Resanta - 220 inverter repair.

Resanta - 220.

Repair of welding inverters

» data-medium-file=»https://i2.wp.com/trigenn.ru/wp-content/uploads/2016/07/RESANTA_220-e1469014105559.jpg?fit=291%2C300&ssl=1″ data-large- file=”https://i2.wp.com/trigenn.ru/wp-content/uploads/2016/07/RESANTA_220-e1469014105559.jpg?fit=993%2C1024&ssl=1″ >We received a welding inverter for service Resanta - 220. The device did not turn on. We open the body of the device and look through it. We check the input transistors using the high control circuit, we also check the diodes, resistances, and capacitors connected to this circuit. In our case, the device, in the power circuit, turned out to be all right. Let's go further, go to the control circuit of the board, and also check all the details. In order, and so on, I get to diode D03, which was open, and capacitor C06 showed a capacitance leak. After replacing the above parts. We connected the device to the connectors, plug it into the network and check that the device is working.

Safety measures during repairs of electrical household equipment.

For any type of work, it is mandatory to have a head biret cap, glasses, gloves, and special clothing. These special attributes will protect you from any particles, metal shavings, dried varnish, solvent, pieces of plastic, dried paint, etc. Contact with the head, eyes, face, body skin. When unwinding various types of household welding machines, cases, boards, chassis, radiators, plastic strips. Any particle can break off and end up in the lines listed above. Well, the most important thing is a good mood, endurance and desire to do this type of work. In service workshops or at home, you should have everything you need available. Tools and devices, a set of screwdrivers of various configurations, wire cutters, pliers, special clamps, tweezers, etc. A soldering station and a soldering gun are an essential tool for the job, as in today's devices. Most electrical boards are assembled on SMD parts, where they cannot be soldered with a simple soldering iron, and are too small in size.

A multimeter is also a very necessary device, for these purposes, measuring voltage, resistance, checking transistors, diodes, capacitors, LEDs, transformers, switches. An oscilloscope is also an important device when repairing household appliances. With this device you can achieve good characteristics and parameters in household and welding equipment. A desktop magnifier is a very necessary and important tool for specific work purposes. Today's manufacturers produce very small radio components that cannot be done without this tool. Further

Reading time: 4 minutes

The Resanta welding machine model SAI-220 is very popular among beginners and practicing welders. The technical characteristics are sufficient for full-fledged study and simple repairs at the dacha. The manufacturer positions this device as a household device, and therefore you should not expect miracles from it. But for simple tasks this inverter is more than suitable.

In this article we will tell you in great detail everything you need to know about SAI-220. You will also see the diagram of the Resanta SAI 220 welding inverter. And it will definitely be useful to you if you decide to carry out minor repairs or assemble a similar device with your own hands.

Read also: How to properly install a vice on a workbench

general information

Resanta SAI-220 is a portable welding inverter designed for manual arc welding with coated electrodes. To operate it, it is enough to have a socket and a 220V household power supply. When welding, you can use electrodes with a diameter of up to 5 millimeters. The maximum welding current is 220 Amperes, which is enough for students and summer residents. The open circuit voltage is 85V. The arc ignites without any problems, so you can weld all types of metals.

The equipment in SAI-220 is standard. There are two cables with a holder and a terminal, the cables themselves are 2 meters long each. Also in the box you will find a power cable, its length is 170 cm. We believe that this is clearly not enough to perform some work. So use an extension cord.

There is nothing else in the box. If necessary, you can buy a model with a convenient case, and also purchase a welding mask and other personal protective equipment separately.

The device is equipped with additional functions “anti-stick” and “hot start”. Now even the cheapest inverters have these functions, so they won’t surprise you. But one cannot fail to note the presence of such functionality in SAI-220. After all, the “anti-stick” and “hot start” functions will especially appeal to those who are just starting to learn the basics of welding. They simplify and speed up your work.

Main malfunctions of the unit and their diagnostics

As already mentioned, inverters fail due to the impact of external factors on the “vital” units of the device. Also, malfunctions of the welding inverter can occur due to improper operation of the equipment or errors in its settings. The most common malfunctions or interruptions in the operation of inverters are:

The device does not turn on

Very often this breakdown is caused by a faulty network cable of the device. Therefore, you first need to remove the casing from the unit and ring each cable wire with a tester. But if everything is in order with the cable, then more serious diagnostics of the inverter will be required. Perhaps the problem lies in the standby power supply of the device. The method of repairing the “duty room” using the example of a Resanta brand inverter is shown in this video.

Welding arc instability or metal spattering

This malfunction may be caused by incorrect current setting for a certain electrode diameter.

Advice! If there are no recommended current values on the packaging for the electrodes, then it can be calculated using the following formula: for each millimeter of equipment there should be a welding current in the range of 20-40 A.

Welding speed should also be taken into account. The smaller it is, the lower the current value must be set on the control panel of the unit. In addition, to ensure that the current strength corresponds to the diameter of the additive, you can use the table below.

Welding current is not adjustable

If the welding current is not regulated, the cause may be a breakdown of the regulator or a violation of the contacts of the wires connected to it. It is necessary to remove the unit casing and check the reliability of the conductor connections, and, if necessary, test the regulator with a multimeter. If everything is in order with it, then this breakdown can be caused by a short circuit in the inductor or a malfunction of the secondary transformer, which will need to be checked with a multimeter. If a malfunction is detected in these modules, they must be replaced or rewound by a specialist.

High power consumption

Excessive power consumption, even if the device is without load, most often causes an interturn short circuit in one of the transformers. In this case, you will not be able to repair them yourself. You need to take the transformer to a mechanic to rewind it.

The electrode sticks to the metal

This happens if the network voltage drops. To get rid of the electrode sticking to the parts being welded, you will need to correctly select and configure the welding mode (according to the instructions for the device). Also, the voltage in the network may sags if the device is connected to an extension cord with a small wire cross-section (less than 2.5 mm2).

Often, a drop in voltage causing electrode sticking occurs when using a power extension cord that is too long. In this case, the problem is solved by connecting the inverter to the generator.

Overheat light on

If the indicator is on, this indicates overheating of the main modules of the unit. The device may also turn off spontaneously, which indicates that the thermal protection has tripped. To prevent these interruptions in the operation of the unit from occurring in the future, it is again necessary to adhere to the correct duty cycle (ST). For example, if duty cycle = 70%, then the device should operate in the following mode: after 7 minutes of operation, the unit will be given 3 minutes to cool down.

In fact, there can be quite a lot of different breakdowns and the reasons that cause them, and it’s difficult to list them all. Therefore, it is better to immediately understand what algorithm is used to diagnose a welding inverter in search of faults. You can learn how to diagnose the device by watching the following training video.

Advantages and disadvantages

The pros and cons of the Resanta SAI 220 device are the same as all other inverters in this price category. But let's start with the good.

The first thing you will like is that it works from a regular 220V household outlet. You don't need any special type of connection, just plug the plug into the socket and you're good to go. The main thing is that your household electrical networks operate without strong power fluctuations.

Another plus is the use of modern IGBT-type transistors in the design of this device. Thanks to them, it was possible to introduce additional functions and reduce the dimensions of the SAI-200. You can hang the inverter on your shoulder using the included strap and conveniently transport it or cook it in hard-to-reach places.

Additional features are another big plus. The device is protected from overheating and is equipped with anti-stick and hot start functions. They simplify your work and make welding more productive.

In general, the device is well built. The case is durable, made of metal. And to use this inverter, it is enough to have basic theoretical knowledge. It’s not for nothing that this model is often used specifically for studying. It is easy to use, all adjustments are intuitive.

Now about the disadvantages. First of all, devices like SAI-220 are not recommended for professional welding work. Of course, a master of his craft can make decent seams with a Chinese inverter for 2,000 rubles, but a home craftsman or a practicing student is unlikely to have the same skills.

So, if you want to develop your welding skills, look towards more powerful and technologically advanced welding machines. They will give you more opportunities and unlock your potential.

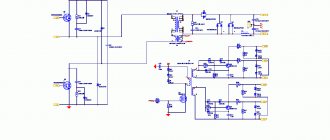

Scheme

Beginners may think that we only need one diagram of the Resanta 220 inverter welding machine from the SAI line. But it is not so. Below we have placed four diagrams at once that will help you perform simple repairs or construct a similar inverter with your own hands.

Read also: How to choose a compressor for a sandblasting machine

№1

№2

№3

№4

We do not recommend performing soldering work unless you have sufficient experience and at least basic knowledge of electrical engineering.

Each electrical diagram is available in high resolution, just open the images in new tabs.

How does an inverter work?

Below is a diagram that clearly shows the principle of operation of a welding inverter.

So, the operating principle of this welding machine module is as follows. The primary rectifier of the inverter receives voltage from the household electrical network or from generators, gasoline or diesel. The incoming current is alternating, but when passing through the diode block it becomes constant. The rectified current is supplied to the inverter, where it is converted back into alternating current, but with changed frequency characteristics, that is, it becomes high-frequency. Next, the high-frequency voltage is lowered by a transformer to 60-70 V with a simultaneous increase in current. At the next stage, the current again enters the rectifier, where it is converted into direct current, after which it is supplied to the output terminals of the unit. All current conversions are controlled by a microprocessor control unit.