance. When drilling tiles, such a crown will last longer than when working with porcelain tiles, because porcelain tiles are a fairly hard material and the drills will wear out faster.

Diamond core bits for large diameter holes

Rules for using diamond-coated crowns:

- low drilling speed (rpm 200-500);

- water cooling;

- use in conjunction with a stationary machine.

Tungsten carbide bits

Crowns with tungsten carbide coating come in a set: four crowns of different diameters, which are fixed to one base.

These drill bits can be used to drill not only ceramic tiles and porcelain stoneware, but also brick, marble, granite and other stone.

Such crowns help to drill a variety of grooves:

- for cabinets

- for shelves;

- for sockets.

Crowns with tungsten carbide coating