What kind of device is this

An electrical contact pressure gauge is a device that is used to control an electrical load depending on the measured pressure. The type and principle of operation of the ECM are the same as that of a conventional technical pressure gauge. The only difference is in the additional elements of the device: signal arrows and contact groups.

These pressure gauges combine the functions of indicating and signaling devices. They allow not only to monitor pressure changes in real time, but also to automatically start or stop technological processes when limit values are reached.

Purpose

Monitoring fuel pressure is important for injection and diesel engines.

If the required pressure is not provided, the fuel will not cope with the resistance of the injectors, the engine will operate intermittently, and fuel consumption will increase. The condition of a modern car is monitored by an on-board computer, if installed. But monitoring fuel system pressure is not its function. This is done by a pressure gauge to check the fuel pressure. It is used to control the elements of the fuel system. It is important that the pressure gauge can be connected in parallel without disturbing the operation of the fuel system (the author of the video is his own mechanic)

Design and principle of operation

When operating a pressure gauge, the principle of equilibrium is used. The measured pressure is balanced by the force created by the elastic deformation of the sensing element, for example, a tubular spring or a membrane with two plates, etc. One end of the device is sealed in a holder, and the other is connected with a lever to a mechanism that translates linear changes into the movement of the arrow on the dial.

Let us consider a pressure gauge device for measuring pressure, the sensitive element of which is a tubular spring. These are the most common meters, as they have good technical characteristics, a simple design, are reliable in operation, and allow measurements to be made over a wide range.

Wide application was achieved due to the simplicity of the device design. It is based on an empty tube with a cross-section in the form of an oval or ellipsoid. The medium being measured acts on the tube, which deforms under pressure. On one side, the tube is connected to the system using a fitting, and on the other, it is connected to a mechanism that transmits deformation changes.

The transmission mechanism consists of the following elements:

- gears;;

- pointer (arrow);

- gear sector;

- leash.

A spring in the form of a spring is inserted between the sector teeth and the gear to eliminate backlash. Since the tube has different surface areas inside and outside, under pressure it tries to straighten. The soldered free end moves the meter needle relative to the scale using a lever. If the maximum pressure does not exceed 25 bar, the accuracy of the device is 2.5, above 25 bar - 1.5.

Kinds

Types of pressure gauges differ according to their operating principle:

- liquid (pipe);

- membrane;

- spring;

- bellows;

- piston;

- piezoelectric pressure gauges;

- radioactive;

- strain gauges (wire).

Each type of the above devices differs in the sensitive element used and operating principle.

Meters differ in purpose:

- General technical, used for measurements in environments that are not aggressive to copper alloys.

- Electric contact. A distinctive feature of the devices is the ability to regulate the measured medium.

- Special. They are designed to measure pressure in different gases; they distinguish between oxygen, ammonia, acetylene, non-flammable and flammable gases. They differ in color.

- Reference. They are distinguished by a high accuracy class, therefore they are used as a sample for checking, testing and adjusting other measuring instruments.

- Ship's. They are used in sea and river transport.

- Railway. Used in railway transport.

- Self-writing. The devices are equipped with a mechanism that records the meter's operating schedule on chart paper.

Pressure gauges are used in industry, in everyday life, and in other fields of activity, depending on the purpose of use and technical characteristics.

Areas of application

Electric contact pressure gauges are used to measure excess and vacuum pressure in various media: liquid and gaseous. They also allow you to control external electrical circuits by turning switching contacts on and off. As such, ECMs are often used in signaling and process automation circuits.

Electrical contact pressure gauges ensure the safety of personnel servicing the equipment. After all, for safe operation of equipment, it is important that its operating parameters do not go beyond acceptable limits. If this happens, thanks to the pressure gauge, the automation will receive the corresponding signal and immediately stop the equipment, preventing it from turning on until the pressure indicator returns to normal.

For example, when the water pressure in the pipeline drops, a pump can be turned on thanks to an electric contact pressure gauge. Or a sound/light signal is simply given - this way the ECM allows you to know that in one of the systems the maximum permissible pressure has decreased or increased.

Electric contact pressure gauges are used to control pressure not only in industrial process lines, but also in household pipelines.

What kind of sensor is this and when is it used?

An electric contact pressure gauge is a sensor that is used to measure excess and vacuum pressure in various media (liquid, gas, steam), is used as a direct-acting signaling device and allows you to control production processes, while a special condition for the medium is to prevent its crystallization.

The ECM is used to issue control signals to actuators that maintain pressure values in the pipeline, as well as compressor units, hydraulic systems, pneumatic equipment or household autoclaves at a certain value.

The electrical contact pressure gauge is popular in many industries and infrastructure systems:

- Energy;

- Metallurgy;

- Oil and gas and petrochemical industry;

- Water supply systems;

- Mechanical engineering installations;

- Heat generation and distribution.

ECMs are also in demand in safety automation systems of thermal power plants, central heating stations and boiler houses.

Types of sensor models

There are many manufacturers involved in the production of electrical contact pressure gauges; some offer a fairly wide range of models; the list below is divided according to various manufacturing plants:

- TM (TV, TMV), 10th series;

- PGS23.100, PGS23.160;

- EKM100Vm, EKM160Vm;

- TM-510R.05, TM-510R.06, DM2005Sg and its analogue TM-610.05 ROSMA.

All of the listed models are divided into pressure gauges with microswitches and with magnetomechanical contacts. Manufacturers also produce devices that are explosion-proof and vibration-resistant or liquid-filled (filled inside with dielectric oil, most often glycerin) so that the readings of the pressure gauge needle do not “jump” with increased pulsation of the measured medium. Glycerin inside the ECM will prevent the needle from moving quickly.

Device

Figure 1. Design of an electric contact pressure gauge.

1 - tubular spring, 2 - holder, 3 - rod, 4 - sector, 5 - trib, 6 - indicating arrow, 7 - dial, 8 - leash, 9 - contact, 10 and 11 - signal arrows (settings).

The electric contact pressure gauge has a cylinder-shaped body. In design it resembles a general technical one. The differences lie in the following additional device details:

- two signal arrows for setting the on/off pressure value;

- contact groups for closing/opening the indicating arrow.

All pointers are located in the pressure gauge on the same axis, but their attachment points are isolated and do not touch each other. The axis of the indicating arrow is isolated from the mechanism and rotates independently of other elements of the device.

The electrical contact part can not only be combined directly with the mechanism of the device, as described above, but also attached to the pressure gauge in the form of an attachment with electrical contacts. In this case, the electrical contact group is placed on the front of the device.

Operating principle of ECM

The operating principle of electric contact pressure gauges is the same as that of technical analogues. But electrical contacts are added to the ECM, and this affects the principle of operation.

The measured pressure enters the tubular spring (1), one end of which is fixed in the holder (2). The second end of the spring is free. When pressure is applied inside the tube, its free end passes through the rod (3) to the sector (4) and the tube (5) with an arrow (6), which is mounted on its axis. The arrow moves along the scale (7) and shows the exact pressure value. The leash (8), which carries the contact (9), moves with it. The leash moves between two signal arrows, or settings (10, 11).

When the pressure reaches the value specified by the settings, the driver closes with the arrow. According to this principle, the electrical circuit to which the device contacts are connected is opened or closed. Closing/opening the circuit causes signaling or control equipment to be turned on/off. The electric contact pressure gauge can be configured to trigger when the pressure level increases or decreases.

Connecting an electrical contact (signaling) pressure gauge

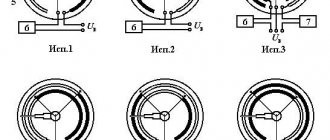

Depending on the purpose, various modifications of ECM pressure gauges are used, having different types of electrical circuits: - type 1 - single-contact for short circuit; — type 2 – single-contact opening; — type 3 – two-contact open-open; — type 4 – two-contact for short-circuit; — type 5 — two-contact for short-circuiting; — type 6 — two-contact open-short.

(For clarity, the following is a designation of possible switching groups on the electrical diagram for pressure gauges of types 3 to 6)

Thus, among the accepted standards for signaling devices, it should be said about the color marking of switching wires of electrical contact pressure gauges. When manufacturing, and accordingly when connecting the connection wires of pressure gauges, the following colors are accepted:

- minimum - blue; — red – maximum; - yellow - general.

Valves with a single-phase electric drive are less common.

Let's consider the automatic control of the electric drive SP0. This electric drive is interesting in that the power supply to the electric motor in the minimum configuration is switched off by the drive itself when the extreme states are reached - the “open” and “closed” positions.

Let's assume that the valve is closed (Fig. 4). When the pressure gauge closes the phase wire through the min terminal and the normally closed contacts kv of the time relay RV, the intermediate relay RPO is activated. This relay closes its power circuit with contacts ko2, turns on the magnetic starter PO with contacts ko1 and connects the neutral wire to the time relay PB through contacts ko3. When the valve is fully open, limit switch S3 connects pin 20 to pin 22, closing the phase line and turning on the time relay. After a period of time determined by the PB relay, the kV contact opens the power supply to the entire opening circuit.

The control circuit for closing the valve is similar to the considered circuit - when the upper limit is reached, the pressure gauge turns on the intermediate relay RPZ and the starter PZ, and the neutral wire on the time relay is also closed. When the valve is completely closed, terminals 23 and 26 are closed through switch S4, starting the time relay. By opening the common kv contact, the closing circuit is de-energized.

Turning on the time relay is necessary to compensate for the inertia of the electrical contact pressure gauge. Without delay, the circuit can be triggered multiple times before the min or max terminals are disconnected from the common wire.

Write additions to the article, maybe I missed something. Take a look at the site map, I will be glad if you find anything else useful on my site.

Source

Advantages and disadvantages of ECM

The main advantage of electric contact pressure gauges is that one device performs two functions at once: it allows you to control pressure and shows its current value. When installing these pressure gauges, no tees or fittings are required since the devices are already assembled in a single housing.

The advantages of the ECM also include ease of setup and accurate visualization of the set pressure response limits. In order to set the threshold values in the pressure gauge, you do not need a specialized tool; an indicator screwdriver is enough. The required values are easily set by rotating the screw in the head located on the outside of the glass of the device.

An electrical contact pressure gauge can replace a pressure switch. The operating principle is the same, but to ensure control of the pressure of a heating boiler, for example, you need two relays (separately low and separately high pressure) or only one ECM with two contact groups.

The disadvantages of ECM are associated with low switching currents. Due to low currents, high-power controlled devices have to be connected through intermediate relays. If you connect them directly, there is a high risk of burning the contacts in the pressure gauge.

Also, until recently, the disadvantages of these devices included low vibration resistance and a fairly high error. But instrument making does not stand still. The performance of modern pressure gauges has been improved, and previous shortcomings have been eliminated.

Types of electrical contact pressure gauges

Modifications of pressure gauges according to electrical diagrams

Depending on the design of electrical circuits, there are various modifications of electrical contact pressure gauges:

- single-contact - they operate either only on closing (version I), or only on opening (version II);

- two-contact - configured for pairs of values (use III-VI).

Version III - pressure gauges with open-open contacts, IV - closed-closed, V and VI - with one open and one make contact, in use. V - left opening, right closing, in use. VI is the opposite.

Figure 2. The most common pressure gauge designs are with two contacts: versions III-VI.

Main types of pressure gauges according to contact design

Depending on the design of the contacts, the following types of electrical contact pressure gauges are distinguished:

- with mechanical (sliding) contacts;

- with magnetomechanical contacts;

- on microswitches.

Pressure gauges with mechanical contacts have the simplest design among ECMs. They are designed to operate at voltages up to 250 V and withstand breaking power up to 10 W or up to 20 VA, respectively, DC or AC.

To increase the reliability of the switching device, magnetomechanical contacts are installed in the ECM. These pressure gauges are capable of switching high currents with increased breaking power of electrical contacts compared to analogues with sliding contacts. They differ from mechanical ones in that small magnets are attached to the back of the device contacts to enhance the strength of the mechanical connection. The breaking power of these pressure gauges has been increased - up to 30 W DC or up to 50 VA AC.

ECM based on microswitches have the same operating principle as others, but are distinguished by high reliability, excellent characteristics of the electrical contact group and compact dimensions. In such devices, microswitches open or close an electrical circuit under the influence of a cam attached to the transmission mechanism. Some pressure gauges may have two transmission mechanisms that are independent of each other: one is connected to the pointer, the other to the microswitch. The inputs of the mechanisms are connected to the sensitive element. Microswitches operate at voltages up to 380 V with a switching current of up to 5 or 10 A, i.e. the device can be connected directly to the signaling and control circuit.

Brief overview of some sensor models and their features

TM-510R.05, TM-510R.06

TM-510R.05 , TM-510R.06 are assembled on the basis of TM-510 pressure gauges, and after installing the electrical contact attachment they become full-fledged ECM.

These ECM models use contacts with magnetic compression, which allow switching high currents with high breaking power of the contacts, compared to devices with sliding contacts.

EKM TM-510R.05 , TM-510R.06 are characterized by a reliable electrical connection under dynamic loads.

Main characteristics:

- Two-pin electrical circuit;

- The maximum possible voltage is ~380 V ;

- The maximum possible current is 1 A ;

- The maximum possible breaking power of the contacts is 30 W ;

What to consider when choosing

When choosing the optimal electrical contact pressure gauge, focus on the conditions of future operation:

- Corrosion protection. If the device will be used in an aggressive environment, outdoors, the best choice would be a stainless steel version or a corrosion-resistant housing. Conventional pressure gauges will quickly exhaust their service life under such conditions.

- Protection from dust and moisture. If the place of future operation of the ECM is characterized by dust and the presence of moisture, it is worth giving preference to pressure gauges with increased dust and moisture protection. Protection against the penetration of dust and moisture during operation of the device is provided by a special shell.

- Vibration resistance. To work in a technological process where there is vibration, you should choose a device with hydraulic filling. Such models are filled with a damping liquid (based on glycerin or silicone), which protects the device from intense abrasion due to vibrations affecting the housing or pulsation of the measured medium. Vibration-resistant pressure gauges work for years where technical ones would not last even a month due to exposure to vibration. In addition, due to the reduction in needle vibrations, vibration-resistant models are characterized by increased measurement accuracy.

- Working with low pressure ranges. If you need to measure pressure ranges up to 50 kPa, pressure gauges with a magnetic design are best suited for this task. They are not sensitive to the number of operations, since their device has no rubbing parts.

- Explosion protection. In conditions of high risk of explosion, special explosion-proof pressure gauges should be used. Such devices are equipped with an explosion-proof enclosure. This shell withstands the explosion pressure in the housing and does not transmit it to the environment. Explosion resistance is also ensured by the “slotted” connection of the housing elements and the low roughness of the surfaces of the fastened parts in the pressure gauge.

One model can combine several types of protection from the influence of the external environment. For example, corrosion-resistant, vibration-resistant electrical contact pressure gauges are popular.

In our catalog you will find ECMs from leading Russian manufacturers. Pressure gauges are supplied with a warranty, passport documentation and initial verification by the manufacturer. Our specialists will advise you on the range and help you choose suitable models.