When laying an insulated pipeline in a trench and then backfilling it, the insulating coating may be damaged, and during the operation of the pipeline it gradually ages (loses its dielectric properties, water resistance, adhesion). Therefore, for all installation methods, except above-ground, pipelines are subject to comprehensive protection against corrosion with protective coatings and electrochemical protection (ECP) means, regardless of the corrosive activity of the soil.

ECP means include cathodic, sacrificial and electrical drainage protection.

Protection against soil corrosion is carried out by cathodic polarization of pipelines. If cathodic polarization is carried out using an external direct current source, then such protection is called cathodic, but if polarization is carried out by connecting the protected pipeline to a metal that has a more negative potential, then such protection is called sacrificial.

Cathodic protection

The schematic diagram of cathodic protection is shown in the figure.

The source of direct current is the cathodic protection station 3, where, with the help of rectifiers, the alternating current from the along-route power line 1, entering through the transformer point 2, is converted into direct current.

The negative pole of the source is connected to the protected pipeline 6 using connecting wire 4, and the positive pole is connected to the anode grounding 5. When the current source is turned on, the electrical circuit is closed through the soil electrolyte.

Cathode polarization technology

In this case, the so-called superimposed current is used. An external conductor (often) or a current source (rarely) is used to apply it to a metal object. Upon contact with an electrically active particle, the following happens: the particle, under the influence of electrical attraction forces, moves to a protective element with a negative charge, where “recycling” of these particles occurs.

The consequences of such “disposal” are obvious - the protective element itself becomes corroded over time and becomes unusable. Therefore, this technology is often called the sacrificial electrode method (instead of our part, the “sacrificial electrode” rusts).

In addition to current and voltage, when working with cathodic polarization, one more important parameter must be taken into account - the ohmic voltage. In a technical sense, this parameter reflects the fact that as an electrical charge flows over time, the current voltage in the circuit drops. The drop itself occurs due to the fact that the cathode current flows along a circuit with a lower charge. If the circuit is assembled correctly, this indicator is quite small - thanks to this, the same current of the same power will always be maintained in the circuit.

Schematic diagram of cathodic protection

1 - power lines; 2 - transformer point; 3 — cathodic protection station; 4 - connecting wire; 5 - anodic grounding; 6 - pipeline

The operating principle of cathodic protection is as follows. Under the influence of the applied electric field of the source, the movement of half-free valence electrons begins in the direction “anode grounding - current source - protected structure”. Losing electrons, the anodic grounding metal atoms pass in the form of ion atoms into the electrolyte solution, i.e. the anodic grounding is destroyed. Ion atoms undergo hydration and are removed into the depth of the solution. At the protected structure, due to the operation of the direct current source, an excess of free electrons is observed, i.e. conditions are created for the occurrence of oxygen and hydrogen depolarization reactions characteristic of the cathode.

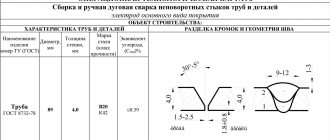

Underground communications of oil depots are protected by cathode installations with various types of anodic grounding. The required protective current strength of the cathode installation is determined by the formula

Jdr=j3·F3·K0

where j3 is the required value of the protective current density; F3 is the total contact surface of underground structures with the ground; K0 is the coefficient of exposure of communications, the value of which is determined depending on the transition resistance of the insulating coating Rnep and the electrical resistivity of the soil rg according to the graph shown in the figure below.

The required value of the protective current density is selected depending on the characteristics of the soil at the oil depot site in accordance with the table below.

Combination of protectors and paints

Often there is a need to protect a gas pipeline from corrosion not only with a protector, but with paint and varnish material. Paint is considered a passive method of protection against corrosion processes and is truly effective only when combined with the use of a protector.

This combination technique allows:

- Reduce the negative impact of potential defects in the coating of metal structures (peeling, swelling, cracking, heaving, etc.). Such defects occur not only as a result of manufacturing defects, but also due to natural factors.

- Reduce (sometimes by a very significant amount) the consumption of expensive protectors, while increasing their service life.

- Make the distribution of the protective layer over the metal more uniform.

It is also worth noting that paint and varnish compositions are often not easy to apply to certain surfaces of an already operating gas pipeline, tanker or some other metal structure. In such cases, you will have to make do with only a protective protector.

Tread protection

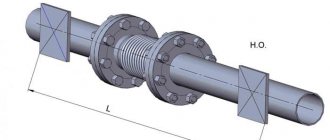

The principle of operation of the tread protection is similar to the operation of a galvanic cell.

Two electrodes: pipeline 1 and protector 2, made of a more electronegative metal than steel, are lowered into the soil electrolyte and connected by wire 3. Since the protector material is more electronegative, under the influence of a potential difference, a directed movement of electrons occurs from the protector to the pipeline along the conductor 3. At the same time, the ion atoms of the protector material go into solution, which leads to its destruction. The current strength is controlled using control and measuring column 4.

Methods for protecting pipelines

Corrosion of pipelines occurs during their operation. Rust formation occurs on pipes inside and outside. Deposits appear on the inside, and the reason for this is chemical reactions between the composition of the transported liquid and the metal. The condition of the surface is also influenced by high soil moisture.

If protection is not provided in a timely manner, a number of consequences may occur. What is important:

- It is recommended to carry out routine inspections at short intervals.

- Carry out repair work periodically, regardless of the presence of corrosion.

- suspension of the functioning of pipeline transport is inevitable, since it is necessary to carry out inspections and carry out scheduled preventative and other routine repairs.

Important! To ensure complete protection, it is necessary to take into account the installation method, contact with aggressive media, and the type of pipeline.

Dependence of protective current density on soil characteristics

| Soil type | rp ohmm | A, A/m2 |

| Wet clay soil: | ||

| — pH >8 | 15 | 0,033 |

| pH = 6-8 | 15 | 0,160 |

| - mixed with sand | 15 | 0,187 |

| Wet peat (pH <8) | 15 | 0,160 |

| Moistened sand | 50 | 0,170 |

| Dry clay soil | 100 | 0,008 |

Corrosion under the influence of stray currents

Rust can arise from an alternating and constant flow of electrons:

- Rust formation under the influence of constant current. Stray currents are currents found in the soil and in structural elements located underground. Their origin is anthropogenic. They arise as a result of the operation of technical devices of direct current, spreading from buildings or structures. They can be welding inverters, cathode protection systems and other devices. The current tends to follow the path of least resistance, as a result, with existing pipelines in the ground, it will be much easier for the current to pass through the metal. The anode is the section of the pipeline from which the stray current exits to the soil surface. The part of the pipeline into which the current enters acts as a cathode. On the described anodic surfaces, currents have an increased density, so it is in these places that significant corrosion spots form. The corrosion rate is not limited and can be up to 20 mm per year.

- Rust formation under the influence of alternating current. When located near power lines with network voltages above 110 kV, as well as in parallel arrangement of pipelines, corrosion occurs under the influence of alternating currents, including corrosion under the insulation of pipelines.

Schematic diagram of tread protection

1 - pipeline; 2 — protector; 3 - connecting wire; 4 - control and measuring column

Thus, metal destruction still occurs. But not the pipeline, but the protector.

Theoretically, to protect steel structures from corrosion, all metals located in the electrochemical voltage series to the left of iron can be used, since they are more electronegative. In practice, protectors are made only from materials that meet the following requirements:

- the potential difference between the tread material and iron (steel) should be as large as possible;

- the current obtained by electrochemical dissolution of a unit of mass of the protector (current output) must be maximum;

- the ratio of the tread mass used to create protective current to the total loss of tread mass (utilization factor) should be the greatest.

These requirements are best met by alloys based on magnesium, zinc and aluminum.

Tread protection is carried out with concentrated and extended protectors. In the first case, the electrical resistivity of the soil should be no more than 50 Ohm-m, in the second - no more than 500 Ohm-m.

Electrical drainage protection of pipelines

A method of protecting pipelines from destruction by stray currents, providing for their removal (drainage) from the protected structure to a structure that is a source of stray currents or special grounding, is called electrical drainage protection.

Direct, polarized and reinforced drainage are used.

Tread protection of pipelines against corrosion - operating principle and diagram

There are two main groups of methods for preventing the destruction (or reducing its intensity) of metals under the influence of external factors (primarily moisture) - active and passive. The first includes electrochemical protection. The reader can familiarize himself with one of these methods of combating corrosion – protective (galvanic) – in this article.

Operating principle

The purpose of tread protection is to minimize the potential of the base material, which ensures its protection from destruction by corrosion. This is done by attaching a special electrode to it, which is often called a “sacrificial anode”. It is selected from a metal that is more active in relation to the base one. Thus, the protector is primarily exposed to corrosion, therefore, the durability of a particular structural element with which it is connected increases (read about cathodic protection).

Efficiency of tread protection

Considered very high. Despite the fact that the costs of implementing tread protection against corrosion are relatively small. If the use of a magnesium anode with the appropriate parameters prevents the destruction of the pipeline metal over a distance of, for example, about 7.5 km, then without it - only by 25 - 30 m.

When to use tread protection

There are plenty of ways to combat corrosion, and there is always a choice. The use of a “sacrificial anode” is advisable:

- if the enterprise does not have the necessary capacity to implement other, more cost-intensive methods;

- if it is necessary to protect small structures;

- to protect metal products (objects) with surface coating (insulation) from corrosion. The same pipelines.

The maximum effectiveness of tread protection is achieved if it is used in environments called electrolytic. For example, sea water.

What metals are used as protectors?

As a rule, this mainly refers to the tread protection of products made of iron and its alloys (steel). Compared to them, metals such as zinc, chromium, aluminum, cadmium, and magnesium are more active. Although these are not the only possible options.

The peculiarity of the manufacture of “sacrificial anodes” is that for their production these materials are not taken in their pure form. Various alloys based on them are used as raw materials. In this case, the specifics of the use of protectors are taken into account. First of all, in what environment is it planned to provide corrosion protection.

For example, if a zinc electrode is placed in dry soil, its effectiveness will be practically zero. Therefore, the choice of one or another protector is determined by local conditions.

Protective countermeasures

Protective protection of a gas pipeline from corrosion involves creating a blocking potential by connecting metal protectors to the pipes with a more negative indicator than the parameter of the pipeline itself. When using this method, no external current source is provided; the required characteristics are created through a galvanic anode element. Under the influence of the protector, cathodic polarization acts on the gas pipeline, which helps stop corrosion processes.

The working material can be zinc, aluminum, magnesium in the form of special alloys (ML, TsO, Ts1 and the like). This type of protection is as simple as possible and does not require additional maintenance. This method, in combination with other methods, can be used to protect individual compartments that are not intersected by adjacent cathodic safety areas. Protective protection of gas pipelines from corrosion is appropriate for special casings at crossings over railway tracks and roads, at facilities with developed underground structures.

The protectors are mounted in rafts of several elements and connected directly to the pipe or cathode output. They are connected to each other using a special cable, steel or copper wire. To increase the protection efficiency, the protectors are located in the filler, which reduces the contact resistance. The composition is magnesium sulfate or sodium with clay. The installation distance of the protectors from the pipeline is about 3-6 meters.

You might be interested in:Which is heavier: a tram or a tank? What is heavier: a tram or a T-34 tank?