One of the most common types of wood and metal milling is the processing performed by a 3D CNC milling machine.. It can be both artistic, or as it is also called, figured, and rough, which is used mainly in construction and the construction of various structures that do not require special precision of parts.

Its main advantage over manual processing is, first of all, the accuracy and quality of the output part; other advantages include the minimal influence of the human factor on the process itself and, of course, a reduction in labor intensity by several times.

Design features of the machines

All machines with numerical control have a similar structure and operating principle, and differ only in the configuration, slightly in the shape of the body and parts. The principle of operation, as you already know, is simple: the milling head moves across the working field, cutting off layers of material and forms the finished product of the required shape.

For each material, the processing program is compiled individually. For example, if this is a 3D CNC milling machine for metal, then the feed and rotation speed of the cutter are selected based on the design features of the machine and the structure of the material being processed. If wood processing is done on a CNC machine, then the program parameters will be completely different.

The quality of the final product will directly depend on the quality of the program.

Structural elements of the machine and their influence on processing

- Tool (in this case, cutters). Serves directly for removing layers of material during work.

- Workpiece fixation system. Secures the part on the workbench. It can be either movable or immobile. Often, industrial machines have fixed vacuum tables. On cheaper options, metal clamps or clamps are installed.

- Servomotors and stepper motors. Designed to set machine elements in motion in accordance with a previously written program.

- CNC controller. Serves to control all machine components (motors, peripherals, protection system).

- Limit sensors. Designed to stop motors in case of program failure and initial positioning of the cutting tool.

As mentioned above, the milling speed directly depends on the selected material and the depth of its milling.

Varieties

The purpose of milling machines is to process parts with shaped and flat surfaces. The technological capabilities of this equipment are expanded due to the presence of such additions as:

- slotting, vertical or universal head;

- universal dividing apparatus;

- device for cutting combs;

- round dividing table.

Models of milling cutters differ in size and type of work performed. Their technical characteristics depend on the brand of the unit and the manufacturer.

Machining centers

CNC milling machining centers are complex devices that allow for the most accurate processing of large workpieces. They are widely used in the following industries:

- automobile;

- aerospace;

- instrument making;

- heavy engineering.

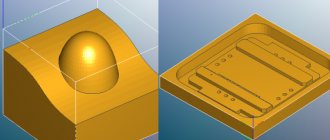

Such centers allow you to perform a large number of operations of various types: boring, drilling and milling. As a result, it is possible to process complex housing parts, molds and dies with a 3D surface. The equipment is divided into 2 types:

- vertical;

- horizontal.

All machines are equipped with special drives and high-quality elements that affect cutting speed and tool positioning accuracy.

Important!

The working body of the equipment (support) has the ability to move in all coordinate systems and rotate along an axis.

Turning and milling

Such 3D machines are widely used in furniture production and carpentry workshops. Using these devices, shaped balusters, structures with circular processing, etc. are made. Turning and milling equipment allows you to drill, cut or turn workpieces with 3D modeling capabilities. Thanks to its equipment with a program control system, it is possible to increase the accuracy of operations, obtaining a better result, and minimize production waste.

Milling and engraving

The support of this type of milling cutter is multi-position with the ability to automatically change tools. The device is installed on a frame, which is a frame with high rigidity. This design allows you to obtain parts without errors in shape and size. The productivity of milling and engraving machines is determined by the following factors:

- quick tool change;

- working feed speed;

- periodic cooling of electrical components in all operating modes.

Modern software used in the equipment makes it possible to control all processes with maximum accuracy and quickly create the necessary product models. Operating according to a given program, the machines produce 3D parts with any level of complexity and cross-section:

- rectangular;

- round;

- square.

These units are used to process the following materials:

- artificial stone;

- wood of any species;

- polystyrenes;

- soft non-ferrous metals;

- acrylic glass;

- composite materials.

Important!

When choosing such equipment, it is recommended to familiarize yourself in detail with its technical characteristics and compare them with the requirements relating to the manufacture of specific parts.

Application

The scope of application of 3D CNC routers is huge:

In fact, automatic machines can be used in almost any production. But they gained the greatest popularity in the souvenir business, since it is here that a lot of different products of different shapes, sizes and designs are constantly needed to be made. On a manual milling machine, such work is completely unproductive, since there is a human factor that significantly slows down the process.

Selecting cutters

As already mentioned, the main error in the process is introduced by the mechanical part of the machine, but only the working tool affects the final quality of the surface. In this case, a milling cutter.

It must be remembered that it is better to carry out processing in several stages (roughing-roughing-finishing) with different cutters and with a gradual decrease in the feed speed.

Types of CNC machines

Although the operating principle is similar for all machines of this type, their design may differ slightly. First of all, this is due to the purpose of a particular machine. Based on this, when choosing a 3D wood cutting machine, you need to carefully analyze it.

- The shape of the workpiece being processed is flat or three-dimensional. This factor affects how the milling head will be positioned and what movements it will make during operation. Also, when choosing a machine, you need to remember to take into account the required spindle power and the size of the working field.

- Type and maximum diameter of working tool. Home machines use cutters with a shank diameter of no more than 8 mm, while industrial machines use composite cutters with a complex design and replaceable knives, reaching a diameter of 120 mm or more.

- Availability of 4 axes. If you plan to three-dimensional milling of parts using the principle of a lathe, then you must immediately take this into account when purchasing. As a rule, most manufacturers install a rotary axis on their machines as an option.

- Number of simultaneously working milling heads (spindles). On industrial machines their number can reach 16 pieces! The rule is this: the more spindles, the faster the milling, but the more difficult it is to write a program.

In fact, the list of all the parameters that you need to pay attention to when purchasing is much longer. But the parameters given here are quite sufficient to navigate the market of automatic machines.

Among the varieties of milling, one can distinguish engraving, which is an insertion into the material to a small depth and the application of a certain pattern or design on it.

General structure and purpose

3D milling cutters are widely used in a wide variety of fields: they can be used in almost any production. In the souvenir business, these machines are most in demand, since it is here that products with a wide variety of configurations, designs and sizes are made. The equipment is also popular in the following areas:

- production of advertising products - engraving of brand logos, creation of complex and massive structures;

- furniture production – production of carved fragments, curved cutting of materials, precise fitting of each element;

- mechanical engineering – turning of parts for a wide variety of mechanisms.

3D milling machines are used even at home to make hobby products. All types of these devices have common principles of operation, however, they may differ from each other in design, which is due to the specialization of a particular model.

On wood

The purpose of this equipment is to create a three-dimensional pattern on the surface of the workpiece. To perform a specific task, the master needs a cutting part, a control unit and a working surface. The wood milling machine has a number of design features:

- the workpiece is secured using a special fixation device; it can remain motionless or move relative to the cutter;

- displacement of machine elements occurs using servo drives or stepper motors; such designs are distinguished by different positioning accuracy;

- The structure of 3D milling cutters contains a CNC block designed for the correct functioning of the motors, due to which the part or cutter is displaced.

The main elements of a wood cutting machine include:

- engines;

- portal;

- cutting tool alignment sensor;

- spindle and its cooling system;

- zero position sensors;

- work table with T-slots;

- false table, PVC foam;

- system unit and cables for connecting it to the machine.

Some models are equipped with sensors for the most accurate positioning and have a function for removing milling waste.

Important!

When choosing a 3D milling machine, it is recommended to pay attention to its power and what size parts it can work with.

For metal

Modern 3D CNC metal milling machines are controlled automatically using computer programs. This equipment is designed for processing metal workpieces in 3 planes with high precision. Models from different groups differ from each other in minor design features, while their main components on all types of units are absolutely the same. Each milling machine, first of all, has a stable base (bed), in which the spindle shaft and gearbox are placed.

A standard milling machine also includes in its structure:

- vertical guides of the frame - when the equipment is turned on, the movement of the console with the gearbox occurs along them;

- trunk - a device for supporting and securing a working tool using special hangers;

- spindle - designed to transmit rotation from the gearbox to the cutters, the accuracy of the work performed depends on the rigidity of this element and its resistance to vibration;

- sled - a structure with a rotating device that carries a longitudinal working surface;

- milling mandrel - a conical rod located at the end of the spindle, the cutter rings are attached to it with nuts.

A 3D router is typically equipped with a cooling supply system, a base plate, and mechanisms for selecting the rotation speed of the spindle assembly, the direction of the table, and for performing other functions. Inside the unit there is one or more electric motors and a block with electrical equipment.