Hot metal stamping

The peculiarity of the method is the deformation of the workpiece after heating it to a certain temperature. Form formation occurs as a result of forced redistribution of heated metal along the recesses of the inner surface of the die.

Features of hot stamping

The process is based on the use of metal plasticity, which increases when heated. Before forming, the blanks are evenly heated in special automatic control units. They ensure maintenance of the required temperature throughout the entire volume of workpieces and eliminate the formation of oxide films.

Equipment used for heat treatment:

- Electrical contact installations. Heating is carried out by electric current passing through the workpiece.

- Induction systems. The heating of the blank occurs due to eddy currents arising in the surface layer of the blank.

- Gas ovens. The temperature of the workpieces increases in an insulated chamber filled with inert gas.

Hot metal stamping is carried out by trained personnel with practical skills and experience in this type of production.

This method produces two types of parts:

- Elongated. These can be: levers, shafts, knobs and others. The work is carried out flat and ends with shaping in blank forging rolls.

- Disk. These include: rings, discs, gears, covers. In this case, the method of upsetting to the end of the workpiece using stamping transitions is used.

Closed method

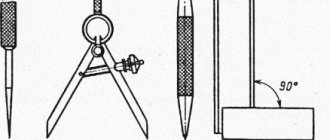

To obtain products of the required shape, presses with a protrusion at the top and voids at the bottom are used. There is a minimum gap between the fixed and moving parts. The connector cavities are located at an angle of 90° relative to each other. The method is used in cases where the dimensions of the finished product and the forging match the parameters.

Open way

In this case, there is a larger gap between the working parts to allow excess metal to drain. Trimming and punching dies and crank presses are used to remove flash. The technology can be used for stamping products of any size. A flawless surface, a uniform structure and metal savings are the advantages of the open method.

Stamping streams

The creation of complex shapes with differences in thickness and height, protrusions and bends is carried out thanks to surfaces that have special depressions, blanking and stamping grooves.

They come in several types:

- Drawing. They are used to increase the length of individual sections by applying frequent blows while simultaneously turning the part.

- Procurement. Necessary for shaping the workpiece and giving the finished product a shape with minimal metal waste.

- Pinch. They are used to reduce the height while simultaneously increasing the width of a separate section of the workpiece.

- Roll-on. They ensure uniform distribution of metal along the axis of the workpiece with an increase in the diameter of individual parts.

- Bending. They are used to form forgings with a bending angle of 90°.

The final necessary shaping of the part occurs in the stamping strands. They are:

- Rough ones. To bring the dimensions of the workpiece closer to the required dimensions of the part and reduce wear on the finishing groove.

- Finishing. They are installed in the middle of the die, and are used for final molding of products. During its manufacture, allowances for shrinkage are taken into account. The extruded metal flows out through the cladding groove.

Additional operations

At the final stage, after removing excess material in the finishing stream, the shape of the part is corrected. This is required to correct its curved axes. Products made of alloy steels and large sizes are processed in a hot state. Small caliber products are adjusted after heat treatment and cooling.

The physical properties are brought to the required values during the final heating. Heat treatment relieves residual stress, reduces grain size and increases ductility.

Cleaning from scale is carried out by mechanical processing. The procedure for large products takes place in shot blasting complexes. Small parts are cleaned in tumbling drums.

Product calibration is used to reduce roughness and obtain accurate dimensions. After this, there is no need to carry out finishing processing; it is enough to sand the resulting parts. For the work, special dies with particularly precise grooves that repeat the configuration of the forging are used.

Advantages and disadvantages of hot stamping

Advantages:

- Saving metal by reducing losses.

- Possibility of manufacturing parts of complex shapes.

- Reduced labor intensity.

- Obtaining products of precise shape and configuration.

- High level of productivity.

The disadvantages of the method include:

- High cost of design and manufacturing of equipment.

- Complexity and energy intensity of the process.

- The maximum weight does not exceed 4 tons.

The hot method is used to produce large series and in cases where the complexity of the shapes and thickness of the products does not allow cold stamping.

History of forging and stamping production[edit | edit code]

Blacksmithing and blacksmithing have a long history. Man has long been aware of the simplest blacksmith tools for forging: a hammer, tongs and anvil, as well as the simplest heating equipment - a forge. The first mechanization of forging processes dates back to the 16th century, when mechanical lever, water-actuated hammers driven by the energy of a water flow began to be used. In the absence of hydropower, piledriver (falling) hammers were used.

In 1842, James Nesmith built the first steam hammer, and in 1846, Armstrong built the first steam hydraulic press. In the same 19th century, driven mechanical and pneumatic hammers began to be used, and crank presses and other crank forging and stamping machines were developed.

Cold metal stamping

The cold method is a technological operation in which a metal workpiece is subjected to deformation without preheating.

Sheet stamping

Parts using this method are produced by pressing metal sheets, strips or rolls. The thickness of the resulting product does not exceed 10 mm. Sheet metal stamping is in demand for mass production of products that are absolutely identical in shape and size.

Two types of presses are used to carry out the work:

- Universal. They are designed for cutting, bending and drawing.

- Special. With their help, deep drawing and specific bending of parts is carried out.

Sheet metal stamping can be carried out using mechanized equipment or automatic presses.

Workpieces for work are cut, if necessary, using mechanical or hydraulic shears. Wide sheets are cut on disc tools with cylindrical legs. The curved contour is made with disk or conical scissors.

Types of operations carried out during sheet stamping

Parts are made in two ways:

- Shape-changing. This includes: twisting, bending, winding, crimping, molding, stretching, flanging. During the operation, the workpiece material is not destroyed, only the shape and size changes.

- Separating. It includes: slicing, piercing, trimming, punching and stripping. In this case, the workpieces are separated during shearing along a given contour.

Pros and cons of the method

The disadvantages of cold sheet metal stamping include the high cost of equipment. The process pays off quickly only in mass production.

The advantages of this method are:

- Ability to perform multiple operations in parallel.

- Obtaining interchangeable parts.

- Increased productivity and efficiency.

- Cost-effectiveness of mass and serial production.

- Obtaining durable parts while maintaining their minimum weight.

- Dimensional accuracy and high surface quality.

Cold stamping is designed to produce products weighing no more than 1 ton. Production of heavier weight products is not recommended.

Volumetric cold stamping

This universal method is in demand in the production of a variety of metal products. There are several types of volumetric stamping.

Cold extrusion

The workpiece is placed in a cavity, from which the metal is extruded into holes located in the working mechanism. It is carried out on crank or hydraulic presses. There are four options for extrusion:

- direct;

- reverse;

- lateral;

- combined.

The ability to obtain products without destruction or deformation of the workpieces is the advantage of extrusion.

Disembarkation

The process is carried out on special machines. A rod or wire is stamped. They are placed in the working area and cut into blanks of established sizes. The cut parts are transferred to the stamping mechanism.

Cold metal stamping in open dies

The method is based on molding parts by filling the die cavity with metal. To facilitate the process and weaken the resistance of the metal base, the parts are divided into transitions, between which they are annealed. Thanks to this, the ductility of the metal increases, the risk of destruction of parts is reduced and the permissible degree of forming increases.

Cold die forging is carried out in open dies. Under cold deformation conditions, closed stamping is used to produce products from non-ferrous metals.

Advantages and disadvantages of die stamping

The main disadvantage of this method is the rapid wear of the dies. The reason for this is the significant mechanical loads experienced by the equipment used.

Advantages of volumetric stamping:

- Producing high-quality products without scale.

- Strength of manufactured parts and dimensional accuracy due to the absence of oxidation.

- High performance.

- Minimum surface roughness of products.

- Possibility of full or partial automation.

- No need to heat the material.

- Efficiency of metal use.

The quality of production depends on the correct assembly and operation of the die.

Roll stamping[edit | edit code]

Roller stamping is a form-changing operation of metal forming, producing axisymmetric parts from a cylindrical workpiece by simultaneous action of radial and axial loads on it. The axial load of the workpiece is created by moving the punch, and the radial load is created by rolling its side surface in rollers or rolls. Thus, roller stamping is a method of complex local deformation, in which one of the main forging operations is combined in one technological process - piercing or upsetting with transverse rolling or rolling. Roller stamping makes it possible to produce round solid and hollow parts, thin-walled and thick-walled small-sized products used in instrument making, as well as large-sized parts with high accuracy and quality with technological efforts that are an order of magnitude smaller than with traditional methods of volumetric stamping. Complex loading of the source of plastic deformation by local periodic action with simultaneous action through a permanently fixed zone makes it possible to obtain a new technological effect that is unattainable by other methods of deformation. Roller stamping helps improve the physical and mechanical properties of the processed metal, ensures the required arrangement of its fibers, which increases the performance properties of the resulting parts. The relatively low cost of equipment, short production preparation time, the ability to quickly change over to a different standard size of a part, and the use of low-power equipment make it possible to use roller stamping in both large-scale and medium- and small-scale production.

Literature[edit | edit code]

- Lermantov V.V. Stamping // Encyclopedic Dictionary of Brockhaus and Efron: in 86 volumes (82 volumes and 4 additional). - St. Petersburg, 1890-1907.

- Golenkov V. A., Dmitriev A. M., Kukhar V. D., Radchenko S. Yu., Yakovlev S. P., Yakovlev S. S. Special technological processes and pressure treatment equipment. M.: Mechanical Engineering, 2004. - 464 pp.: ill.

- Forging and stamping: Handbook in 4 volumes; Ed. E.I. Semenova and others - M.: Mechanical Engineering, 1987. - T.2: Hot stamping; Ed. G. A. Navrotsky. — 384 p.

- Bryukhanov A. N., Rebelsky A. V. Hot stamping. Design and calculation of dies. M.: Metallurgizdat, 1952. 665 p. from illus.

- Pomeltsov S.V. Handbook on cold stamping. — 2nd ed., rev. and additional - M.: Rosgizmestprom, 1948. - 139 p.

Magnetic pulse stamping[edit | edit code]

In magnetic pulse stamping, electrical energy is directly converted into mechanical energy, leading to deformation of the workpiece. For stamping, the workpiece is placed in a strong pulsed magnetic field created by a solenoid with a connected capacitor bank. Under the influence of this magnetic field, eddy currents arise in the workpiece; the interaction of the magnetic field induced by them with the magnetic field of the solenoid leads to deformation. The process takes place in several tens of microseconds[1].