Advantages of wood cutting machines

The presence of professional equipment radically changes the entire production process, including in the field of carpentry. The advantages of purchasing a machine include:

- Possibility of unique wood processing. Using the machine, you can give any shape to the processed base.

- High equipment performance. All professional machines have sufficient power to ensure long-term uninterrupted operation.

- Precision performance with proper handling of the equipment.

- High quality. Just after a little training and “breaking in” of the tool, you can produce interior items and souvenirs for sale or to order.

- All models from a quality manufacturer are safe to use. If the device overheats, the automatic shutdown system is activated. This feature significantly extends the service life of the machine.

- Most woodworking equipment does not require complex maintenance; just regular inspection of components and cleaning of the working part from shavings and dust is enough.

- Low noise level.

The advantages also include a large selection of woodworking machines, each of which is designed for specific tasks. The future owner should only indicate the scope of work and, in accordance with this, select the most suitable equipment model.

Recommendations for choosing a woodworking machine

Purpose of the machine.

Woodworking equipment differs in purpose.

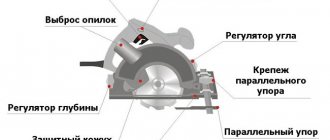

- Sawing machines are designed for sawing boards, bars, planks both in width and length. These are simple in design and affordable models, where the role of the equipment is played by a saw blade.

- Planer-thicknesser machines allow you to obtain ideal evenness and smoothness of a wooden surface. Two knives are installed on a rotating shaft, which, when rotating quickly, remove a layer of wood to a depth of 3 mm.

- Milling machines are distinguished by the variety of equipment used. The equipment is more expensive, but allows you to perform complex operations, turning a wooden blank into a work of art.

Engine power and speed.

The electric motor is responsible for the productivity of the woodworking machine. Since motors operating from a household network do not have high power (1-2 kW), it is possible to achieve high-quality wood processing due to high speeds. If for cutting a shaft rotation speed of 4000-5000 rpm is sufficient, then for planing a speed of 9000-10000 rpm will be required. In some milling machines, the motors spin up to 20,000 rpm.

Accuracy and ease of settings.

Modern woodworking machines allow us to produce high-quality products. But for this you need to learn how to use stands, stops, guides and other devices. The accuracy of processing most often depends on this.

Safety.

Since even household models rotate cutting equipment at enormous speed, the operator’s work is accompanied by a number of dangerous factors. Therefore, when purchasing a machine, you should pay attention to the availability of protective devices and emergency shutdown systems.

We have selected 11 of the best woodworking machines for the home for review. You can purchase them in the trading network of our country. When allocating places, the editors of the expertology magazine relied on the opinions of experts, taking into account feedback from Russian consumers.

Types of sawing machines

There are many areas of use for woodworking machines, and many types of equipment. One of the most common types is the sawing machine.

Such devices are designed for sawing logs and timber. Depending on the operating principle, the following types of machines are distinguished:

- Sawmills, which refer to stationary equipment that makes longitudinal and transverse cuts using a linear saw. The installed saws perform reciprocating movements, and the master only guides the working part. Such devices were among the first to be developed, are large in size, and are quite difficult to maintain.

- Sawmills have now been replaced by circular saws. Depending on the model, such designs can be manual or automatic. Circular saws cut logs in a vertical and inclined plane.

Also included in sawing machines are band models. The working part is presented in the form of a rotating belt.

Such designs are quite cheap, but are intended primarily for harvesting primary material, since they do not have sufficient accuracy.

Manufacturers of sawing machines

Construction stores are filled with all sorts of options for such equipment, so quickly choosing the right model can be difficult. Experts recommend taking a closer look at units from well-known manufacturers, the quality of which is confirmed by positive user reviews:

- MakitaCorporation - the main activity of the Japanese corporation is related to the production of professional-type electric and gas tools for construction work. The range includes over 1000 models, ensuring efficient processing of any materials. The advantages of the units include the reliability of the engines and the quality of components. They are often used for work characterized by extreme loads.

- Metabowerke GmbH is a German company that produces equipment for industrial and manual processing of materials. The Metabo brand's core slogan, “when you need reliability,” guarantees users the purchase of a powerful, durable and ergonomic tool that ensures efficient construction work in the toughest conditions.

- TechTronic inductries is a Japanese company that develops, produces and sells power tools and garden equipment under the Ryobi brand. All products are assembled at our own factories in the USA, Germany, and China. The popularity of the models is due to high quality, equipment with innovative technologies, the ability to carry out most of the assigned tasks, and low price.

- Einhell Germany AG is a German company that produces tools for construction, repair work, gardening and recreation. Its innovative products are represented in markets in more than 90 countries. The models are assembled mainly at Asian enterprises. In its work, the company adheres to the principle of combining simple solutions with high quality, which allows it to produce goods at an affordable price.

- Zubr OVK is a Russian company producing construction equipment. The brand’s devices are valued for their high reliability, quality, ease of use, and low price. By constantly updating the range and improving previously released units, the company is able to timely meet the growing needs of users.

- Bosch , a German corporation, is a reliable supplier of construction tools and household appliances. The brand's leading position in the market is due to the quality, reliability and functionality of its products.

Types of planing machines

Another variation of woodworking equipment is planing machines. Such structures are designed to remove the outer layer of wood. In this case, the cutting part is located deep in the material being processed.

The following types of planing equipment are distinguished:

- One-sided models that process only one plane of a wooden workpiece.

- Double-sided models capable of removing both the top and bottom layers of wood from a part.

- Often special rimming machines are used that process 3 or 4 edges of the workpiece.

There are also jointing machines that remove a layer of wood at a given angle.

The best planer-thicknesser woodworking machines for home

To obtain a perfectly smooth and even surface of a wooden workpiece, you cannot do without planing. To do this, it is best to purchase a household planer-thicknesser machine. Today they are sold at affordable prices. Here are some interesting models.

JET JPT-8B-M

Rating: 4.9

The Swiss development JET JPT-8B-M was created for home use. It allows you to perform two important operations: planing and thicknessing. Experts highly appreciated the mobility of the machine; it is lightweight (28 kg) and compact. The manufacturer installed a powerful (1500 W) brushed motor on its product with a rotation speed of up to 9000 rpm. The machine can process wooden blanks up to 120 mm thick; the planing depth is adjustable from 0 to 3 mm. In the “thicknesser” mode, the movement speed is 6 m/min, while 2 mm of wood is removed in one pass. The maximum processing width reaches 200 mm.

Users speak flatteringly about the cast frame, compactness, and ease of operation. The disadvantages most often include Chinese assembly.

Advantages

- lightness and compactness;

- ease of operation;

- high-quality surface treatment;

- acceptable price.

Flaws

- The build quality is poor.

Bison SR-330-1800

Rating: 4.8

The Zubr SR-330-1800 thickness planer demonstrates high processing accuracy. The Russian manufacturer equipped it with an electronic indicator; the planing depth is adjusted using a rotary handle. Workpieces up to 150 mm thick are automatically fed into the cutting zone at a speed of 4 or 6 m/min. The maximum planing depth is 3 mm with a width of up to 330 m. The model is driven by a powerful motor (1800 W), developing up to 9000 rpm. The machine is inferior to the review winner in weight (40 kg), which makes it difficult to move and transport.

Domestic craftsmen liked the model for its stability, good planing quality, ease of settings, and powerful motor. Among the disadvantages, there is a large weight and a small actual planing depth (1 mm).

Advantages

- electronic ruler;

- powerful engine;

- large processing width;

- affordable price.

Flaws

- heavy weight;

- shallow planing depth.

Features of using lathes

Lathes are used to remove a piece of wood in a circular manner. Similar designs have found their application in the furniture industry, and are intended for the manufacture of decorative cases, facades, and fasteners for sets.

All known models differ in engine power, housing size, installation method and degree of automation:

- Manual models are purchased, as a rule, for home use. Using this design, you can successfully produce a small furniture set for your home or to order. On the case there are power buttons, speed controllers and other technical parameters. All changes are made manually.

- Automated equipment has a template for producing specific parts. The specified parameters are entered into the machine operating program, but control and maintenance are performed by humans.

There are also automatic designs that are widely used in furniture production. These machines operate according to specified algorithms and are not used in everyday life.

How to choose the right model

The selection of a suitable model of a multifunctional machine is made based on a combination of several factors:

- size, design of the machine (desktop or stationary);

- set of functions;

- price.

When considering the option of interest, you need to pay attention to the number of knives on the planing shaft. The more there are, the cleaner the surface, but the more difficult it is to install and configure. In addition, you need to check what the spindle rotation speed is (if there is a milling function), the rotation speed of the knife shaft and saw blade.

Each of them has its own requirements - for a cutter, a speed of 5-6 thousand rpm is recommended, but for a saw blade, more than 3 thousand rpm is not recommended - the tool overheats and begins to dangle in the cut, which is fraught with undesirable consequences.

Expert opinion

Levin Dmitry Konstantinovich

It is also necessary to pay attention to the size of the machine and determine whether it will fit in the workshop. It is necessary to provide a reserve of space so that you can freely work with sufficiently long workpieces. Another important parameter is the supply voltage. Some models require 3-phase power, which is not available in every area.

Woodworking combination machines are useful and effective equipment for the home workshop. With their help, you can make any wooden products, from simple furniture to fence slats or slats for a greenhouse. The quality and composition of products are limited only by the skills and experience of the master, but not by the capabilities of the equipment.

Wood drilling machines

In furniture cases or facades, many interior items require through or blind holes. Woodworking drilling machines are used to perform this task.

Distinctive features of such devices are the ability to drill to a given depth and maximum accuracy.

The following types of drilling machines are distinguished:

- With vertical type of action. The spindle has a vertical direction.

- There are spindles with horizontal direction.

- Spindles are available for deep drilling.

Some modern machines can operate on an inclined axis, which is used for the manufacture of complex wooden structures.

Today, drilling equipment is often replaced by milling machines, which greatly facilitate the work of the master. Such devices are more convenient in practical use, which determines the buyer’s choice.

Wood bending machines

Interior styles such as Baroque require not simple furniture, but furniture with relief facades and details. Woodworking bending machines were developed specifically to solve such problems.

- The main purpose of such structures is to give the wooden surface the desired shape.

- The device is equipped with special clamps and forming heads.

In appearance and principle of operation, a bending machine resembles a hydraulic press, which gives the workpiece a complex shape, relief or imprint.

Equipment for assembling parts

Woodworking machines also include assembly structures. Such devices are capable of fixing adjacent parts using screws or nails.

Also on the list of tasks performed you can find the processing of fixation points, upholstery work for future furniture, and the application of various decorative coatings.

Leading manufacturers

Combined machines are in high demand, so many companies manufacture them. Among them there are world-famous manufacturers and relatively young, little-known companies.

Do you pay attention to the brand when buying an instrument?

Of course! Not really

The list of manufacturers includes:

- Jet (Switzerland);

- BELMASH (Belarus);

- Enkor (Russia);

- Makita (Japan);

- Bosh (Germany);

- Dewalt (USA);

- Zubr (Russia);

- Metabo (Japan).

Expert opinion

Levin Dmitry Konstantinovich

The above list cannot be considered an exhaustive list of manufacturers. There are many more of them, but it is impossible to name all the names - there are many of them. You should choose the right model based on the combination of technical characteristics and functionality.