Screw pumps are positive displacement pumps. There are other names for these pumps: screw, gerotor, worm and eccentric pumps.

Screw pumps are a type of rotary-gear pumps and are conventionally divided into single-screw and multi-screw. A multi-screw pump is one in which the main drive screw (rotor) is helically meshed with one or more driven screws. When the drive screw rotates, the driven screws also begin to rotate. Multiscrew pumps have a higher efficiency and the ability to create higher outlet pressure. In this article we will look at the operating principle and design of pumps that are most often used in industrial production - single-screw pumps.

Single-screw pumps can be divided into high-performance pumps for pumping large volumes of product and screw pumps for barrels, Eurocubes and other mobile containers. The main difference between these two types is their purpose. The former have a massive structure and are designed to pump a large volume of liquid without immersing any of its parts in the container. The latter, on the contrary, have in their design a submersible part of such a diameter that can be installed in the filler hole of the barrel. However, these pumps have a similar design, are self-priming and are capable of pumping viscous liquids.

Let's consider the design and operating principle of a screw pump. Any screw pump can be divided into two parts. The first part drives the working body of the pump, thereby causing the pump to pump liquid. It includes a motor and gearbox. The second is the mechanical part of the pump, thanks to which the liquid is pumped with a certain performance and pressure.

Pump motor and gearbox

Closed-type asynchronous electric motors are most often used to drive a screw pump. The electric motor power can reach 15-20 kW, and the shaft rotation speed varies from 300 to 1500 rpm. Many manufacturers of screw pumps can offer a pump with an electric motor, which is equipped with a frequency converter. If the frequency converter is of a standard type, then it is usually mounted on the vertical part of the trolley, on which the screw pump itself is located. This is done for those cases when it is necessary to pump liquid from different containers with one pump. In the case when there is no need to move the pump, it is installed permanently and in this case frequency converters with a wireless control unit are used.

As a rule, all screw pumps are equipped with reduction gears in their design. The gearbox is the connecting link between the engine and the mechanical part. It serves to change the number of revolutions coming from the electric motor to the pump itself. A reduction gear reduces the number of revolutions and increases torque. Sometimes there are gearboxes that can change the direction of rotation of the electric motor shaft. The amount of torque is very important when the pumped liquid has high viscosity and density. Structurally, the gearbox consists of several gear wheels that are in sequential engagement with each other, despite the fact that the diameter of the wheel on the electric motor side is always smaller than the diameter of the wheel on the pump side. That is why the output gearbox always has more torque and lower angular velocity. Together, the electric motor and gearbox are called a gearmotor.

The most important characteristic in this case is the gear ratio. It shows how many times the torque has increased and how many times the speed transmitted by the electric motor has decreased. Manufacturers of screw pumps offer geared motors with different gear ratios that are suitable for almost any task. When selecting a gear motor, you should adhere to the following rule: the higher the viscosity and density of the pumped product, the higher the gear ratio should be, because in this case there will be a high torque and a lower angular speed of the pump working body. The pump will be able to draw viscous liquid from the container into the working chamber without overloading the electric motor. Here, the power of the electric motor itself is also no less important, because the liquid still needs to be supplied over a distance. However, the required pump pressure is determined not only by the power of the electric motor, but also by the design features of the mechanical part.

In addition to electric motors, screw pumps are equipped with pneumatic motors powered by compressed air. They are usually found on vertical drum pumps and are similar in design to the air motors of centrifugal drum pumps.

How best to use

When purchasing a screw pump for an equipped source, you will have to take into account certain operating rules. By following simple recommendations, the homeowner will be able to significantly extend the life of the device.

To operate a screw pump in a well, it is advisable to select a pump that can be well mounted on the wall of the shaft. It is advisable to install the device at an optimal depth so that the likelihood of the water level dropping to a critical level is minimal. This will prevent the device from running dry.

It is advisable to maintain a distance of at least 1 meter from the bottom so that liquid mixed with sand is not pumped through the water supply. When purchasing a screw unit, you don’t have to worry about the reliability of the operation of such equipment. The design of the product and the basic principle of operation were specially developed in such a way that the water intake hole was located above the engine itself. The working unit, thanks to this design, can be cooled naturally. The probability of fire in this case is practically zero.

Features of water intake are decisive in the selection of functional characteristics of equipment. Before selecting a suitable pump, be sure to take into account all the required control parameters.

Mechanical part

The main components of the mechanical part of a screw pump can be considered the rotor (1), stator (2), pump housing (3), bearing housing (4), mechanical seal (5) and universal joint (6). All these parts are connected in series to each other and are located inside special supports (7).

The driveshaft, also called the “thrust”, has hinges at both ends. One hinge, through the adapter shaft, connects the “rod” to the gear motor, the second hinge to the pump rotor. The cardan shaft is the connecting link for transmitting torque from the engine to the rotor. In addition, since the cardan shaft has a hinged connection, torque can be transmitted at an angle relative to the axis of the electric motor shaft. To prevent the hinge mechanism from coming into contact with the pumped liquid during pump operation, they are placed in special sealed casings made of the same material as the “rod”.

The driveshaft is located inside a cylinder, which is the pump housing. The housing is connected by flanges, on the one hand, to the pump stator, and on the other hand to the bearing housing.

On top of the pump body there is a pressure pipe, which can have a threaded or flanged connection. Since screw pumps can pump liquid reversely, this pipe may well not be a supply pipe, but a suction pipe. In addition, the pump nozzle comes in the form of a loading funnel.

Loading funnels (or hopper) are used when the pumped product has a high viscosity, is pasty, and does not have flow properties. In these cases, the cardan shaft is replaced with an auxiliary transport (feed) auger, which also has a swivel joint. In addition to transmitting torque, the auxiliary screw moves the product loaded into the funnel to the gerotor pair.

The gerotor pair is the most important component of a screw pump, which consists of a moving part - the rotor and a stationary part - the stator. The stator is a steel sleeve in the inner part, which has a spiral-shaped uniform elastomer layer obtained as a result of the vulcanization process. The metal of the stator housing and the inner elastomer layer are inseparably connected to each other. Depending on the purpose of the gerotor pair, the stator can be made of various materials. In a screw pump, the stator is sometimes called a cage and sleeve, and the rotor is called a screw, auger, or worm. The rotor is a screw that rotates inside the stator.

The rotor is a single piece, but it can be roughly divided into two parts. The first part is the head for attaching the rotor to the cardan shaft. The second is the rotor body itself, which has the shape of a spiral and is in constant contact with the holder during pump operation. The stator and rotor are a friction pair with internal cycloidal engagement. The gerotor pair of the screw pump is attached with flanges to the pump body. At the end, depending on the direction of rotation of the rotor, it has a suction or supply pipe.

To seal the pump drive, the design provides a mechanical seal. It is located between the “rod” hinge and the bearing housing.

The bearing housing is a unit consisting of two angular contact bearings and an adapter shaft, which, on the one hand, is connected to the gear motor using a key or splines, and on the other hand, it is pivotally connected to the driveshaft.

A horizontal screw pump can be designed with a bypass. This modification of the pump is used when a flow control device (for example, a solenoid valve) is additionally installed in the pressure line. The bypass allows you to avoid switching off the pump motor every time the valve in the supply line closes. When the valve is closed, the pump continues to operate and pumps liquid in a circle from the pressure pipe back to the suction pipe, thereby avoiding excess pressure in the area from the pump to the valve.

The design of a deep well pump - design features of the unit

The design of domestic deep-well pumps can be different. It all depends on the type of motor, operating principle and parameters of the units. Each submersible deep-well pump consists of two main parts - a built-in or external motor, and a multi-stage pump unit.

The built-in motor is usually located at the bottom of the pump - this protects the motor from contact with water. Above the engine there is a drive shaft of the unit, wheel guides and special blade-shaped outlets.

Depending on the type of deep-well borehole pump, it may be equipped with additional spare parts. The vibration pump device, in addition to the motor and shaft, also includes a special glass and a vibrator that creates the high pressure necessary for operation. The vibrator itself consists of an armature, adjusting washers and a rubber shock absorber. The latter is compressed during pump operation, thereby creating the conditions necessary for water intake. All elements of the vibration pump are located in a durable housing.

Another type of deep water pumps is centrifugal units, which are a little more complex in design and more durable in operation. It is because of this that most buyers prefer this particular submersible pumping equipment. The main role in such a device is played by the blade outlet attached to the engine of the unit. Pumps of this type almost do not overheat due to the fact that the bearings inside its structure are cooled through contact with the pumped water. Most centrifugal pumps are equipped with built-in automation that protects the equipment from dry running and voltage surges in the home electrical network.

All elements of the centrifugal pump are located in a durable, sealed stainless steel housing.

Pump operating principle

The pump is connected to an electrical circuit or pneumatic line. When the pump is turned on, the electric motor shaft begins to rotate at a certain number of revolutions per minute. The rotation of the electric motor shaft is transmitted through a coupling connection to the gearbox shaft. The gear wheels of the gearbox, which are in sequential engagement, reduce the number of revolutions at the output of the gearbox and increase the torque. Through the adapter shaft located in the bearing assembly, the angular speed of the gear motor is transmitted to the cardan shaft or transport auger, which in turn drives the pump rotor through a swivel joint.

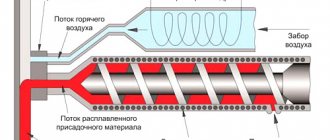

Let's consider the variant of operation of a screw pump, where the pipe on the side of the gerotor pair is suction, and the pipe on the side of the pump body is pressure. The direction of rotation of the moving parts of the pump occurs in accordance with this diagram (from right to left or counterclockwise, if you look at the end of the rotor from the liquid suction side). The screw rotates in the stator. Since the center of rotation of the rotor is shifted relative to the central axis of the stator by the amount of eccentricity, and the elastomeric layer of the stator has a spiral shape, a vacuum cavity is formed on the side of the liquid inlet into the pump. Liquid is sucked into this space. The rotor turns 90 degrees and this cavity with the liquid in it is hermetically closed while the liquid itself moves inside the stator of the gerotor pair. When the stator is rotated 90 degrees, in addition to closing the cavity with liquid, a new discharged cavity is formed, into which a certain volume of liquid enters.

With each subsequent rotation of the screw, a new portion of liquid enters the gerotor pair, and the previously received liquid receives more and more movement. Since the rotor body also has a spiral shape along its entire length, in conjunction with the stator it forms several closed volumes. It is through these volumes that the liquid moves when the rotor rotates, moving away from the suction point, and since these cavities are sealed, the pumped liquid cannot flow back to the suction side. Next, the pumped liquid under pressure enters the pump housing from the gerotor pair and exits the pump through the pressure pipe. If the moving parts of the pump rotate clockwise, then the pipe of the pump housing is suction, and the pipe of the gerotor pair is discharge.

Screw Vacuum Pumps

A screw vacuum pump is an oil-free pump that is a combination of two helical rotors with different thread directions.

Vacuum pumps are equipped with 2 rotors that rotate in different directions. Thus, the liquid medium enters the space between the cylinder and the screw chambers.

Advantages:

- high pumping speed;

- no oil vapor in the work area;

- maximum pressure below 10-2 mm Hg. Art.;

- operation from atmospheric pressure;

- resistance to liquid and vapor content in the pumped medium.

Specifications:

- maximum outlet pressure: up to 30-35 MPa;

- Efficiency within 50...75%;

- productivity: up to 6,000 l/min;

- maximum speed: up to 6,000 rpm;

- working environment temperature: up to 150…180 °C;

- viscosity of pumped liquid substances: up to 1,000,000 cP.

Geometry of gerotor pairs

The performance of a screw pump depends on the volume of the closed cavities of the gerotor pair and the speed of the gear motor, and the pressure created by the pump depends on the number of closed cavities per unit length of the gerotor pair and the power of the electric motor. Since the characteristics of a screw pump largely depend on the geometry of the gerotor pairs, we will consider this issue in more detail.

There are several design geometric factors that directly affect the output characteristics of a progressive cavity pump, as well as the limitations of their use. Such factors can be considered: the number of closed cavities of the gerotor pair, the cross-sectional diameter of the rotor (and stator, respectively), the volume of closed cavities between the rotor and stator.

With equal length of the gerotor pair, various modifications are possible in terms of the number of closed cavities. For example, let's consider two versions of a screw pair with the same diameter and equal length. The option with a large number of closed volumes has a smooth supply of product due to the relatively low flow rate at an increased pressure value, as well as high suction capacity. In addition, due to the increased inlet cross-sectional area, larger particles can be pumped. It is also worth noting that this design of the gerotor pair eliminates as much as possible the possibility of liquid leakage from it after the pump is stopped. The advantage of a design with fewer closed volumes is high productivity. This is due to the fact that the volume of each specific cavity, in this case, is larger than in the first option. This design has high volumetric characteristics with a long turnaround time due to the long contact line between the rotor and stator. Therefore, when designing and selecting a screw pump for a particular consumer task, it is first necessary to be guided by the geometry of the gerotor pair and the characteristics of the geared motor.

Materials of screw pump parts

The casing parts of the screw pump, which include the pump housing with pipes and the stator housing, are made of stainless steel or cast iron. Since pumps are often used in the food industry, and the housing material is in direct contact with the pumped medium, food grade stainless steel is used for manufacturing (as a rule, it is low-carbon austenitic steel AISI 304 (08Х18Н10 and its varieties depending on the number of alloying elements). In other cases, they use malleable cast iron with a flake form of graphite. This type of cast iron, among others, has the greatest ductility, which minimizes the formation and development of cracks during operation, provides high corrosion resistance. The internal part of the stator is made of elastomeric materials NBR - synthetic polymer (nitrile butadiene rubber ), EPDM is a synthetic elastomer (ethylene-propylene rubber). Barrel screw pumps often have a spiral-shaped internal part made of the universal fluoroplastic material PTFE (polytetrafluoroethylene). This material is chemically resistant to almost any aggressive liquid, as well as to low and high temperatures . This soft plastic material also has low adhesive properties. The rotation parts (propeller shaft and rotor), as well as the protective housing of the swivel joint, are made of stainless steel.

Operating principle and design of a screw pump

In a standard screw household electric pump, the working screw is made in the form of a spiral pin made of corrosion-resistant material, which is chrome-plated steel, stainless steel or high-strength plastic. The liquid sucked in by the rotating screw enters a technical polymer holder and is then pushed out into the upper outlet of the electric pump.

The screw electric pump used in everyday life consists of the following main components (Fig. 7):

1 — Electrical part with a vertically mounted single-phase electric motor with a dry rotor and an oil-filled chamber separating the engine compartment from the hydraulic part; a starting capacitor is located inside the lower part of the housing.

2 — The hydraulic part consists of a housing, a water intake filter and a working auger rotating in a cage made of elastic polymer (rubber) - an assembly of a screw and a rubber coupling pushes the liquid entering the housing through perforated holes 3 to the outlet pipe.

3 — The water intake part is a stainless steel cylinder with holes made in the side walls to draw in water.

4 — On the top cover of the pump, made of brass or stainless steel, there is an outlet pipe and lugs.

5 — The outlet pipe is made with an internal thread with a standard diameter of 1 inch, a check valve and a water-lifting hose are attached to it.

6 – A nylon or metal cable in synthetic protective insulation is tied to the eyes.

Rice. 7 Design of a screw pump

Types of installation of screw pumps

As already mentioned in this article, vertical screw barrel pumps are one of the types of screw pumps and are similar in design and principle of operation to horizontal ones, but have a narrowly targeted application.

A standard screw pump is installed on a horizontal surface and secured to it using special supports. The barrel is installed vertically in the container. However, there are non-standard installation options: vertical for a conventional screw pump and horizontal for a barrel screw pump. In this case, the direction of flow of the product through the pump changes, that is, the discharge pipe becomes the place where the liquid enters, and the suction pipe becomes the discharge pipe. Replacing the horizontal installation of a screw pump with a vertical one is usually due to the consumer’s desire to save production space or when it is simply limited. This once again confirms the variability of this type of pump.

COST, TERMS AND CONDITIONS OF DELIVERY OF SCREW PUMP ONV

1. The cost of serial screw pumps of the ONV series can be found in the PRICE LIST, but if you need a pump with special requirements, please fill out the technical specifications online:

2. The price includes packaging and loading. Transport, installation and transport insurance are not included in the price. 3. Production time, if the pump is not in stock, is up to 26 working days. 4. Terms of payment -50% advance payment, 50% upon readiness. 5. Warranty period 12 months.

ONV series pumps are manufactured in Russia at the Nekrasovsky Machine-Building Plant JSC (Yaroslavl region). Production includes the full production cycle from procurement to assembly operations.

Accessories

As mentioned earlier, for ease of operation, horizontal screw pumps can be supplied on mobile transport trolleys. The trolley pump option is used when there is a constant or periodic need to pump liquids in different parts of one workshop or the enterprise as a whole. The trolley can, as a place for installing additional equipment, approx. frequency converter.

For barrel screw pumps, by analogy with horizontal screw pumps, a bypass valve is installed. The bypass valve is connected directly to the pump discharge pipe. During operation of the pump, the pumped liquid acquires inertial force. When the valve in the supply line is closed and the pump motor is stopped, fluid continues to flow out of the pump, creating pressure. To avoid rupture of the pressure hose, a bypass valve is installed. It is mechanically adjusted to open at a certain pressure and allows liquid, which moves by inertia, to flow back into the container.

Since barrel screw pumps are designed to operate in mobile containers, they must be constantly installed from one container to another. Since the mass of these pumps is much greater than that of barrel centrifugal pumps, their reinstallation from container to container takes a lot of effort from the operating personnel. Therefore, the motors of barrel screw pumps are produced with an additional mounting bracket. It provides easy installation and dismantling of the pump using a hoist or crane beam. If the production facility where the barrel pump is used does not have lifting mechanisms, you can purchase a special trolley for barrels with a lifting device.

Scope of application of screw units

An important point is that the screw pump is designed to pump not only water, but also steam, gas and other liquids. The water that rises from the well serves a variety of purposes:

- Drinking and solving various household problems.

- Filling tanks, fountains and pools.

- For powering irrigation and drip irrigation systems.

- For the accumulation of various containers, for example, boilers and heating boilers.

To use screw units, all design features of such a device should be taken into account. The most commonly installed screw pumps are:

- Water supply of a suburban area. Many summer cottages are located at a great distance from the central water supply network.

- Some models are characterized by the fact that they can carry out complete or partial water purification.

- Liquid supply from wells. Design features determine that the device can be operated even if the container is severely clogged. The screw pump device provides the required pressure in the pipeline.

- Some models are installed during construction work to pump out groundwater or melt water. An example is also the pumping of paints and other similar substances.

The main operational characteristics determine the widespread use of screw units in a wide variety of industries. The screw pump can last for a long period, but the choice must be made depending on the operating conditions.

Advantages and disadvantages

The advantages of screw (screw) pumps are much greater than the disadvantages. Let's consider what advantages this type of pump has in comparison with others:

- The pump is a positive displacement pump and each rotation of the rotor is equal to a certain amount of pumped medium, so it is possible to precisely regulate the performance.

- The pump is self-priming.

- Since the rotating parts are directly connected to each other, and the volumetric cavities between the stator and rotor are sealed, the pump has a high efficiency.

- The pump can be used in both horizontal and vertical positions.

- The pump can pump liquids in different directions, as it has a reverse function.

- Capable of pumping non-viscous, viscous, highly viscous and even non-Newtonian liquids.

- The pumped product is not subjected to shock or compression, as a result of which its structure is not destroyed (the flow regime is close to laminar).

- Various designs of the pump are possible based on the user's task (with a bypass, with a loading funnel, on a trolley, with a frequency converter).

- Possibility of obtaining high performance and stable discharge pressure at different numbers of rotor revolutions.

- Possibility of pumping liquids saturated with gases, since the pump is not sensitive to cavitation and hydraulic shock.

- Silent operation of the mechanical part. When the pump is running, noise is heard only from the pump drive.

- Low energy consumption when using an electric motor as a drive.

The disadvantages of screw pumps include their high cost, associated with the complexity of their manufacture, as well as their mass and dimensional indicators. In addition, this type of pump is not designed to operate without liquid, as this will lead to failure of the pump stator.

Operating principle and purpose of the device

The operating principle of each screw unit is based on the movement of liquid along the screw axis inside the chamber. The axis is formed between the surface of the housing and the helical grooves by inserting the helical projections into adjacent grooves. Thanks to this operating principle, a closed space is created inside the device, which does not allow liquid to move back out of the device.

Nowadays, screw pumps are used in many areas of human activity. Most often this equipment is used:

- In food factories - in food production, units are used as dispensers;

- In construction - pumps are used to supply mixtures used for the production of self-leveling floors and roofing;

- At wells, devices pump out contaminated water with a large amount of impurities. A screw well pump can be used both for a source with clean water and for a well with sand;

- In the chemical industry, screw pumps pump large volumes of thick substances for further processing.

High reliability and the ability to operate under high loads make screw pumps one of the most progressive types of pumping equipment.

Applications of screw pumps

Screw pumps are actively used in various industries. Due to the specifics of the product being manufactured, namely high viscosity and density, these pumps are widely used in the food industry. They are used in winemaking (wine, grapes), in the dairy industry (butter, yogurt, sour cream, ice cream, cream, milk, kefir, cottage cheese, cheeses, margarine, condensed milk), in confectionery (honey, molasses, chocolate, jam, jam, jelly, mousse, cream), for various sauces and seasonings (mustard, ketchup, tomato paste, mayonnaise), etc. They are used in the cosmetics industry (shampoo, liquid soap, hair dyes, lipsticks, creams), the oil industry (petroleum, bitumen-polymer materials, diesel fuel, fuel oil, gasoline), and the chemical industry (detergents, inks, paints, glue , acids, alkalis), pulp and paper industry (flocculants, sludge, paints, paper pulps, tall oil, pulp-water slurry, dyes), as well as in the treatment of domestic and industrial wastewater (flocculants, coagulants, sludge, sludge, lime milk , sapropel).

Installations of submersible screw electric pumps UEVN5 for oil production

This type of pump is a twin screw unit, designed for pumping out layers of oil liquid of sufficiently high viscosity from deep wells, as well as liquids with low density and a high gas content.

UEVN5 units are capable of pumping liquids through their working volume with the following characteristics:

- The maximum level of viscosity of a liquid substance should not exceed 110-3 m3/cm;

- The quantitative content of inactive gas in the receiving area of the unit cannot be more than 50% of the total volume;

- The inclusion of abrasive particles in the treated liquid should not exceed 0.8 g per liter;

- The maximum temperature of oil underground at the moment of suction by the pump can be up to 110 degrees;

- The inclusion of H2O in the pumped substance is maximum 99%.

This type of device includes three main elements: a submersible pump, an electric motor with increased protection from moisture, and a tubing string. The UEVN5 submersible screw pump is supplied with electricity using a ground-based transformer and a complete mechanism, which are connected to the installation motor using high-load armored cables and fixed with special clamps.