Here you will learn:

- What is a hand water pump

- Purpose of manual models

- Advantages and types of hand pumps

- Types of hydraulic pumps

- Pump classification

- Other types of mechanical pumps

- What to look for when choosing

- Assembling a homemade hand pump

- Washing machine pump

- Water pump from compressor

A manual water pump is a simple and practical device that will help out in the event of a lack or instability of power supply. You can buy such a device or make it yourself.

How to make a high pressure pump?

How can you make a high pressure pump? Where can I find good step-by-step instructions with photos or videos?

How can you make a high pressure pump?

The simplest method for making a high-pressure pump is to slightly modify a car hydraulic jack. For example, a 3-ton jack with a cylinder diameter of 28 cm has an area equal to 6.15 cm2. This allows you to obtain a pressure of 488 atmospheres. Converting a jack into a pump involves replacing the long rod with a short piston, and attaching a plug to the top. Holes should be made in the plug for the valve, filling hose and pressure gauge, which are mounted there. To operate the pump, a cylinder containing a working gas under a pressure of 300 atmospheres is used.

Where can I find good step-by-step instructions with photos or videos?

I think that step-by-step instructions are not required for such a modification. I am attaching a diagram of how the jack works before and after the modification, as well as a photo of the completed pump assembly. In case something remains unclear, watch the video

Source of the article: https://www.remotvet.ru/questions/18297-kak-sdelat-nasos-vysokogo-davlenija.html

Other types of mechanical pumps

Manual mechanical water supply devices have been used since ancient times and have now been replaced by industrially produced models. In some cases, in the absence of electricity, the use of mechanical factory units is ineffective, and craftsmen come up with their own diagrams and drawings on how to make a hand pump for a well with their own hands.

If in the above case (water intake from a well) the principle of operation of industrial units can be used, then for water intake from open reservoirs they use their own developments based on ancient technologies.

Archimedes screw

Archimedes screw and its uses

The design was invented by a Greek thinker in 250 BC and consists of a cylindrical pipe, inside of which there is a screw; the system is lowered into an open body of water at a slight angle. During operation, the rotating blades capture water and move it up the pipe, at the end of which it is poured into the prepared container.

An analogue of this installation is an electric screw pump designed for constant water intake from deep water sources.

Hydraulic ram

Hydraulic ram

Mechanic Montgolfier is the creator of a hydraulic pump that raises water using its kinetic energy. Its principle of operation is to shut off the fast flow with a valve, after which water under pressure enters the hydraulic tank located above and is then delivered to the consumer through a floor hose. The device operates in repeating cycles; some manufacturers produce hydraulic pumps using artisanal methods.

Airlift

Aerolift - operating principle

The German engineer Karl Loscher developed this method in 1797; its essence consists of pushing out liquid from a hollow pipe lowered into a source with air. To operate the airlift, air is pumped into the lower part of the pipe through the inlet pipe using a hand pump; its bubbles dissolve in water and, due to their light weight, rise to the surface along with the liquid.

To prevent liquid from entering the pressure air hose, inflation is carried out through the nipple.

This design can be used in the presence of electricity by connecting a compressor instead of a mechanical pump.

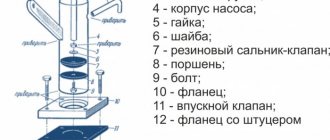

Homemade piston pump

Some craftsmen make piston pumps themselves. The usual design consists of a working chamber made of a welded pipe; a metal or plastic disk with a rubber sealing ring along the diameter is used as a piston. To ensure water supply using a homemade design, holes are drilled in plastic or metal piston discs to install a check valve system.

Homemade piston pump design

Most modern mechanical units, like surface electric pumps, are capable of lifting liquid from wells up to 10 meters deep. The highest delivery height is provided by a rod pump, which operates in a similar way to electric submersible types. Its body and operating valve can be lowered into a source up to 30 meters deep, providing intake at a similar distance to the water surface.

Among all types in everyday life, the most common are piston hand pumps, which are mounted directly above the outlet of the casing well pipe, with suction occurring through a pipe lowered into the hole with a check valve.

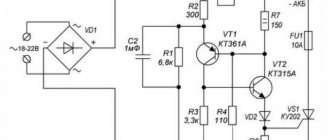

Homemade high pressure pump

Good day everyone. So I built a high pressure pump and decided to show it. I know what the city is now, but it’s not relevant, but still. The design is noticeable but functional. Material: Italian plumbing brass pressed at 320 atm. and d16t rod, plus brake pipes and hoses. The pump turned out to be three-stage (the first stage is an auto-compressor), the second is a pump with a cylinder diameter of 19 mm. , the third stage is a pipe with a diameter (internal of course) of 25 mm. and a painter from a jack.

Length 0.5 m. width 0.2 m. From one cycle 30 atm. in 200 cc cutter. This is a cycle (we turn on the autocompressor, easily make 15-20 strokes with the pump and press it with a jack, also without strain).

ASDAND

This is a cycle (we turn on the autocompressor, easily make 15-20 strokes with the pump and press it with a jack, also without strain). It's still a bit complicated. And cumbersome. And even Autocompressor + Jack! NOT WEAK)) ———- One lever. Pumps two pistons. One by one. ALL !

If you select a tube with an internal diameter of 6-8 mm for the third stage, with a smooth (probably even polished) surface, then you don’t have to press anything after the pump. Or maybe even two stages are enough - a compressor and a thin tube.

Konstantin_E

If you select a tube with an internal diameter of 6-8 mm for the third stage, with a smooth (probably even polished) surface, then you don’t have to press anything after the pump. Or maybe even two stages are enough - a compressor and a thin tube. Agree ! ))

Konstantin_E

If you select a tube with an internal diameter of 6-8 mm for the third stage, with a smooth (probably even polished) surface, then you don’t have to press anything after the pump. Or maybe even two stages are enough - a compressor and a thin tube.

Couldn't the third stage be made from a small piston with a cylinder from a hydraulic jack?

santey

Couldn't the third stage be made from a small piston with a cylinder from a hydraulic jack? What if so? Extremely simple. pump just with rubber Yes! The book is “Underwater Hunting. Directory" E.G. Khorkhordin. The proven design of the “direct” pump is described there. With a diameter of 10 mm, they write, you can get up to 150 kg/cm2. From 12mm - up to 100kg/cm2.

I have a question running through my head, why bother shaking your hands when there are three phases at home?))) this thing needs to be mechanized somehow. some kind of compressor to sculpt or something... ak150 can’t be found

santey

I have a question running through my head, why bother shaking your hands when there are three phases at home?))) this thing needs to be mechanized somehow. Some kind of compressor to sculpt or something.. AK150 can’t be found. It was here. A lot! Search misses you.