Resanta inverters are a line of high-quality professional and non-professional welding machines that meet all requirements and have very high performance indicators. They are used for arc welding with stick electrodes, scientifically called MMA welding.

With their help, you can perform precise surface and deep welding and produce welding products of any complexity and design. Due to the fact that the company produces a number of different devices, which we will talk about in more detail later, they are available both for home use and for use in small production.

- A little about the manufacturer

- Product range

- Let's look at the features and characteristics

- Consumer Opinions

History of brand development

Resanta welding machines are the only representatives of arc welding equipment in their price class. Indeed, compared to analogues, all models compare favorably in cost. The domestic consumer gradually developed the mindset that low cost is a direct indicator of low functionality or quality.

However, the Resanta model range allows a variable approach to the issue of choosing a device, both for a specific area of application and for a wide profile. In simple words, offers from the manufacturer should be of interest to everyone involved in welding work.

The company's experience begins to accumulate in 1993, when for the first time the electrical equipment market was replenished with devices bearing the Resanta brand. Initially, all production facilities were localized in the city of Riga. The newly formed enterprise was engaged in the production of voltage stabilizers. After analysts recorded an increase in demand, the company decided to expand, not only in terms of product range, but also geographically.

Resanta entered the Russian market in 2003. Almost immediately the company established itself as a responsible and customer-oriented supplier. The quality of Resanta products meets all modern standards. Production technologies do not stand still. Developers are constantly introducing advanced technologies to make the equipment competitive.

Multi-level quality control accompanies the entire production cycle. Attracting new customers is facilitated by well-functioning work with potential and actual customers. First of all, consumers note the high level of support service. In addition, a network of representative offices has been opened in Russia to provide service and repair of welding machines.

The inverter principle of voltage conversion is that the entire process consists of two time periods. During the first period, alternating current becomes constant through transformations, and in the second period, alternating current is again obtained, but with an increased frequency. For welding in MMA mode, coated electrodes are needed. Absolutely all models are considered compact, which allows them to be transported or used for high-altitude work.

Welding masks Resanta

It is impossible to work with welding without a welder's mask - you will immediately get a retinal burn, which is called a “bunny burn.” Light filters protect the eyes from damage from infrared and ultraviolet radiation. Protect the body of the mask from flying splashes and scale. Both must be reliable and provide maximum protection.

Resanta welding helmet: MS-1, MS-2, MS-3 and MS-4

Resanta produces several types of welding helmets:

- MS-1 - with an automatic light filter based on liquid crystals TSK-3201. There are two modes: welding and grinding, a dimming regulator, which allow you to use the mask both for welding and as a protective shield when working with an angle grinder or other similar tools. Price 1500-1800 rubles.

- MS-2 - with TCK-4000 filter. There are three adjustments: degree of dimming, sensitivity, delay time (how quickly it responds when the brightness of the light changes). Step change in darkening. Price 1900-2100 rubles.

- MS-3 - TCK-3202 filter, the adjustments are the same as in MS-2, but the change in transparency of the filter is smooth. Also, the adjustment range for Resant MS-3 is 9-13DIN, while for Resant MS-2 it is 10-12DIN. Price 2600-2800 rubles.

- MS-4 is the cheapest (price 1200-1400 rubles) and the simplest mask. Light filter TSK-2101. It works only at positive temperatures, even with a slight decrease it begins to “slow down”.

All main technical characteristics of Resanta MS welder masks are given in the table.

Technical characteristics of masks

And a video review of the Resanta MS-1 welding mask.

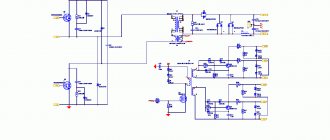

Several welding inverter circuits:

Diagram of the Resanta SAI 220PN inverter welding machine

Diagram of the Resanta SAI 160 inverter welding machine

Diagram of the Resanta SAI 220 inverter welding machine

Model categories

All welding equipment from the Resanta company can be divided into several groups, the main of which, naturally, are welding machines. However, the number of device modifications is quite large, and therefore is divided into separate categories that combine models according to the main technical parameter.

- Resanta SAI PA. This group includes those operating in semi-automatic mode. The semi-automatic machine implies the presence of a mechanism for drawing the wire, and the delivery set also includes a control valve for changing the gas supply speed. All control is carried out from a single panel.

- SAI inverter. In fact, this category should have opened the line, since these were the inverters that the company initially produced. They were designed to operate in MMA mode using piece electrodes.

- Resanta SAI PN. Model adapted for operation at reduced voltage. It is often called simplified, since it is designed for household needs and is relatively inexpensive. The minimum supply voltage threshold is 140 V.

- Model range of SAI AD. Designed to work in TIG mode, that is, argon arc welding.

- Resanta SAI PROF. It is considered a professional device, as it provides for adjustment of the welding arc. Even more adapted to low voltage. Used in congested networks.

- Model SAI K. The index “K” denotes a feature characteristic of the entire line - compactness. Welding machines are highly mobile and are used in confined spaces and during high-altitude work.

How is power supplied to the equipment?

One of the reasons for the high popularity of Resanta brand inverters as equipment for the home workshop is that they successfully operate from a conventional electrical network with a voltage of 220 V. Some models, which is especially convenient for performing work in places where there is no centralized power supply, can operate from autonomous sources of electric current - gasoline or diesel generators.

It is very important that the electrical outlet to which the Resanta inverters are connected is grounded, since they comply with protection class IP 21.

So that when the inverter is operating, the machine installed in the electrical panel does not turn off the power supply, it must withstand a current of at least 16 A (when welding at a current of 190 A).

To connect the welding inverter, you need to make a dedicated power line

Features of choosing a model

When you decide to purchase a suitable and functional welding machine, you need to make the right choice. First of all, having given preference to the Resanta brand, you should know that real owners consider the devices of this company to be quite successful, which have many advantages and are not without their disadvantages.

Expert opinion

Bagrov Viktor Sergeevich

Welder of the highest 6th category. He is considered a master of his craft, knows the intricacies and nuances of the profession.

It is traditionally believed that Resanta devices are more suitable not for industrial use, but for home use.

Professionals note that the devices of this company are very convenient, but during prolonged use they often suffer from unexpected breakdowns. Of course, the work may be different, and here you should not blindly blame the manufacturer. This is why there is a stereotype about inverters as amateur models.

The duty cycle of all devices is 70%. This indicator indicates the time of direct welding out of the total amount of time the device was turned on. It should be noted that the figure is not the lowest, given the low cost.

It is recommended for domestic use to pay attention to models of the SAI or SAI PN series. The Resanta SAI model is powered from a household network and can withstand small voltage fluctuations. According to the passport data, the device operates stably in the voltage range from 154 volts to 242 volts. If you really look at things, then at a voltage below 190 V some problems arise, the electrode sticks. The only way out of this situation is to switch to electrodes of a smaller diameter.

For those living in rural areas, voltage drop is one of the main problems of power supply. It also happens that the voltage drops below 190 V. In this case, you should choose one of the models of the AIS PN series, which will allow you to work even at 140 V.

If you need to have standard operating parameters with reduced dimensions, then a model of the “Compact” category is suitable. Let us remind you that the letter “K” will appear in the model name. The weight of such a welding machine is reduced by 1.5 times compared to similar models. The remaining categories are positioned as professional; they have additional functions that may not be useful in everyday life. And high power levels of welding current are of no use to novice amateurs.

Having decided on the category, you need to select a modification of the welding machine. The determining factor here will be the maximum value of the welding current. It is convenient to identify it by just one name. The value of the maximum current in amperes is written as an index after the abbreviation AIS. For example, SAI-160 is designed for a maximum current of 160 amperes.

The power of the device should be selected depending on the intended types of work. What matters is the thickness of the metal or the diameter of the suitable electrodes. 160 A inverters are suitable for welding with electrodes with a diameter of 3 mm. You can choose a model with a certain power reserve, otherwise the device will work according to marginal parameters, however, such a step may cost some money, because, in fact, the cost depends on the power.

The Resanta SAI-220 or SAI-250 models, as the name suggests, are considered more powerful. Indeed, the maximum current in them reaches 220 and 250 amperes, respectively. With such devices you can weld with five or six millimeter electrodes. Each device is supplied with a technical data sheet. All characteristics are included in it. Before choosing, you need to pay attention to the type of network, type of welding, additional functions, maximum current and power.

Technical characteristics of welding inverters Resanta SAI and SAI PN, SAI K

| Welding inverter model | Maximum current consumption, A | Open circuit voltage, V | Arc voltage, V | Maximum electrode diameter, mm | Weight, kg | Price |

| SAI-140 | 20 | 75 | 25 | 3,2 | 4,3 | 110 $ |

| SAI-160 | 22 | 80 | 26 | 4 | 4,5 | 120 $ |

| SAI-190 | 25 | 80 | 27 | 5 | 4,7 | 155$ |

| SAI-220 | 30 | 80 | 28 | 5 | 5 | 180$ |

| SAI-250 | 35 | 80 | 29 | 6 | 5,2 | 220$ |

| SAI-60PN | 22 | 80 | 26 | 4 | 5,7 | 170$ |

| SAI-220PN | 25 | 80 | 27 | 5 | 6,4 | 200$ |

| SAI-250PN | 35 | 80 | 29 | 6 | 7,7 | 250$ |

| SAI-160K | 28,5 | 85 | 4 | 3,4 | 130$ | |

| SAI-190K | 32,5 | 80 | 5 | 4,3 | 155$ | |

| SAI-220K | 36,5 | 80 | 5 | 4,5 | 180$ | |

| SAI-250K | 42,5 | 80 | 6 | 4,6 | 210$ |

Reviews

To be honest, there are reviews, both positive and negative. Each user emphasizes the relatively inexpensive cost of the device, the availability of additional functions and compactness. However, many complain about the frequency of breakdowns. This is especially true for models released after 2012. Everyone noticed that the quality of the products had dropped significantly, although the price had also dropped.

In repair shops, experts give their verdict. Most breakdowns are due to non-compliance with operating rules. It clearly states that you cannot keep the device next to a working grinder, sharpening or grinding machine. If dust gets inside the housing, the device may burn. It is also not adapted to humid environments. Do not cover the housing, thereby impeding air circulation.

Those who are lucky consider Resanta brand equipment to be quite good, provided that the conditions and basic operating requirements are met.

Operation of Resanta welding inverters

In the operating instructions for these welding machines, the requirements and recommendations are as follows:

- Do not use a grinder, electric saws, grinders or other tools near the unit that generate a large amount of dust when working.

- Do not cover the case during operation: forced cooling using coolers (fans). If you close the air flow, the device will overheat and may burn out.

- Do not work in damp areas or in the rain.

- If you bring the inverter into a warm room from frost, you must wait at least two hours until the condensation dries.

Switching order

Before turning on the device, check that the switch is in the off position. Connect the power cable and workers, plug it into the outlet. Set the minimum welding current on the regulator, then press the “on” button. Shutting down is carried out like this: first turn it to minimum, then turn it off with the toggle switch, and then from the network. If the work is finished, disconnect the wires and put them back in place.

When unrolling cables or using an extension cord, make sure that all wires are fully unrolled and do not intersect. Do not leave cables spooled; this creates an inductor that will negatively affect the equipment.

Practical recommendations

Resanta SAI inverters have overheating protection. It automatically turns off the device when the temperature approaches critical. But it’s better not to let it turn off. Work in intermittent mode: cook for 7 minutes, let the unit cool for 3-5 minutes. There is no need to turn it off during these intervals.

There is no need to turn off the power when switching off due to overheating. Just wait 5-7 minutes. Do not turn it off even if you have a short break in your work: the less often you turn on the equipment, the longer it will last. Inrush currents, although there is a “soft start” function, have a bad effect on this type of equipment. Therefore, turn off the inverter only if the break is more than an hour.

If you want Resanta SAI to work normally, periodically clean the insides of dust. Especially if you worked close to a source of dust or after a long period of inactivity.

You need to cook stainless steel with Resanta using reverse polarity.

If you are going to lengthen the working cables, increase their diameter, the voltage will drop less. If you place it at 10 meters, the cross-section is preferably 25mm2.