Profilograph, Profilometer

Profilograph - (from profile and ... graph) in metalworking, a device for measuring surface irregularities and presenting the results in the form of a curved line (profilogram) characterizing the waviness and roughness of the surface. The profilogram is processed using a graphic-analytical method. The principle of operation of the profilograph is to sequentially feel the surface with a needle perpendicular to the controlled surface, transforming the vibrations of the needle optically or electrically into signals that are applied to film or paper. The first profilers appeared in the 2nd half of the 30s. 20th century and were optical-mechanical devices with signal recording on film or photographic film. In modern profilers, needle vibrations are usually converted into electrical voltage fluctuations using inductive, capacitive, piezoelectric and other transducers. Profilographs consist of three blocks: a frame with a measuring table and a drive, an electronic unit and a recording

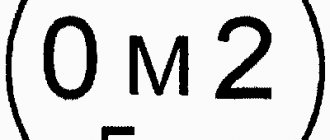

device. A diamond needle with a radius of curvature of 2–12 μm is located in the profilograph sensor. The static pressure of the needle on the measured surface is 1-20 mn (1 mn = 0.1 gf), and under dynamic conditions it is within the range of 0.06-1.2 mn per 1 μm of axial movement of the needle. Recording a profile in devices with electrical signal conversion is most often performed on metallized paper. For ease of deciphering, the profilogram is drawn on an enlarged scale. An increase in recording the measured heights of irregularities in the vertical direction is possible in the range from 400 to 200,000 times. Horizontal enlargement is achieved by moving the paper faster than the needle speed (up to 100,000 times). The error of the vertical magnification of the profilograph for different types of devices is from ± 5 to ± 10%, and the horizontal magnification is no more than ± 10%. Profilographs are usually manufactured combined with a profilometer and are equipped with a variety of equipment that provides recording of the profile of parts of various configurations. Profilometer - from profile and ... meter), a device for measuring surface irregularities with the measurement results readout on a scale in the form of values of one of the parameters used to evaluate these irregularities - surface roughness. The first profilometers appeared almost simultaneously with profilographs. In profilometers, the signal is obtained from a sensor with a diamond needle moving perpendicular to the surface being monitored. After an electronic amplifier, the signal is integrated to produce an averaged parameter that quantitatively characterizes surface irregularities at a certain length. The most common are profilometers with a constant integration path equal to the working length of the palpation path, and readings on a scale after palpation is completed. They also produce profilometers with a sliding integration path, shorter than the length of the palpation path, and readings while the needle moves along the surface. The error of the profilometer readings ranges from ± 10 to ± 25%. The vibrations of a diamond needle can be converted into electrical voltage in several ways. Improving the profilometer involves expanding the number of averaged vertical and horizontal readings that characterize the state of surface irregularities, equipping the profilometer with analyzers that make it possible to evaluate surface irregularities in another way - through the harmonic components that form a curve characterizing them.

Profilograph

The invention relates to measuring technology, in particular to devices for monitoring roughness. The invention is based on magnifying a three-dimensional interference pattern with a microscope, copying a preliminary holographic image of the surface microrelief, and a scanning electromagnetic field indicator is used in measurements. Technical result: increased accuracy, increased number of palpation paths, reduced operational registration time, the ability to study the real picture of the microrelief. 3 ill.

The invention relates to measuring technology, in particular to devices for monitoring roughness.

Profilographs are known that are based on contact methods for measuring surface microrelief parameters. The sensitive element of these devices is a mechanical probe (diamond needle) sliding over the surface, which, through a lever mechanism, transmits information about the microrelief to the transforming element (inductive, piezoelectric, electrodynamic), where electrical signals corresponding to the vertical movements of the probe are generated [1]. Disadvantages Such profilographs are limited in their ability to register in the form of a profilogram only information along the path of the probe’s movement, increased design and technological requirements for the diamond needle and lever mechanism (strength, adjustment of the mating places of parts), which increases the cost of production of such devices. In addition, at the stages of transmitting information from the sensitive element through the converting element to the measuring circuit, various types of distortions arise. As a prototype, a hologram copying device was selected using the restoration method with preliminary magnification, using a reconstructed real image containing a laser beam splitter, optical converters and a recording medium - thick-layer emulsion [2]. The disadvantage of this device is the insufficient degree of magnification of the reconstructed image, which does not allow obtaining contour maps of the microrelief of the surface under study for subsequent data processing. The problem to which the invention is aimed is to ensure magnification, accuracy and measurement capabilities of the reconstructed holographic image microrelief of the controlled object. This is achieved by the fact that in a profiler containing laser beam splitters, optical converters, recording media - thick-layer emulsions, the three-dimensional interference pattern is enlarged by a microscope when recording and copying a holographic image of the surface microrelief, and an electromagnetic field indicator is used for measurements. Essence The invention is illustrated by drawings. Figure 1 shows a diagram of recording a transmission volumetric hologram with preliminary magnification; Fig. 2 is a diagram for copying a hologram using the restoration method with preliminary magnification; in Fig. 3 is a diagram for restoring a real image. The profiler has a recording circuit, a hologram copying circuit, and a circuit for restoring a copy hologram image. The hologram recording circuit (Fig. 1) contains a laser 1, a laser radiation beam splitter 2, optical converters in the form of mirrors 3 and lenses 4, a measurement object 5, a microscope 6 and a recording medium - a thick-layer emulsion 7. The hologram copying circuit (Fig. 2) contains laser 8, beam splitter 9 of laser radiation, optical converters in the form of mirrors 10 and lenses 11, object - real image 12, microscope 13, hologram - original 14, hologram copy 15. The image restoration circuit (Fig. 3) contains laser 16, lens 17, a copy hologram 18, a real image 19 and a scanning electromagnetic field indicator 20. The profilograph works as follows. Preliminary magnification is used in order to obtain high resolution in a small field of view. The object for the hologram is an actual enlarged image of the object. A beam of coherent laser radiation 1 (Fig. 1) is directed to a beam splitter 2, with the help of which two beams are obtained - the object and the reference. The reference beam is directed by the system mirror 3, lens 4 and beam splitter 2 directly onto the recording medium - thick-layer emulsion 7. The object beam falls on the object 5, the hologram of which is recorded, is reflected from it, passes through the microscope 6, and hits the recording medium 7. As a result of interference waves of the reference and object beams propagating in a thick-layer emulsion, planes are formed, illuminated by light of higher intensity. After the hologram is developed, layers of blackening form on the illuminated planes, i.e. Bragg planes are created, which have the property of partially reflecting light. Thus, a three-dimensional interference pattern is created in the emulsion of the recording medium 7. When reconstructing a volumetric hologram, only one image is formed due to the reflection of the reconstruction beam from the hologram in only one direction, determined by the Bragg angle. Accurate formation of a real image without iterations or resizing requires the fulfillment of two conditions. The first condition is that when recording and restoring a hologram, the light used must have the same wavelength. The second condition is that the direction of propagation and the shape of the wave front incident on the hologram during reconstruction must exactly correspond to the complex conjugation of the reference beam used during recording. To ensure a sufficient degree of magnification of the reconstructed image, the profilograph uses a scheme for copying the hologram using the restoration method with preliminary magnification, when as of the object, a reconstructed real image is used (Fig. 2). A beam of coherent radiation from laser 8 (Fig. 2) is directed to a beam splitter 9, with the help of which two beams are obtained—reconstruction and reference. The reference beam is directed by the mirror 10, lens 11 system to the copy hologram. The reconstruction beam falls on the original hologram, and on each of the set of recorded diffraction gratings its own object wave is restored, corresponding to a certain point of the microrelief. The resulting actual image of the microrelief is enlarged using a microscope. The object beam from the actual enlarged image falls on a hologram copy, where a holographic record is formed. The actual image restored from the copy will be non-pseudoscopic (orthoscopic). A beam of coherent radiation from laser 16 (Fig. 3), passing through lens 17, falls on a hologram copy 18 and restores an enlarged actual image of the base section of the microrelief of the surface under study. The holographic system included in the profiler should provide a pre-screen image during restoration (image " hanging in the air") to subsequently obtain contour maps of the microrelief of the surface under study. For this purpose, an indicator 20 of the electromagnetic field is used. The indicator is a charge-coupled device (CCD) used in digital photographic equipment. The microrelief image is a reconstructed electromagnetic wave, which is identical in amplitude and phase to the wave reflected from the surface area captured on the hologram. Under the influence of the restored electromagnetic wave, each microcapacitor of the CCD is charged. The amount of charge is determined by the intensity of the wave (the brightness of the image). The profilograph electronics sequentially remove charges from each capacitor. Information about the captured microrelief contour maps is transferred to a personal computer for subsequent data processing. The profilograph device includes a kinematic unit (not shown), which allows using a CCD to record the microrelief profile in two mutually perpendicular directions, through a given step x along the X axis and y along the Y axis. The accuracy of reconstructing the microrelief profile is determined by the size of the capacitors and the magnification of the microscope. So, in order to ensure the restoration of the microrelief profile Ra = 0.001 μm, provided that the linear size of the microcapacitor H = 200 μm, you should select a microscope with a magnification of N1 = 2500 in the hologram recording circuit, and a microscope with a magnification of N2 = 800 in the hologram copying circuit, i.e. To. H=N1N2 Ra. The use of the proposed profiler allows you to increase the accuracy, the number of palpation paths, reduce the operational time of recording roughness, and study the real picture of the microrelief. Sources of information 1. GOST 19300-73. Equipment for measuring surface roughness using the profile method. Profilometers. Contact systems. M., Types, Basic parameters.2. J. April, A. Arsenault, N. Balasubramanyan and others. Optical holography: Transl. from English /Ed. G. Caulfield. - M.: Mir, 1982. - T.2 - P.622.

Claim

A profiler containing a laser beam splitter, optical converters, a recording medium - a thick-layer emulsion, characterized in that the three-dimensional interference pattern is enlarged with a microscope by copying a preliminary holographic image of the surface microrelief, and a scanning electromagnetic field indicator is used for measurements.

DRAWINGS

,

,