A safety (safety) belt is one of the most important elements of a safety system for work at height. Safety belts are also used when repairing roofs, working at heights, and other activities related to raising a person above the ground and in a place where there is a need to position the worker in a certain place or keep him from falling. It is important to understand the different types of safety harnesses, as each of them is designed and used for a variety of purposes.

Why do you need a mounting belt?

The mounting belt belongs to the category of equipment that is a necessary element if work is performed at height or in conditions dangerous to the human body. According to safety regulations, it is prohibited to perform any work without the use of support and safety devices. At the same time, we should not forget that the installation safety belt cannot act as a 100% guarantee of safety, even if the highest quality materials and high-strength fittings are used.

Installation work using a safety harness

In addition, the mounting safety belt must be used in conjunction with harnesses, among which there are support and positional, safety and restraining ones. This provides additional safety, since a fall from a great height can cause paralysis of the lower limbs. In this regard, the belt is only a method that can hold the body in a working position. Consequently, for work at heights, such a belt will only act as a means of performing a holding function. When purchasing a mounting safety belt, you should not save on it, as this is a guarantee of human safety.

In addition, the mounting belt for high-altitude work is capable of providing an orthopedic function. If you choose this safety item as correctly as possible, it will protect you from the development of radiculitis and osteochondrosis while constantly in limbo. Very often it is used not only as insurance, but also as an item that helps with evacuation.

How to use rope access systems

Permission to work at heights: who is not allowed

This system is used for ascending or descending along an anchor line. The work is in limbo. The use of this system is associated with a very high risk, therefore it is used only for trained specialists (EMERCOM employees, law enforcement agencies). These employees must be well trained and have some experience, and must be over 18 years of age. Special medical examinations are required: medical examination.

Rope access systems

What is a mounting belt?

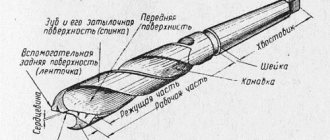

When considering the design features of mounting belts, it is worth paying attention to what elements they consist of:

Installation work using mounting belts

- a belt that, depending on the size of the person, can be adjusted in volume to the required levels to ensure maximum comfort;

- sash - a soft lining that is located under the inside of the belt. With its help, chafing of the skin is prevented due to a fairly rigid belt and comfort is ensured when performing very long work;

- metal rings made in a D-shape. This is a component element of such a part as a carabiner for a mounting belt;

- safety cord in the form of a polymer rope;

- shock-absorbing devices - often serve to absorb energy in certain critical situations;

- tool sockets. If the tool mounting belt has such a socket, then this frees the worker’s hands from objects that are not needed at a certain point in time.

How to put on a safety harness correctly?

Tips for builders |

01/16/2017 Construction and installation work often takes place at a certain height, with a risk to the health and life of the working specialist. If the employee is likely to fall, the height is more than 1.8 m or less than 1.8 m above mechanisms, water, protruding parts, etc., as well as when climbing or descending a vertical ladder for more than 5 meters and other situations described in the Regulations on labor protection during work at height, then it is impossible to do without appropriate personal safety devices.

Familiar to many, the mounting belts that will be discussed in this article are a mandatory element of equipment not only for an industrial worker or a “climber” of a cleaning company, but are also successfully used in hiking trips, rock climbing, and even during rescue operations. The mounting safety belt, also called a safety belt, has its own design features and has some nuances of preliminary testing and subsequent operational use.

Types of mounting belts

When considering mounting safety belts, you should pay attention to the following types:

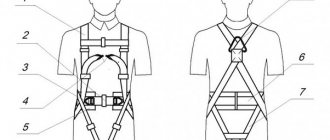

- safety harness in the form of an installer's safety belt with straps on the hips and shoulders for fastening;

- a safety harness designed for installers working at height. Often equipped with a shock absorber and a sling made of polyamide;

- mounting belt, which can provide different options for attaching straps: with hip and shoulder straps, with a secure grip, anchor line and other important elements.

The most reliable is the 5-point mounting belt. Its peculiarity is that it has 5 points at which fastening occurs. This ensures maximum safety for the installer working at height.

Photo of mounting belts for tools

When performing work at height, it is important to ensure that you can ensure the most comfortable work with the tool. A special mounting belt is also provided for the tool. It is very convenient when performing various tasks, since getting the necessary device will be quite easy and simple. And at the same time, you don’t have to constantly go downstairs in order to find the necessary tool.

This belt is equipped with a huge number of pockets, as well as a special system of tightening straps. With their help, you can adjust the five-point mounting belt exactly to the person’s figure to ensure convenience during work. Such mounting belts can be represented by the following types:

- shoulder;

- waist;

- in the form of a vest.

Regardless of which type is preferred, each of them copes with the functions assigned to it. At the same time, during the selection process, you can also pay attention to the photo of mounting belts intended for tools. This is necessary for a better understanding of the design features.

Builder's Belt with Hammer Holder

Tool belt bag

Bag - belt with screwdriver holder

Installer belt with screwdriver holder

Tool belt

Requirements

Depending on the size and type of an object such as a five-point safety belt, the corresponding requirements are determined. They are expressed in the following technical characteristics:

- in the dorsal part the width should be no less than 80 mm;

- the length of the halyard should be in the range of 1400-1900 mm;

- in the process of adjusting the mounting belt, its length should provide a volume of 640-1500 mm.

These are the key features to look for when purchasing a mounting belt. Among the requirements, it is worth paying attention to the possibility of:

- withstand enormous loads;

- use of high-quality materials that are tear- and tear-resistant;

- as well as comfort and ease of use.

Testing of mounting belts

Before the mounting belt is put into operation, it is tested. This is a necessary measure, since this item ensures human safety when performing any work at height. When performing tests, all requirements that the five-point mounting belt must meet are checked. Several methods are used for this.

- The belt is secured to a cylindrical rigid beam using a buckle. A ring placed on a belt is attached to the winch. For 5 minutes, a load of about 4000 N is created.

- The second type of test is almost the same. It only differs in that a load of 4000 N is suspended from a ring located on the belt.

In the same way, a rope sling is checked, to which the same load is suspended. But everything happens only when the carabiner for the mounting belt is fully secured.

What is a safety harness

This harness holds the worker on the rope and ensures even distribution of the resulting loads. It must be adapted to the type and duration of work performed. Working at height involves risk, so a safety harness is very important to keep the worker on the rope and protect him from falling.

Such a harness is understood as an element of a safety system for working at height, which reliably holds a person in a given place and prevents a fall.

Harness testing

The test rules are as follows:

- Inspection of the harness should be carried out each time before starting work for damage and loosening of components;

- the belt should be at the waist, other straps should also be in place;

- adjustment of the dorsal point and tightening of the shoulder straps are required;

- connecting the shoulder straps to the belt using buckles and carabiners.

Harness

GOST requirements for the production of belts

Construction safety belts produced by domestic and foreign manufacturers must comply with the requirements established by GOST. This document prescribes the basic standards and rules for the development and use of safety products, their types and classification, requirements for the materials from which various parts and elements of the belt are made.

Special conditions apply to the design of safety belts.

Photo from the site www.kuzalians.ru

Safety devices should be convenient and comfortable to use:

- Do not cause pain when using them, do not hinder movement or complicate breathing.

- The parts must be firmly connected to each other to prevent the person from falling out of the belt.

- The fastener should be easily adjusted by a worker who is already wearing gloves.

- Metal parts of the structure should not come into contact with the body.

- The design of the safety product should, if possible, protect the worker’s back from injury and prevent the development of diseases such as osteochondrosis or radiculitis, and the straps and sash should be wide enough to avoid problems with poor circulation in the arms and legs.

- Attaching the carabiner is a quick and simple process, taking the user no more than three seconds. The lock and safety device should generally close automatically.

- The belt must fix the position chosen by the worker and keep it at a height.

GOST has also developed basic requirements for the parameters of safety belts, which should guide manufacturing companies - the length of the belt and sling with a halyard, the width of belts and straps, the maximum permissible loads for strap-on and strapless types of products, the dynamic and static mass of the load that occurs during free fall.

All protective and performance properties must be maintained during the service life declared by the manufacturer. Usually it is two years. The service warranty card covers the same period.

Requirements for materials from which safety belts are produced

This is another important point that you should pay special attention to when choosing and purchasing a safety belt. The design parts of the safety product must be made of safe materials, which are specified in GOST.

Belt slings, which are chains, are made of metal, most often steel, and ropes are made of nylon. The halyard is made from a metal sheet using the casting method. All metal parts of the structure must withstand strong negative temperatures, up to -40 degrees, and also have an anti-corrosion coating. This will protect them from rusting processes in case of possible precipitation.

The sash is made from natural materials that have warming properties, the belts and straps are made from artificial and synthetic materials. The use of leather in the production of load-bearing parts is not permitted for safety reasons. Safety belts must be brightly colored.