The question of how to cut metal tiles is quite acute for an inexperienced amateur builder. Doing this using conventional tools is not very convenient, due to the fact that the metal sheets of this material are not smooth, but wavy.

Therefore, a jigsaw, in the absence of skill, often breaks files and tears tiles, and when working with ordinary hand metal shears, after a couple of hours you will regret that you chose this material for your own metal roofing.

Why you can’t cut metal tiles with a grinder

Therefore, cutting of metal tiles is often carried out with a “grinder” - an electromechanical angle grinder with an installed abrasive disc.

It easily passes through sheet profiles and gets the job done quickly. However, this solution to the problem has a significant negative side.

Note!

All manufacturing companies in their instructions for installing the material always mention how to cut metal tiles.

It is said that cutting it with an angle grinder using an abrasive disc is strictly prohibited.

Moreover, the warranty for the material in this case is automatically canceled.

The fact is that such a roof covering with metal tiles will begin to leak after a year or two from premature rust in those areas where the grinder has destroyed the protective coating.

The structure of all types of metal tiles is not fundamentally different and is a layer cake. In its middle there is a thin sheet of steel with a protective coating of zinc.

Layers of polymer and paint are applied on top of the tiles, and the back side is also painted.

If an abrasive disc is used to cut metal tiles, its temperature increases significantly, the properties of the steel itself change, and the zinc coating also melts.

But the layer of protective polymer undergoes the most significant damage. Plastisol, polyester, pural, used for this, are not resistant to such high temperatures.

When working with an abrasive disc, the roofing material receives defects not only in the cut area, but also where the sparks fly.

This leads to the formation of primary corrosion centers, which then spread to large areas of the coating. The result is premature destruction of the metal roof.

Now that we have answered the question in the negative whether it is possible to cut metal tiles with a grinder, let’s find out what should be used to do this.

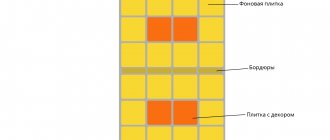

Methods for preparing the base

Putting the excursions aside, let's consider the methods and technologies of finishing. One of the attractive ways to decorate a room, making its design unique, is to apply decorative plaster to the walls. The following options are available:

- Textured;

- Mineral;

- Venetian;

- Structural, called “bark beetle”.

Decorative plaster in interior design

Decorative plaster, with all its advantages, also has one drawback, common to all types. Apply it to a prepared, flat and smooth surface. The walls are brought to a suitable state in several ways:

- Ordinary plaster;

- Cement, gypsum or acrylic putty;

- Drywall.

Ordinary plaster is one of the main ways to level walls. This is explained by the low cost of the constituent materials - cement, sand, lime, and the relative ease of application. But the disadvantages of this type of finishing are also revealed. Is it worth lifting several tons of sand and cement to the 12th floor if the problems of uneven walls are solved differently?

So how can you cut it?

Note! The ideal option is to order all cutting from the material manufacturer, according to exact roofing drawings. The second optimal solution is to choose the size of the tiles so that they do not have to be cut.

- You can also use a jigsaw to cut metal tiles.

When this is not possible, you can use electric sheet metal nibblers. It can be either a separate tool or made in the form of an attachment to an ordinary drill.

- An acceptable alternative to electric ones is manual roofing shears.

- A circular electric saw with a carbide blade with a reverse angle and a fine pitch is also suitable.

- How to cut metal tiles

? This can be done either with a hand hacksaw or with a jigsaw with special files. It should be said that the disadvantage of a hacksaw for metal, when cutting such material with it, is that it, without any problems making even cuts in a straight line, cannot be used for curved cutting of profiled sheets. In addition, to cut metal tiles with this tool you need to equip a special workbench. - You can also use a hand-held circular saw with a cutting wheel for aluminum. Such discs for cutting metal tiles are extremely reliable - one is enough for ten roofs. They cut cold, so the protective polymer coating on the tiles does not fade or collapse.

- When there is no alternative to a grinder and an abrasive disc, and you still cannot take advantage of the manufacturer’s warranty, then it is necessary to at least protect the material from sparks. They are the main evil, since there are many of them, and you can’t keep track of where they fall.

Advice! And one last thing.

Whatever tool you use for cutting metal tiles, be sure to tint the edges of the material that are left without protection with façade paint, or lay them so that they go under the top sheets of the covering.

Instructions for installing a metal tile roof with your own hands.

Preparatory work.

A metal roof begins with measurements and calculations. Since the process of manufacturing metal tiles involves pressing them out of a very long sheet of metal rolled into a drum, it is possible to produce sheets of metal tiles as long as the length of the roof slope. Sometimes, with a particularly long slope, it is necessary to divide these large sheets (the entire length of the slope) into several smaller sheets. This is due to the complexity of installation and transportation of especially long sheets.

Initial estimates are made based on the project drawings. However, immediately before ordering, it is necessary to measure the size of the structure itself. The length is taken equal to the length of the roof slope. By the way, during installation, the sheet of metal tile is allowed 40mm above the eaves so that a ventilation hole is formed on the ridge. When cutting sheets lengthwise into several parts, their length must be increased by the size of the overlap, one transverse wave, in most cases this distance is about 250 mm.

The width is calculated according to the multiple of the useful width of the sheet relative to the width of the roof slope. The easiest way to do it is with simple rectangular slopes. However, even in this situation, each slope is in any case measured and calculated separately.

When calculating, the profile of the cornice should form a transverse pattern in the form of a single line, and with different lengths of sheets, their pitch should be a multiple of the pitch of the transverse wave.

If it is necessary to trim sheets at the installation site, metal tiles can only be cut with a special tool or metal scissors. The use of abrasive cutting discs is prohibited.

In addition, after the cut, it is necessary to thoroughly clean the surface of metal shavings, otherwise they will rust and ruin the appearance of the roof. By the way, the rule of removing chips applies not only to cutting sheets; do not forget to carry out this procedure after drilling them when fastening them.

In addition to removing excess debris from the sheets, remember not to step on them unnecessarily. However, if this is necessary, then you should move in soft shoes and only in those places where the sheathing passes, carefully stepping into the bend of the wave.

Before installing the sheets themselves, you will initially need to attach the end strip and cornice using galvanized nails.

And if there is an internal joint in the roof structure, then (in the place of this joint) a special strip for the valley is attached.

Metal roofing installation technology.

- The installation of sheets begins directly: with a gable roof - from the end, with a hip roof - from the highest point of the slope. The wave of each subsequent sheet should overlap the wave of the previous one.

- Sheets can be mounted both from left to right and in the opposite direction, but it is still necessary to observe the order of overlap of the sheets.

- To achieve straightness of the cornice line, at the very beginning it is necessary to fasten several sheets together without attaching them to the sheathing. Then, having secured them with one screw at the top, we once again level the bottom and fasten them to the sheathing. Self-tapping screws with a sealing washer are screwed into the profile deflection under the transverse wave. For one square meter of area you need to use 8 screws.

- After completing the installation of metal profile sheets to the sheathing, you will have to attach the wind and ridge strip. The latter is attached with a sealant lining under it.

- Well, and finally, snow retention strips are attached at a distance of 350 mm from the roof eaves. The upper part of the snow-retaining strip is attached with long self-tapping screws through to the sheathing, along every second wave. The lower edge is attached with regular-sized self-tapping screws only to sheets of metal profiles, again along every second wave.

- Installation of such through elements as roof windows and fire hatches must be installed in accordance with the instructions attached to them, but in any case, all joints when through elements pass through the roofs must be reliably sealed.

In conclusion, I would like to note that installing a metal tile roof with your own hands is not such a difficult undertaking as it seems at first glance. It is better to carry out the installation yourself than to entrust this task to visiting hackers.

Happy installation!

Working with die-cut scissors

Since the tile profile can have turns of up to 90º, it is quite difficult to cut it with ordinary sheet metal shears. Hence the conclusion - it is better to use die-cut scissors.

Manual nibblers

If you are interested in how metal tiles are cut, you will find out that they will not heat the metal; in addition, they are convenient for making curved cutting.

The tool is small and has handles that are comfortable for cutting. At the same time, they pass all turns without problems, regardless of their bend.

It should be noted that the maneuverability of nibblers depends mainly on the length of the die holder.

The longer it is, the more convenient it is to work with the tool. This element can be rotated. With its help, you can turn the handle both perpendicular to the cut and along it. The angle of inclination of the handle itself is also adjustable, thanks to this it is possible to avoid resting on the profile being cut.

This tool does not create burrs, and working with it takes no more time than cutting with an electric saw.

Note!

Before cutting metal tiles, keep in mind that this must be done sequentially, moving from one sheet to the next.

At the same time, do not forget to protect other tile sheets and additional elements from getting chips on them.

Watering and feeding dahlias in autumn

When it comes to watering, the gardener has to act against nature.

The plant, preparing for winter, strives to stock up on moisture, accumulating it in the internodes located in close proximity to the roots. Thanks to this, the tubers will not dry out and active growth will be possible in the spring. However, if there is too much water, it will cause waterlogging of the root collar and rotting of the tubers. To prevent this from happening, watering is stopped two or at least one week before digging up the plants. If it rains more often, the flowerbed with dahlias is covered with a moisture-proof film so that as little water as possible gets to both the plant itself and the soil.

As for fertilizing, restrictions are introduced here too. When preparing plants for dormancy, the last time fertilizers (potassium and phosphorus) are applied no later than August 20. Dilute 1 tsp into 10 liters of water. potassium sulfate and superphosphate and spend an average of 2–3 liters of solution on each bush.

Electric metal shears

Nibblers

There are three types of electric tin snips.

- Die-cut. With this tool you can cut both profiled sheets: corrugated sheets and metal tiles, as well as those welded from several elements, for example, pipes or ventilation ducts. The operating principle of the device is based on cutting out a small piece of material with each punch stroke. You can start using the cutting shears either from the edge or from the middle of the workpiece, but in the latter case you will need to drill a hole with a drill to start cutting.

- Electric knife shears for cutting metal tiles . Their cutting element is two single-edged knives. One of them is movable, the other is stationary, and a metal sheet is placed between them. When working with such a tool, there is absolutely no waste left. The disadvantages of these electromechanical sheet shears are the inability to make sharp turns, and they can only cut from an open edge.

- Slotted shears for cutting metal tiles

. This tool can easily handle both non-ferrous and ferrous sheet metal, and various coatings of the material will not interfere with them. Thanks to the open-type cutting head, slotted electric scissors produce precise and neat cuts, and there is no distortion of the material. The advantage of such a device is its convenience when it comes to shape cutting. In this case, the processed sheet is not subject to deformation. In addition, the resulting chips do not get inside and can be easily removed from the work area. Initially, slotted electromechanical shears were intended for the installation of ventilation systems, but then professional roofers began to use them when assembling metal roof coverings. It is worth noting that if your primary goal is high quality cutting, then slotted scissors are the best tool.

Main types of scissors

For cutting sheets of metal tiles, different types of scissors can be selected. Each type has its own characteristics, structure and principle of operation. The main varieties include:

- Nibblers for metal tiles. They are universal products, as they can be used to produce both high-quality, even cuts and beautiful curly ones. The length of the matrix holder in such a tool can be different, and this parameter determines how maneuverable the scissors will be. They have a simple principle of operation, since a punch moves in them, and each of its moves is accompanied by the fact that a small piece is cut out on the sheet. They can be used not only when working with metal tiles, but also when cutting welded products, pipes or corrugated sheets.

- Knife. These scissors are equipped with 2 knives with one blade. It is between them that a sheet of material must be placed. One of these knives is constantly moving, while the other remains in a stationary position, so no waste is guaranteed. The disadvantages of using this type of scissors is that it is impossible to make round cuts, so it is allowed to start working only from a certain edge of the sheet.

- Splined. These metal cutting shears are equipped with a special open cutting head, which guarantees the ability to work with the thickest and most durable sheets. This ensures a truly high quality cut, with no distortions or irregularities.

Important! The most popular are nibblers and standard electric shears.

Classification of electric scissors

- Sheet (cut) - perform straight and curved cuts in sheet material. Depending on the model, steel and aluminum sheets with a thickness of 1.6-4.5 mm can be processed. The lower knife is stationary, fixed on a bracket, the upper one is on a cutting device that moves up and down. Square knives are secured with screws. They can be turned when the working side becomes dull. Knives are consumables. When cutting, no chips are formed, the edges of the material are smooth, and do not require additional processing. Depending on the thickness of the material, it is necessary to adjust the distance between the knives.

- Splined - make cuts of any configuration in sheet material. Advantage: the ability to work with closed, previously installed structures, cutting air ducts, profiles of any type. The resulting chips are cut off with built-in cutters. Material thickness up to 1-1.6 mm. The cutting system consists of a lower support blade and an upper cutting pair of knives. They are selected and installed according to the type of work: for straight or curved cuts, for cutting particularly strong steel.

- Die-cutting (nibblers) - cut out sheet metal of any shape: wavy, corrugated. Suitable for pipes and profiles. Allows you to make straight or curved cuts, including at an acute angle, in hard-to-reach places. The maximum thickness of the material is 1.6-3.5 mm. The metal is cut out when the upper element, the punch, hits the matrix located below. Both items are consumables. During operation, chips are formed.

- Reinforcing - electric are designed for cutting reinforcing bars, used in construction. The rod is installed between two knives, which are compressed under the action of a hydraulic system.

Sheet, slotted or die-cut

Structurally, the cutting part of electric scissors is a mechanism of one of three types.

Reinforcement

Already from the name it becomes clear that these are the only scissors that are designed exclusively for working with reinforcement. They are capable of cutting studs, corrugated or smooth reinforcement, and wire rod up to 20 mm thick.

Details

Questions

Is it possible to cut metal tiles with an angle grinder?

Manufacturers do not recommend cutting metal tiles using an angle grinder (grinder). Such actions can provoke the formation on sheets of:

You can cut metal tiles with a grinder, but when laying them on the roof, you should not do this - the task is too dangerous. Moreover, as a result of the work, metal filings fly off, which remain on the surface of the profiled sheet and after a while they begin to rust and spoil the appearance of the roof. If, when cutting with a grinder, the waterproofing layer is damaged, then all the moisture will begin to get inside the roof, to the sheathing, and this will lead to damage and corrosion.

Helpful advice! If you need to cut metal tiles with a grinder, then it is important to add another 1-2 cm to the specified size, so that you can then trim it with special metal scissors. The process is labor-intensive but effective.

How to cut metal tiles?

When choosing tools for cutting sheet metal tiles, it is important to approach them responsibly, since otherwise noticeable chips will form, which will become the main reason for the loss of stability of the roofing system to aggressive environmental factors. Cutting metal tiles to size must be done taking into account the preservation of the protective sheet layer.

Among the suitable tools for cutting galvanized profiled sheets, we highlight:

Each method has its own nuances

Electric scissors for cutting metal tiles

When installing metal type sheet tiles, electric scissors are an indispensable tool. They make it possible to cut sheets with maximum precision, with a perfect and even cut. These metal tile scissors have certain positive qualities:

There are three types of electric shears for metal tiles:

Please note that cutting metal tiles with die-cut shears is equivalent to the speed of an angle grinder, but does not heat the corrugated material. Such a tool can make turns even 90 degrees and does not leave burrs on the edges.

Hand scissors

Mechanical scissors for working with metal sheet tiles have proven themselves as a hand-held and mobile universal tool. It is presented on the market in three types:

Taking into account the fact that the cutting process for sheets of metal tiles with hand scissors is quite labor-intensive, it would be more expedient to use them only for curved cutting. To achieve a perfectly even cut, it is recommended to leave a small gap of 0.1-0.2 cm between the ends of the tools when compressing the blades, and they should not fully converge. It turns out that the movements seem unfinished. This simple technique will prevent the formation of hangnails.

Circular saw

If you think about how to cut metal tiles, then such an electric tool is highly efficient and versatile, and it is also suitable for working on wood, plastic and metal. Cutting metal tiles with circular saws has many advantages:

When using electric tools, you should not make only curved cuts or work at heights, because there is a risk of injury. The blade for cutting metal tiles for a circular saw should be made of carbide type materials and teeth curved back. Only with this approach will it be possible to create smooth edges and prevent damage to the decorative layer.

Cutting with a jigsaw

This type of tool is distinguished by cutting speed and the ability to make curved and straight cuts, which is effective and convenient when arranging a roof made of metal tiles. Due to the presence of lighting and a specialized blowing device, the polymer layer on sheet-type tiles will not be damaged. But for an even cut, it is important to fix the profiled sheet well so that it does not deviate from one side to the other. To cut metal tiles, you only need to buy a file with a wavy pattern and small teeth. It is important to work with an electric jigsaw at a slow pace, otherwise the sheets will begin to bend and the protective coating will be damaged.

Cricket for cutting tiles

The use of a special drill attachment for cutting sheet metal tiles is extremely popular. It makes it possible to quickly cut roofing wave material. Especially this adaptation of their punch and matrix shows its effectiveness when cutting a round hole. After switching on, the punch will be brought into working condition and will make strips in the sheet from above. This requires experience, and it is recommended to practice in advance using the remaining material. The width of the cut will be 0.3 cm, which is important to take into account when cutting the material. You can also use this nozzle to cut stainless steel (0.8 mm thick), galvanized steel, copper, iron and brass (up to 1.5 mm thick), aluminum (up to 0.2 cm thick). In general, the operating principle of the device is very similar to the operation of electric scissors.

How to cut roof tiles correctly

The technology for cutting sheets of roofing material involves performing the following actions:

In addition to an angle grinder, you can use this pattern to cut sheets with other suitable tools.

Features of cutting metal tiles

When cutting metal tiles, the protective layer should not melt.

Metal tiles include several layers:

- base – sheet of steel;

- protective layer of zinc - thickness varies depending on the type of material;

- passivating layers and primers - improve adhesion, protect against moisture;

- decorative coating - creates color, sometimes a pattern. The thickness of the coating varies greatly.

The main strength component is metal, but the tool must be selected taking into account other factors. While metal easily tolerates high heat, the same cannot be said about other layers of the composition.

General information

pros

Among the advantages of profiled steel sheets are:

Taking into account the presence of a figured relief, cutting of the material is carried out in compliance with certain rules. There are several methods for cutting metal tiles when laying them so as not to damage them. This question is extremely relevant when covering roofs of complex shapes, as well as when designing junctions with pipes and designing internal corners.

Features of cutting metal tiles

If you use abrasive devices, you can see the following negative phenomena:

Please note that only cold methods are effective for processing or cutting metal tile sheets. The ideal option would be to order the roofing material already cut, since after using abrasive tools the manufacturer’s warranty will no longer be valid.

If you follow the main tips regarding cutting and installing a roof made of metal tile sheets, it not only looks beautiful, but is also durable and reliable. Galvanized profiled sheets can last for almost half a century, and only after 10-20 years do they need to be repaired, painted, or even replaced if necessary. They do not cause any difficulties during installation and are lightweight, which makes it possible to use them on a building with a weak foundation and insufficient load-bearing capacity of the rafter system. Roofing made of metal tile sheets is not damaged by deformation due to changes in temperature or high humidity. Moreover, such a roof can self-clean from snowdrifts.

Professional advice ↑

When choosing a working tool, it is advisable to be guided by the following recommendations:

- In cases where it is necessary to make a cut in the longitudinal direction, you can use a regular hacksaw or special scissors.

- If you need to cut contours in a shape, the most suitable tool is a circular electric saw with a special attachment for cutting.

- In any situation, it is undesirable to use an abrasive tool.

- When laying metal tiles, you should mark the coating material in such a way that the number of cuts is minimal.

In conclusion, let us once again draw attention to the fact that tiles with a metallized base are an especially durable and rigid roofing material. That’s why, before cutting metal tiles, you should definitely decide on the choice of a tool suitable for processing it.

Only after this will it be possible to begin laying a new or restoring previously damaged coating.

https://youtube.com/watch?v=rVlwpKjiIo4%3F

2021 stylekrov.ru

Finally

And yet, if you are not a professional roofer, then you won’t find a better option than a drill attachment . It can be an excellent help both on the roof and in everyday life. If you need to cut metal without squealing and fiery splashes, like from an angle grinder, please do so. In addition to the convenience of operation, the fact that you do not need to buy an expensive device is captivating. The attachments themselves are not that expensive and fit on any drill. For professional work with metal tiles, such attachments are rather weak, but for home use they are the best option.

Whatever you use to cut, it is better to treat the cut edges with paint , such as façade paint.