A screwdriver has long become a mandatory part of the tool arsenal of every home or apartment owner. This universal device will save effort and time during many types of repair work. But for large volumes of the same type of operations, for example, when performing finishing work on an ongoing basis, purchasing professional equipment cannot be avoided. One such tool is a belt or cassette drywall screwdriver.

Inconveniences when installing drywall using a conventional screwdriver

If you need to install gypsum boards over a fairly large area, then using a universal screwdriver will be accompanied by a number of significant inconveniences:

- The low speed of tightening the fasteners leads to a significant waste of time.

- Hardware is not always firmly attached to the slots of the bit. This leads to the fact that you have to fix and guide the screws with your free hand. In this case, installation will require at least two people: one holds the drywall fragment in the right place, and the second fixes it with self-tapping screws.

Many people are familiar with the problems that arise when controlling the position of a screw by hand at the beginning of screwing. The bat sometimes slips off the head and can become embedded in your finger or hand. In addition, the rotating self-tapping screw with its sharp thread edges damages the skin on the fingers. It is inconvenient to use gloves during this operation: they begin to wrap around the hardware. At large volumes, this causes serious damage to the fingers.

- A large number of fastening hardware must be kept somewhere close to the installation site. Usually they are placed in a pocket or a handy container. All this leads to the loss of screws, and it’s inconvenient to get them out.

Main advantages

The tool is not cheap, but most home craftsmen prefer this model for the following reasons:

- thanks to interchangeable nozzles, you can screw in self-tapping screws of various diameters and different shapes. For more expensive models, nozzles are initially included in the kit, but for cheaper models you need to purchase them yourself;

- it screws in self-tapping screws easily and quickly, so soft materials, such as drywall, are not injured during operation;

- when working, you do not have to exert any physical effort, you just need to press the power button of the device;

- self-tapping screws do not get lost or fall apart.

However, the owner must periodically purchase consumables for this tool, for example, a tape for feeding screws. If you use the tool infrequently, it will not be affordable. But, if a home craftsman uses a belt screwdriver daily or at least several times a week, then the cost of its maintenance can increase significantly. If you constantly operate the device at maximum power and at maximum speed, the battery will quickly discharge, and electric models consume a large amount of electricity.

Advantages of a professional screwdriver over a regular one

Belt screwdrivers eliminate the above disadvantages:

- They have a high rotation speed, which allows screws to be screwed in literally in a split second. From the outside, the process looks more like the work of a pneumatic hammer than a screwdriver.

- This tool is equipped with a tape or cassette equipped with self-tapping screws. Standard capacity is 40–50 pieces. This quantity is sufficient to securely fix a sheet of drywall to the frame.

- The device of the guide nozzle guarantees the position of the self-tapping screw strictly perpendicular to the plane into which it is screwed. The tapered spout makes it easy to work in hard-to-reach places, such as corners of the room. Thus, the second hand is freed, and the installation of drywall can be done alone, even on the ceiling (provided that a lift is used).

- An attachment for screwdrivers with a magazine allows you to limit the depth of screwing in hardware, and also protects gypsum boards from damage by their heads.

USEFUL INFORMATION: Electrical wiring under drywall: laying wires in the wall, duct and ceiling

In addition, such a specialized tool is highly reliable and durable, as it was originally designed and created with large volumes in mind. Manufacturers also pay close attention to the ergonomics of the tool.

The best screwdrivers with a standard belt attachment

Makita DFR750RFE - expensive, high quality, efficient: indispensable for large-scale finishing work

The Makita DFR750RFE cordless shop screwdriver is designed for construction crews; it’s not worth buying a narrow-profile tool for 25,000 rubles. This price is set not only for the name.

The set includes two Li-Ion batteries with a capacity of 3 Ah, an automatic charger, and a convenient carrying case. The screwdriver is designed for continuous operation during one shift: without overheating. Comfortable handle, ergonomic body.

Advantages:

- Impeccable quality, high reliability, no restrictions on continuous use.

- Good protection against dust and moisture.

- Robust housing, thanks to the one-piece design of the screwdriver and the belt feed mechanism - no backlash.

Flaws:

- The high cost limits the range of users.

- There is no way to detach the attachment and use a separate screwdriver.

- No speed switching.

Types of belt screwdrivers and features of working with them

Structurally, these devices can have two designs:

- A device equipped with a stationary device for supplying hardware from a store. This is a highly specialized tool that is used only when installing plasterboards.

- A special attachment attached to a universal screwdriver. It is clear that in this case it must have the necessary parameters of rotation speed and torque. This option allows, after removing the nozzle, to use the device for other operations performed with self-tapping screws of different sizes that fit the slots.

Based on the method of power supply, a distinction is made between cordless and corded tools. The undeniable advantage of the first is high mobility. Carrying wires to the installation site is inconvenient and sometimes difficult. But for large volumes of work, batteries have to be recharged quite often, so professionals prefer to use a tool powered from the mains.

Working with such a device has its own specifics: the device is started for the entire installation cycle. Tightening of the self-tapping screw begins at the moment the nozzle is pressed against the surface of the gypsum board and takes a fraction of a second. After which the feed mechanism is triggered, and the next self-tapping screw in the tape appears under the bat. This cycle continues until the store is empty or the installation of a piece of drywall is completed.

Screwdriver for installation of plasterboard structures

Belt screwdrivers for drywall can be divided into two options:

- In the first case, a special tape attachment is used, which is mounted on a household tool. The advantage of this solution is that the feeder can be removed at any time and the equipment can be used as usual. In addition, it becomes possible to use non-standard hardware.

- In the second case, the mechanism for automatically feeding self-tapping screws is installed by the manufacturer, and its dismantling is impossible. If there is no tape with self-tapping screws, the screwdriver simply will not work.

In addition to the ability to detach the feed mechanism, band screwdrivers can differ in power consumption and weight.

Some disadvantages

Naturally, any tool, even a professional one, has its drawbacks. They also exist for belt screwdrivers:

- High price. The price varies from 13 to 45 thousand rubles depending on the model and manufacturer. An attachment for a universal tool will cost an average of 9 thousand rubles. Therefore, only those who professionally work with drywall buy such a tool.

- Narrow specialization. For the sake of high rotation speed, we had to sacrifice the amount of torque. Installing drywall does not require much force, but for working with other materials the torque may not be enough. In addition, non-intended use is only possible for models with a removable nozzle.

- The need to purchase consumables: tapes or cassettes. Moreover, screwdrivers from each manufacturer are designed for the use of “original” products. And they are not always available in the assortment of nearby hardware stores.

USEFUL INFORMATION: How to seal a hole in drywall with your own hands (video)

When a self-tapping screw is squeezed out of a plastic tape, it is greatly deformed. Some craftsmen manage to reuse such consumables from certain brands (for example, Bosh). But reused tape does not provide reliable fixation of hardware. It is still allowed to be used when covering walls, but when covering ceilings it is better not to try it.

The best screwdrivers with a belt attachment

Bosch MA 55 1600Z0000Y – simplicity of design: the key to reliability

The open design of the nozzle ensures reliable operation of the mechanism. The components are not clogged with dust, and the technical condition can be monitored.

The parameters allow you to work with popular fastener sizes: self-tapping length 25–55 mm, shank diameter up to 5 mm, head diameter 9.5 mm. The attachment is designed to work with standard tapes.

Advantages:

- Robust, reliable design, the absence of additional adjustment mechanisms is beneficial: there is simply nothing to break.

- The convenient screw depth regulator does not damage soft materials, such as drywall.

- High positioning accuracy, full visual control.

- Provides good speed.

Flaws:

- The nozzle is long - additional space is required during operation.

- Limited compatibility, even within its own brand. You can only work with two models of screwdrivers: Bosch GSR 6-25 TE Professional and Bosch GSR 6-45 TE Professional.

- High price, as for an additional nozzle: almost 10,000 rubles.

DeWALT DCF6201 Y - professional device at half the price

The main advantage of the DeWALT tape attachment is its low cost (by brand standards, of course). The price of the tool is 5900 rubles. The screw magazine is equipped with several adjustments, allowing you to quickly change the tape.

Positioned for use within DeWALT's own brand, but will fit some models with a different logo. You can select the “mother” tool when purchasing an attachment.

Advantages:

- Durable closed housing, protected from dust and moisture.

- After fastening to a screwdriver, it can be rotated around an axis in any direction, with a ratchet lock. (This feature is only available when used with the DeWALT tool.)

- Convenient feed guide configuration: the belt does not jam in any position of the tool, regardless of length.

Flaws:

- The heel of the rest that is too wide limits visibility: it is inconvenient to aim in low light.

- In the lower position of the guide handle, the backlight lamp of the screwdriver is blocked.

- Sometimes it misfires, especially when using inexpensive tapes.

- The nozzle is quite heavy - the overweight makes your hand tired.

Kress SMV – a well-equipped attachment for professionals

The automatic belt mechanism is suitable for all Kress TBS series screwdrivers. This is real German quality, even the external inspection inspires respect: durable body, precise fit of all parts, many adjustments.

At the same time, the price does not go beyond competitors: no more than 6,000 rubles. There is no compatibility with other brands, although the seat is similar to Metabo.

Advantages:

- Light weight of the nozzle: only 500 g. When working for a long time on an outstretched arm, the brush practically does not get tired.

- Precise multi-stage screw depth adjustment. There is a preset scale, as befits a professional instrument.

- Instant fixation on the “mother” screwdriver.

- The openwork (and at the same time very durable) design of the stop allows you to accurately position the screw in the work area.

- Includes an additional handle for left-handed use.

Flaws:

- Screw diameter restrictions: 8mm head, 4mm shank. For this class of instrument, more is possible.

Household or professional

As you know, professional screwdrivers are more expensive, but this is no coincidence. They are made with a large margin of safety, for which higher quality and more expensive materials are used. In addition, they have more power, which makes it possible to screw in longer screws and/or work with tougher materials.

The difference between a professional and household screwdriver in resource

To decide whether you need a household or professional screwdriver, assess the amount of work that will need to be done. If you are starting construction or major renovations, you probably need a professional or semi-professional model. If you need a tool periodically to unscrew/tighten something from time to time, a household tool is more than enough. With such work, the professional tool resource simply will not be in demand. So choosing a screwdriver based on this criterion is not very difficult.

How to choose a belt screwdriver and what characteristics to look for when purchasing

Power . As a rule, we are talking about power consumption, that is, how actively the tool consumes electricity. This parameter allows you to indirectly judge the performance, weight and dimensions of the device. The more powerful the screwdriver, the longer it can work without overheating. In addition, a more powerful model usually has higher torque, which means it can handle harder materials and larger fasteners.

But at the same time, powerful electric motors are proportionally larger and heavier than their less powerful counterparts, so it can be simply inconvenient to operate a productive professional screwdriver. The power of the simplest electric screwdrivers can start from 100 watts, but with such a screwdriver you can’t count on much. Typically, a 500-watt device is sufficient for domestic use. Screwdrivers with a drill function can be equipped with motors of 1000 watts or more.

Maximum speed . Shows how quickly the screwdriver can unscrew the equipment. For working with fasteners, this parameter is not of fundamental importance: the difference between 3000 and 5000 rpm is difficult to notice by eye, and such values are not needed when driving screws. For a drill-driver, on the contrary, the number of revolutions can be, if not critical, then a very important indicator.

The larger it is, the faster the tool will be able to drill soft materials and the more accurately it will work with hard ones. In practice, the ability to regulate speed during operation is of much greater interest than their maximum frequency.

Maximum torque. It is measured in Newton meters and shows with what force the screwdriver tightens the fastener. Allows you to judge how large the screws are for the tool. A derivative of the maximum torque can be called a parameter such as the maximum diameter of a screw or hole in concrete, steel and wood.

Nutrition . A screwdriver is a power tool that can be powered by mains power or a built-in battery. The first option, as a rule, differs in performance. The second is mobility, because such a screwdriver is not tied to an outlet and can be used even in places where there is no electricity. The best option here is a device with the ability to operate both on battery power and mains power.

Battery type . Nickel-cadmium (Ni-Cd) and nickel-metal hydride (Ni-MH) batteries are sometimes found in nature, but almost all modern manufacturers use predominantly lithium-ion (Li-Ion) batteries. They are somewhat more expensive than their analogues, but are distinguished by high capacity with small dimensions and weight, low self-discharge, and most importantly, the absence of memory effect. If you have a smartphone or laptop, then you know what to expect from a lithium-ion battery.

Battery capacity. Measured in ampere hours. The higher it is, the longer the tool can work without recharging. However, the weight and dimensions of a more capacious battery will also be larger.

Battery voltage. Power tools most often use batteries with a voltage of 12 volts or more. The higher it is, the more productive the device is usually - this parameter can be considered an analogue of power for network models. For most tasks, an 18-volt screwdriver is sufficient.

Patron . The accessories can be attached to the screwdriver in various ways. Key chucks are rare in screwdrivers - they are too inconvenient. The two most commonly used options are a quick-release chuck, which you need to unscrew and tighten by hand, and a magnetic holder, which holds the bit using a magnetic field. The first type is more universal and is found in drills and screwdrivers.

The second one is simpler and more convenient to use, but, say, it won’t work to clamp a regular drill there without a special adapter.

Reverse . This function is present in every screwdriver, which distinguishes them from conventional drills. Reverse allows you to rotate the equipment in both directions, which means you can tighten the fasteners, unscrew them, and at the same time free the stuck drill if necessary.

Dimensions and weight. This is often forgotten when choosing, but holding an instrument that is too large or too heavy is simply inconvenient. When making a purchase, be sure to hold the screwdriver in your hands and imagine whether you can comfortably operate it for a long time.

Additional functions. A modern screwdriver is not just an electric one, but a complex electronic device, often equipped with a large number of additional functions. Among the most useful options: work area illumination, electronic speed control, power button locking, soft start, as well as electronic protection against overheating, overload and short circuit.

How do band screwdrivers work?

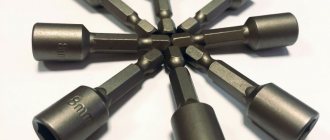

A screwdriver with a tape for self-tapping screws resembles a weapon with a loaded magazine. As a rule, the tool is immediately equipped with several attachments, which allow the master to use fasteners of a wide variety of sizes. The work process is facilitated by the fact that the main part of the device has a compartment equipped with consumables.

When a self-tapping screwdriver is turned on by pressing a button, one of the fasteners works as intended. The compartment itself comes into operation and a new one takes the place of the retired consumable.

It is worth noting that such a system simplifies the work process and allows you to conveniently store fastening materials.

In addition, during the operation of the device, the master can also regulate the rate of its operation.

Important! Models produced by renowned manufacturers have a long shelf life and can be supplemented with consumables.