The formation of openings in walls, partitions, panel structures and other structures may be required for a variety of purposes. But even a small-diameter installation passage can cause many problems during the creation process. Especially when it comes to solid building materials: brick or concrete. When working with soft surfaces, not everything is clear either. In such cases, traditional hand tools are used to drill holes. However, the work process itself requires skill and care, since the risk of deformation of the areas adjacent to the processing site increases. One way or another, each case involves its own drilling nuances, which should be examined separately.

In what cases are drilling operations used?

The areas of application of technical devices and equipment for creating holes by drilling are quite extensive. First of all, we are talking about repair and installation operations, during which builders create channels for laying communications. Moreover, the size of such holes can vary from 1 to 20 cm. Small passages are necessary for wiring cables of telephone lines, information networks, etc. Such work requires delicacy and high precision. Therefore, it is recommended to use an electric tool for drilling holes, which can be represented by a multi-function drill. Also, the need to create holes may be due to the laying of engineering and communication networks. This group of installation activities includes the installation of water, gas supply, and heating systems.

Types of drilling tools

As varied as the parameters of drilling operations are, the range of tools designed to implement them is equally wide. The classic and most common type of such means is the mentioned drill. By the way, it also suggests several subtypes. For example, there are traditional mechanical drills, corded and cordless versions that can perform tasks away from an outlet. There are also groups of special tools. They are designed to work with specific hardware. For example, a beginner in carpentry may have a question about what is the name of the tool for drilling cylindrical holes for the purpose of further inserting round tenons? For such operations, perkas are used - these are center drills that allow processing even across the fibers.

A separate group presents more powerful devices that work with concrete. Manufacturers offer both manual hammer drills and massive machines-like units for such tasks. The features of such equipment include increased productivity and the ability to form large niches in walls of any complexity. A tool for drilling holes in concrete can perform its tasks thanks to special equipment, which is most often represented by diamond cutting elements.

Wood working tool

In such work, a twist drill is most often used as part of a mechanical drill. With this set you can process not only wooden workpieces, but also plastic and thin metal. Depending on the requirements for the hole parameters, the appropriate drill size is selected.

There are also several types of work items in this category. For example, to obtain large-diameter niches, spoon attachments are used, while for small gaps it is more profitable to use screw or auger devices. Regardless of the type, the tool for drilling holes in wood provides a special cutting pattern. The fact is that the cutting edges process the fibers of the material in such a way that the resulting particles with sawdust are discharged along the screw grooves and do not interfere with the further process.

Drill accessories

There are several accessories for drills that can make the process easier and make a large hole smooth:

- Drilling jig. This device is a housing in which there are several guide bushings for drills of different diameters. The material used to create the bushings is harder than drill bits, so you don't have to worry about the tool moving to the side while drilling and widening the hole.

- Drill guide. This product allows you to fix the tool in such a way that it does not deviate to the side during drilling. If such a product is not available, the tool may move to the side, resulting in an uneven edge. It can also be mounted at an angle. But when drilling metal products, this is usually not required.

- Drill stand. A DIY product like this can be an inexpensive replacement for a drilling machine, as it allows you to carry out work more comfortably. When using a stand, a fixed tool moves along the bar using a lever. In this case, displacement is completely eliminated, since the workpiece being drilled is securely held due to the presence of a clamp.

Using these products, you can greatly facilitate the process of drilling metal products.

Perforation as a type of drilling

It has already been noted that in construction most often it is necessary to create holes with a diameter of several centimeters. Of course, there are exceptions. But perforation even requires working with a tool that provides an accuracy of about 0.25 mm. In such operations, drills are used, the diameter of which on average varies from 4 to 8 mm. Perforation itself is one of the ways to create small but complex holes in large quantities.

Usually a round one is used, but a rectangular processing pattern is also found. The target material is paper and cardboard sheets folded in bundles, and the tool for drilling holes of this type represents a separate group. Basically, special knives are used for such tasks, differing in size, shape of the cutters, perforation steps and other parameters. The drills used have a cutting edge on the outer edge. This makes it possible to make precise holes along the entire length of the channel.

Features of large diameter holes

This procedure is more complex than deep drilling. Cutting work is carried out either using a crown or using a cone drill. Crowns for metal are similar to products for concrete and drywall. The only difference is the material used to create the cutting edge.

Drilling can also be carried out with standard products in several stages. To do this, first use a nozzle of small diameter. Then a larger tool is selected.

The most convenient way is to use cone drills. Such devices allow you to drill a large hole in one go. To do this, the tool is simply recessed into the material.

Read also: How to check a commutator motor with a multimeter

Metal tool

Creating holes in metal workpieces can also be done with punches. Typically, such a tool is used when working with sheet soft material. For thick workpieces, special machines or electric drills are often used. Often there is a need to expand existing holes or only the upper parts. Such recesses may be required for further screwing in bolts, screws and screws with masking heads. For this, either special drills with appropriate attachments or a countersinking tool are used.

A special feature of working with metal is the use of a machine vice that holds the workpiece. For wood, such equipment is not necessary. So, the workpiece is secured between the jaws by rotating a special screw. If a tool for drilling holes in metal in the form of a machine is used in combination with a vice, the locking device can be fixed directly to the working platform. But that is not all. Some models of drilling machines are equipped with locking mechanisms with convenient devices for adjusting the position of the workpiece.

Concrete drilling tool

In the processing of concrete and brick walls, equipment is used in the form of electric, hydraulic and other drilling rigs with an impact effect. As already noted, the entry level of this group is a hammer drill. But also modern electric drills in some modifications have the option of connecting impact. Another thing is that the power of such models will be enough only for one-time operations with thin walls. Diamond drilling of holes in concrete is most in demand. The tool for performing such activities is, in essence, a machine to which an electric motor is connected.

The features of such units include three points. Firstly, it is a highly durable design with a housing that ensures reliable installation of the equipment where work is performed. Secondly, there is a power drive, which determines the ability of rather large cutting elements to perform complex drilling operations. Thirdly, these are crowns and drills, which themselves are high-strength diamond parts that require cooling during operation.

Types of drilling tools

For drilling concrete, various attachments are used, differing in shape, size of the working part and type of shank. Drilling small diameter holes is done with drills and drills. In cases where large holes are required, carbide or diamond bits are used.

Concrete drill bits

A concrete drill is a cutting tool and is used to create holes of small diameter (maximum 16 mm). Any drill consists of a working part and a shank. The working part, in turn, is divided into a calibrating section and a cutting edge. The cutting edge ensures that the tool penetrates the material, and the calibrating section located behind it has special grooves to remove drilling products . It is this that determines the diameter of the future hole and the smoothness of its edges.

The shank serves to secure the drill in the equipment used. Drills for concrete are available with shanks of two modifications: for an impact drill and for a rotary hammer. The drill shank has the appearance of a solid cylinder. The shank of the hammer drill has longitudinal grooves that ensure tight fixation of the tool in the chuck.

There is a certain limitation: thin drills cannot be used to drill deep holes

A concrete drill, as a rule, has a tip in the shape of the letter T. The tip is made of pobedite, an alloy of cobalt and tungsten, which is not inferior in strength to diamond . Pobedite tips retain their edge sharpness for a long time and easily withstand overheating. The diameter and length of the drill are interrelated: the larger the diameter, the longer the drill. For example, a tool with a diameter of 10 mm can be 540 mm long, but a tool with a diameter of 6 mm can be only 150 mm.

When choosing a drill, you should pay attention to the uniformity of the color of the tool and the color itself. Based on this feature, it is determined what finishing treatment the drill was subjected to. The steel-gray tint of the nozzle indicates that this procedure did not take place. The black color of the drill means that hardening has been carried out with superheated steam. If the tool has a yellowish tint, this indicates that it has undergone a finishing treatment such as tempering to reduce the internal stresses of the steel. But the best performance characteristics are provided by drill bits coated with a thin layer of titanium nitride, which have a bright golden color.

Concrete drills

A drill with a drill can only cope with soft and cellular concrete. To drill reinforced concrete, a hammer drill and a special type of drill (impact drill), which is usually called a drill, are used . The choice of drill depends on the conditions of the work being carried out, the properties of the material, and the total power of the hammer drill. With their help, you can make holes with a diameter of 4-30 mm and a length of 50-1000 mm.

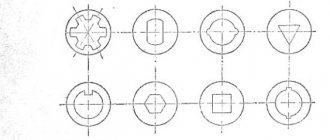

The difference between drills lies in the number of working edges and the form of their sharpening. To remove concrete dust and other drilling products from the hole being processed, a structural part of the drill, such as a spiral rod, is used. The steepness of its spiral affects the rotation speed of the drill and the final speed of the work being carried out. Inside the rods of some drills there are cavities into which dust is drawn in when the tool rotates, creating the effect of pumping out air.

Currently, the following types of drills are used for drilling concrete:

- screw The length of such drills is 100-1000 mm, so they can be used to make holes of considerable depth;

- spiral. Used for drilling large diameter holes;

- flat. Designed for drilling holes of small diameter and depth.

One of the main structural elements of a drill bit is its shank. For this reason, for a specific hammer drill model, drills with a strictly suitable shank configuration are used.

Drills for drilling concrete are available with shanks of the following modifications:

- SDS-plus with a diameter of 10 mm;

- SDS-top with a diameter of 14 mm;

- SDS-max with a diameter of 18 mm.

The protrusions and recesses on the drill shank serve to secure the drill in the hammer drill chuck and directly affect its rotation

When choosing a drill, you should pay attention to the shape of its cutting surface. The best option, but also the most expensive, would be a tool with self-sharpening cutting edges, and a more economical one - with a centering spike. A drill with a cutting head in the form of a centering spike will drill a hole so that its internal surfaces will not delaminate.

In addition to the head, the drills also differ in the type of soldering. The most common is pobedit soldering from compositions of varying strengths:

- soft will win is used for lightweight concrete;

- medium-strength will win used for processing heavy concrete;

- Victory high strength is used for especially strong concrete and granite.

Advantages of diamond tools

But any strength will not cope well with the processing of reinforced concrete. Therefore, diamond tools are now widely used to drill holes in this material, as well as in concrete of different strengths.

Diamond tools are chosen for such obvious advantages as:

- no restrictions on drilling material. Diamond tools can be used both for drilling concrete and for drilling the reinforcement present in it;

- no restrictions on the diameter and depth of holes;

- absence of vibrations that destroy the integrity of the treated surfaces;

- high precision of work performed.

For the production of tools, crumbs with diamond grain sizes of 150-500 microns are used. These can be natural diamonds, or rather, waste from the jewelry industry, which are distinguished by a wide range of hardness, size and shape. Synthetic diamonds are produced by heating carbon to very high temperatures and under great pressure. Tiny diamond grains obtained using this technology are in no way inferior to natural crystals, but their cost is an order of magnitude lower. Synthetic diamond chips are characterized by greater dimensional stability, purity and hardness , which ultimately provides increased wear resistance of cutting edges.

Diamond chips are mixed with metal powder. The resulting mass is formed into products of various shapes (diamond segments) using special presses. After this, the segments are sintered using powder metallurgy technology. The metal powder, after sintering, forms a so-called matrix designed to hold diamond grains.

Diamond segments are attached to the cutting tool base using:

- laser welding . Such a connection can withstand high temperatures, so a tool obtained using laser welding can be used for both dry and wet drilling of concrete;

- sintering (formation) of diamond segments directly on the edge of the tool body. Such a tool is also able to withstand high temperatures and can be used for both dry and wet methods of drilling holes in concrete;

- soldering with high temperature solder. The tool can withstand temperatures of no more than 600 degrees, so it can only be used for drilling with water. It should also be taken into account that for effective drilling with a diamond tool, it is necessary to comply with the condition of constantly removing sludge from the hole being drilled, and water washing is considered the most effective way to remove sludge. Tools made using this technology are most widely used in modern construction.

Soldering with high-temperature solder is today considered the most technologically advanced method of attaching diamond segments

The consumer properties of a diamond tool depend on both the characteristics of the diamond grains and the properties of the matrix. A necessary condition for maintaining the cutting properties of a drill or bit is constant wear of the matrix.

The wear rate of diamond segments should be:

- not very high, in order to eliminate the pointless waste of efficient micro-incisors;

- not very low so that the diamond grains can be opened in time as the micro-incisors chip away.

In other words, the optimal matrix hardness is selected depending on the material being processed. Diamond grains chip relatively quickly when processing hard materials such as granite or quartz . If new grains do not open in time, the diamond segment will become “salted.” For this reason, soft matrix tools made using bronze or tin powder are used for drilling hard materials.

When processing soft materials, such as limestone, the diamond grains wear out slowly. To prevent these grains from falling out of the matrix too quickly, powders from hard metal alloys, such as tungsten carbide, are used as a binder.

For drilling medium-hard materials (concrete screeds, reinforced concrete), segments with medium-hard matrices (cobalt, nickel, iron) are used..

As for diamond grains, the higher the hardness of the material being processed, the finer the grains should be and the higher their concentration. For processing soft materials, segments with larger diamond grains are used.

Concrete drill bits

Externally, the crown looks like a piece of steel pipe, in the walls of which holes are made to allow concrete chips and dust to escape during operation . One end of this pipe is capped with a flange (shank) for fastening the tool in the hammer drill chuck. The flange has special fixing grooves that comply with the SDS standard. At the other end of the pipe there are cutting teeth and a protruding centering drill, which fixes the position of the crown during drilling and prevents it from “walking” during rotation.

There are many types of concrete crowns. They differ depending on the diameters of the holes being drilled, the type of fastening in the chuck, and the hardness of the material being processed. Currently, crowns are produced in two main modifications - for impact and non-impact drilling modes.

Depending on the material of manufacture and design, crowns can be divided into:

- serrated bits for impact drilling;

- diamond bits for hammerless drilling;

- KS standard crowns with diamond coating.

The cutting edge of gear bits is formed by separately soldered teeth made of especially strong alloys

Serrated bits are designed for use with impact drills and rotary hammers . Their main disadvantage is the possibility of tooth destruction when meeting the reinforcement of concrete surfaces. Although the teeth themselves have a fairly high strength, which makes it quite possible to cut metal, the impact drilling mode creates unacceptable loads on the solder joint, which leads to their breakage. Therefore, such crowns can only be used for drilling in pure concrete or brick walls.

Diamond core bits are a more technologically advanced cutting tool and are used with rotary hammers and drills in hammerless drilling mode . They have a smooth cutting edge with small notches, made by spraying fine diamond or corundum sand.

The technology of non-impact drilling with a diamond core has a number of significant advantages compared to the impact method:

- reduced noise level during tool operation;

- less dust;

- absence of impact loads on the treated surface leading to the formation of cracks;

- high dimensional accuracy and quality of cuts of the drilled hole.

Diamond core bits easily cope with metal fittings. They have working diameters from 10 to 650 mm and allow you to drill holes up to 1.5 m deep. Bits with a diameter of up to 100 mm can be used with both professional equipment and household drills without the use of forced cooling. Large diameter crowns are used exclusively with professional drilling machines and with mandatory water cooling.

Crowns of the KS standard have a cutting edge with protruding segments with built-in diamond crystals. Crowns of this type successfully replace carbide gear bits. They are used for drilling holes in monoliths and slabs made of particularly strong grades of concrete. KS crowns have the longest service life.

The modern market is filled with crowns with various performance characteristics and advantages. The most popular tools are those produced under the brands Bosch, AEG, Cedima, Rothenberger, Tyrolit. Domestic manufacturers Adel, Alaton, Niborit, EuroPrice, Splitstone also offer high-quality products.

Features of using crowns for concrete

Serrated carbide bits are effective when paired with a hammer drill. Hammer drill chucks use the SDS fastening standard, which provides for the presence of special locking grooves in the drilling tool shanks . This fastening system allows you to easily and quickly change attachments without the use of clamping keys. In addition, it provides the tool with free movement along the drilling axis, which is necessary for the full release of impact energy into the surface being processed.

Diamond core bits require the use of rather complex technical devices that allow drilling to be carried out without shock or vibration.

The drilling rig is usually fixed in a certain way , which greatly facilitates the work of the operator, who does not need to hold the tool, but only move it in the required direction. This achieves very high quality and accuracy of holes.

When starting drilling, you should install the centering drill at the point corresponding to the center of the future hole. If the crown does not have a centering drill, then it is necessary to apply its cutting edge to the wall surface with all teeth simultaneously.

Excessive pressure should not be applied to the tool until the bit has penetrated enough into the concrete to stabilize the desired direction. To effectively remove dust, it is recommended to use a construction vacuum cleaner with a special hose attachment . The main feature of drilling with a crown is that it does not need to be periodically removed from the hole being machined for inspection or cooling, but can be continuously drilled to the required depth.

Diamond Drilling Technology

There are several types of drilling machines that implement diamond cutting technology. The most common type is the electromagnetic drill. It is equipped with two engines. Direct processing is carried out under the influence of about 3 thousand beats per minute. In this case, the second motor rotates the diamond drill itself, the speed of which is adjusted by the user in accordance with the requirements for the result. Depending on the bit used and the force potential available to the machine, the operator can expect to obtain a hole in the range of 30-160 mm.

Of course, such high performance characteristics also determine the corresponding investments that diamond drilling of holes in concrete requires. A tool whose price is 100-150 thousand rubles can be classified as entry-level. The middle and most common segment is represented by installations with a power of about 2.4 kW, capable of forming holes of about 40-250 mm. Such equipment can be purchased for 200-250 thousand.

Equipment for drilling concrete and features of its use

Impact drills, rotary hammers, electric and hydraulic drilling machines are used for drilling concrete surfaces. Impact drills and hammer drills are used to drill holes with a diameter of up to 30 mm .

To create large holes, special drills are used, which are similar in appearance to a regular drill, but differ from it in some design features.

The main differences between drills and drills:

- the bormotor operates with the expectation of increased load torque, therefore it has increased power and reduced speed;

- The drill spindle has a hollow design that provides water supply to the drilling area.

For drilling with crowns with a diameter of up to 600 mm, electric boring machines are used . They are produced on the basis of very reliable and durable gearboxes and electric motors. Almost all electric motors have a safety clutch, electronic overload protection and starting current regulation. Bormotors with a powerful three-phase asynchronous motor also have a thermal switch built into the winding.

Some electric drills can be equipped with handles, which allows drilling to be done manually. But it must be remembered that this equipment creates a huge torque, so manual drilling can only be used for small holes and with great care . The slightest jamming of the tool threatens to dislocate the operator’s arm.

Drilling holes of large diameters creates such a high load torque on the spindle that it is impossible to hold the drill in your hands

Therefore, the drill bits are mounted on a frame with the ability to move in the direction of the axis of rotation of the drill bit. In most cases, the frame column can be inclined at an angle to the wall or to the floor. The tilt angle ranges from 0 to 45 degrees . The bormotor together with the frame make up the so-called drilling installation.

For drilling with crowns larger than 600 mm, hydraulic drills mounted on powerful frames are used. itself is small and light, but complete with the frame it is a heavy and bulky electro-hydraulic unit , which provides the necessary pressure and oil flow for the bormotor.

When preparing to drill concrete, you should choose the right drill bit, bormotor and bed. When choosing a nozzle, it is necessary to take into account not only its diameter, but also the material for which it is recommended. When selecting a frame and drilling machine, you should pay attention to the fact that equipment specifications usually indicate the maximum drilling diameter, calculated for soft materials. If you have to drill reinforced concrete, then it is better to choose a frame and drill with a “reserve”. Insufficient rigidity of the bed can cause vibration and, as a result, accelerated wear of equipment and tools .

The bed should be firmly fixed. The most reliable method of fixation is dowel fastening to the drilling surface . For this purpose, there is a special longitudinal groove in the bed platform. When choosing where to drill a hole for a dowel, it is necessary to take into account that the maximum rigidity of fixing the frame is ensured by the fastening located in the middle of this groove.

The second method of fixing the frame involves the use of a spacer fastening device , the length of which can be adjusted in the range of 1700-3100 mm. This device must be rested against the platform or inserted into the column of the frame. Then you should adjust the length of the fastening device until it touches the ceiling and firmly wedge it between the ceiling and the frame.

The third option for fixing the frame is vacuum fastening . In this case, the bed is equipped with a vacuum plate. A special pump is used to create a vacuum. This method of fixing equipment requires a perfectly smooth and even surface and, despite its convenience, is considered the least reliable.

After fixing the frame, a drilling tool is installed on it and the drilling attachment is secured. After assembling the installation, you should check the connections for play . It should be remembered that even the slightest play can cause the diamond segments to bend outward or inward of the crown (the so-called “tulip formation”).

Checking for the absence of play should be carried out before each drilling:

- if play is detected in fixing the frame, it is necessary to tighten the dowel fastening or re-adjust the length of the spacer device;

- if there is play in the frame carriage, the carriage guides must be adjusted;

- if there is any play in the bormotor spindle, preventive maintenance of the bormotor will be required;

- Play in the fastening of the drill bit can only appear if the bit is not screwed onto the spindle.

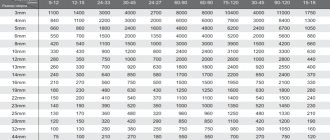

It is believed that the maximum drilling speed with minimal wear of the cutting tool can be achieved with an optimal linear speed of the segments within 3-6 m/s . When calculating bit rotation speed, a number of variables are taken into account, including the moment of inertia of the tool, the diameter and mass of the spindle, the distance from the center of the spindle to the center of mass of the bit, and much more.

Accurate calculation of the bit rotation speed allows you to avoid the self-oscillation mode of the drilling rig, increase the penetration speed, and increase the service life of the equipment

Therefore, when choosing the optimal speed, you should use the plate on the bormotor, which indicates the recommended range of drilling diameters for each of the gearbox gears.

Before starting drilling, it is necessary to ensure a water supply to the work area. If possible, the water supply should be uninterrupted. The flow of water from the water supply can be adjusted using a special handle on the drill. If there is no running water, you can use a special water tank with a pump and pressure gauge.

Water washes away sludge from the drilling area, “refreshes” the diamond segments, and prevents overheating of the cutting tool . When adjusting the water supply, follow the basic rule - the instrument should under no circumstances overheat until tarnish appears. Otherwise, the solder may melt, causing the diamond segments to detach from the nozzle body.

In this case, it is necessary to ensure that the sludge is completely washed out of the hole. If the water flows out slowly and does not carry the sludge with it, it is necessary to increase its flow rate . If the water in the tank runs out, drilling cannot be continued. Drilling without washing out the sludge will immediately become ineffective, and overheating of the working attachment will instantly melt the solder and render the tool unusable.

The bormotor should be turned on with the nozzle raised, and then drilled carefully and without much pressure until the cutting segments are completely hidden in the concrete. When inclined drilling, it is allowed to water the tool from the outside until it is completely drilled. If drilling is performed with a long bit of small diameter, then drilling into concrete is recommended to be done at low speeds.

When drilling in unreinforced concrete, very little force is required. Usually the bormotor’s own weight is enough for this . When drilling reinforced concrete, you should carefully increase the clamping force, while also increasing the water supply. While working, you must constantly listen to the sound of the operating machine. If you hear a characteristic clanging sound, which indicates the presence of a cut piece of reinforcement in the working area, you must stop the drill and remove the reinforcement from the hole being drilled. Re-drilling also begins with the crown fully raised.

Diamond segments can become “greasy” when drilling particularly strong concrete . This will be indicated by a noticeable decrease in penetration rate even with increased clamping force. In this case, the crown must be removed and the diamond grains “opened” by briefly drilling into an abrasive material, such as brick.

It should be borne in mind that the manufacturer, when producing diamond cutting segments, always tries to find a compromise between two opposites:

- increase processing speed;

- increase the resistance of diamond segments to wear.

The total penetration of crowns (resource) is a difficult value to predict. It depends on the drilling conditions and the strength of the material being processed. .

The average drilling speed is just over 2 m/hour

In any case, the penetration rate is more important than the total penetration length with one tool, since the total cost of drilling concrete is less dependent on the cost of the diamond tool. The main components of the cost of this work are wages for personnel, the cost of daily delivery of the drilling rig to the site, depreciation of equipment, etc.

When drilling, do not overload the drilling machine . The main reason for the increase in load torque on a cutting tool is the friction of the nozzle against the walls of the hole. If friction has increased as a result of the bed moving, it is necessary to turn off the unit, remove the attachment, securely fasten the bed and carefully drill into the concrete again. If the cause of friction is irregularities in the geometry of the nozzle, then it should be replaced.

If there is a need to drill holes whose depth exceeds the length of the crown, use extension rods . They can have a length of 200, 300, 400, 500 mm. The rods can be connected to each other to obtain the required drilling depth. After drilling is completed, the drill must be thoroughly cleaned and the threaded connections of the spindle and attachment lubricated.

Drilling instructions

Work begins with preliminary marking of the work area where drilling will be carried out. Depending on the tool, marking the cutting point can be done with a pencil, marker or using a core. Next comes the preparation. At this stage, you should check the integrity of the housing and the reliability of fixation of the working element. And if we are talking about an electric model, then it is necessary to evaluate the quality of the network connection. When the hole drilling tool is ready for use, the operation can begin. Experts do not recommend applying excessive force to provide mechanical impact on the workpiece. Especially when it comes to wood.

Advice from the experts

When carrying out work, I advise professionals to pay attention to the following features. They are divided into three categories:

- preliminary (preparatory) stage;

- stage of work;

- compliance with safety regulations.

At the first stage you need:

- select the necessary equipment (machine, electric or hand drill), depending on existing capabilities;

- based on standards and reference literature, determine cutting modes and acceptable types of drills for future operations;

- choose a marking tool (if this is not available, make it yourself);

- select a drill fixation device.

The preliminary stage should end with checking the reliability of the fastening of the drill and the workpiece. If a drill lock is used, its reliability should be checked.

Work on drilling holes must be carried out in strict sequence with the drawn up technological map or technical process. Particular attention should be paid to:

- the drill must be brought to the location of the future hole only after it has reached the specified rotation speed;

- The drill should be removed only while it is rotating (preferably at minimum speed if it is possible to change the rotation speed);

- monitor the cutting process (for example, if the cutting edge does not perform a drilling operation, therefore, the drill material is softer than the workpiece material);

- for drilling non-through holes, it is necessary to provide a clamp or mark that allows you to determine the depth of the passage in the material;

- When working on CNC-equipped machines, it is necessary to control the sequence of operations performed.

An important element when carrying out drilling work is compliance with safety regulations. It requires compliance with the following rules:

- ensuring reliable fastening of all structural elements;

- organizing conditions for removing the resulting chips;

- compliance with the temperature regime (preventing overheating of the drill and workpiece);

- use of special clothing and protective equipment (hands, eyes, open areas of the body);

- there should be no loose elements hanging on the clothing;

- long hair should be tucked into a headdress (this will prevent it from getting wrapped around the rotating elements of the machine).

Using professional advice will allow you to perform the drilling operation efficiently and obtain holes with a high degree of accuracy in the places specified in the design documentation.

If you find an error, please select a piece of text and press Ctrl+Enter.

Ways to prevent drill overheating

A powerful and productive tool is usually equipped with automatic means of supplying water to the cutting head. This allows you to protect equipment from overheating and extend the service life of the same crowns. However, the tool for drilling holes does not always include such technological solutions in its design. This usually applies to machines that work with diamond elements, which quickly enter a high-heat stage. In other cases, for example, when working with a hammer drill, it is recommended to provide a separate container with cold water. The liquid can be used to wet the nozzle as the work progresses.

Tips for drilling different materials

When working with wood, you should use a mechanical hand tool in the form of a drill or a brace. Typically, the stop is pressed with the left palm, and the operator rotates the handle with the other hand. In this case, the direction of movement is clockwise. As the process is completed, the pressure should be reduced, which will allow the formation of the most even cut along the edges. Working with metal is greatly simplified through the use of automatic machines. In this case, the user only needs to correctly install the workpiece in a vice and adjust the unit to suitable drilling parameters. The main work with diamond drills occurs at the preparation stage. Reliable fixation and adjustment of the cutting elements is the main thing that a tool for drilling holes in concrete requires from the user.

The types of attachments for such equipment are very widely represented and differ in different ways. Therefore, it is important to decide on this part of the preparation. Diamond drills exist in sizes from 8 to 16 mm in diameter. Depending on the requirements for the hole, one or another nozzle is selected. Next, the characteristics of the drill are taken into account in terms of its ability to cut concrete. Manufacturers produce such elements specifically for working with concrete grades M250-M500.

Hassle-free drilling

During work, you can use a small section nozzle, as well as a used grinding wheel for an angle grinder. It is important to remember that it should have a smaller diameter than the hole being created.

Before carrying out work, a circle for the hole is marked on the workpiece, and the second circle will be smaller than the first by a distance equal to the diameter of the drill used. After this, 2 holes are marked in opposite places of the circle. It is necessary to retreat 3 mm from them and mark the places for drilling. Thus, drilling occurs along the entire drawn circle. If additional work is necessary, some areas will have to be processed with a chisel. This will create jagged edges that will then need to be filed down. It is important to ensure that during work the circumference does not increase, i.e. do not expand the planned diameter.

Cone drill

The described types of drills are made from tool steel. The shanks of such products can be hexagonal or cylindrical. The cutting edge removes all burrs, so the edge is smooth. The end of the drill head has a sharpened point that allows pre-drilling of the material.

Using these products you can:

- create cuts with a diameter of up to 30 mm;

- forget about jagged edges;

- carry out boring of various diameters without changing the nozzle.

Thanks to step drills, you can create cuts of various diameters in sheet steel up to 4 mm thick. Unlike a simple cone drill, when using such products, the drilled diameter is fixed.

The disadvantages include:

- the need to use tools with low speeds and high torque;

- sensitivity even to small distortions.

Despite these disadvantages, this attachment allows you to conveniently work with metal plates, quickly drilling circles of the required diameter.

Metal crown

Metal processing is a complex process, so such work is usually carried out using specialized equipment. To carry out work at home, you can use core drills.

Such products allow you to make the edges round and centered. In this case, a standard drill is used for drilling. The products consist of several parts:

- crown;

- centering attachment;

- product shank;

- screws that are necessary for fastening.

When using a core drill, the speed of work increases up to 10 times. Another advantage is the ability to accurately drill in the range from 1.2 to 15 cm.

In this case, there is no need to perform alignment during drilling. It is also worth noting that such drills have higher wear resistance compared to twist drills.

Before starting work, a centering drill is installed in the center of the circle, after which drilling is carried out. After this, the drill is retracted and the work is carried out with a crown.