Laying and installing pipelines is a complex engineering task. The characteristics and location of the supporting structures that take on the load from the pipeline along with the transported substance are of great importance for the reliable operation of the system. An important element of this system is the sliding support for pipelines, which supports the pipe, allowing it to move along and across its axis.

Product purpose

Sliding pipeline supports fix the line in the calculated position. They promote uniform distribution of loads and eliminate abnormal pipe displacement. The products are made of metal and have significant mechanical resistance.

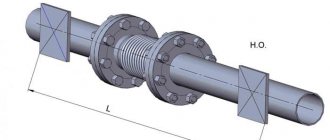

Sliding supports for pipelines are in demand when installing compensators that level out temperature stresses during the transportation of hot mixtures.

Each compensator is installed between two supports. In the presence of insets and misalignments, additional retaining elements are used.

Sliding supports under the highway provide protection from external factors:

- seasonal temperature fluctuations;

- strong gusty wind;

- icing;

- intense precipitation;

- vibration impact caused by the proximity of the network to technological equipment or railway tracks.

Pipeline sliding supports do not require complex maintenance. It is enough for the operating organization to periodically inspect the products for damage and natural wear.

Reliability and durability

Factors ensuring the reliability and durability of support and suspension systems:

- A staff of experienced, highly qualified specialists who regularly undergo retraining and certification;

- Using only the best raw materials for the production of products - metal, foundry blanks, forgings;

- Purchase only high-quality components and certified materials (protective compounds, paint and varnish products, components for welding);

- Regular verification of measuring instruments in accredited laboratories;

- Operational control and final acceptance with issuance of a quality certificate.

When producing pipeline supports in Moscow, we take into account the specific climatic conditions of the region. Due to high humidity, the outer surface of the supports is coated with modern anti-corrosion compounds. During transportation and storage, protection against corrosion is ensured by applying a special mastic, and galvanic galvanization with subsequent passivation (performed at the request of the customer) can protect against rust during operation of support and suspension systems.

Key Benefits

Sliding supports for pipelines have a lot of useful qualities.

- Saving network geometry . The supports prevent the line from bending under its own weight and ensure safe operation of thick-walled pipes. They are indispensable when laying highways with complex contours.

- Preventing the opening of compound connections . Support structures ensure the pipes remain in constant position and extend the service life of flange and coupling units.

- Maintaining the integrity of the line at the point of contact . The contact of the support and the pipe does not lead to deformation of the latter. The thoughtful design of the holding elements ensures that the line is secured without the risk of damage.

- Help with network upgrades . The supports have a high load-bearing potential. They will help organize additional branches, connect filtration equipment and storage tanks.

- High-quality load transfer . Support blocks redistribute loads onto supporting structures. This promotes rapid stress relief and minimizes pipeline wear.

Laying most large networks is impossible without sliding supports. With their help, lines transporting steam, drinking water, chemical reagents, and petroleum products are organized.

Operating principle

Sliding supports are modular structures. They are fixed within the working plane and have specified stroke parameters. The products provide axial displacement of the pipe, maintaining its position in space.

A typical support consists of two components.

- Base . A channel of a set size that mates the product with the supporting base.

- Holding block . Pipe fixing unit. The design of the holding element depends on the type of sliding support for the pipeline.

Parts in contact with the surface of the pipe have elastic gaskets. They guarantee high-quality contact of surfaces and eliminate abrasive wear.

Types of supports

Sliding supports differ in many respects:

- dimensions;

- Climatic performance;

- features of fixation;

- degree of freedom available to the restrained section of the pipe;

- spatial orientation of the product;

- materials used in production.

Manufacturers offer to buy sliding supports for pipelines in five designs.

- Clamps . Products in demand for above-ground construction of highways. To fix the pipe, clamps with a given radius are used. The network moves in the longitudinal and transverse directions, friction reduction is achieved through graphite lubricant. The product can be retrofitted with brackets that additionally secure the line.

- Ball . Solutions for heating networks laid in trays and outdoors. The supports are equipped with cages with balls. They promote free movement of the pipe in the axial and transverse direction. The products are designed for large-sized highways and have a significant service life.

- Roller . Supports for tunnel pipe laying. The standard rollers form a thrust cone, eliminating horizontal movement of the object. The surface of the rollers is made of a material that is safe for metal and polymer.

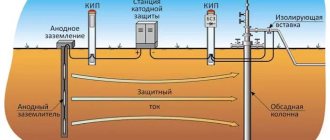

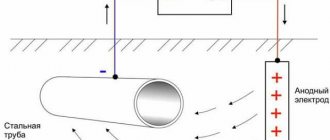

- Dielectric . Designs that protect the highway from static electricity and stray currents. Dielectric modules are used only with steel pipes and are required when laying networks at facilities with high electrification.

- Rope ropes . Devices with a spring block. They absorb intense vibrations and are indispensable when working in seismically hazardous areas.

The list of supports used on the site is determined by the design documentation. In some cases, several types of products are used.

Installation of sliding support structures

The distance between sliding supports is determined in accordance with the purpose of the pipeline systems and on the basis of strength and deflection calculations. The span is determined depending on the installation method, the parameters of the transported substance and the diameter of the pipeline. Weight, wind and other external loads are taken into account. Installation of movable supports is carried out before pulling the pipes into the cases. This is done so as not to damage the factory insulation. To reduce friction, graphite lubricant is applied to the contacting surfaces. Areas of insulation damaged during welding are painted over.

The importance of using sliding support structures has been proven by theory and practice in the design and operation of a huge number of operating pipelines. Extensive application experience has been accumulated, and many regulatory documents have been created to simplify the design of pipeline systems. But the importance of the task requires careful attention and a qualified approach.

- Author: admin

Rate this article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!

Carrying out installation activities

The installation of sliding supports for pipelines is carried out by specialized specialists. They take into account the characteristics and purpose of the network, the design of support modules, external factors, and the requirements of regulatory documents.

Main stages of installation.

- Component distribution . The supports are placed in standard places. They are specified in the project and agreed upon with the installation team.

- Fixation of supports . Products are fixed within the working planes.

- Pipe laying . A highway is laid on top of the supports. The event is being conducted with caution. The main task of the workers is to correctly position the line to prevent damage.

- Broaching the main components . The support is securely connected to the pipe.

Welding may be used during the work. In this case, the seams are cleaned and painted.

The reliability of fixation of the supporting elements is checked by quality control department employees. They conduct a visual inspection and use auxiliary equipment if necessary.

Defects associated with distortion, jamming or destruction of the support must be corrected immediately.

Preliminary product check

Supports that do not have the following defects are allowed for installation:

- deep corrosion damage;

- traces of use or partial repair;

- mechanical deformation caused by improper storage or transportation;

- damage to insulators, springs or other elements that ensure the functionality of the product;

- geometry violation caused by manufacturing defects.

A defect report is drawn up for supports that are unsuitable for use. The products are disposed of or returned with a complaint to the manufacturer.

Acceptance of supports involves checking the accompanying documents. The absence of a quality passport and certificate of conformity may raise questions among quality control department employees.

How does a fixed support for pipelines work?

Fixed structures are necessary in cases where rigid fastening of the system is required. In this way, it is possible to prevent its shifts in any of the possible directions.

Fixed elements are used in the installation of pipelines, which are installed in the following ways:

- external;

- internal (underground).

During the installation of sections of the system, the supporting structures are fixed using reinforced concrete frames. You need to understand that the latter are located at different distances from each other, dividing communications into segments. The length of the segment is related to the characteristics of the special compensators installed on it.

During both external and underground installation of communications, fixed elements are actively used. If a channelless method is used for laying underground, choose supports with high-quality waterproofing. Usually the role of the latter is played by a polyethylene shell. When it comes to external installation, galvanized waterproofing is preferred.

For a fixed installation method, the following elements are used:

- steel pipe;

- steel sheet obtained by hot rolling;

- polyurethane foam (PPU);

- heat-resistant tape;

- galvanized shell;

- centralizer;

- polyethylene shell.

For the manufacture of fixed steel supports for pipelines, the most durable and reliable grades of this metal are used.

The steel sheets used in this case can be of three types - it all depends on the quality:

- ordinary;

- low alloy;

- structural (considered the highest quality).

A centralizer is an element that simplifies the alignment of pipe ends before connecting pipeline elements. Today there are two types of centralizers:

- external;

- internal.

In accordance with the name, external ones perform alignment from the outside of the pipe and can be:

- link;

- eccentric;

- hydraulic jacks.

The first ones are necessary for centering pipes with a cross-section in the range of 57–2,224 mm. Unlike other models, they have increased resistance to low temperatures, since they are made from frost-resistant steel. Eccentric centralizers can be used when working with pipes of any cross-section. The latter type is used exclusively when aligning pipes with very large weights or when there are deformations on them. Such devices provide a force of 12 tons.

If we talk about internal centralizers, they are distinguished by one important feature: they allow long-term welding of pipes from the inside. As a result, the quality of seams is significantly improved. However, these products also have disadvantages, the main one of which is their heavy weight, that is, their transportation is impossible without special equipment.

Fixed support structures for pipelines are used in construction:

- main gas or oil pipelines;

- various types of communications at enterprises;

- pipelines to nuclear power plants and thermal power plants.

In addition, it is the fixed elements that are used in the construction of communications in regions with low temperatures, thus increasing the service life of the entire structure.

These elements are installed in systems used in completely different areas. They divide the entire system into separate segments in which bellows-type compensators are installed. The latter are designed to protect the pipeline from deformation that is possible when the ambient temperature drops.

Fixed supports of steel process pipelines are welded to platforms and mounted to the pipe using fasteners. To achieve the greatest reliability, metal plates are also welded close to the ends of the clamp.

Frameless supports

Frameless supports are simple devices used to perform basic operations. The products are used when laying new highways, as well as repairing and operating existing networks.

There are several types of frameless supports.

- OPB1 . Frameless supports in the first design. The product is a spacer that follows the outer contour of the pipe. It prevents direct contact between the main line and the static base and maintains the mobility of the line.

- OPB2 . The second version of frameless supports. Model includes clamp and spacer. At the end of the clamp there is a metric thread, which is in demand when creating detachable connections.

The use of open-frame solutions is regulated by the project.

Product characteristics

The parameters of the supporting elements are specified in the accompanying documentation. The name of the products contains their type, as well as the production standard. Each standard regulates the production of a group of supports with its own unique characteristics.

GOST 14911-82 and OST 36-94-83

Within the framework of the standards, supports OPP1, OPP1, OPP2, OPP2 are manufactured. The products have the following parameters.

- AKI1 . The diameter of compatible pipes is from 18 to 48 mm, vertical load is from 22 to 15 kN, height is from 70 to 100 mm, weight is from 0.43 to 0.62 kg.

- OPH1 . The diameter of compatible pipes is from 18 to 48 mm, vertical load is from 22 to 15 kN, width is from 52 to 85 mm, weight is from 0.77 to 1.11 kg.

- AKI2 . The diameter of compatible pipes is from 57 to 1620 mm, vertical load is from 45 to 236 kN, height is from 100 to 150 mm, weight is from 1.24 to 21.33 kg.

- OPH2 . The diameter of compatible pipes is from 57 to 630 mm, vertical load is from 45 to 161 kN, width is from 115 to 710 mm, weight is from 1.7 to 55.6 kg.

GOST 14911-82 also regulates the production of OPKH3 and OPP3 supports. They have double fastening units and increased resistance to vertical loads.

Series 4.903-10 Issue 5

Multifunctional sliding supports, designated by the index T. The series includes solutions for the implementation of various projects.

- T13 . Sliding bearings with transverse reinforcement and two support blocks. The products work with pipes with a diameter of 32 – 630 mm, and have a weight from 0.70 to 18.24 kg. The length of the structures is 170 mm.

- T14 . Analogous to T13, compatible with a large number of pipes. The supports are used when laying highways with a diameter of 32–1420 mm, their length is 340 mm, and their weight reaches 88.58 kg.

- T15 . Supports with a rigid base and two curved guides. The latter provide pipe retention and axial displacement. Products with index T15 have a working diameter of 194 – 1420 mm, their length is 680 mm. The maximum weight of the product reaches 130.7 kg.

- T16 . Clamp sliding supports with a rigid frame and a hemispherical guide. The clamp is secured by two threaded rods located at the ends of the structure. Pipes with a diameter of 194 – 630 mm are compatible with T16. The length of the products does not exceed 170 mm, weight – 37.5 kg.

- T17 . An analogue of T16, characterized by the presence of paired clamps and a larger frame. The product works with lines with a diameter of 194 – 1420 mm, its length reaches 340 mm, and its weight is 187.83 kg.

- T43 . Dielectric supports designed for objects with a high degree of electrification. The products facilitate the installation of pipelines with a diameter of 32 – 1420 mm. Their length varies in the range of 160 – 680 mm, weight is 0.44 – 38.41 kg.

Along with the listed devices, T21 ball bearings, T20 double-roller bearings and T19 single-roller bearings are produced.

Channel sliding supports (SPOk)

SPOk - sliding backing supports for channel gaskets are manufactured according to the requirements of album 1-487-1997.00.000. This album describes the design of the product, provides the procedure for its use, sets out standards for the manufacture and installation of pipeline systems using the formula Du / Dn, where Du is the nominal diameter, and Dn is the outer diameter of the shell, in the range from 200/400 to 1400/1600.

MOVABLE PIPELINE SUPPORTS SERIES 1—487—1997—00.000, FSO1, FSO2

MOVABLE PIPELINE SUPPORTS SERIES 4.903—10

ISSUE 4, 5 (T3,T4,T5,T13,T14)

MOBILE PIPELINE SUPPORTS SERIES 5. 903 – 13 TC

ISSUE 8 -95 (TS623, TS 624, TS 625, TS 626, TS 627, TS 631)

Purchasing products from the manufacturer

produces and sells sliding supports for industrial and municipal pipelines. The products comply with industry standards and can be used at critical and hazardous facilities.

Key advantages of the enterprise.

- Significant assortment of goods . The organization offers all types of supports. Clients can order supports for nuclear power plants, experimental enterprises, and thermal energy facilities. The list of products is periodically expanded. Offers that meet modern needs appear regularly.

- Assistance in product selection . Experienced managers are at the service of buyers. They talk about the parameters of support elements and offer solutions that are optimal for the target object.

- Manufacture of products according to customer drawings . The company produces non-standard supports according to customer drawings. It is enough for the client to provide technical documentation and agree on working issues. If necessary, the drawings are finalized, diagnostic cards are generated, and a product passport is developed.

- Reasonable prices . The plant does not use the services of intermediaries and interacts with the buyer directly. This approach eliminates the payment of third-party fees and commissions.

- Cooperation with transport works with leading domestic carriers. Products are sent anywhere in Russia and delivered in a short time.

The company catalog will help you get acquainted with the full list of products. It includes sliding and fixed supports, compensators, and reservoirs.