Heating to high temperatures is a necessary component of many technologies that are used in home creativity, commercial activities and industrial production. Factory heating devices are highly efficient and, accordingly, have a price that not everyone can afford. A do-it-yourself muffle furnace for hardening metal can be assembled at minimal cost with excellent performance characteristics. To achieve the desired result, you should familiarize yourself with the device, operating principle and possible options for assembling a 1000 degree oven with your own hands.

Classification of muffle furnaces

Based on the type of heating elements, muffle furnaces are divided into:

- electrical;

- gas.

By purpose they are divided into:

- for metal melting;

- for firing ceramics;

- for melting glass;

- for hardening metal;

There are also industrial and homemade muffle furnaces.

Industrial muffle furnace with automation

But it is impossible to make gas-powered stoves at home, although gas is cheaper than electricity, since such experiments are prohibited by law. Electric oven control provides convenient temperature control.

According to their design type, muffle furnaces are divided into:

- horizontal (the simplest);

- vertical or potted type;

- bell-shaped;

- tubular.

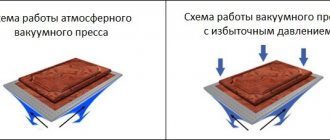

Heating can be carried out in air, in a vacuum or in a gas environment. At home, it is only possible to design a furnace with heat treatment of products in an air environment.

When you make a muffle furnace yourself, you can give it the desired shape and volume, and decorate it in a style suitable for the interior.

Main parts of the structure

- The outer part of the furnace, the shell (body). It is convenient to use a disused gas stove, or rather an oven from it or an electric stove, as a body for a future muffle furnace. To use them, all plastic parts are dismantled. In cases where it is not possible to use such housing options, it is welded from sheet metal (thickness of at least two millimeters).

- Thermal insulation layer. This part of the design is extremely important. The efficiency of the furnace and the heat loss it will incur depend on its quality. The inner layer of thermal insulation is a fireproof (fireclay) brick that can withstand temperatures up to one thousand degrees.

- The outer layer, which reduces heat loss to the surrounding space, is laid from perlite or basalt wool. Asbestos is unsafe to use; when it is heated, carcinogenic substances are released into the atmosphere.

- Elements that directly heat the workspace. The heating elements inside the muffle furnace are spirals twisted from nichrome or fechral wire. Thickness 1 mm. Nichrome (nickel-chrome) wire is very ductile and resistant to corrosion.

- Fechral (aluminium, chrome, iron) wire is somewhat cheaper due to the absence of aluminum in the composition and also has the necessary properties for its use in a muffle furnace.

List of materials and tools for assembling the structure

- grinder (machine for grinding and cutting materials) with cutting wheels for metal;

- welding machine;

- sheet steel >2mm thick;

- metal corners;

- fireclay fire-resistant brick;

- fireproof mixture;

- heat-resistant silicone;

- basalt thermal insulator (cotton wool, density 200 kg/m3) or perlite;

- safety glasses and respirator;

- nichrome (fechral) wire with a cross section of 1 mm;

- wire cutters or metal scissors.

Manufacturing of the device

In this case, we will tell you how to make a vertical muffle furnace for firing ceramics with your own hands.

To do this you will need the following tools:

- angle grinder (grinder) and 1-2 wheels;

- electric arc welding and electrodes;

- metalworking tools, including wire cutters;

- 2mm nichrome wire.

and materials:

- 2.5 mm steel sheet or used oven body;

- corner;

- fittings;

- basalt wool;

- refractory fireclay brick;

- fireproof mortar;

- silicone sealant.

Purpose of the equipment

Why do you need a homemade heating chamber at home? It can be intended for various needs: firing of ceramic products, hardening of cutting steel elements and melting of metals. The thermal chamber can be heated either by electricity or run on gas.

The external shape and internal design of the furnace can take different configurations. The main task is to achieve a certain temperature regime in a limited container space.

DIY Tips

- Separating fireclay bricks and drilling holes to install the heating element.

When created from fireclay bricks, any pottery tempering requires the use of a heating element. And if there is a need to place an appropriate solution, then it will be necessary to make cuts and technical cavities in the ceramic material. It is best to first mark the entire location of the element and only then resort to making cuts. All this can be done at home using simple power tools.

You should start by sawing the seams using a cutting machine with a special diamond wheel. And then it will be necessary to remove the resulting areas of ceramics. And here it is best to use a hammer drill. Since this will avoid cracking and damage to the material and each of the elements. You should not use a hammer and chisel, because when hit, cracks may form, which will subsequently lead to the unusability of each of the elements.

- Choice of small or large muffle furnace.

Homemade stoves selected and created must be obtained with an understanding of the technical processes in which they will take part. And here a logical question arises: to create a larger oven or to implement a more miniature solution. If jewelry is melted down, a minimal amount of internal space will suffice. This will allow for more practical use of the products and will not require additional space.

But in the case of blacksmithing, it will be necessary to create more significant design solutions that will allow melting and hardening of metal.

Watch the video in which the user demonstrates in detail the structure of a self-made muffle furnace:

Disadvantages of homemade design

Each device is not without certain shortcomings, and a homemade device also multiplies them. Given the set goal, you can sacrifice some requirements for the sake of fulfilling others. However, everyone should know the list of negative consequences.

A homemade design is deprived of all guarantees, including safety guarantees. Evaporation of metal from the heater coil can lead to it being contained in the form of impurities in the composition of the precious metal being processed. Homemade thermal insulation will not provide full concentration of heat in the firebox, so the body of a homemade stove is very hot and requires careful handling. By the way, this is also a disadvantage of some factory models. Failure to properly monitor and regulate temperature may result in the oven not being able to perform a particular heat treatment task. https://www.youtube.com/watch?v=ABWK3hD9f1E

Ready-made factory-made ovens are designed to perform a fairly narrow range of tasks, but this is more an indicator of professionalism than a disadvantage. The main parameters and scope of application of a particular device are indicated in its passport.

The leaders in the production of compact and stationary muffle furnaces are such companies as TSMP Ltd (England), SNOL-TERM (Russia), CZYLOK (Poland), Daihan (South Korea). The presented list reflects the top list of companies for evaluating suppliers of high-temperature equipment to the Russian market.

Do-it-yourself muffle furnace: manufacturing instructions

Stage one. The inside of the cylinder is lined with basalt wool.

High temperature mats

Fastening basalt wool to the body with ceramic buttons

Stage two. Thermal insulation is being constructed, for which, as mentioned earlier, you only need to take fireclay bricks. The procedure is as follows: seven bricks must be joined in the body so that they form a pipe. In the future it will serve as a working chamber.

Marking the refractory of a muffle furnace

The bricks are laid out in a row, and marks are made on each of them at which they will be cut. Next comes the actual cutting, after which the bricks must be of such a shape that they can be connected into one hollow pipe. To simplify the procedure, the bricks can be numbered. At the end of cutting, the pipe is assembled, tied with wire, and the symmetry of the shape is checked. If necessary, adjustments are made.

DIY muffle furnace

Stage three. Nichrome wire is twisted into a ø6 mm spiral by winding it onto a base (used electrode, pencil, etc.). The brick is then removed from the body and placed back in a row.

Laying the heating coil

Stage four. A spiral is applied to the bricks and future grooves are marked. The correctness of the lines is measured by the building level. As a result, the laid spiral should lead from the bottom to the top of the pipe. Contact of the turns is not allowed, as this may cause a short circuit.

Stage five. To bring out the ends of the spiral and connect them to the machine with a stabilizer, three strips cut from ceramic tiles with polypropylene channels for the wire are inserted between a pair of bricks. These channels will greatly simplify future repair work.

Stage six. The finished structure is placed in a steel case. In this case, one brick is placed on the bottom of the body, pre-coated with fire-resistant glue. To remove the ceramic channels, holes are made in the housing in appropriate places.

The finished structure is placed in a steel case

Stage seven. The same sheet steel is used to make the lid. A circle is cut to the size of the structure, and for more reliable fixation, fireclay bricks (1 pc.) are attached to it on top. Then the handles, canopy and metal latch are welded. The edges of the lid in contact with the walls of the oven are covered with a layer of fire-resistant silicone. Silicone is applied only to a previously degreased surface.

d43a33c3a7afd155c436c14ef42ac831.jpeOven cover

Oven cover

Oven cover

Stage seven. Test run. To allow the structure to dry completely, place it in a warm, well-ventilated place. The use of any heating devices is prohibited as this may lead to cracking of the masonry. After drying, the coils are connected to a machine with a stabilizer, and the heating power and operating temperature are adjusted.

When operating the oven, the lid must be tightly closed.

Finishing work

The working chamber for the furnace is made of brick or ceramics. After this, it is placed in a pre-prepared steel case, which already has thermal insulation

It is very important to note here that there must be a distance of at least 4 cm between the walls of the chamber and the walls of the housing. Insulation is placed in this gap

The cover for the muffle furnace must be made of two layers of metal, between which there is a layer of thermal insulation. Naturally, you must not forget about arranging a handle for opening the oven.

After this, you need to make several holes in the housing through which the wires of the heating element and thermal sensor can be brought out. The connection occurs to a separate cable, which, to increase security, will be attached to a 20A machine. A ceramic cartridge can be used to connect the output and cable. Steel pipes are used as legs for the body. They can be welded or screwed. If a bolted connection is used, the bottom of the chamber must be raised so that the bolts are on the outside.

Areas of application

The layout used must allow the required amount of material to be placed for processing.

It is worth dividing all furnaces into types of application for working with the material:

- hardening of metal and Kremlin products;

- firing and bringing the material to a certain structure, imparting strength;

- tempering, imparting plasticity to the material to make the corresponding products;

- blacksmithing, for splitting metal for subsequent processing and creating more acceptable sizes and workpieces;

- laboratory studies to study the effect of temperature treatment on metals and alloys of various formulas.

This division allows you to determine the types of temperature conditions and the total volume of the furnace, creating all the necessary design solutions and formulas for independent design of a muffle furnace.

Refractory masonry

We buy fireclay bricks at the construction market. This brick is intended for laying furnaces of stoves and fireplaces. This brick is able to withstand prolonged exposure to heat at a temperature of 1000 degrees and repeated cycles of cooling and heating, has a high heat capacity and thermal inertia. As a binder, it is best to buy a special fireproof dry mixture for laying fireclay.

Fitting and marking

Varieties and distinctive features

In order to be able to create a high-quality stove with your own hands, it is worth understanding what types it is divided into, taking into account the fuel and energy consumed, namely:

- gas;

- electric.

This separation allows the use of various energy sources, which allow heating the space inside the created structure. At the same time, a stove with installed elements for electric heating is more popular. This allows you to control the temperature inside the structure if it is necessary to process certain raw materials.

A modern muffle furnace has its own characteristics in design and resulting production capabilities, namely:

- in the resulting design and volumes of internal space;

- methods and methods of heating the internal space of the furnace;

- use of special protective formulas and functions;

- operating temperature parameters.

Depending on the temperature obtained, all furnaces are divided into three types:

- moderate temperature ovens, with parameters of 100-500 degrees Celsius;

- medium ovens, with temperatures of 400-800 degrees Celsius;

- high-temperature oven, with parameters 400-1400 degrees Celsius;

- ultra-high temperature stoves, they heat up to 2000 degrees Celsius.

How to choose the right device?

To operate the equipment as efficiently as possible, you need to pay attention to the following characteristics:

- options;

- maximum possible loads;

- power;

- maximum firing temperature;

- operating voltage;

- supply voltage;

- uniform heating;

- safety of equipment operation;

- price.

First of all, you need to decide on the volume of the working chamber, as well as the temperature range

In addition, be sure to pay attention to the difficulty of heating

Types of laboratory furnaces

No less important indicators when choosing equipment are the speed and uniformity of heating of the muffle chamber.

Depending on individual requirements, you can choose a horizontal or vertical oven: the first has a fairly large capacity, and the second heats up in a short period of time.

Laboratory muffle furnaces are equipped with open or closed heating elements. Devices of the first type are ideal for use in conditions where it is necessary to heat the chamber to a high temperature in a short time. However, such equipment is more susceptible to the negative effects of various aggressive substances released during the processing of objects.

Ovens that use a closed heating element have a longer service life and uniform heating of the working chamber, but it takes much longer to reach maximum heating. A significant disadvantage of devices of this type is that if the heating element breaks down, the entire chamber will have to be replaced.

The simplest design is for equipment that has a single-stage thermostat. Its main feature is that from the very beginning the chamber is heated to a certain temperature, and then it is maintained throughout the working process. Most often, these kilns are used for simple tasks such as drying or firing.

For more complex analytical work, muffle furnaces are used, which operate through special software control.

They allow you to adjust the heating process to several different levels. Control occurs using a microprocessor with a digital indicator and an audible alarm.

If necessary, the program can be launched automatically.

To choose a working stove, you need to check the equipment for any mechanical damage (chips, abrasions, scratches, etc.) on all components.

Useful video

Watch the video, which shows how to start making a muffle furnace: what materials and tools are required, what needs to be done first, and what actions are not recommended.

1ba8d3678997cd1220be3ef58cf59f99.jpe ce84308707c136bdb783c4f4656f6cf0.jpeMaking the lid

- Cut a circle out of steel, identical in diameter to the already fully assembled structure.

- Place fireclay bricks on top of the glue - it will provide sufficient sealing.

Weld handles on the sides to make it convenient to lift and remove the lid, and a latch for closing.

Cover the edges with fireproof silicone; before doing this, be sure to degrease the surface (even White Spirit will do).

Let us remind you that when the oven is operating, it must be closed. Excessive air ingress will lead to rapid wear of nichrome.

What should the ventilation be like?

In reality, manufacturing, or rather the process of firing ceramics itself, is not so beneficial to health. And then many can conclude that the stove has no place in the house at all. There should be a special closet for her. Many people think even longer that they pollute the air a lot and so on and so forth. But compared to other indicators of pollution, the emissions from such a stove are simply nothing to the air.

But for those who dared and brought the stove into the house. What kind of ventilation should there be so as not to cause harm. So, the room must be well ventilated, since the firing time is many hours and during this time there is a constant release of substances that are harmful to health. Ventilation options for a room with a stove for firing ceramics:

- several open windows will help make air move and remove all odors and harmful particles immediately from the window;

- a special design of the ventilation system (a hole with a fan in the wall itself, through which air from the street will be taken into the room and emissions from the stove will be removed);

- Downdraft system and Updraft are special ventilation systems that craftsmen have thought out specifically for rooms where kiln firing takes place.

Here are many ways to help your hands not give up your favorite activity, and your health not to suffer from the harmful release of substances during firing.

Possible difficulties and problems when creating a furnace

When manufacturing a device, difficulties arise with the selection of material and installation of a temperature control system. Incorrectly selected materials lead to rapid destruction of the muffle. Thus, some craftsmen, to save money, use low-quality bricks and clay-sand mortar instead of fireclay. This leads to cracks in the muffle and heat loss.

The cracked muffle is temporarily sealed with a solution of fireclay clay. The camera needs to be removed and replaced with a new one.

If the furnace is connected to the network without a thermostat, the temperature in the muffle is not controlled. This leads to damage to products that require firing at a given temperature. To solve the problem, you should purchase a thermostat and electrical equipment, assemble a control unit and connect it to the heating elements of the muffle.

Safety precautions

- You can work with the stove only if there is grounding.

- It is forbidden to start work if there are chips or cracks on the body.

- Do not touch the device during operation.

- It is strictly forbidden to touch a working spiral.

- Constant supervision is required during operation of the stove.

Despite the relative ease of manufacture, such a device is not very common among home craftsmen. This is due to high electricity costs. Some people think that it is possible to make a muffle furnace using wood - well, if you can find a log with a calorific value of 14,000 kcal/kg, then yes, it will work. Although it is still better to use a forge as such “firewood” - it was under such conditions that the first such furnace in history was invented.

If you still have questions about how to make a muffle furnace with your own hands, watch the video instructions.

Video 2 Do-it-yourself muffle furnace

Creating a muffle furnace body

You can create the muffle furnace body yourself or use blanks. As a workpiece, you can use an old oven, an electric or direct heating oven, a refrigerator, or a washing machine. It is also worth considering that it is necessary to remove all plastic parts, since they are not adapted to high temperatures.

You can create the case yourself. Sheet metal is suitable for this. You should choose a material whose thickness is more than two millimeters. A rectangular box should be made from it using a welding machine.

Sheet metal is suitable for creating the body

If you want to construct a cylindrical muffle furnace, you should bend the metal into a radius and weld the seam.

To protect the metal from corrosion, it is advisable to cover the stove with special fire-resistant paint. A special thermal insulation layer will improve the properties of the oven. It serves to reduce heat loss, thereby increasing the heat in the chamber. For the thermal insulation layer, you can use basalt wool, as well as perlite.

Automation with temperature-time tasks

There are three types of automation for hardening furnaces. The cost of organizing furnace control increases along with the comfort of use. The simplest option is a simple thermostat with a thermocouple as a temperature sensor. This device will simply maintain the set temperature with a hysteresis of about 30–50 °C. The holding time is controlled manually, as is the moment the temperature point is reached.

More advanced automation is being developed specifically for electric ovens. Thermal controllers of the Autonics TCN4 type have a proportional power control function, providing adjustable hysteresis up to 1 °C. The device is also equipped with additional functions, such as an alarm when the set temperature is reached. If desired, the alarm channel can be used to activate a time delay relay installed in series with the thermostat.

The most advanced in this regard are automation devices for Profile-M type furnaces. They differ not only in built-in power relays, but also in the possibility of more flexible configuration. Such controllers have a preset timer, and also have the ability to configure heat treatment with a complex temperature profile, sequentially setting the duration of time periods during which a certain temperature should be maintained.

rmnt.ru

Preparing fire bricks

The main and very first step towards creating a muffle furnace is preparing refractory bricks with chamfers in the right place for better fit of the joints during assembly. To do this, take a solution of fireclay clay and pour it into special molds.

It is important to note that:

- Six or seven (optional) refractory brick blanks must be very carefully adjusted at the joints to ensure a muffle without cracks. Next, you need to press all the bricks together with chamfers and fix them in this position with a special tie. It can be made from a metal tape 2-3 cm wide. At the ends of the tie it is necessary to provide devices that tension the tape. After assembly, you will get a six or seven-sided muffle design.

- Then, you need to make several transverse cuts in each refractory brick blank. They will house a heating element in the form of a spiral. The grooves are made with an abrasive saw. In one workpiece the grooves are made with an inclination, and in the rest - horizontal. The distance between the grooves is at least 2 cm, and the configuration must match the diameter of the electric spiral placed in them.

Assembling and pouring the frame

Having assembled the muffle into one whole, you can begin to manufacture the frame (casing). To do this, you need to select a metal pipe of the required diameter. In this case, there must be a gap of at least 150 mm between the bricks and the frame for better insulation and reduction of heat loss from the electric furnace. If there is no ready-made pipe, the casing can be made independently from galvanized sheet steel.

The assembly of the muffle and the furnace casing must be performed in the following order:

- Place the fireproof structure on a level surface.

- In two boards made of plank, thick plywood or chipboard, cut holes corresponding to the diameter of the stove casing.

- Insert the lower part of the casing into one shield, and the upper end of the pipe into the second.

- The shields must be fastened so that they do not slide along the smooth metal surface. This will prevent deformation of the sheet metal and accidental movement from its place during further work.

- Then a solution of heat-resistant and heat-insulating material is carefully poured into the space between the muffle brick and the casing.

Assembling and checking the oven

Assembly begins with the manufacture of the muffle furnace bottom, which can be made as a separate structure. This will make it easier to transport the stove in parts to the place of its use.

- A cylinder with a diameter equal to the dimensions of the casing and a height of 25-30 cm is made from a galvanized sheet. Legs made of a pipe or profile metal with a cross-section of 2 cm are attached to it to eliminate fire hazards.

- You need to make holes at the bottom end of the workpiece and weave a wire mesh through them. It will be a holding element for the poured and hardened solution made of heat-resistant material. The lid of the muffle furnace is made in the same way, in which it is necessary to provide a technological hole for ventilation.

- In the grooves of the muffle, lay a spiral of the required diameter, length and cross-section of the wire, so that the turns do not touch. Exit the ends of the wire through ceramic tubes. All that remains is to connect the electrical wires and test the resulting structure.

That's all for now, see you in the next lesson.

Method two. We make a stove without having a metal casing at hand

The manufacturing process in this case is not much different from that described above, but there are definitely some nuances here. Let's start with the fact that the working volume of the design below will be about 13 liters. The spiral, as mentioned above, can warm up to a thousand degrees in just 1.5 hours, while the temperature of the outer walls of the device will not exceed 100 degrees. The algorithm of actions should be as follows.

Step 1. First, using a 4x2 centimeter profile pipe (with a square cross-section), we build a stand for the device. After this, we paint the finished stand with enamel.

Step 2. We attach a sheet of galvanized steel on top of the stand (its thickness should be approximately 0.1 centimeters), using “metal” self-tapping screws.

Step 3. We make the walls from fireclay bricks and a special fireplace composition (everything is the same as in the previous version). After the solution hardens, we make grooves for the spiral.

Step 4. We assemble the bottom from brick separately, and use the same mortar for fastening. Before continuing work, wait until the structure is completely dry. Do not forget to wet each brick immediately before laying.

Step 5. We lay a thermal insulation layer on top of the metal base (we can use the same basalt wool for this). In order to maximize compaction of this layer, it must be moistened before fixing the brick bottom.

Step 6. We continue the traditional laying of the stove, but we try to ensure that all voids and seams are carefully filled.

Step 7. We traditionally make the lid for the chamber from fireclay bricks, but at the same time we fasten them together with a metal tie.

Step 8. Place the spiral in the prepared grooves and insulate the structure from the outside with thermal insulation material. Next, we cover everything with sheets of galvanized steel, which are cut according to the dimensions of the resulting chamber.

As you can see, this requires knowledge not only in the furnace business, but also in the field of electricity. You can see another possible manufacturing method in the video below.

Necessary materials

Directly for the manufacture of the furnace you will need the following materials:

- fireclay brick

- one and a half kW spiral

- heat-resistant clay or mortar

After its manufacture, it is placed in a casing. It can be welded from 2 or 3 mm steel sheets. Its dimensions are taken based on the size of the oven. You can also use an old gas or electric oven as a casing, after first removing all plastic parts and elements from it. The space between the furnace and the casing is filled with insulating material such as mineral wool.

Vertical loading kilns are better suited for ceramic firing. In furnaces where work will mainly be carried out with melting, hardening or other processing of metals, the heating process of the product should be controlled by using a temperature sensor; workpieces are loaded into such chambers horizontally.

Let's look at a step-by-step example of a muffle furnace

In this case, an old iron rectangular tank is used for the casing. It needs a little tweaking and it will be fully suitable for its role. Using a grinder, I cut off the edge of the tank, which has a round hole, 5-10 cm wide. Along the edges we drill holes for fastening the door to the body on the curtains.

The work should begin with planning: Assemble the oven dry from brick, make markings on it from the inside, in those places where the spiral will need to be laid. In the brick, according to the markings made earlier, using a drill, using a Pobedit drill, you should make indentations. In the illustration below, the drill is placed at an angle to the groove, this is how the desired result can be optimally achieved.

We put the prepared brick into the oven; an external frame for it should be made from the corner. We put a spiral into the grooves. We coat the entire structure with a solution of mortar and water. All cracks should be sealed.

Next, you should make an electronic unit that will control the heating of the coil. Moreover, heating the oven will not be easy, but it will be a stepwise heating. For this, a step thermostat is used. A stand should be made for the muffle furnace to avoid losses below. The frame from the corner is cut out and welded at the corners, legs are welded on the sides, also from the corners. A row of plates is welded on top.

We use special fiberglass heat shrink. It serves to protect a thermocouple, the characteristics of which are as follows: chromel-alumel (TCA) diameter 0.5 mm, length 1 m. We also use a ceramic tube with two holes for a thermocouple. You will also need thick heat shrink to power the spiral. We put a heat-resistant fiberglass casing on the thermocouple, and insert its end into a ceramic tube. At the top of the stove, a hole is made with an ordinary drill and a thermocouple must be inserted there and covered with a lethal solution. Let it dry.

To connect, you will need a special heat-resistant wire for electric ovens. The coated stove is hidden in a casing; its thermal insulation will be provided by basalt wool. At the top of the casing body you need to make a hole for the output of power wires and a thermocouple to control it. Before final packaging in cotton wool, a test connection of the oven should be made.

The device itself is installed on an asbestos sheet. The placement of cotton wool should be carried out wearing medical gloves. Control unit for the furnace. Next, we proceed to the manufacture of the furnace control unit.

The set of components consists of:

- housing (taken from a small electrical panel)

- electromagnetic contactor (in this case also “Soviet”)

- terminal blocks (one ceramic one for connecting the nichrome spiral from the muffle furnace to the power wires, and more made of fire-resistant plastic for the main switching)

- 16A automatic; bolts, nuts, engravers; thick wire and plug

- thermostat Profile-M-1K multi-stage single-channel

The thermostat can heat according to a complex schedule; you can set the heating time and temperature during this interval.

This is what the finished device looks like:

Method one. Making a chamber stove from a refrigerator or washing machine

For such a design you will need only three main elements:

- metal body (suitable for a washing machine or refrigerator);

- heating coils;

- chamber made of fireclay material.

When everything necessary for work is ready, we proceed directly to the manufacturing process.

- First, it strengthens the bottom of the metal case. We use a steel corner for this purpose (as an option, it can be replaced with an ordinary pipe with a diameter of 1.5 centimeters). We weld pieces of corners/pipes into the corners of the bottom - they will serve as support legs for us.

- In addition, we need to similarly strengthen the top of the frame, the door, and at least one of the sides (the one to which the door hinges will subsequently be welded).

- We lay a 1-centimeter layer of basalt wool on the bottom of the body (a similar layer must be laid on the inner walls). To avoid deformation of the insulation under the weight of the chamber, we lay several pieces of metal corner or rectangular pipe. At the end of these procedures, we cover the insulation with a sheet of metal.

- After this, we decide on the fireproof material that we will use in the manufacture of the chamber. Ideally, these should be fibrous fireclay slabs, which can either be cut on site after purchase or ordered in the required sizes. Our DIY clay kiln requires six of these slabs.

- We bind the bricks using mortar, which corresponds to the marking of the material. There is also a cheaper option - ordinary fireclay clay or fireclay masonry mixture.

- Now we begin the laying itself. We adjust the bricks as tightly as possible relative to each other, making the seams between them no larger than 0.5 centimeters. If necessary, we cut individual bricks to the required dimensions.

- We start laying from the bottom of the box. Dissolve the mixture with water and mix thoroughly. Before installing each brick, we moisten it with water, otherwise the mixture will dry too quickly.

- We begin to raise the walls. We place sheet metal and insulation in the gap between the body and the brick layer. If the brick is laid flat, then we can not use insulation.

- The upper part will take more time: the bricks along the edges need to be laid with a slight upward slope, and trapezoidal blocks must be laid between them.

- We weld the hinges and adjust the door. We must ensure that the gap between the brick layer of the body and the door is minimal.

- After the masonry has dried, we begin the next stage of work. On the surface of the bricks we must make grooves into which the heating coil will be laid. We use a spiral of nichrome wire 0.1 centimeters in diameter; the diameter of the coil will be about 0.5-0.7 centimeters. The grooves should be the same depth/thickness.

- When heated, the wire can expand, and the spirals, in turn, “climb out” of the grooves. Therefore they should be recorded. The image below shows the main ways to install spirals:

There is another way - to build a chamber from heat-resistant brick, since this material is sold everywhere and is used for laying stoves and fireplaces. For the chamber of such a furnace, it is recommended to use lightweight bricks marked “ShL” (for example, “ShL-0.5”).

This mixture is sold in the same place where bricks or fireplaces are sold. To fix the brick on a metal surface, add a little cement to the mixture (about 30 percent of the total volume).

Note! To create the outer layer, we prepare the solution separately - with the addition of cement.

The door is also lined with fireclay bricks. We make a quarter around the perimeter in such a way that a protrusion eventually appears (we will place it in the stove window).

- using small pieces of wire;

- through a groove located at an angle;

- by means of a groove having a protrusion;

- using an MKR tube.

Note! A very important point: the turns should not contact each other!

- We make 2 circuits from the spirals so that the temperature can be adjusted using a switch (the same as in an electric stove).

- We mount a ceramic plate on top (for example, from a burner) and fix the ends of the spiral with bolts.

- We will equip our kiln for firing clay with our own hands with the switch shown below, in which there will be three contacts on one side and two on the other.

- We mount the switch in such a way that its pin goes out, i.e., onto the front panel. We connect all the wires, on the side where there are only two contacts, we connect zero and phase.

- We connect the cables leading from the plate to the other three contacts. Typically, one of the cables should close a pair of contacts on the edge of the plate.

- As a result, we should get the following: at the first “speed”, the spiral circuits will be connected in a certain sequence, since in this case the temperature will be the lowest.

- This, in principle, ends the furnace manufacturing process. At the end, we need to thoroughly dry the structure, for which we place it in open sunlight or next to a heating radiator for at least 1-2 months. After this period, we need to perform final drying by running the device for 3-4 hours at the minimum “speed”. When steam is no longer billowing from the structure, the device can be turned off - it is completely dry. We can proceed directly to firing!

We bring the ends of the spirals upward.

If the “speed” is second, then only 1 circuit will be connected due to the fact that the temperature will be higher. It is characteristic that this should be the circuit that is drawn from below, so that the elements located in the lower part are also heated.

Finally, at the third “speed” the circuits are connected simultaneously - here the temperature will be maximum.

FAQ

Many questions that arise during the assembly of the stove are the same for most users. This allows you not to wait for them, but to immediately clarify:

Is there a need for a power reserve for the spirals, or is it necessary to wind the spiral exactly as calculated? In this case, the power reserve acts in the opposite way - if you give a reserve length, the resistance will increase and the degree of heating will decrease. It is recommended to act in strict accordance with the calculated indicators. Is it possible to use regular construction bricks instead of fireclay bricks? Ordinary brick cannot withstand high temperatures and begins to crumble. In addition, it has high thermal conductivity, due to which the furnace body will become very hot. Is a metal casing required, or is it possible to tighten the fireclay bricks with metal clamps and plaster them with a composition for stoves? The housing is necessary so that the stove can be moved from place to place. If this is not necessary and the oven is stationary, you can do without the housing. If you use ready-made heating elements, will you get a normal muffle furnace? No, heating elements should not be used for such installations. It will not be possible to obtain the required temperature; the heating elements will take up too much space and will quickly burn out. If the electrical wiring in the house and in general in the area is dilapidated, is it possible to connect a muffle furnace to it? The stove can be connected bypassing the house wiring - run a separate cable to the common panel. However, if the line itself is in poor condition, it is better not to take risks. You can leave all your neighbors without electricity.

Heating the muffle with gas

A homemade muffle furnace can operate not only from electricity, but also under the influence of a gas burner. You can purchase such a heating element or make it yourself.

To create a gas burner, you need a metal pipe 10-15 centimeters long. The diameter of the pipe should not exceed a few centimeters. First, you should make a through hole near the edge for connecting the gas tube. It is also necessary to make several one-sided holes perpendicular to it. They are necessary to ignite the device.

For a gas burner you will need a metal pipe 10-15 centimeters long

The gas tube is made of copper, its diameter does not exceed 0.8 centimeters. Threads are required at both ends of the tube. In the middle of the device you need to make a small blind hole for the gas to escape. One hole must be closed with a plug, and a gas cylinder must be connected to the other. When combining elements of the device, be sure to install a valve between the hose and the burner, as it will protect the structure from fire.

Operating rules

The electric oven may only be plugged into a reinforced socket. You can also run a large cross-section wire directly from the shield. In addition, it would be useful to install a circuit breaker.

Since this device model has exposed wires, you need to be extremely careful with it. Do not touch the coils while the oven is running. To avoid accidents, it is recommended to install a limit switch on the door, which will turn off the unit when the door is opened. If you are not very good at electrical work, seek the help of a specialist who can help make the device as safe as possible, including grounding it.

Lining and arrangement of the firebox

The very concept of a muffle furnace implies the presence of a muffle - an internal heat-resistant capsule that covers the heating circuit spiral, protecting it from small debris and scale. The muffle, as a rule, is removable in furnaces, which allows for repair and replacement of heating elements.

The main difficulty is to manufacture the muffle and the heating assembly body at the same time. To do this, you will need two types of heat-resistant ceramics: one for making the body with grooves, the other for the thin-walled muffle. For a ceramic base, it is better to use a mixture of refractory clay with an aluminum oxide content of at least 30%. The clay should be diluted with excess water and left to swell for a day, after which the settled water should be removed from above and only the swollen sediment should be left.

The ceramic body of the heater is massive, so it cannot be made from a pure binder; a filler is needed. Glass fiber, dry quartz sand or crushed fireclay are good options for the latter. The total clay content in the solution should not be less than 50% by volume; as a result, the mixture acquires the consistency of a viscous plastic paste. If the composition turns out to be more liquid, excess moisture is removed by adding small portions of building gypsum immediately before use.

Fireclay powder

The heater body is made on a three-dimensional corrugated cardboard template, the dimensions of which should be 15–20 mm larger than the planned dimensions of the firebox on each side. First, you need to wind a cord or silicone hose of the appropriate diameter onto the template, forming the required number of grooves for the spiral. After this, the template with the cord must be covered with clay on all sides, avoiding the formation of voids and achieving a wall thickness of at least 40 mm. The addition of alabaster helps the piece maintain its shape before firing. Carefully remove the cardboard insert from the dried ceramic body and pull the cord out of the grooves.

For the lining of the firebox, ceramics made from higher quality kaolin are used. Enriched clay of the KFN-2 brand is optimal; as a filler it is better to use crushed fireclay of high purity with a content of about 20–25% by volume of dry components. The mixture is mixed as described above and used to form the internal lining.

To ensure that the muffle can then be easily separated, spirals are inserted into the ceramic body in advance. Then the inner surface is covered with scraps of newsprint according to the papier-mâché principle. You should get at least 8–10 layers, while the inner surface should contain as few irregularities as possible. After the paper has dried, a refractory lining compound is applied to the inside. It is better to do this in several passes, giving time for excess moisture to evaporate; as a result, the muffle wall should reach a thickness of 15–20 mm. In this state, the entire assembly dries for several days until the plasticity is completely lost and a ringing sound appears when tapped.

After drying, primary firing is carried out - voltage is applied to the spiral and the hot product is kept for 4-6 hours. During the firing process, fechral passes the crystallization threshold and, becoming more fragile, takes the form of channels. The clay in the ceramic liner and muffle is baked and vitrified, becoming resistant to cyclic temperature changes. Well, the paper and glue residues simply burn out, forming a minimum technological gap for easy removal and installation of the muffle.

With this manufacturing method, you can use some tricks. For example, forming a ceramic body on a cone-shaped template to make it easier to remove the muffle. It would also be a good idea to extend the front part of the assembly, where there are no heaters, or place a small coil at the bottom of the chamber. Several copies of the muffles themselves can be made at once for one furnace.