Powered by gasoline | 06/26/2016

Modern construction cannot be imagined without earthmoving machines, one of which is a manual trencher. With its help, trenches can be dug in soil of any hardness without any problems and in a short period of time. Engineering communications, communication and power supply cables, and pipelines are laid in them. And today, in this article, we will introduce you to this amazing device.

Areas of application

Trenchers are machines that have a wide range of options, which allows them to be used in various fields, namely:

- arrangement of open pits for laying utilities;

- formation of trenches for laying the construction base;

- digging ditches to install drainage systems in areas with high humidity;

- loosening the soil for further planting of various plants;

- dismantling the road surface for the purpose of laying a new road surface, repairing or installing utilities;

- cutting individual elements from sandstone and other similar materials;

- excavation of a tree along with an impressive lump of earth for replanting the plant in another place.

This technique is also used when performing other types of excavation work. The machine can be used for any type of soil and at any time of the year.

Additional information about the purpose of the model

The trencher described above is used to develop trenches in frozen and thawed soils of the 3rd category. The shape of the recess will ultimately be rectangular. The soil may contain inclusions of crushed stone, the diameter of the elements of which reaches 50 mm. The exception is waterlogged or loose soils, where it is quite difficult to obtain a formed trench.

This mini trencher is designed for use in temperate climate areas. You can work at any time of the year, and the ambient temperature should range from -10 to +30 °C. The relative air humidity should not be higher than 80%. It is also important to pay attention to the dust content of the air - it should be less than 0.1 m3.

Design Features

A similar trench-digging machine consists of the following elements:

- Tractor . This is a machine that activates the operating mechanism of the equipment and is responsible for the movement of equipment in a straight line during the construction of a pit. To control the tractor, a driver's cabin or a hinged visor is used.

- Cutting part . It is this element that ensures the excavation of soil and the formation of a ditch of certain dimensions.

- Dumping device . With the help of this element, soil is thrown or loaded from the pit being formed.

- Hydraulic cylinders and rods . These elements are responsible for the movement of the working part when forming a trench, as well as holding it in one safe position when the equipment moves along the roadway.

In addition, some models of machines are equipped with a blade or mounted loading elements in the front of the equipment, which allows it to be used not only for digging pits, but also for digging trenches after installing utilities.

Additional device information

The trencher includes:

- frame;

- mounting panel;

- folding plow;

- bar chain;

- tension mechanism.

The body contains a guide beam - the bar chain slides along it. The drive sprocket shaft and bearing are installed in the drive bracket. The mounting panel consists of horizontal beams and brackets that fit the coupling device. A mounting panel with six bolts is attached to the body.

The soil is removed from the edge of the trench using a sprocket and auger, which are mounted on the drive shaft. This design prevents soil from falling back into the trench. If you have to work near fences or walls, the auger must be removed. To do this, unscrew the auger mounting bolt.

Types of cars

There are several types of machines, depending on their design features.

Chain

This type of technology is in demand among users. The working body of this machine has the following device:

- Frame - is a rectangular frame made of high-strength metal, which imparts rigidity to the structure;

- Sprockets - tension and wire, the first of which is located at the end of the bus and provides chain tension, and the second is on the shaft of the reduction gear and it activates the chain;

- A chain is an element located in one or two rows, consisting of several links into which cutters or scrapers are inserted.

- Side auger - an element designed to remove soil that the chain digs up;

- Shoe is an element that is located on the tire of the working mechanism and is responsible for cleaning the chain from adhering soil;

- Reduction gear – activates the chain;

- A single hydraulic cylinder is an element designed to adjust the dimensions of the pit and to raise the working device to a safe position.

Chain trenchers are recommended for use in constructing trenches 0.15 m wide and up to 5-6 m deep.

Rotary

This is a technique with a wide range of applications. The equipment design is as follows:

- Frame – an element on which the working part and other devices are fixed;

- Rotor – a disk on which working cutting mechanisms are placed;

- Protective casing – protects the control cabin from stones and rocks flying out from under the rotor during operation of the mechanism;

- Hydrostatic drive – a device that drives the rotor;

- Hydraulic cylinders are mechanisms that help deepen the working part of the equipment;

- The rear support wheel is a device for setting the required digging depth and for transporting equipment along the roadway.

Rotary-type equipment is recommended to be used to create wide channels up to 2.5 meters, the depth of which reaches 3 meters. The main advantage is high performance.

Flaws:

- large dimensions, which makes it difficult to deliver equipment to the digging site;

- high cost of work.

Tracked

Such equipment is installed on crawler tractors. The machines are equipped with a rotary or chain type working body.

Advantages:

- high cross-country ability;

- good degree of adhesion to the soil;

- high motor power;

- the possibility of positioning the frame and working body in different positions;

- Possibility of using equipment on hilly terrain.

Flaws:

- cannot be moved over long distances without using a special carriage.

Manual

This is a convenient tool that is small in size. The device is recommended for use in summer cottages and private houses. Simple models consist of a gasoline engine and a chain working element.

There are also models characterized by high power and performance. Such devices are attachments to walk-behind tractors, walk-behind cultivators and self-propelled units.

The manual device is recommended for use in the construction of narrow shallow channels up to 1 meter.

Description of trencher brand TKMG-1200

This manual small-sized trencher is a device that does not require registration with the State Technical Supervision Authority. In the manufacture of this model of equipment, foreign components are used, including a Japanese gasoline engine. The drive of the working body is hydraulic.

Among the main advantages of this model are:

- durability;

- operational reliability;

- stepless speed control.

You can adjust the rotation of the cutting chain yourself. It should also be mentioned that this equipment has higher power due to the hydraulic drive. The gasoline engine works exclusively to rotate the hydraulic pump.

The manual trencher TKMG-1200 has an acceptable cost. It is quite often compared with analogues produced in England, the USA and Germany. However, foreign analogues, although equipped with a hydraulic drive, are much more expensive. The advantages of this installation are not only the cost, but also the presence of additional options in the form of the ability to install winter chains. They provide anti-slip properties. The installation can be supplemented with a trailer for transportation to the work site.

Advantages and disadvantages

Trenchers have the following advantages:

- high speed;

- a large number of additional options;

- can be used for any type of soil thanks to the powerful working body;

- the possibility of arranging canals at any time of the year;

- ease of use;

- reducing the likelihood of soil collapse, since the edges of the ditch are smooth;

- reducing the cost of transporting soil;

- possibility of digging channels of various sizes;

- can be used in any weather at any time of the year.

In addition, if the equipment is used on the roadway, the area of destruction of the coating is reduced.

Flaws:

- high cost of equipment;

- Some types of equipment require additional equipment for transportation.

Cons of trenchers

Trenchers have many advantages, but consumers also note their disadvantages. Among the others, the first and foremost is the high cost. It sometimes affects the fact that the buyer cannot afford such narrow-profile equipment, because they have to use it infrequently. Another disadvantage is the expensive rental of equipment. In addition, you can use it only with certain skills. But if you nevertheless purchased such equipment, you may encounter the problem of storing it, because for this you will need to allocate a separate place.

However, a trencher in a private household may be useful only once or twice, when you are constructing a house and outbuildings. Therefore, before purchasing such a unit, you need to think three times, because otherwise you may spend money on an unprofitable purchase.

Equipment selection rules

When choosing a technique, it is recommended to focus on the following points:

- Soil type.

- Dimensions of the trench to be dug.

- The size of the area where the work will be carried out, as well as the size of the equipment.

- Machine performance - it is best to choose models with the highest performance, as they will help you finish the job quickly.

Buy or rent

If you are involved in an activity that requires the regular use of the described units of special equipment, then it would be more advisable to purchase it than to lease it. However, it should be borne in mind that a manual small-sized trencher can cost you 150,000 rubles. minimum. The maximum cost reaches 500,000 rubles.

If you are purchasing a trencher to solve a specific task, then it is better to rent it. The machine is selected individually, and the leasing cost usually includes the operator’s labor, as well as the cost of additional materials.

Rating of the best manufacturers

Both domestic and foreign companies are engaged in the production of trenchers. Below are the best ones.

Caterpillar

This is an American company that is popular all over the world. It produces various types of special equipment, including trenchers. Machines from this manufacturer are recommended for use in construction, agriculture, etc. The equipment is suitable for constructing shallow trenches for laying utility lines.

Vermeer Manufacturing Company

This is another popular American company. It represents several lines of trenchers of different types.

Expert opinion

Kurdin Sergey Sergeevich

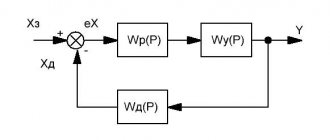

The manufacturer's equipment is equipped with electronic control using a microprocessor system. It synchronizes the operation of the tractor and the working part of the equipment. This process not only simplifies the operation of the machine, but also allows you to quickly detect a malfunction if it occurs.

Case Corporation

This is a French company engaged in the production of trenchers. This equipment is made of high-quality materials and is distinguished by high-quality assembly. However, it does not have very high productivity, which is the main drawback of the technology.

Raditsky Machine-Building Plant LLC

This is a Russian Bryansk manufacturer that produces rotary trenchers based on tracked tractors. These are large-sized machines, the use of which is recommended for constructing wide and deep ditches.

DSUE "Dmitrov Excavator Plant"

The manufacturer produces chain-type equipment. The machines are highly productive. The equipment can be used at any time of the year, since it is equipped with several types of chains, including for frozen ground.

JSC "Mikhnevsky Mechanical Repair Plant"

The manufacturer offers users chain-type equipment for use at any time of the year. The plant's equipment is of high quality and productivity. In addition, the machines have a long operating period without any malfunctions.

OJSC "Kopeysk Machine-Building Plant"

This is a Chelyabinsk manufacturer that produces chain and bar-type mining machines. The equipment is recommended for use on frozen soils. The equipment is distinguished by high quality, ease of use and a long service life.

Soil characteristics

First of all, evaluate the characteristics of the soil and the conditions for its development.

It is very important. Based on the characteristics of the soil, you can determine which trencher is capable of laying a trench in a given soil and what its performance will be in these specific conditions, because it is clear that the machine works much faster and more efficiently in soft soil than in rocky soil. Soil characteristics can vary dramatically in different places, sometimes located literally an hour's drive from one another. It is even more important to know the properties of the soil if you are going to work in an unfamiliar area. Machines and techniques that work well in one place may not work at all in another. And the reason is not necessarily that the machine cannot cope with the new job - it may simply be equipped with a cutting chain with the wrong type of teeth (see choosing the right type of teeth below). For example, the machine perfectly lays trenches through potato fields, but becomes absolutely helpless on rocky soil.

Therefore, in order to select a trencher that is optimally suited to given conditions, it is recommended to use the experience of local dealers/distributors of the trencher manufacturer, who have specialists familiar with local conditions on their staff. They will help you choose the right car. The manufacturer can provide general advice on machine specifications and other issues, but conditions vary across the country. Local dealers are well acquainted with their specifics, and their experience should be used, especially since consultation is free.