Manufacturer's warranty applies!

- Be a legal entity or individual entrepreneur

- Conclude a supply agreement

- Purchase welding equipment and materials from ITS-Ural

Didn't find the product you were looking for? Contact us - we will deliver equipment to order or offer an alternative solution.

Thank you for contacting us! The manager will definitely contact you as soon as possible.

Design features and operating principle

A three-phase step-down transformer provides a falling external characteristic.

The rectifier consists of components and parts:

- frame;

- control Panel;

- winding;

- rectifier;

- stabilizer;

- circuit breakers;

- fan.

The cooling system is forced, the fan turns on automatically along with the equipment. On the body of the device there are:

- push-button switch;

- control panel with digital display and adjustment knobs;

- ammeter;

- network connector;

- welding cable connectors;

- warning lamp;

- ground bolt.

Rotating handles allow you to smoothly adjust the current strength and other parameters. In case of overheating, the rectifier automatically switches off.

Contents of delivery

The VD series welding rectifier is supplied complete with:

- current converter;

- passport;

- power cable.

The new device is packaged in cardboard boxes. They indicate the model and technical characteristics of the rectifier. Additionally, holders for coated and non-consumable electrodes may be included.

Varieties

Comparative characteristics of the welding machine VD 306 in various design changes.

| Options | VD-306B | VD-306M UZ | VD-306 UZ |

| Dimensions, mm | 690×360×640 | 1 040×360×315 | 660×565×510 |

| Weight, kg | 87 | 65 | 104 |

| Rated current, A | 300 | 315 | 315 |

| Operating mode, % | 25 | 55 | 65 |

| Current regulation limits, A | from 25 | from 30 | from 30 |

| No-load current, A | 70 | 75 | 80 |

All rectifiers listed in the table have the same indicators:

- 3 phases;

- industrial voltage 380 V;

- working – 32 V;

- smooth adjustment.

The digital display and stepless control allow you to precisely adjust the equipment to the required mode.

Unacceptable operating conditions

Considering the design of the device, the welding transformer VD 306 is prohibited from operating in rooms where the atmosphere contains:

- dust;

- vapors of caustic substances;

- fire hazardous atmosphere;

- substances that destroy insulating materials.

Important! Working in conditions harmful to the machine leads to the destruction of the equipment and endangers the health of the welder.

For modifications

- transformer;

- rectifier;

- magnetic shunt;

- emergency shutdown system;

- fan;

- casing

The VD-306 rectifier feeds the electric arc and operates with a direct current output. Performs surfacing and welding. Connects to industrial current 380V.

Operating parameters of VD-306:

- current 315 A;

- mode 60%;

- voltage from 32 V;

- welding current limits 30 – 315 A;

- the adjustment is smooth.

The rectifier is packaged together with a 3 m cable and a passport in the usual version and with ultrasonic climate protection. Protection degree IP22. The ground clamp is located on the base of the chassis.

The presence of a welding choke in the design of the rectifier makes it possible to weld high-alloy steels with a non-consumable electrode in an argon environment with or without the use of filler wire.

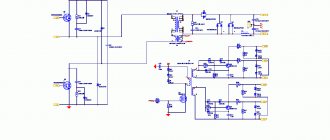

Setting modes and circuit

Opening and closing the magnetic shunt changes the inductive leakage. The shift is made by rotating the handle on the top of the body. The current value required for operation is set depending on the electrodes used and the type of metal being welded.

Current is supplied to the primary winding, then the inductor forms a saturated electromagnetic field. It creates an excitation current, which stabilizes and passes through the rectifier to the holder, forming an arc.

Another rectification circuit is also used, using diodes or thyristors in continuously variable welding machines

What I bought at a flea market.

My instagram akakasyan Our group club79283215 Chinese factory from the inside kzgolds.info/town/bejne/0Kyox4K9lbXQvLc.html Megafactories of China - JLCPCB kzgolds.info/town/bejne/t8ral4LNxMOzo5Y.html World Electronics Market kzgolds.info/town/bejne/ttC6mnea16a plsk.html

My laboratory equipment Laboratory power supply ali.pub/2tmanr buyeasy.by/redirect/cpa/o/pgut. Multimeter 1 ali.pub/2tm7hm buyeasy.by/redirect/cpa/o/pgus.

Multimeter 2 ali.pub/2tm7xk buyeasy.by/redirect/cpa/o/pgus.

Multimeter 3 ali.pub/2tmcks buyeasy.by/redirect/cpa/o/pgut.

Multimeter 4 ali.pub/2tm9qb buyeasy.by/redirect/cpa/o/pgus.

Current clamps ali.pub/2tm9yo buyeasy.by/redirect/cpa/o/pgus.

Capacitance and inductance meter ali.pub/2tm945 buyeasy.by/redirect/cpa/o/pgus.

Universal signal generator ali.pub/2tmgij buyeasy.by/redirect/cpa/o/pguu.

Oscilloscope ali.pub/2tmb1d buyeasy.by/redirect/cpa/o/pgut.

Transistor tester ali.pub/2tma7t buyeasy.by/redirect/cpa/o/pgus.

Thermometer ali.pub/2tm8sa buyeasy.by/redirect/cpa/o/pgus.

Frequency meter ali.pub/2tmigc buyeasy.by/redirect/cpa/o/pguu.

Electronic load ali.pub/2tmagy buyeasy.by/redirect/cpa/o/pgus.

Intelligent chip tester ali.pub/2tmicu buyeasy.by/redirect/cpa/o/pguu.

Soldering iron ali.pub/2tmbm6 buyeasy.by/redirect/cpa/o/pgut.

Microscope ali.pub/2tminc buyeasy.by/redirect/cpa/o/pguu.

Make money on Aliexpress

epngo.bz/epn_index/29c81 Return 8.5% of purchases ali.pub/21o6mg Our sites

Subscribe to our VK groups club79283215 club54960228

My second channel is kzgolds.info/done/O9r.html.

My Instagram akakasyan

Assistance in the development of projects donatepay.ru/d/aka

Technical characteristics of welding rectifier VDU-506

Welding rectifier VDU-506 is a universal rectifier with thyristor control. Its versatility is manifested in its ability to provide:

- welding with coated electrodes;

- welding in shielding gases;

- flux cored wire welding;

- submerged arc welding;

- air arc cutting.

The rectifier is designed both for completing manual arc welding stations with piece metal electrodes, and for equipping semi-automatic machines of the PDG type for mechanized welding in a shielded gas environment of products made of low-carbon, low-alloy, carbon and corrosion-resistant steels on direct current. The straightener is adjustable and has a hard and falling external characteristic.

The rectifier is connected to a three-phase 380 V network and consumes 62 A from it at full load. The range of welding currents and operating voltages is quite wide: 50–500 A, 18–50 V.

| supply voltage, V | 3x380; 3x220 |

| rated welding current, A | 500 (PN=60%); 390 (MON=100%) |

| limits of welding current regulation, A | |

| for tough specifications | 60–500 |

| for falling characteristics | 50–500 |

| operating voltage regulation limits, V | |

| for tough specifications | 18–50 |

| for falling characteristics | 22–46 |

| open circuit voltage, V, no more | 85 |

| rated power, kVA, no more | 40 |

| welding cycle duration, min | 10 |

| overall dimensions, mm (LxBxH) | 820x620x1100 |

| weight, kg | 300 |

Expert comment:

By purchasing VDU-506, you receive:

- DC arc welding Welding from a rectifier is stable and stable, the technological effect in terms of the quality of seam formation and low spatter corresponds to the best samples. The rectifier ensures easy ignition and stable arcing at any current within the control range. The rectifier can work according to a given program with a manipulator or as part of a robotic complex. For this purpose, there is a special connector through which a standard signal (0–10 V) is supplied.

- Ease of use Smooth regulation of welding current (at falling) and voltage (at rigid external characteristics) is carried out by a resistor on the control unit (local regulation), as well as from a semi-automatic device or automatic device (remote regulation). The rectifier is equipped with a remote control for remote activation and regulation of welding current.

- To move within the welding area, the rectifier is mounted on a four-wheeled trolley with two handles. There are special handles with holes for lifting the rectifier.

- Transformer Features:

- designed for operation at ambient temperatures from –10 °C to +40 °C;

- versatility;

- ease of use;

- high arc stability;

- smooth regulation of welding current and voltage over the entire range without switching for each type of external characteristics;

- high technological properties;

- reliability and trouble-free operation.

Attention! The power source can be supplied at the consumer's request for a voltage of 220 or 380 V. At the user's request, the rectifier is equipped with a semi-automatic welding machine or automatic machine.. et.ua

et.ua

Detailed product description

The welding rectifier VDU-506 is designed for manual arc welding with coated electrodes on direct current, as well as for completing semi-automatic and automatic machines for welding steel products in shielding gases on direct current. It is an adjustable thyristor rectifier with a rigid or falling external characteristic.

The difference from the VDU-506S version is the classic construction and the absence of a combined current-voltage characteristic in semi-automatic welding mode.

The welding rectifier VDU-506 works in conjunction with the semi-automatic PDGO-510-5, with stabilization of the welding wire feed speed and the ability to remove the feed mechanism from the rectifier at a distance of up to 30 m, optimal for workshop conditions when welding at arc currents up to 450 A (PV = 100% ).

The welding rectifier VDU-506 has the following main technical solutions:

- smooth regulation of welding current in MMA mode and welding voltage in MIG/MAG mode;

- availability of a 36 V socket to power the gas heater;

- thermal overload protection;

- quick-release, safe current connectors;

- insulation class N;

- forced cooling.

is an official certified representative of JSC Nauchno-Proizvodstvennaya with the right to sell and maintain welding equipment and materials produced by the Group’s enterprises (trademarks “ESVA”, “Selma”, “ITS”).

terms of Use

According to the instructions, operation of the welding rectifier is possible only if the following conditions are met:

- The work is carried out in enclosed spaces with a functioning ventilation system. Work outdoors is permitted only in normal weather conditions.

- The level of dust in the working area should not exceed the maximum permissible concentration adopted for industrial premises.

- The temperature range is from -10 to +40 Cº.

- The working area is located at an altitude of up to 1000 meters above sea level.

- The humidity level of the production area should not exceed 80%.

During operation, the device should not be subjected to external mechanical influences.

Classification and labeling

All versions of welding rectifiers are divided according to the following parameters:

- According to the phase of the current used: single or three phase. The former are compact, but do not allow smoothing out significant voltage ripples and obtaining significant processing currents at the output, therefore they are used mainly for welding machines for household use.

- According to the method of controlling the strength of the welding current.

- According to the type of current-voltage characteristic.

- According to the current rectification circuit. It can be single-phase (used in low-power devices), three-phase or six-phase (the latter is used in high-power units exceeding 1000 kVA). In turn, three-phase rectification can be implemented using bridge or ring circuits.

- Depending on the number of posts served - single-post or multi-post.

The marking of welding rectifiers is regulated by the requirements of GOST 13821-77 (for single-station units) and GOST 18142-85 (for semiconductor units). It includes the letters VD (arc rectifier), the third letter U (universal), or M - multi-station. This is followed by the value of the welding current in amperes multiplied by 10, and (optionally) the series number. Thus, for example, the universal welding rectifier type VDU-504 is designed to produce direct current up to 500 A.

GOST 13821-77 establishes the following relationships between the energy characteristics of a welding rectifier and the duration of its continuous operation. In particular, in the range of welding currents 400...630 A, the minimum operating voltage cannot be less than 24...25 V, and duty cycle - more than 60%. At currents of 800 A or more, the minimum voltage is 26...34 V, and duty cycle can reach 100%.

Symbol structure

Let's decipher the name using the example of a welding rectifier VDU-506S UZ1:

- B – rectifier.

- D – arc;

- U – universal;

- 5 – welding current strength, which is indicated in hundreds of amperes;

- 06 – serial number of the model;

- C – manufacturer’s marking. In this case, the rectifier was produced by an electrical engineering company located in Crimea.

- UZ1 is the nature of the execution and the category of placement of the model.

Operating conditions are subject to the requirements of Interstate Standards.

General information

This device is characterized by a variety of work performed. Depending on the type of design, the rectifier can be used in the following types of welding work:

- Electric arc welding. Coated electrodes are used as filler material.

- Work in a protective gas environment. In this case, the equipment is equipped with a feeding mechanism of the PDGO-510 type.

- Submerged arc welding. For operation in semi-automatic mode. In these works, the filler material is flux-cored wire.

- Work as a manipulator. Some models are equipped with a rectifier as a current source.

General information and characteristics

The welding machine model VDU-506S U3 is a mobile welding rectifier designed for manual arc welding using a coated electrode. The device operates on direct current, the body is made of durable metal, and there is a forced cooling system. This model produces up to 500 Amperes and requires 380 Volts for power.

Please note that VDU 506 is a single-station device. If you need to organize several jobs at once, then it is better to purchase a multi-station welding rectifier.

Also, in addition to manual arc welding, you can cut and surfacing metals using the same coated electrodes. Additionally, you can connect a feed mechanism and a torch to the machine to use it in MIG/MAG mode. Please note that for MIG/MAG welding, the VDU 506 you choose must include a feed mechanism. You must purchase the burner yourself.

By the way, the VDU 506S U3 rectifier differs from the classic transformer for the better. Its design includes thyristors. Thanks to them, the device has improved functionality. For example, it is capable of stabilizing voltage and current, as well as working remotely.

Peculiarities

There is a myth that a welding rectifier cannot be used indoors. But this does not apply to the VDU 506 model. It feels great in the presence of natural ventilation (cracks, open windows, etc.). And even more: this device is capable of operating at very low temperatures down to -40 degrees.

However, this rectifier is not intended for welding in explosive atmospheres. The released vapors and gases can damage the welding machine or completely destroy it.

We are accustomed to thinking that a transformer and rectifier are difficult-to-use devices. This is largely true. But the VDU 506 model does not have many disadvantages. The arc ignites easily and burns stably, provided that you have provided sufficient voltage in the network to power the device. All this is possible thanks to improved characteristics. We can say that VDU 506 is a significantly modified version of the classic rectifier.

Safety precautions when using this device

Safety requirements do not differ from standard rules for the operation of electrical installations:

- It is not allowed to allow persons who do not have the appropriate permit to work with the rectifier.

- Operation without grounding is prohibited. Occupational safety regulations require that a sign “Do not turn on without grounding” be placed on the housing. It is not permitted to use another welding machine for grounding. This work must be carried out by a qualified electrician.

- Operation without a protective casing is prohibited.

- Before moving the device on the job site, it must be de-energized.

- Before dismantling the side parts of the casing, it is necessary to disconnect the device from the power supply.

- It is prohibited to operate the device if the conductive insulation is damaged.

- When working with a rectifier, it is necessary to use personal protective equipment - a mask, leggings, and overalls.

- It is prohibited to touch live elements.

- It is forbidden to look at the electric arc without protecting your eyes with a mask with light filters.

- Finishing work on mechanical cleaning of the welding seam must be carried out wearing protective glasses to avoid the ingress of slag fragments.

The lineup

Marking VD-306 means arc rectifier, 30 A rated current, model version 6. The unit has been operating for several decades in various conditions where other welding machines cannot withstand and quickly break down. Therefore, modernized devices have been created on its basis. The VD-306 series has many modifications. The most popular models among welders:

- VD-306D for large-scale production and work in field conditions;

- rectifier VD-306Sh operates from a network of 380 W and consumer 220 W;

- the improved VD-306M1 allows you to cook additionally with alternating turns;

- VD-306I is an upgraded modern inverter device based on a rectifier.

In addition, there are models made in various climatic versions for work in northern and tropical conditions.

Areas of use

The significant weight makes the device an unacceptable option for home work, despite the simplicity and reliability of the design. Welding inverters will cope much better with simple tasks in a summer cottage or garage. In addition, the cost of the rectifier is quite high for the average user.

Therefore, these devices are successfully used at various industrial enterprises that require the connection of thick-sheet products with deep welding of the seam. As practice shows, subject to timely maintenance and compliance with safety requirements, the device can operate for 20 years or more.

Preparing the device: rules of use

Before starting work, you should inspect the integrity of the housing, insulation of cables and hoses. Check all contacts, terminals, clamps. After this, you should connect the case grounding and turn on the device.

Before starting work, you should set the settings and make a test seam. after that you can start working.

Welder of the 5th category of the central steelworks plant of Large-sized metal structures Bogdanov S.D.: “Dust settles on the windings and microcircuits of the equipment and leads to overheating and disruption of operation. If there is a compressor on site, the rectifier should be blown with a stream of compressed air through the air intake slots before operation. If work is carried out outdoors with normal dustiness, cleaning should be done once a week. Welding in an industrial enterprise with a large number of stations requires daily maintenance of the device. After this, you can begin checking connections and terminals. If there is no compressor, the dust is removed with a soft brush.”

Design and principle of operation of a welding rectifier

The rectifier components include:

- Primary winding.

- Rectifier block.

- Cooling system.

- Control equipment unit, including a current stabilizer and automatic fuses.

- Protective housing with trolley.

- Control Panel.

The operation of the welding rectifier is as follows. The primary current from the network enters the input winding of the transformer. If a saturation choke is used as a rectifying device, then an electromagnetic field is first formed in its circuit, inducing the corresponding excitation current. This current is stabilized and transmitted through the rectifier unit to the electrode holder to initiate an electric arc.

Depending on the purpose, other rectification schemes can be used. For example, using power diodes (this is how current rectification is realized in VDU-504) or using thyristors. A thyristor current rectifier allows you to set the current value not stepwise, but smoothly, which is much more convenient.

Since semiconductor elements heat up intensely during operation, they are structurally enclosed in a ventilated housing. The straightening process itself can be organized according to various schemes:

- Conventional smoothing of current ripples (for low powers);

- Bridge, where current ripples are smoothed out in all three phases, and the oscillation frequency increases from 60 to 300 Hz;

- Ring, with two secondary windings (at the same rectification frequency, requires a more complex transformer device);

- Six-phase, with a symmetrical choke, due to which the pulsation frequency is halved (used for the most powerful models of welding rectifiers).

The functionality of rectifier units depends on the electric welding method used. For manual welding, a decreasing current-voltage characteristic is used, which is achieved either by increasing the resistance values on the transformer windings, or by inversion - using the feedback principle. Each of the schemes has its own limitations. When the resistance increases, it is necessary to use ballast rheostats. In turn, welding inverters are characterized by low processing currents and cannot operate with long duty cycle values.

Frequent breakdowns and how to fix them

During operation, the user may encounter the following problems:

- The device is constantly disconnected from the power supply . There may be several reasons: a short circuit at the rectifier terminals, breakdown of thyristors, or a short circuit to the housing of the secondary winding of the transformer. An ohmmeter should be used to localize the breakdown. After this, eliminate the problem.

- There is no voltage at the output . As in the previous case, there may be several reasons: failure of the voltage regulator, failure of the fan, failure of the wind relay, open circuit or failure of thyristors.

- Operation on harsh external characteristics is not possible . In this case, you should check the feedback circuit for voltage - there is a break somewhere.

- Unstable operation on falling and hard external characteristics . Most likely, the control signals do not reach some thyristors. First of all, you should check for the presence of signals. In case of absence, it is necessary to sequence their formation and find the cause of the break. To do this, you should use an oscilloscope. The average pulse value is 1.5-2 V.

- Unstable operation at hard specifications . This picture is observed when the circuit of the auxiliary winding of the inductor is broken.

If you have professional skills, you can easily repair this device.

[/stextbox id='alert']Important. All repair and maintenance work should be carried out only after disconnecting from the network.[/stextbox]

How to make a straightener?

If you have minimal technical knowledge, making a welding rectifier with your own hands is not difficult. We first select a ready-made transformer with a step-down effect of the required range. Most often this is very difficult to do, and you have to wind it yourself. Detailed instructions for assembling the rectifier.

Welding rectifier circuit

We propose to make the simplest homemade welding diode rectifier. It must be assembled using a bridge circuit and mounted on a radiator so that the device is cooled all the time. The fact is that powerful diode lamps (VD type). To ensure a falling or hard characteristic, it is necessary to include a special inductor in the circuit. Next, a rheostat is attached to ensure smooth adjustment of the operation of the rectifier.

The electrical circuit of the rheostat is quite simple, you can wind it around the core with your own hands, you only need a simple copper or aluminum wire. But before work, you need to calculate the required resistance: the voltage adjustment depends on the diameters of the turns.

To make the task easier, you will definitely need not only a detailed instruction manual, but also a circuit diagram.

The lineup

The company that produces this welding equipment offers a wide selection of devices of various modifications. The “VD” category of devices can be presented in various designs, depending on the requirements. Each new model is assigned its own article number, expressed in letter form.

1. VD-306I - inverter-type device, average cost 26,000 rubles.

The functionality of the inverter, which affects the operation of the welding arc, deserves special attention. The model is equipped with the following operating modes:

- “hot arc start”;

- "arc force";

- "anti-sticking".

Video:

2. VD-306D. These representatives of the “VD” family have found their application mainly in industrial production.

Such devices are distinguished by a high degree of reliability and unpretentiousness in difficult operating conditions. Equipped with thermal protection of the transformer and rectifier unit. Requires power supply with mains voltage 380V. The maximum output power is 25 kW. Cost - 110,000 rubles.

3. VD-306M1. Using this type of welding equipment, you can carry out work in AC or DC mode.

The maximum power of such a device is 24 kW, regardless of the welding mode. The main area of application is the industrial sector. Price - 45,000 rubles.

4. VD-306Sh. This type of rectifier can be connected to both industrial and domestic networks.

The maximum output power value is 23 kW. The average cost is 35,000 rubles.

Manufacturer companies, cost

Initially, the production of such equipment was launched at the JSC Electric Machine Building enterprise in Simferopol. Currently, the market is witnessing the emergence of an increasing number of enterprises focused on the production of devices of the “VD” series.

To answer the question: where is the VD-306 welding rectifier produced, just go to the website, which provides a list of the most common enterprises producing similar products.

The prices of the welding rectifier VD-306 today are within 30,000 rubles. The cost varies depending on the popularity of the manufacturer and component parts supplier.

PS Despite the fact that welding rectifiers VD-306 are somewhat inferior in some respects to their modern analogues, it should be noted that, other things being equal, such equipment is the best in its class in terms of price-quality ratio.

Analogues of this product can be viewed and touched in specialized welding stores.

If after this you still have questions, you can try the equipment in operation at the ITS-Ural production site (the service is provided for goods that are available at the warehouse in Yekaterinburg).

For details about the Equipment Test Drive service, call +7 (343) 222-1-999.

Own production

ITS-Ural LLC is part of the ITS group of welding equipment factories. JSC Nauchno-Proizvodstvennaya is a leading Russian manufacturer and supplier of welding equipment and consumables. This large specialized financial and industrial group unites developers, industrial enterprises and centers for the sale and service of welding equipment.

was founded in 1991 and today is a large industrial and financial group, which includes JSC Elektromashinostroitelny (Simferopol), JSC ELEKTROSVARKA (JSC ESVA) (Kaliningrad).

The fundamental activity of ITS-Ural LLC is a comprehensive solution to problems to ensure welding production in the Ural Federal District. The company's head office, retail stores, production and warehouse are based in Yekaterinburg.

Own service center

The official service center is located on the territory of the company’s production and warehouse complex. Maintains and repairs equipment for welding, cutting and surfacing of the SELMA and ESVA plants, brands BIMArc, Svarog, Resanta, Kedr, Aurora, etc.

Types of rectifiers

There are several types of rectifiers:

- welding thyristor rectifier VD 313 SE, VD 306;

- inverter power rectifier (welding);

- throttle;

- transistor (station wagon).

What is the difference between these devices?

Thyristor power supplies are suitable for various types of arc welding electrodes and can be used for welding work on rods.

Advantages:

- Higher efficiency compared to conventional rectifiers.

- Excellent arc characteristics, much smaller spark.

- Single row current control

- Easy to implement remote control function

- Good strength against voltage fluctuations

- Suitable for outdoor use.

- This is a multi-station welding rectifier - vdm - 1201, 2x313, vdm-1202 s, 1001, selma, BC ma, 6303 s.

The throttle rectifier is designed for welding in the most severe operating conditions (quarries, mines, pipelines, etc.). It provides semi-automatic welding and surfacing for currents up to 650A. In semi-automatic welding, the operating voltage is adjusted in steps. The single-station welding rectifier is represented by VDU 505, 504, VDU 506, DUGA professional and DUGA industrial.

Circuit: Throttle rectifier

In addition to the main choke, the welding arc power supply system has another one built into the parametric section, which can significantly improve the quality of the weld due to the stabilization of welding. As a rule, in addition to the main power winding, an auxiliary winding is also used, which serves to regulate the inductance of the inductor and, thereby, controls the peak point during a short circuit or voltage surges.

The inverter rectifier is used to convert incoming alternating current into direct current, represented by models esab, man,. This current switches on and off very quickly, creating a pulsed, high-frequency DC current. Typical frequencies range from 10,000 to 20,000 Hz, but data up to 100,000 Hz is possible. The inverter, like the entire welding rectifier, needs to be checked every six months. The welding inverter rectifier is represented by the models electron 125, sun 600, 318m1, arc, neon (naks), afterburner, power, paton, terminator and anode (USSR).

Video of economical operation of a welding rectifier

Transistorized welding power sources have been developed for precise control of welding parameters. The speed of operation and response of transistors is very fast, hence such power sources can be adjusted to give any desired I-V reading between direct current and constant type voltage. In addition, the control system can be programmed to set the variable current and voltage during the actual welding operation. These technical features make the universal transistor welding rectifier particularly attractive for welding pipes, ventilation passages and shafts. Welding can be carried out using free-standing electrodes.

Almost every master has gasoline welding rectifiers (Esva, Loris). These are quite convenient portable devices, with which it is convenient to carry out work on the road or in the open air. There are very good reviews about the fubag welding rectifier, and its characteristics indicate that the device is also suitable for use in a local power supply network. In addition, these devices are often equipped with a portable charger.

If we distribute rectifiers by area of application, we get the following table:

| Application area | Rectifier name |

| For surfacing metal under a flux layer | vdu |

| For simultaneous power supply of several welding stations | VKSM |

| Used to power the welding machine when working with structural and alloy steels. Widely used in public utilities, everyday life, small workshops and workshops. | VDMSH |

| In cold car engines, an arc frequency universal device is often used. | VDUCH and VDC |