Soldering borax is used as a flux when using silver or brass solders. The soldering process is the creation of permanent connections, using hard or soft solders.

The borax is intended for soldering using brass and silver solders.

How to use borax when soldering materials together

Soldering where hard solders will be used means that materials with a melting point of more than 400°C will be used. Light solders have temperatures below this value. Brazing usually involves using a mixture of boric acid and borax.

The composition of borax is such that it easily dissolves in water. When burned, it takes the form of a glass mass; its melting point can fluctuate within the following limits: 700-900°C. When soldering with borax, salts are formed that will need to be removed, for which mechanical cleaning is used.

Table of composition and use of borax.

Borax is a high-temperature flux that is used to join cast iron and steel, and copper alloys. In this case, medium-melting solders are more often used: copper, brass, gold and silver. By melting borax, you can dissolve metal oxides and clean the surface of the elements being joined. When completing soldering, remove any remaining salt.

Borax mixed with boric acid 1:1 produces boric flux. The components must be well mixed, then they must be ground in a porcelain mortar.

The solvent is heated in distilled water, then evaporated to obtain a solid residue. For greater flux activity, chloride or fluoride salt can be added to the mixture. You can consider an example with the connection of copper elements.

Usage

Before connecting parts, you need to pay attention to their preparation. The latter is in the following sequence:

- Clean the joints of the elements from dirt and corrosive damage using a scraper with coarse bristles. The flux itself will deal with the oxide film on the surface.

- Use a blowtorch flame to heat the joints of the structures to be welded.

- During heating, leave a gap of at least 1 mm between the elements.

- Introduce borax with solder into the gap, also heated by a lamp, while continuing heating.

- When borax crystallizes, turn off the blowtorch.

- After the parts have cooled, remove salt deposits with a brush.

The first soldering with borax may not be successful due to the small amount of the substance. It is recommended to select it practically. To improve the seam, you can use boron flux with the addition of fluoride or chloride elements.

How to solder copper elements using borax

It often happens that it is necessary to solder copper and copper pipes at home. Many water supply systems installed in modern homes are made from this material. When repairing such plumbing fixtures, it is desirable that the contractor is well acquainted with the necessary actions and the properties of the material.

When connecting copper elements, the advantages of brown soldering are as follows:

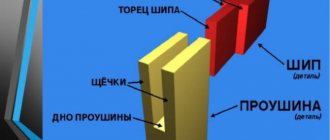

Hard soldering diagram.

- the connection can be made regardless of what the initial temperature of the product is;

- can be combined by soldering copper, that is, metal, with non-metals;

- most of the resulting connections can be unsoldered if necessary;

- parts and solder interact perfectly;

- the shape and dimensions of the metal product are maintained quite accurately, because the base metal does not melt;

- Capillary soldering can provide good strength and high productivity.

This type of soldering has a special technology, which makes it possible to obtain a connection in several steps:

- surfaces intended for soldering are prepared for work;

- Contaminants are cleaned from the surfaces of elements, the oxide film is removed, which requires the use of flux in the form of borax;

- the elements being connected are heated to a temperature equal to the temperature at which the metal of the base material melts;

- liquid solder is introduced into the gap between the parts;

- interaction occurs between the parts and the solder;

- the solder crystallizes.

Stages of soldering with borax

The whole process consists of successive steps, the implementation of which is mandatory:

- Careful preparation of workpiece surfaces before heating.

- Cleaning is carried out to get rid of oxide films, this is where technical drill is needed.

- A blowtorch heats the surfaces to be welded to the desired temperature.

- Heated metal solder in a liquid state is introduced into the space between the parts.

- The essence of the connection is the combination of the base metal with liquid metal solder in a well-heated state.

- The process ends with the final crystallization of the solder.

Tools and materials

To perform the work you will need the following equipment:

- Cutter for copper parts (if necessary).

- Brush for applying borax flux paste.

- Tin solders.

- Flux paste.

- Burner.

Materials and tools for soldering.

Burners may be different. Some are equipped with piezo ignition, but there are also those that are produced without it; here the use of gas cartridges is provided. Expensive burners without ignition are not particularly popular. More often, Polish burners with piezo ignition are used instead - they cost little and better meet user requirements.

The procedure will be as follows:

- the surface of the connection must be cleaned using a special brush, and if we are talking about pipes, internal treatment must also be carried out;

- it is advisable to carry out a final cleaning using emery cloth so that the metal is polished to a shine;

- Flux is applied with a brush - in this case borax - both on the outer surface of the joint and on the inner;

- ensure that the parts are pressed: they are inserted into one another or pressed together.

Subsequent work must be carried out with special attention, since the performer is dealing with an open flame. The gas burner is ignited, then the connection is heated. It should be heated for 15-20 seconds.

Now you need to take the solder and process the edge of the connection with it. Three seconds are enough for the procedure.

To solder copper pipes or other elements, brass wire is used for the additive. Borax can be poured onto the soldering area. You can look at the process in more detail.

Popular manufacturers

Soldering borax is sold under two brands:

- A – used when working with non-ferrous metals, frit, earthenware and others;

- B – indispensable for enamel, glaze, technical equipment, wire and plumbing elements.

Popular manufacturers of this substance today include Rexant, ZUBR, Latus and others . These products are in good demand among consumers, as they have high quality characteristics and an affordable price.

Buisky Chemical Plant, KhimPek and Xiamen have also proven themselves well.

How is the soldering process performed?

When performing soldering at home, you need to understand one subtlety. When borax has been stored in powder for a long time, it is better to melt it first, for which a crucible or fireclay is used. The resulting substance should be crushed into a powder and placed for storage in an airtight container.

Tightness is a prerequisite: the powder is hygroscopic, and due to the presence of moisture in the flux, slags with metal can form.

Before applying flux, the soldering area is heated red-hot. It is better to heat not the soldering area itself, but next to it, gradually transferring the heat to the junction of the elements. When the parts have warmed up, the joint should be sprinkled with a small amount of borax. At the same time, monitor the temperature, wait until the borax melts well and spreads over the soldering area in the form of a film.

It is better to solder with brass, the rod is dipped in borax, after which you need to wait for the powder to melt. The flame that the soldering torch emits should be close to the soldering area, but you don’t need to hold it like that for long. This way you can get a connection with slag and a layer of scale, which will be difficult to remove. Immediately before the solder is applied, the soldering area should be red and the melted borax should be bluish. This moment can be considered optimal for adding solder.

Next, a solder bar coated with borax powder must be brought to the soldering site and heated to the temperature at which the solder begins to melt (in the case of brass, until it glows orange). The melting point of brass and borax is almost the same. Next, the actual work process begins.

Read also: What kind of plug does a bosch oven have?

How to solder copper pipes

Before you start soldering, you need to prepare the following tools and consumables:

- brushes with metal bristles for cleaning joined surfaces;

- devices and tools with which the parts to be joined will be cut to the required sizes;

- gas burner or blowtorch;

- solder, which is selected depending on what material the parts being connected are made of;

- borax, the characteristics of which must meet the requirements of GOST 8429-77;

- brushes necessary for applying flux.

Flux, solder and torch are the main components for soldering copper alloys

Particular attention should be paid to the choice of gas burners, which are presented in a large assortment on the modern market. Such a device, designed to ensure complete heating of the base metal and solder, can be equipped with automatic piezo ignition or manufactured in a classic design. You should only choose burners that use a piezoelectric element for ignition if such a device is manufactured under a well-known brand. Otherwise, it is better to purchase a regular high-quality burner that will provide you with uninterrupted operation for a long time.

Cleaning the joint before soldering

The soldering process itself using borax, including preparatory procedures before its implementation, is most conveniently considered using the example of connecting two pipes made of copper. This process is performed in the following sequence.

- The internal surfaces of the connected pipes are thoroughly cleaned, for which a jaw with metal bristles is used.

- External cleaning of copper pipes, carried out until their surfaces have a metallic shine, is carried out using emery cloth.

- After thorough cleaning, borax is applied to the internal and external surfaces using a special brush.

- Copper pipes coated with flux at the future connection must be joined together. After this you can start soldering.

- Before starting the process, the pipe surfaces must be heated to the required temperature, for which a gas burner is used. The surfaces of the products to be joined should be exposed to flame for at least 15–20 seconds.

- After the surfaces of the pipes are heated to the required temperature, solder is introduced into the soldering area, which also melts under the influence of the flame of a gas burner. Molten solder should be applied evenly to the surfaces of the parts to be joined to ensure the quality and reliability of the joint being formed.

Applying flux to the soldering area

After soldering using borax, the resulting connection should be inspected, for which destructive and non-destructive methods can be used. Most often, such control is performed when inspecting the resulting connection for the presence of external defects. A magnifying glass can be used to perform this inspection, which reveals many joint imperfections.

Use of boric acid and borax in soldering

Boric acid, borax and their mixtures can be used in soldering in cases where copper, iron and zinc have to be dealt with. They are usually used successfully for soldering low-carbon steel and iron (galvanized or non-galvanized) with copper, copper-zinc and silver solders that do not contain manganese and nickel, as well as copper, bronzes (especially ferrous), tombac and brasses with a high melting point - copper-zinc and silver solders (without manganese and nickel).

Crystalline borax (Na2B4O7*10H2O) begins to melt at a temperature of 75 degrees; as heating increases, it loses water and gradually turns into anhydrous salt (Na2B4O7), melting at 783 degrees. Boric acid (H3BО3) melts at 570g. But its active temperature is much higher than that of borax. Therefore, when soldering above 1050g. Boric acid is used, and at lower temperatures (below 800 degrees) - borax.

Since boric acid becomes liquid at a higher temperature, adding it to borax makes the flux thick and viscous, requiring an increase in the operating temperature of soldering.

When soldering alloys containing acidic oxides (for example, silica when soldering cast iron), oxides or sodium salts in the form of sodium hydroxide (NaOH) or sodium carbonate (Na2CO3) can be added to the fluxes.

Where and how is borax used?

From a chemical point of view, borax is a sodium salt with the complex name “sodium tetraborate decahydrate”. With its participation as an active element in the protective flux mixture, a wide variety of metals are combined, up to complex and capricious alloys, for example, copper.

According to this technology, additional metal solders are used for joining; they can also be of different compositions.

Tools and consumables for soldering.

At a high temperature, the borax begins to melt, as a result of which the surfaces to be welded are cleaned with the simultaneous dissolution of oxides in the hot flux mixture.

The essence of this process is the formation of salts followed by surface crystallization. This crystalline deposit is easily removed after the welding process.

What is borax

In this case, the reaction follows the following equation:

the fusible salt (Na2O)2SiO2 turns into slag.

Borax, boric acid and their mixtures have been used as soldering fluxes since ancient times. One of the advantages of boron compounds is their lack of corrosive effect on the seam. Despite this, flux residues after soldering must be removed, since the glassy mass of flux formed during soldering makes it difficult to control solder joints, especially for density.

In addition, during prolonged use, flux residues crumble and turn into a porous substance that can absorb moisture, which can cause corrosion of the product.

To remove residues of borax, boric acid or their mixture, the product should be washed with water or subjected to mechanical treatment.

Both require quite a long time; to speed up cleaning from flux, sometimes the hot product after soldering is immersed in water. The effectiveness of this method is explained by the large difference in the coefficient of thermal expansion of the metal and the flux, as a result of which, upon sudden cooling, the latter cracks and is easily removed with a steel brush. However, such cooling after soldering is not acceptable.

If, when soldering with brown and boric acid, the seam is not always cleaned of fluxes, then removal of residues containing NaOH and Na2CO3 is a mandatory operation, since these compounds cause intense corrosion of the product. This requires long and thorough rinsing of the product with water.

Peculiarities

How to use borax in your work to get the highest quality results? To answer this question, we will talk about all the stages of soldering using borax. First of all, you need to prepare the metal. Clean it from dirt and corrosion. Pay special attention to stubborn stains; they must be removed with a rough brush. The oxide film does not need to be removed, since the borax will handle it itself.

Then, using a blowtorch, you need to heat the surface of the parts to be welded. Leave a small gap between the pieces. Add borax and solder into it, preheated with a blowtorch. Once the borax begins to crystallize, you can stop heating. When borax hardens, it becomes transparent and forms a lot of salts. Remove them from the metal surface. It is important to follow the sequence of operations and not to overdo it with the amount of flux. It's hard to say how much borax to use because it depends on the metal and the weld you want to create. Experiment and with experience you will begin to understand which dosage is preferable. Borax can be used in powder form, or you can make boron flux from it. Boric flux is widely used for soldering copper pipes and cast iron parts. Mix boric acid and borax in a one to one ratio. Then you need to crush the resulting mass in a bowl, and then evaporate it, getting rid of excess liquid. Fluoride and chloride salts are added to the dry residue. Boric flux is ready! It has active properties, allowing you to solder copper parts faster and with better quality.

Technical drill

Technical borax Na2B4O7 - 10H2O loses water during melting and dissociates to form atomic boron. The resulting atomic boron diffuses into the surface of the part. Optimal boriding mode: current density at the cathode 15 - 0 20 A / cm2, voltage 2 - 14 V, temperature 930 - 950 C, holding time 2 - 4 hours; this results in a diffusion layer with a thickness of 0 15 - 0 35 mm. [1]

Technical borax is produced in two grades. [2]

Technical borax is recrystallized from hot water (temperature about 60 C), the crystals of borax decahydrate that fall out during cooling are filtered on a Buchner funnel and dried between sheets of filter paper. During long-term storage, borax crystals may lose part of the water of crystallization, so they must be stored in a jar with a ground-in stopper or in a desiccator, at the bottom of which a porcelain cup with a saturated solution of sodium bromide containing an undissolved excess of this salt is placed.

Species that make up

A balanced alloy based on the dominant metal for creating permanent connections between metal parts by introducing a fusible connector with local heating is solder.

Soldering methods, limiting the effect of temperature on parts, mechanical strength of the connection, and resistance to corrosion determine the variety of types.

Technological requirements for filler:

- Free flow after passing the liquidus temperature.

- Wetting of joint surfaces.

- Mechanical stability, limited shrinkage, heat tolerance, immunity to external influences in the solid state, electrical conductivity.

Soldering brass - a reliable connection at home

A weighed portion of technical borax 0 4596 g, titrated with a solution of HC1 with R0 1062, 21 20 ml was consumed. [4]

Industrial drill supplied by industry contains hygroscopic and crystallization moisture, which, when entering the weld pool, sharply increases the gas porosity of the weld metal. In addition, part of the borax, when moisture evaporates from it, foams and is blown out by the flame, as a result of which areas of the metal are exposed and oxidized. [5]

Borax is obtained from common technical borax (Na2B4O7 - 10H2O) after calcination in an oven at a temperature of 700 - 800 C on a stainless steel baking sheet or in an open fireclay crucible filled with ciu in height at V, due to the strong swelling of borax when heated. After calcination, the borax is ground in a mortar or ball mill. This borax should be stored in a hermetically sealed jar. [6]

For the production of 1 ton of technical borax containing 99 0 - 99 8% Na2B4O7 - 10H2O, 0 9 - 1 t of boron-calcite (40 - 42% B2O3), 0 14 - 0 18 g of soda, 0 10 - 0 15 t of bicarbonate are consumed and 0 01 g of bleach. [8]

To obtain calcined borax, technical borax is poured into an open porcelain or fireclay crucible at 1/10 of its height and placed in an oven at 700 - 750 C. After swelling and settling, the borax is ground into powder in a ball mill or mortar and stored in vessels with an airtight lid before use. [9]

Experimental work carried out at TatNIPIneft showed the possibility of using technical drill as an indicator element for identifying oil-bearing reservoirs flooded with injected fresh or formation water based on different rates of dissolution of the penetration zone. [10]

The temporary compressive strength of gypsum NBSS samples with the addition of 2 25 and 2 50% technical borax is given below. [eleven]

To sustainably maintain the pH value of the drilling fluid, starting from a depth of 5600 m until the end of drilling, it was decided to use technical borax, and soda ash to precipitate calcium and magnesium ions. [12]

Sulfonol, Progress, ANP-2 and a mixture of surfactants (OP-7 sulfonol), reagents (CMC and KSSB), as well as technical borax were tested as retarders for the gypsum solution. However, only with the introduction of borax was the required strength of the gypsum stone obtained. [14]

They produce technical and food grade borax. Technical borax is obtained by reacting boric acid and soda in a boiling solution. After separating the sludge on a filter, borax crystallizes from the cooled solution, which is separated in a centrifuge and washed. Food grade borax is obtained by recrystallizing industrial borax. [15]

Read also: Capacitors with precious metals: list with photos

For aluminum

powder for alloys with a small percentage of magnesium rods for argon welding. Provides tightness. Requires extensive washing - actively corrodes.

Castolyn FBK 192, flux cored solder. Recommended for thin-walled structures with preliminary tinning and creating a gap around the perimeter of 0.2 mm. Shell composition Zn-98%, Al-2%. Advantages of the material:

- No residual corrosion;

- Stability of wettability and fluidity at t 440;

- Acceleration of crystallization;

- Reliable fusion of aluminum with stainless steel, galvanized ferrous metal, copper.

Castolin 192 is suitable for restoring internal threads in body parts, repairing and sealing surface holes, including without applying patches. Overlapping connection.

Welding of copper and copper alloys

When welding copper and its alloys, it is necessary to take into account some properties of copper (high thermal and electrical conductivity, the ability to absorb oxygen and hydrogen) and the components included in its alloys (zinc, tin).

For copper, the following types of welding are mainly used: gas, electric arc with carbon electrode and metal with coatings, in shielding gases and submerged arcs.

When gas welding copper

filler rods made of pure electrolytic copper or copper containing up to 0.2% P and up to 0.3% Si are used.

Copper pipe connection

Copper pipelines are expensive. The investment can be justified with careful installation, which is often carried out by capillary soldering using borax as a flux.

It is worth noting that today, other fluxes are sold that are more convenient to use. One pipe is inserted into the second or fitting so that the gap does not exceed 0.4 mm.

Soldering time is short, 3 minutes. It is important that the parts remain stationary during operation. In order for the borax powder to stick to the surface, the copper is first heated with a torch.

For pipes with a diameter of up to 108 mm, the soldering process is carried out at low temperatures not exceeding 450°. The seam is wide (up to 50 mm), but not very strong. Wide pipes with a diameter greater than 159 mm are soldered at high temperatures. Only professionals can perform the procedure.

In both cases, the solder melt penetrates well into the capillaries of the parts, which contributes to the formation of strong connections. It is recommended to remove any remaining borax.

It must be remembered that soldering is accompanied by the formation of smoke, so you can only work in ventilated areas.

Source: svaring.com

Soldering flux

The last two elements vigorously deoxidize the weld pool.

The most common flux for welding copper contains 70% borax, 10% boric acid and 20% table salt.

The power of the burners when welding copper, due to its high thermal conductivity, should be 1.5-2 times greater than when welding steel.

Copper welding is carried out at an increased speed (to avoid overheating of the metal near the welding site) with the torch mouthpiece tilted at an angle of 70-80° to the surface of the product. Products made of copper of large thickness are heated during welding of the second torch. It is recommended to forge a copper weld at 400–500 °C in order to increase its mechanical properties, and anneal the product to obtain a fine-grained structure. The welding flame should be normal.

When welding copper with a carbon electrode

You can use an open or closed (submerged arc) arc.

When welding with an open arc, filler rods made of phosphorous copper are used with a coating applied to them, which includes borax, acid and sodium phosphate, silicic acid and charcoal. When welding copper with a closed arc,

special fluxes are used.

Copper products, and especially sheet material, can be arc welded using a copper electrode

. In this case, copper welding, including automatic welding, must be carried out under a layer of flux.

Brass

They are welded mainly with an acetylene-oxygen normal flame and an electric arc (carbon electrodes). When welding, the same fluxes and rods are used as when welding copper. Currently, automatic welding of brass with an electric arc submerged arc (copper wire) has been mastered.

Bronze

welded by gas, arc and argon-arc welding. Tin bronze at a temperature of approximately 600 ° C becomes increasingly brittle, so the welding process must be carried out on supports. The purpose of the linings is to remove excess heat in order to accelerate the cooling of the bathtub metal.

When gas welding bronze, borax is used as a flux, and when welding aluminum bronzes, AF-4a grade flux is used.

Date added: 2015-12-22; ;

SEE MORE:

Application in forging

Borax is also used as a flux when carrying out such technological operations as forging. When forging is performed, which is accompanied by significant heating of the workpiece being processed, a thick layer of scale forms on the surface of the workpiece. There are also frequent cases when the workpiece is simply burned out, which leads to a significant deterioration in its characteristics. To avoid this, the surface of the workpiece during the forging process is sprinkled with a thin layer of borax, which acts as a flux.

In conclusion, a practical lesson in video format on soldering copper using flux.

Source of the article: https://met-all.org/obrabotka/prochie/bura-dlya-pajki-flyus-primenenie-gost.html

Borax in the household 02/17/2017 10:45

Borax in the household

There are so many chemicals that are not in stores now – it’s just mind-boggling! Meanwhile, very often all this diversity consists of 3-4 drugs in a variety of packages and combinations. In reality, all this endless variety of prices and packaging differs in how promoted the brand is, and in the useless flavors and dyes.

Borax or Borax is one of the remedies that has recently been used very widely. Its chemical name is sodium tetraborate, chemical formula is Na2B4O7. This chemical compound is considered toxic, but is used in the food industry as a preservative E285. True, in Russia and the USA the use of this food additive is not recommended, although it is no more poisonous than table salt. However, we are interested in this chemical preparation not as a product, but as a universal remedy for a wide variety of household uses.

So, the uses of borax

1. Cleaning the oven. Requires 8 tbsp. spoons of baking soda, half a glass of salt and 4 tbsp. spoons of borax. All this should be dissolved in warm water. The resulting solution or paste, depending on the amount of water, can perfectly clean the oven walls. After cleaning, rinse the oven with warm water.

2. Universal cleaner for smooth surfaces. Dissolve in 2 cups of warm water for 2 hours.

spoons of borax, 2 tbsp. spoons of 10% vinegar and 3 drops of tea tree oil. Use the resulting mixture with a sprayer. This product also works great as a dishwasher cleaner.

3. Window cleaning liquid. Dissolve 2 teaspoons of borax in 3 glasses of water. Spray the glass with the solution and wash it with regular newsprint or a microfiber cloth.

4. Solution for washing organic contaminants. Dissolve in 300 ml of water for 1 hour.

BURA flux for soldering

a spoonful of borax. The solution ideally removes grease and can be used for washing bathtubs, sinks and tiles.

5. For cleaning pipes. Mix half a glass of borax, the same amount of soda and add a glass of 10% vinegar. After half an hour, add a liter of boiling water, stir and use to clean the pipes, pouring the mixture into the location of the blockage.

6. Liquid for cleaning toilets. Dissolve half a glass of borax in 2 liters of water. Clean with a stiff brush dipped in solution. You can pour the solution into the toilet and wait a couple of hours until the dirt gets wet. Then clean the toilet with a brush and rinse with clean water.

7. Bleach for washing. Add 2 teaspoons of borax and the same amount of soda to the washing water. Thus, along with the whitening effect, the water also softens. If there are yellow stains on the laundry, they can be moistened with water and wiped with borax until they disappear.

8. A preparation against flies, mosquitoes, ants, cockroaches and other insects. Mix a glass of sugar and borax with half a glass of cocoa. Sprinkle the drug in places where insects accumulate. If you need to get rid of flies and mosquitoes, then the drug can be poured into jar lids and placed in open places.

9. Washing powder. Mix 200 g of crushed laundry soap, one and a half glasses of borax and the same amount of soda ash. Mix everything thoroughly and add 10-15 drops of aromatic essential oil to your taste. That's it, your homemade washing powder is ready.

10. Flux for soldering and welding. For soldering with hard brass and silver solders, boron flux is used, which is a mixture of borax and boric acid in a 1:1 ratio. For soldering steel and cast iron, boric acid should not be added.

In addition to the above applications, this substance is also used as an antiseptic to protect various organic materials from damage by fungus, rot and mold during construction and insulation of buildings. Borax also has fire retardant properties, meaning it increases fire resistance. This is explained by the fact that its crystalline hydrate contains 10 water molecules and when heated, all of it is released, allowing materials impregnated with such a compound to resist fire for a long time.

Read also: How to weld a pipe through light

In the cosmetics industry, borax is used to make various shampoos, ointments, gels and powders, as well as in bombs and bath salts. This reagent is also used in medicine as an antiseptic, antiviral and antifungal agent, for washing, rinsing, and lubricating lesions of the nasal and oral cavity in some infectious diseases.

Borax is a safe natural substance. In order to be poisoned by it, you need to swallow a very decent amount. Ingestion of up to one teaspoon of this reagent does not cause any unpleasant sensations in a person. The semi-lethal dose (LD50) when tested on rats was about 3 g per 1 kg of weight. But, nevertheless, some safety measures should be observed when handling this chemical: – when working, you must use protective gloves; – store in a closed container, in a cool place, out of reach of children and animals; – this substance should not be added to food; – contact with eyes is undesirable, and you should not rub it into the skin.

You can purchase borax from our company. Leave a request on our website!

There are many types of solders used during soldering. Each of them has its own advantages, which makes it useful for a particular area. Drill brazing flux is often used for soldering difficult metals such as cast iron, steel or copper, but can also be useful for other procedures. This is one of the most common and time-tested fluxes that are used both in the industrial sphere and in the private sector. Soldering borax is relatively inexpensive and can be used for many types of soldering. It gives a complex effect, which simplifies the process and does not require the addition of other components, although in the jewelry industry there are also more complex fluxes based on it.

A drill for brass soldering helps not only improve the soldering properties of metal, but also clean its surface from excess films, deposits and other things that can damage a high-quality and reliable connection. In its pure form, it is a high-temperature flux, the melting point of which is approximately 700-900 degrees Celsius. But the properties of the material allow it to be easily dissolved in water, resulting in a softer flux. The degree of dissolution determines how high the melting point of the material will be. Over the course of its existence, soldering specialists have come up with many ways to use and create combinations for this material. Soldering borax is produced in accordance with GOST 8429-77.

Imported

- IF 8001 Interflux is one of the best fluxes for lead-free soldering of SMD components, including work with BGA chips. Quite expensive. Does not require rinsing.

- IF 8300 BGA Interflux (30cc) – for soldering BGA packages. It is a gel. Free from harmful halogen.

- IF 9007 Interflux BGA is a no-clean soldering paste for soldering with lead solder. After work, it leaves a barely noticeable layer of flux with high resistivity.

- FMKANC32-005 – weakly activated no-clean cream. Shows good results when soldering BGA chips and working with infrared soldering stations.

Flaws

- After use, a deposit of salts forms, which must be removed mechanically;

- It is necessary to choose storage areas that are free of moisture, since high humidity will cause the flux to deteriorate;

- To prepare the material for use, you need to spend time and choose the right proportion, which can lead to errors.

Varieties of Borax

There are two main varieties that relate to the appearance of the material. The first option is the solid form. Borax soldering flux is supplied in the form of a powder with fine solid fractions. Thanks to this, it is easy to lay it on the metal surface before soldering in the required quantity and it will not spread at the same time. This variety is supplied in a special box that protects the material hermetically from the penetration of moisture and other foreign factors. Fractions are white.

The second type, which is more often used for lighter metals and their alloys, is diluted borax. In this case, you are offered the same material, but dissolved in liquid. Due to this, it can be used at lower soldering temperatures. Using this type is also easier, since small parts are simply dipped into the liquid, after which they can be soldered. This is used both in the jewelry industry and in other places where small items are worked. Contacts, wires and other types of equipment come into good contact with dissolved flux. Despite the fact that the principle of using borax for soldering in liquid form is somewhat different from the standard one, they have almost the same effect.

There are also varieties in the form of mixtures, when other fluxes are also used. This is necessary in cases where it is impossible to achieve the desired results using one substance. Proportions and composition depend on specific goals. Most often it is combined with boric acid.

Composition and physicochemical properties

The composition of borax for soldering includes sodium chloride and barium chloride, in some cases boric acid is added to it. It is not used in its pure form for all procedures, since this would require too high a melting point. Drill soldering powder is a high-temperature flux, so its main property is resistance to high temperatures. It is worth noting that the material perfectly retains its chemical properties even at a lower concentration than what is supplied. Thus, the flux solution has a fairly high level of dissolution of the oxides of all base metals for which it is used.

It can also dissolve fatty films and other unnecessary things that will interfere with the normal soldering of the material. Brown soldering protects against many types of defects that can occur in work.

Composition and properties

The chemical nomenclature of soldering borax indicates that it is a crystalline hydrate of the sodium salt of tetraboric acid . If the substance contains 10 water molecules, then it is called sodium tetraborate decahydrate. In simple words, it is a salt that is surrounded by a shell containing 10 or 5 water molecules .

A temperature of 64 degrees causes decahydrates to melt and lose water in the process. Borax is dehydrated at a temperature of 380 degrees Celsius. Tetraborate is characterized by withstand heating up to a temperature of 742 degrees and melting when it increases.

Borax contains sodium chlorine, barium chlorine and, in some cases, boric acid. Flux in the form of a solution has a high ability to dissolve metal oxides, as well as fatty films and anything unnecessary that can prevent the adhesion of materials.

Thanks to the use of borax during soldering, many products are produced without defects.

This is interesting: Step (conical) drill for metal: selection, application, sharpening