The meaning of the ruler

A modern ruler-pattern has two purposes and, accordingly, two definitions. On the one hand, it is a tool for drawing or checking irregular curves. Many such devices can be seen in engineering departments. Drawing patterns come with variable and constant curvature. A ruler with variable curvature has a device with which you can change its configuration. Usually made of steel.

On the other hand, a measuring pattern is a tool without a scale, rather a template for tracing and controlling the contours of curved parts or parts . Typically, this is a steel plate with a working edge cut according to the profile of the product. Where and when this product was invented, and who first began to cut out parts and lay out walls along the finished contour, is now difficult to determine. The idea turned out to be fruitful and today various patterns, templates, squares and rulers are used in all spheres of human activity.

Straightening plates and rulers

The quality of scraping is checked using surface plates and rulers.

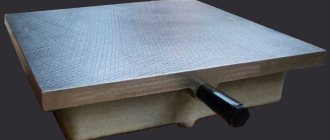

The shape of the calibration plates can be square or rectangular. Slab sizes from 200X210 mm to 1000X1500 mm.

A square or rectangular slab of a certain size is cast from gray cast iron. The slab is made hollow to make it lighter; Stiffening ribs increase its strength. The working surface of the slab is smooth and well processed. The stove is lifted using two handles. Small slabs are installed on workbenches; Large slabs are placed on special metal stands.

Calibration flat, angular and prismatic cast iron rulers are manufactured with a length from 500 to 3000 mm and a width from 40 to 100 mm.

Straight edges used for scraping

a - flat; b - flat I-beam; in - angular.

Straight edges, like slabs, are cast hollow, and their working surface is carefully processed.

The surface plate is used when scraping products with wide surfaces; straight edge - when scraping long narrow surfaces.

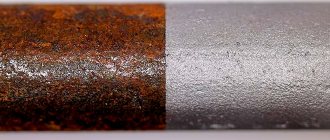

Irregularities on the surface being treated are visible after it comes into contact with a painted testing tool.

Verification plates and rulers must be protected from corrosion, dirt and shavings, and impacts. When working, you must use the entire surface of the surface plate. After finishing work, the surface plate is cleaned, lubricated and covered with a wooden lid. Rulers are stored in special cases.

Questions

- What metal are calibration plates and rulers made of?

- How is the surface plate constructed?

- What is the surface plate used for?

- What is a straight edge used for?

- How are surface plates and rulers stored?

Scraping techniques

The surface is scraped as follows: carefully wipe the working surface of the surface plate dry with rags and apply a thin and even layer of paint to it, carefully wipe the surface that needs to be scraped (for example, a cast iron tile), apply it to the painted surface of the surface plate and move the tile in a circle two or three times. times, pressing lightly. The tiles painted in this way are clamped in a vice and the painted areas are scraped off with a scraper. Scraping involves gradually removing the colored protrusions.

Flat surfaces are processed with a flat scraper with straight cutting edges. Take the handle with your right hand, and press the scraper with your left hand, as shown in the figure below.

Techniques for scraping a flat surface

The scraper is installed at an angle of 25 - 30° to the surface being processed. You need to shave without bending, keeping the body in a free position.

The working stroke is moving forward (away from oneself). When idling (moving backwards), the scraper must be raised. During the working stroke, the scraper removes a layer of metal up to 0.01 mm thick. The scraper must be moved forward each time by 12 - 15 mm in different directions. To get a smoother surface, scrape in three stages (rough, semi-finish and finishing).

During rough scraping, traces and risks of primary processing are removed. They work with a scraper 20 - 30 mm wide. In this case, the direction of the working stroke of the scraper is changed each time so that the traces of the scraper from the subsequent pass intersect the traces of the previous one.

During semi-finish scraping, the most protruding areas identified after checking for paint are removed. They work with a flat scraper 12 - 15 mm wide.

Finish scraping produces the surfaces of very precise products. In this case, scrapers with a width of 5 - 12 mm are used. Each time after removing paint-covered areas with a scraper, the surface is cleaned with a brush and thoroughly wiped with a rag.

The treated tile is again placed on the surface plate, removed and the resulting stains are scraped again. This continues until the number of spots on the surface when checking for paint reaches the established norm.

Questions

- What should be done to the surface before scraping?

- What kind of scraper is used to process a flat surface?

- What is the working stroke of a scraper?

- How to install a scraper on the surface to be treated?

“Plumbing”, I.G. Spiridonov, G.P. Bufetov, V.G. Kopelevich

The continuous growth of socialist industry requires the constant replenishment of plants, factories and transport with new workers. Modern mechanical engineering and metalworking are waiting for well-trained workers, since with the development of technology their qualifications should also increase.

You guys are entering a new period of training in your chosen specialty. In the fourth, fifth and sixth grades, you studied metalworking operations, as well as drilling and lathes, acquired certain skills and learned working techniques.

Now you will make various tools, perform more complex plumbing work, and repair equipment.

To successfully cope with this task, you must read a lot, draw up a work plan yourself, and show more ingenuity when performing it. Care, diligence, skill and patience always give good results.

Now your task is to improve your acquired knowledge, skills and abilities.

With the help of teachers, you will prepare yourself for industrial activities. The day is not far when you will graduate from school and become workers. Over the years of study, you need to consolidate and deepen your knowledge, learn to work well.

Your tasks will become increasingly difficult. Everything will help you become a true locksmith specialist.

Locksmith work is widely used in various sectors of the national economy.

Therefore, a mechanic must have a good understanding of drawings, know the equipment and tools used, be able to perform metalwork work, be disciplined, and independently solve production problems.

For this purpose, starting from the seventh grade, excursions and practical training are organized for you in factories and repair shops. In production you will get acquainted with many metal-cutting machines, and you will be able to work on some of them yourself. Everything will depend on you.

The 24th Congress of the Communist Party of the Soviet Union outlined new tasks for the development of all sectors of the national economy, in particular mechanical engineering and metalworking.

The decisions of the congress paid great attention to equipping plants and factories with new modern equipment.

To keep up with the times, acquire knowledge and be able to work on new machines and machines, you need to study a lot and persistently.

The Soviet state provides students with every opportunity to master the types of work they are studying in order to become good specialists and active builders of a communist society.

“Plumbing”, I.G. Spiridonov, G.P. Bufetov, V.G. Kopelevich

Polishing is a metalworking operation in which parts are processed with fine-grained and soft materials: various types of GOI paste, cloth, flannel, felt. Polishing can be done manually or mechanically. Polished by hand using...

Every worker has rights strictly protected by Soviet laws, written down in the Labor Code (LLC). Enrollment is formalized by order (instruction). When applying for a job, you must present a work book, passport,…

According to existing worker rules, apprentices should not be allowed to perform any work without appropriate safety instructions. Students working in production are given introductory, ongoing and repeated instructions. The purpose of the induction training...

The goal of socialist production is the most complete satisfaction of the growing material and cultural needs of members of society through continuous growth of production. The main indicator of labor organization in industrial enterprises is its productivity. Labor productivity...

By studying in school locksmith workshops, you master the profession of a locksmith. In addition to the acquired technological information and acquired skills and abilities in plumbing operations, you need to know about the personal hygiene of the worker…

Portable lighting or connecting cords of electrical household appliances are connected to the electrical circuit using plugs. In the base of the insulating material of the plug socket, two brass sockets are fixed, to…

In production premises, in addition to switches, general switches are installed. In large houses, switches allow you to immediately turn off an entire section of the electrical network (for example, a floor or a group of apartments). At school, switches are installed in distribution ...

Often you have to connect the wires of the electrical cord to the socket, switch, plug socket and to the terminals of electrical appliances. To do this, the ends of the connected wires are most often sealed with a ring if they are put on bolts, sometimes...

If the device does not work, then you should: by turning on a table lamp or a special test lamp, check whether the plug socket is working; If the socket is working, check by turning on the same lamp to see if the cord of the device is damaged...

Substances through which electrical charges are transmitted are called conductors of electricity. Good conductors of electricity are metals, soil, solutions of salts, acids or alkalis in water, graphite. The human body also conducts electricity. From metals...

The basic electrical quantities of an electrical circuit include current, voltage and resistance. Current strength Current strength is understood as the electric charge passing through the cross-section of a wire per unit time. Using expressions...

Wires connect power sources to electrical consumers. For electrical installation work and for electrical household appliances, an electric cord is usually used. The cord consists of two twisted insulated wires. Electrical cord Cord wires…

Ruler-pattern in industry

Shoes are sewn using patterns, cookie molds are made, even the smallest garment is cut using a ruler. But besides these well-known industries, such devices are used in aircraft manufacturing, shipbuilding, automobile manufacturing, in the construction of houses and roads, tunnels, in finishing work for architectural and interior decorations. Using such lines, non-standard decorative bricks and many other different parts and products are formed, which must be absolutely identical in size and configuration.

Shipbuilding patterns are distinguished by their unique shape, with many combinations of curves and smooth lines. Therefore, the creation of such rulers is possible using the template-plaz method (plaz or plaz - area). The plaza room must be spacious enough so that the entire theoretical drawing can be transferred to the floor plane. Previously, such a drawing was made with graphite pencils on a light wooden floor.

Pattern ruler in construction

Arranging arched openings using patterns greatly simplifies and facilitates this labor-intensive operation. It consists in the fact that the ruler is made in accordance with the design of the structure, installed between the walls and secured. Brickwork is done according to the pattern. The Roman staircase is constructed in approximately the same way. Templates are made according to the shape of the steps. Most often, such stairs are installed in swimming pools, and the steps, in fact, are an extension of the bowl. The steps of Roman stairs usually increase towards the bottom, and each one has its own pattern.

Types of pattern rulers - marking

Flexible patterns - rulers with variable curvature - are used to capture and reproduce irregular curves. They are a strip of flexible steel to which spacers are attached to hold the rail in a given position. The pattern triangle is used for marking and checking right angles, is used in metalwork to check the perpendicularity of the arrangement of parts and parts, and is made of stainless steel.

Straight edges are used to check flatness for clearance and straightness. They are made from high-quality hardened steel, accuracy class 0 or 1. LD grade with polished working surfaces located on both sides at an angle in the shape of a knife, is used to control the accuracy of metalwork and pattern work. The LT and LC rulers have three- and tetrahedral shapes; a radius groove runs along all working parts.

Model ШД – straight edge, used to control the plane of machines, tables and other working surfaces. It is made of tool steel, the cross-section is an I-beam with a wide working surface. The UT ruler is triangular, angular, and is used to control the flatness of the surfaces of metal products using the “spot on paint” method (the clarity of the contact trace is checked). These rulers are made of cast iron. Most often, such metal rulers have a heat-protective coating.

- Author: Manager Andrey

Rate this article:

- 5

- 4

- 3

- 2

- 1

(1 vote, average: 1 out of 5)

Share with your friends!

Ruler and verification: what's what?

If we talk about a ruler in general, then it is a tool with which it is possible to draw straight lines on a flat plane. It is used to make spatial measurements, constructions and calculations. The measuring instrument looks like a graduated scale, the price of which will depend on the purpose of the device. Sometimes, for convenience, some types may include useful reference data. The material for production is usually wood or metal.

A straight edge, unlike a regular one, has greater functionality, because it is designed to check how straight the surfaces of parts in machines, machines and other types of factory technological equipment are . A straight edge can be used to make measurements not only by direct direct application, but also in cases where comparison with a lumen sample is used along with a combination of a method that allows you to determine such deviations using special tiles and rulers, as well as in a set of probe and tiles together with a lever indicator .

A ruler with verification can have several implementations; among its types it is worth mentioning the following: patterns, bridges and wedges.

Pattern rulers have a double-sided bevel, although in work they also use three- and even tetrahedral models for checking. Testing instruments, which have a somewhat strange name - “bridges”, explain it by their design and similarity to a small bridge - they have a wide working surface of the SD and ShP type, usually having a rectangular or I-beam section. Well, the wedges are located at angles with three edges. The size of such rulers usually starts from 8 cm and ends at four meters. The tool is made of special steel, used for especially durable products, as well as cast iron with high strength.