The seeds of many vegetable crops are tiny in size: this complicates the sowing procedure, and thinning is subsequently necessary for normal plant growth. Cultivation of crops becomes complex and painstaking, and as a result of high seed consumption, production costs increase. To save resources and make the work of workers easier, a manual precision seeding seeder is used, which will be discussed below.

Why do you need to use mechanization?

The amount of harvest obtained per unit area of land depends on the timeliness of agricultural work. To ensure healthy plant growth, all operations must be carried out at optimal times. The quality of seed work is of great importance. Nowadays, manual labor is still used. This is a very labor-intensive process that requires a lot of time and the involvement of additional workers, which affects the profitability of the enterprise.

Manual work also makes accurate sowing difficult. Further care of plants becomes more complicated. The way out of this situation is to use small-scale mechanization machines, the category of which includes a manual vegetable precision seeder. It guarantees high-quality and timely planting of small-seeded vegetable crops. This is a very useful model, the peculiarity of which is the economical consumption of seed material.

The precision seed drill is used for sowing work and field experiments on farms and private farms.

Operating principle of the unit

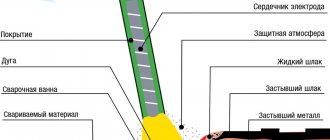

A manual precision seed drill is driven by the person doing the sowing. When pushing the unit along the soil surface, the wheels and shaft rotate. The seed material is loaded into the hopper and through a conical insert enters the well of the dosing shaft. There are grooves on the shaft that are filled with seeds. The required portion is selected from the hopper, and the residual material is swept away from the recesses using a brush. As a result, one seed remains in each hole. With further rotation of the shaft, the seed falls through a special hole onto the soil into the prepared furrow.

It is advisable to use this device in small areas with different surface profiles (flat, ridges, beds). The mechanical means ensures high quality and short laying times, and affects the accuracy of the results. As a result of using such equipment, overconsumption of expensive seed material is eliminated.

Design

The design of the precision seeder is very simple:

- It consists of a solid body mounted on a wheeled platform.

- For ease of control, the mechanism is supplemented with holders.

- The hopper is equipped with a lid that prevents seeds from spilling out or being blown away by the wind. It is made in a certain shape, so there are no dead zones in the corners of the hopper where seeds accumulate.

- The dosing shaft can be with one or two rows. The special design provides better grip, movement of seeds under the brush and clearer discharge. The shaft, which acts as a dispenser, rotates freely, ensuring sowing of seeds for any vegetable crops.

- The width of the row is set with special markers.

- The trapezoidal coulter, located at the base of the seeder, cuts a furrow and facilitates the shedding of soil into it after seed placement. Additionally, fertilizers can be applied. Thanks to the special shape of the coulter, lumps of soil do not get into it, and this in turn prevents jamming.

- The whiskers ensure free release of seeds along the step of the dosing shaft.

- A special seal helps reduce the germination time of seeds.

If necessary, seeders are connected into multi-row blocks for mechanized sowing using small wheeled tractors.

This is done using connecting strips. This method of joining is also advisable if it is necessary to organize work together.

What is a corn seeder

A corn seeder is equipment that sows seeds into the soil. Before their appearance, this was done manually: grains were scattered in the field, trying to fill empty spaces. However, it is impossible to sow evenly by hand. For this purpose, special equipment is used - mechanical seeders.

How does she look

The design of the corn seeder consists of the following parts:

- frame mounted on wheels;

- sections with seeds;

- seed storage;

- dosing devices.

Depending on the number of sections in the seeder models, the planting row is determined. To adjust it, just remove or add drums to the frame. The technology for planting various types of corn depends on this.

Reference! With cross sowing technology, when the seeder goes along and then diagonally or across the field, sections are removed from the frame.

All corn seeders come in 3 types:

- universal - they work using seeds of various crops, but do not add fertilizers;

- combined - add seeds to the soil along with fertilizers;

- special - use only 1 type of seeds.

All devices consist of the following sections:

- compartments for seeds (usually 1-2);

- a mechanism that closes furrows;

- coulter, with the help of which grooves are made in the ground with the same depth;

- a sowing apparatus that delivers seeds in uniform portions into special seed tubes.

Principle of operation

Each seeder has a similar operating principle:

- Seeds are fed into the machine.

- Placed in the soil at the required depth and at an equal distance from each other.

- They are sealed using a special mechanism.

A pneumatic mechanism is used to crush and remove lumps. To be able to use the seeder on a problem field, crop residues are cut with special discs. After this, the skid coulter enters the ground without problems.

This is interesting:

What is a garlic seeder?

Technology for planting potatoes with a walk-behind tractor

Requirements for manual seeders

In the process of sowing, agricultural specialists face various problems.:

- Injury to seeds as a result of the use of insufficiently thought-out seed-growing equipment. This entails poor seed germination and failure to complete the harvest plan.

- Labor intensity when switching to sowing another crop. The process takes a long time.

- Pulsating seeding, uneven seeding over the area, difficult setting of seeding rates when using existing units.

An improved set of agricultural machines and the use of a seeder that uses a reel sowing device will help prevent the occurrence of such situations. Such a device meets the following requirements:

- eliminates mixing of seeds of different sizes;

- prevents mechanical damage to seed material;

- eliminates losses;

- ensures stability of the process and uniform distribution of seeds;

- guarantees accuracy when adjusting according to consumption standards in accordance with the geometric parameters of the site;

- carries out sowing to ensure the required area for plant nutrition.

Today, about 60-80% of the market is occupied by foreign equipment; American manual seeders are in great demand. However, our enterprises also produce good products, the design of which takes into account soil and climatic characteristics.

Modern specimens make it possible to control the parameters of the technological process, taking into account changes in various factors. Such designs reduce the error when sowing long plots.

Advantages

A manual single-row precision seed drill will help you quickly and efficiently sow a garden bed, vegetable garden or field. It makes the gardener’s work much easier, since you don’t have to bend over to make a hole and place the seed in the ground. A specially thought-out design simultaneously makes a furrow, introduces seed material into the soil, digs it in, and marks a furrow for the next row.

The use of a seeder is considered effective and appropriate, since it:

- increases labor productivity;

- reduces production costs;

- helps to increase the profitability of growing vegetable crops;

- reduces the cost of obtaining a unit of production;

- reduces the time it takes for breeders to create new varieties;

- prevents overconsumption of valuable seed material;

Experts say that as a result of using such technology, productivity increases by 10-15%, and seed consumption decreases by 18-20%.

Manual single-row mechanical seeder Slobozhanka for precision seeding

Manual single-row row-crop seeder Slobozhanka SZ SOR vegetable precision sowing of seeds You can order and buy a manual seeder Slobozhanka single-row row-crop device for automatic sowing of seeds, sunflower seeds, pits and grains in the area of your dacha, garden and vegetable garden on the website: https://www.tvoidomisad. ru/shop/205/desc/sejalka-ruchnaja-odnorjadnaja-propashnaja-slobozhanka-sz-sor-tochnogo-vyseva-semjan When automatically planting seeds and pits into the soil, any damage to them is excluded. And all thanks to the well-thought-out design of the manual mechanical planter Slobozhanka. The frame of the manual seeder is very durable and made of alloy steel. The design of the device is coated with durable powder paint that protects the product from corrosion. This provides it with a long service life for many many years. The sowing device performs spot nesting and dotted economical sowing. Thus, agricultural work in the process of sowing seed material is greatly facilitated. The vegetable and grain seeder fully meets operational safety requirements. Design of a manual grain seeder The single-row row-crop seeder (the video clearly demonstrates the offered product) includes a durable frame. The frame is made of two steel strips located parallel to each other. The following are fixed on it: - in front - a support drive wheel; - in the middle - a brush sowing device with a harrow, a coulter and a seed hopper; — behind there are control handles and a rolling wheel. Technical characteristics and parameters of the manual seeder - Height: 34 cm (without handle). — Width: 19 cm. — Length: 108 cm. — Dimensions of the compacting wheel: 32/18 cm. — Capacity of the seed chest: 2.5 cubic meters. dm. — Width between rows (maximum): 0.45 m. — Sowing depth (maximum): 150 mm. Design features and principle of operation The following are installed on the body of the Slobozhanka manual seeder: - a harrow; — seed hopper equipped with a rotating disk; — coulter with seed drive; — brush sowing device. On our specialized Internet portal you can buy a seeder at the most affordable price. The mechanical seeder is controlled thanks to the presence of a driven support wheel and a chain drive. During operation, the brush rotates and captures the seeds, directing them to the seed drive. Passing through the hopper container and the disk (rotary), they then enter the coulter valve. The opener is mounted on a lever interconnected with the finger disk. By adjusting the finger disk, the desired frequency of placing seeds in the furrow with the coulter is set. Then the seeds sown in the soil are covered with a cover and rolled with a wheel. The finger disc is located on the shaft on the left side of the seeder. The precision seeding drill is equipped with a marker that can be adjusted to a certain distance between the rows. They mark a trail for further excavation. Before the start of sowing work, the grain sowing rate is established. The landing rate is set by fixing the rotary disk at the desired level. The rotating disc is located behind the hopper. The number of nests per 1 m row can be 2 or 4. The number is adjusted by fixing the finger disk in a certain position; — width between rows (determined by a marker located on the bar); — deepening of the opener. For dotted seeding, the valve remains open and fixed with a special stop. The correct adjustment of a manual precision seed drill can be checked by making a test run. Detailed instructions for setting up and operating the equipment are included in the factory configuration. We thank the plant manufacturer of the seeder, the Electromotor Plant, for providing photos and videos for the device. Slobozhanka manual single-row mechanical seeders can be used to sow any types of vegetable seeds, grains, herbs, seeds and sunflower seeds. For example: - Cucumbers, watermelons, melons, tomatoes, peppers, eggplant, onions, white cabbage, cauliflower; — Peas, radishes, vetch, fodder and table beets, carrots, parsley, dill, herbs, lettuce, beans, peas, and many others. Where to buy a device for automatic sowing of seeds. You can order and purchase a manual row-crop seeder Slobozhanka right now on the website at factory price. We will provide you with a long warranty on the purchase of the unit. We send a device for sowing seeds to any region of Russia, Kazakhstan, Kyrgyzstan, Belarus and Armenia. We deliver your purchase by Post, Courier Service or Transport Company. As numerous user reviews testify, the Slobozhanka seeder has a lot of advantages. Which led to its demand for processing large, medium and small areas. You can buy a manual seeder from us using the convenient website interface. Or by contacting our customer information support specialists. The minimum retail order is 1 automatic vegetable, grain and herb seeder. You can order and buy a single-row manual seeder for seeds, sunflower seeds and grains Slobozhanka, a mechanical row-crop planter for automatic sowing and planting of vegetables, carrots, beets, sunflowers, tomatoes, radishes and other crops at the dacha, garden and vegetable plot on the website: https://www. tvoidomisad.ru/shop/205/desc/sejalka-ruchnaja-odnorjadnaja-propashnaja-slobozhanka-sz-sor-tochnogo-vyseva-semjan Or by phone: 89277260320, 89608033739, 89063753197

For which crops is a manual precision seeding seeder used?

The spot seeder is suitable for a huge range of garden crops. Thanks to removable elements, it can quickly be adjusted to a specific hole size corresponding to the size of the seed material. The unit allows you to adjust the row spacing (up to 50 cm) and planting depth (1-15 cm).

These technical devices are used for:

- corn;

- beets;

- sunflower;

- Luke;

- carrots;

- spinach;

- asparagus;

- salad;

- beans;

- peas;

- lentils;

- rice;

- tomatoes;

- cucumbers;

- zucchini;

- watermelons;

- pumpkins;

- melons;

- squash;

- radish;

- turnips;

- soy;

- fennel.

The transition to sowing a new type of seed takes a few seconds. The burial depth is adjusted using an adjusting screw. Additionally, the unit can be equipped with a hopper for fertilizer, which is applied directly at the time of sowing the seeds.

A manual precision seed drill will make your work easier, save time and pay for itself within several seasons!

Range of modern seeders

If making a planting unit yourself causes difficulties, it is recommended to immediately purchase ready-made structures. The assortment on the market is quite large. The American model of precision seeding “1001 - B” is equipped with 6 replaceable discs. With such a seeder you can plant 28 types of vegetable crops. Using the adjusting screw, you can change the planting depth.

Newtechagro seeders are single-row types. Designed for sowing beets, carrots, onions, and cabbage . But such designs are expensive.

But there are also cheaper analogues - precision seeders "SOR - 1/1". They are also single-row, can be equipped with a bush or brush sowing unit, the row marker is 0.5 m. This is quite enough for an average garden.

Using a manual seeder can significantly reduce labor costs, increases the speed of the planting process, simplifies the technology, significantly improves the quality of crops, and hence excellent harvests in the future.