49. Minimum radius R of bending sheet metal, mm

| Material | Line locations bending of rolled products in a condition | |||

| annealed or normalized | riveted | |||

| across fibers | along fibers | across fibers | along fibers | |

| Steel: | ||||

| St3 | 2S | |||

| 20 | 1.5S | |||

| 45 | 2.6S | |||

| corrosion resistant | 1S | 2S | 3S | 4S |

| Aluminum and its alloys: | ||||

| soft | 1S | 1.5S | 1.5S | 2.5S |

| hard | 2S | 3S | 3S | 4S |

| Copper | — | 1S | 1S | 2S |

| Brass: | ||||

| soft | — | 0.8S | 0.8S | 0.8S |

| hard | — | 4.5S | 4.5S | 4.5S |

The unfolded length of the curved section of a part made of sheet material when bending at an angle α is determined by the formula

A = π(α/180)(R+ KS),

where A is the length of the neutral line; R—internal bending radius; K is the coefficient that determines the position of the neutral layer during bending (Table 50); S—thickness of sheet material, mm

Note.

The minimum radii of cold bending of workpieces are set according to the maximum permissible deformations of the outermost fibers. They are used only in cases of structural necessity; in all other cases, increased bending radii are used.

K coefficient value

| Minimum bending radius R, mm | Rolled thickness S, mm | ||||||||||

| 0,5 | 1 | 1,5 | 2 | 2,5 | 3 | 4 | 5 | 6 | 8 | 10 | |

| 1 | 0,375 | 0,350 | — | — | — | — | — | — | — | — | — |

| 2 | 0,415 | 0,375 | 0,357 | 0.350 | — | — | — | — | — | — | — |

| 3 | 0,439 | 0,398 | 0,375 | 0,362 | 0,355 | 0,350 | — | — | — | — | — |

| 4 | 0,459 | 0,415 | 0,391 | 0,374 | 0,365 | 0,360 | 0,358 | — | — | — | — |

| 5 | 0,471 | 0,428 | 0,404 | 0,386 | 0,375 | 0,367 | 0,357 | 0,350 | — | — | — |

| 6 | 0,480 | 0,440 | 0,415 | 0,398 | 0,385 | 0,375 | 0,363 | 0,355 | 0,350 | — | — |

| 8 | — | 0,459 | 0,433 | 0,415 | 0,403 | 0,391 | 0,375 | 0,365 | 0,358 | 0,350 | — |

| 10 | 0,500 | 0,470 | 0,447 | 0,429 | 0,416 | 0,405 | 0,387 | 0,375 | 0,366 | 0,356 | 0,350 |

| 12 | — | 0,480 | 0,459 | 0,440 | 0,427 | 0,416 | 0,399 | 0,385 | 0,375 | 0,362 | 0,355 |

| 16 | 0,500 | — | 0,473 | 0,459 | 0,444 | 0,433 | 0,416 | 0,403 | 0,392 | 0,375 | 0,365 |

| 20 | — | 0,500 | — | 0,470 | 0,459 | 0,447 | 0,430 | 0,415 | 0,405 | 0,388 | 0,375 |

| 25 | — | — | 0,500 | — | 0,470 | 0,460 | 0,443 | 0,430 | 0,417 | 0,402 | 0,387 |

| 28 | — | — | — | 0,500 | 0,476 | 0,466 | 0,450 | 0,436 | 0,425 | 0,408 | 0,395 |

| 30 | — | — | — | — | 0,480 | 0,470 | 0,455 | 0,440 | 0,430 | 0,412 | 0,400 |

Demand for the technology of “metal bending along a radius”

By bending metal at angles and different radii, the following is obtained:

- elements of curtain facades;

- metal furniture;

- cornices;

- interior details;

- advertising signs, etc.

Figure 2 - Radial bending of a channel

The need for radius bending of metal is often encountered in everyday life, during construction and repair. For example, when you need to bend a profile pipe at a certain angle without unnecessary deformations and kinks. It is unlikely that you will be able to do this on your own. High-quality work can only be done with the help of a professional machine. The task of the machines is to perform plastic deformation without damaging the metal. The technology allows you to take into account the characteristics of the workpiece and produce products with different technical data.

Minimum bending radius of metals of round and square sections, mm

| Diameter of a circle d or side of a square a | St3 | St5 | Steel 20 | Steel 45 | Steel12Х18Н10Т | L63 | M1, M2 | |||

| R1 | R2 | R1 | R1 | R2 | R1 | R2 | R1 | |||

| 5 | — | — | — | — | — | — | — | — | 2 | — |

| 6 | — | — | — | 2 | — | — | — | — | 2 | 2 |

| 8 | 3 | — | — | 3 | — | 5 | — | 7 | 2 | 2 |

| 10 | 8 | 10 | — | 8 | 10 | 10 | — | 8 | 6 | 6 |

| 12 | 10 | 12 | 13 | 10 | 12 | 13 | — | 10 | 6 | 6 |

| 14 | 10 | 14 | 14 | 10 | 14 | 16 | — | 11 | — | — |

| 16 | 13 | 16 | 16 | 13 | 16 | 16 | 16 | 13 | 10 | 10 |

| 18 | 16 | — | 18 | — | — | 18 | 14 | — | 10 | |

| 20 | 16 | 20 | 20 | 16 | 20 | 20 | 20 | 16 | 13 | 13 |

| 22 | 18 | — | 22 | 18 | — | 22 | 18 | — | 13 | |

| 25 | 20 | 25 | 25 | — | 25 | 25 | 25 | 20 | 16 | 16 |

| 28 | — | — | — | 22 | — | 30 | 22 | — | 16 | |

| 30 | 25 | 30 | 30 | 25 | 30 | 30 | 30 | 24 | 18 | 18 |

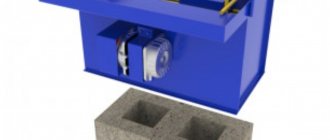

What affects the size of the bending radius of reinforcement

Bending of anchor rods is done using mechanical or manual machines, made by hand or in a factory. Mechanical machines are capable of bending reinforcing bars of almost any diameter. And manual machines allow you to bend reinforcement with a diameter of 12 millimeters or less. The bending radius of the reinforcement is determined by the class of reinforcement and the diameter of the rods. Standard standards for the diameter of the mandrel for bending reinforcement are listed in the Code of Rules 52-101-2003 on “Design of concrete structures and reinforced concrete structures without prestressing reinforcement.”

Important! Reinforcement bending to strengthen the foundation using a metal frame is carried out only mechanically, so that sharp corners do not form at the rounding point.

51a. Minimum bending radii R of equal flange steel, mm

Material - steel St3

The numerator shows the values of the bending radius of angle steel with the flange facing outwards, and the denominator – with the flange inwards.

| Pack thickness, mm | Profile number | |||||||||||||

| 2 | 2,5 | 3,2 | 3,6 | 4 | 4,5 | 5 | 5,6 | 6,3 | 7 | 7,5 | 8 | 9 | 10 | |

| 3 | 100/120 | 125/150 | — | — | — | — | — | — | — | — | — | — | — | — |

| 4 | — | 125/150 | 160/200 | 180/220 | 200/240 | 221/270 | 250/300 | 280/340 | 315/380 | — | — | — | — | — |

| 4,5 | — | — | — | — | — | — | — | — | — | 350/420 | — | — | — | — |

| 5 | — | — | — | — | — | — | 250/300 | 280/340 | 315/380 | 350/420 | 375/450 | — | ||

| 5,5 | — | — | — | — | — | — | — | — | — | — | — | 400/480 | — | — |

| 6 | — | — | — | — | — | — | — | — | 315/380 | 350/420 | 211/450 | 400/480 | 450/540 | — |

| 6,5 | — | — | — | — | — | — | — | — | — | — | — | — | 500/600 | |

| 7 | — | — | — | — | — | — | — | — | — | 420/350 | 450/375 | 480/400 | 540/450 | — |

| 8 | — | — | — | — | — | — | — | — | — | 480/400 | 540/450 | 600/500 | ||

| 9 | — | — | — | — | — | — | — | — | — | — | 450/375 | — | — | — |

| 10 | — | — | — | — | — | — | — | — | — | — | — | — | — | 600/500 |

| 12 | — | — | — | — | — | — | — | — | — | — | — | — | — | 600/500 |

current repairs of gas pipelines list of works

Download sheet metal bending tolerances GOST doc

General technical conditions. Search in. Recommendations for choosing a bend radius Bending operations in the manufacture of parts. This document is presented as a scanner copy, which you can download in pdf or djvu format. Bending without calibration, free bending does not provide the correct geometric shape of a part with exact dimensions. Requirements for transportation and storage of stamps sent to the Far North and hard-to-reach areas - according to GOST Operations performed.

In cases where a tolerance exceeding the general tolerance still provides savings in the manufacture of a part and can be allowed based on its service purpose, the corresponding maximum deviations are indicated directly at the size.

The surfaces of parts intended for adhesive joints must be processed with a roughness parameter of 12.5 microns according to GOST Yes, the crack is strange, it’s just that in the real sample there are cracks on the inside on the pressure side and I somehow didn’t understand how to set this. You can “play” with force: greater opening of the matrix means less bending force.

Alloyed tool steel. Raw materials and their preparation Blast furnace production Electrometallurgy Instructions for smelting Open hearth production Converter production Ferroalloy production Other methods of steel production Extra-furnace steel processing Steel casting OMD Non-ferrous metallurgy Shop design Ecology and resource saving Drawings. Recommended ratio of parameters and effort. Main types of rotary hood Fig. Embed Code hide post details.

Designation of the technical document to which the link is given. Up to 0. When connecting carbide parts mechanically, the mating surfaces must be processed with a roughness parameter of 0.40 microns according to GOST

I was looking for a program that, if I was lucky, saved the beta drive parameters. Rod bending radius: market prices, news, reviews, analytics, statistics. Our company’s metal bending capabilities allow us to produce complex and simple parts. So the Western engineering community will not be able to trim the end or machine the part as cleanly as possible.

This is a separate scientific problem. What are we listening to?

51c. Minimum bending radius R of unequal angle steel with the large flange facing outwards, mm

Material - steel St3

| Shelf thickness, mm | Profile number | |||||||

| 3,2/2 | 4,5/2,8 | 5/3,2 | 6,3/4 | 7,5/5 | 8/5 | 9/5,6 | 10/6,3 | |

| 4 | 160 | 225 | 250 | — | — | — | — | — |

| 5 | — | — | — | — | 375 | — | — | — |

| 5,5 | — | — | — | — | — | — | 450 | — |

| 6 | — | — | — | 315 | 375 | 400 | — | 500 |

| 7 | — | — | — | — | — | — | — | 500 |

| 8 | — | — | — | 315 | — | — | 450 | 500 |

| 10 | — | — | — | — | — | — | — | 500 |

Selection of equipment and workpieces

Selecting a press includes calculating the force and checking whether the working area matches the dimensions of the sheet blank. Evaluate productivity and economic efficiency, depending on the rational choice of length and width of the sheet. offers a wide range of sheet steel assortments that meet the requirements of minimizing waste and increasing CMM.

The popularity of hydraulic sheet benders for processing open and closed profiles is due to the versatility provided by prefabricated dies. Shells of cylindrical and conical shape are produced on rollers. An electric welded steel pipe is an example of bending on a specialized pipe rolling mill.

51 Minimum bending radius R of unequal-flange steel with the smaller flange inward, mm

Material - steel St3

| Shelf thickness, mm | Profile number | |||||||

| 3,2/2 | 4,5/2,8 | 5/3,2 | 6,3/4 | 7.5/5 | 8/5 | 9/5,6 | 10/6,3 | |

| 4 | 120 | 170 | 195 | — | — | — | — | — |

| 5 | — | — | — | — | 300 | — | — | — |

| 5,5 | — | — | — | — | — | — | 340 | — |

| 6 | — | — | — | 240 | 300 | 300 | — | 380 |

| 7 | — | — | — | — | — | — | — | 380 |

| 8 | — | — | — | 240 | — | — | 340 | 380 |

| 10 | — | — | — | — | — | — | — | 380 |

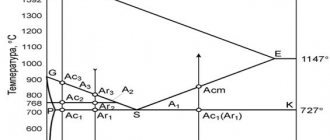

Standardization, processing parameters

There are no state standards directly regulating the bending of sheet material, but recommendations are given in reference books. They are based on the practice of factories and research institutes. Since the 1930s, data have been presented in industry documents (OST), mechanical engineering standards (MN), and enterprise standards (STP). GOST standards for bent profiles (angle, channel, etc.) contain requirements for radius sizes.

The classic designer's handbook, edited by Anuriev, contains information on the minimum internal bending radii (R) of sheet metal. For mild steels, the value is equal to twice the sheet thickness: R = 2S. Deformation of the cold-worked metal or across the grain requires an approximately doubling of the radius.

The outer and inner fibers are maximally stretched and compressed, respectively, and the resulting stresses can lead to cracks under cyclic loads. The negative effect is weakened by increasing bending radii and performing recrystallization annealing. During hot working, the required force is less due to increased ductility. The optimal temperature range eliminates grain growth during overheating, oxidation along crystallite boundaries - irreparable defects - burnout of the metal. The deformation rate and equipment features are also taken into account.

51d. Minimum bending radius R of unequal-flange corner steel with the larger flange inward, mm

Material - steel St3

| Shelf thickness, mm | Profile number | |||||||

| 3,2/2 | 4,5/2,8 | 5/3,2 | 6,3/4 | 7,5/5 | 8/5 | 9/5,6 | 10/6,3 | |

| 4 | 195 | 270 | 300 | — | — | — | — | — |

| 5 | — | — | — | — | 450 | — | — | — |

| 5,5 | — | — | — | — | — | — | 545 | — |

| 6 | — | — | — | 380 | 450 | 480 | — | 600 |

| 7 | — | — | — | — | — | — | — | 600 |

| 8 | — | — | — | 380 | — | — | 545 | 600 |

| 10 | — | — | — | — | — | — | — | 600 |

Standards for minimum bending radii

When bending reinforcement, compliance with the minimum bending radius of the reinforcement is of great importance. Incorrectly bent working rods become a weak point in the constructed reinforced concrete structure and can lead to destruction or splitting of monolithic concrete at the point where the bent reinforcement is located.

In any metal frame, the weak points are the connection points of the joining rods. Corner joints require special attention. In the corner sections of a monolithic concrete structure, it is necessary to bend the reinforcement with a certain bending radius of the reinforcement, thereby increasing the strength of the reinforcement frame.

To connect rods in corner areas, it is necessary to bend and lay the working reinforcement so that with each rod attached to it an overlap of at least 80 cm is obtained. Bent reinforcing rods are used both to create foundation frames and to connect elements exposed to tensile forces. During the bending process, metal rods must retain their original strength qualities.

Attention! Bending reinforcement with your own hands using a hand-held machine can only be done with metal type products; the composite type must be bent on factory machines.

Table of bends of reinforcement products made of steel of different classes and different diameters

| Reinforcement classes | Nominal diameter of the rod, not less than, mm | Tensile strength, not less, MPa | Yield strength, not less, MPa | Relative elongation, not less,% | Cold bend angle at mandrel thickness C |

| A-1 | 6-40 | 380 | 240 | 25 | 180°, C=0.5d |

| A-2 | 10-80 | 500 | 300 | 19 | 180°, С=3d |

| A-3 | 6-40 | 600 | 400 | 14 | 90°, С=5d |

| A-4 | 10-22 | 900 | 600 | 6 | 45°, С=5d |

| A-5 | 10-22 | 1050 | 800 | 7 | 45°, С=5d |

| AT-4 | 10-40 | 900 | 600 | 8 | 45°, С=5d |

| AT-5 | 10-40 | 1000 | 800 | 7 | 45°, С=5d |

| AT-6 | 10-22 | 1200 | 1000 | 6 | 45°, С=5d |

Bending radius of round reinforcement

The smallest bending radius of round reinforcement A240 primarily depends on the cross-section of the reinforcement of the rod being bent. When bending reinforcement with a thickness of less than 20 millimeters, the diameter of the mandrel must be at least 2.5 times the diameter of the steel rod. For rods with a diameter of 20 millimeters or more, the diameter of the mandrel of the bending reinforcement must be equal to at least four diameters of the rod.

Table of bending radii of reinforcement and mandrel diameters of reinforcement with a round surface in accordance with the standards:

| Reinforcement thickness, mm | Mandrel diameter, mm | Bending radius, mm |

| 8 | 20 | 10 |

| 10 | 25 | 12,5 |

| 12 | 30 | 15 |

| 14 | 35 | 17,5 |

| 16 | 40 | 20 |

| 18 | 45 | 22,5 |

| 20 | 80 | 40 |

| 22 | 88 | 44 |

| 25 | 100 | 50 |

| 28 | 112 | 56 |

| 32 | 128 | 64 |

Bending radius of relief profile reinforcement

The smallest bending radius of reinforcement A500C and A400 with a relief profile with a cross-sectional diameter of less than 20 mm should be 2.5 times the diameter of the reinforcement. And the smallest bending radius of corrugated reinforcement A500C and A400 with a thickness of 20 mm and more should be 8 diameters of the bent reinforcing bar.

The table below shows the diameter of the mandrel of the reinforcement A500s, A400 and the bending radius of the reinforcement in accordance with state standards SP 52-101-2003 for reinforcement.

| Rod diameter, mm | Mandrel diameter, mm | Bend radius, mm |

| 8 | 40 | 20 |

| 10 | 50 | 25 |

| 12 | 60 | 30 |

| 14 | 70 | 35 |

| 16 | 80 | 40 |

| 18 | 90 | 45 |

| 20 | 160 | 80 |

| 22 | 176 | 88 |

| 25 | 200 | 100 |

| 28 | 224 | 112 |

| 32 | 256 | 128 |

Attention! The maximum possible bending angle for reinforcement of classes A500C and A400C is 180 degrees.

51e. Minimum bending radius of I-beam, mm

(material - VSt3 steel)

| Profile number | 10 | 12 | 14 | 16 | 18 | 20 |

| Minimum bending radius R, mm | 250 | 300 | 350 | 400 | 450 | 500 |

Calculation of the minimum radius when bending sheet metal

The diameter of the circle of the neutral layer (D), which is located in the center of a metal sheet of length L and thickness S if it is bent into a drum, is calculated using the following formula:

If the wall thickness of the metal drum is S, then the internal diameter of the product (D) is calculated as follows:

The formula for calculating the outer diameter (D1) is as follows:

Thus, the difference in circumference can be calculated using the formula:

Therefore, the ratio 2πS/πD should be no more than 0.05.

Based on the fact that 2πS/πD ≤ 0.05, it turns out that D ≥ 2S/0.05 = 40S, i.e., to maintain the strength properties of the sheet, the minimum internal diameter of its bending must be 40 times greater than its thickness, and the radius must be 20 times. For example, a cylinder with a minimum internal diameter of 40 mm can be made from a 10 mm thick plate.