A screwdriver is an indispensable tool for every self-respecting owner. It is found in almost every home, and you don’t have to be a specialist or master to be able to use it. People began to widely use this tool back in the 18th century, and since then the screwdriver has undergone significant evolutionary changes. In addition to the fact that new types of slots have appeared, changes have also affected the handles, which are able to reach the target even in hard-to-reach places.

Basic provisions

Just like several centuries ago, a screwdriver consists of three main elements: a handle, a rod and a tip. The handle of all screwdrivers is almost the same, the main properties that it should have are: ease of holding in the hand, strength of the material and, necessarily, impediment to electricity. As for the rod, it can be of different lengths, depending on the inaccessibility of the fastening element that needs to be tightened or unscrewed. The tip has many variations, depending on the type of fastener to which the tool will be applied. The following types of tips are distinguished:

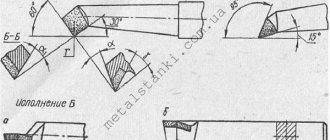

- Flat . The oldest type of standard tip, considered the most common. The tip is made in the form of a narrow straight plate and is used when replacing door handles, sockets, repairing electrical appliances, and so on.

- Cross-shaped . It is also no less common type than the flat tip. It is made in the form of a cross with four equally spaced edges. Thanks to its spline arrangement, this type of tip has improved adhesion to the surface of the fastener, allowing you to unscrew and tighten elements with better effect. It is used in self-tapping screws for wood and metal, in motorcycles and cars, and in household appliances.

- Cross improved . It is made in the same form as a regular cross, but has additional slots placed between the main ones, one for each span. In this way, an even greater effect of tightening bolts and screws is achieved. It is widely used in fastening furniture products.

- Hexagonal . This tip is made in the shape of a regular hexagon. Due to the tight contact with all the walls in the slot of the fastening element, the maximum effect is achieved, which is superior in efficiency to the cross tip. Used on furniture screws (confirmant), bicycles.

- Six-pointed . It is a hexagon with pointed corners and is used for small bolts in mobile phones and other complex devices.

- Square . An equally common type of tip, most often used in computer technology.

- Triangular . This type of tip is made in the form of a triple slot, resembling a triangle with blades equidistant from each other. Used in household kitchen appliances. Easily replaced with a flat-head screwdriver of the required width.

Which tip is preferable?

We will not talk about the type of tip, but about the material of its execution . After all, the functionality of a screwdriver depends on the strength of the tip. With prolonged use, especially if the type of screwdriver is incorrectly selected to match the slot, the tip quickly wears out, its edges may crumble and lose their original shape. Working with such a tool is inconvenient and significantly increases the amount of time required for repair or installation. To prevent this from happening, many manufacturers use high-strength materials for the tip, such as molybdenum steels or chrome vanadium alloys . Many screwdrivers have a magnetic tip that can hold small parts, which will be very convenient when working with small screws.

Markings

Each nozzle has its own marking, which is applied to the tool in the form of a Latin letter or a combination of several letters and numbers. So, the tips have the following designations:

- Flat - SL (Slotted). Marked with numbers indicating the length of the tip 1−10 mm.

- Cross-shaped - PH (Phillips). They have the following numbers indicating the diameter of the tip: 000 (1.5 mm), 00 (1.9 mm), 0 (2 mm), 1 (2−3 mm), 2 (3−5 mm), 3 (up to 7 mm), 4 (from 7.1 mm).

- Cross advanced - PZ (Pozidriy) PX (Phillips Square-Driv and Philips Quadrex).

- Six-pointed - TORX. They are designated by the letters E4-E44.

- Hexagonal - HEX (Hexagonal).

- Square - Robertson.

- Triangular - Tri-Wing.

When determining what type of tool to use, you must also consider the size of the fastener.

Some types of special tips for screwdrivers have an empty circular recess in the middle of the slots; such screwdrivers are called “vandal-proof” because they have a narrow range of applications and not every person has in their arsenal of tools.

Accessories

There are no individual accessories for screwdrivers. They are complemented only by kits that combine diverse types of attachments or screwdrivers.

Such a kit often consists of a housing with recesses for convenient placement of basic and spare parts.

- Small or budget kits are small plastic cases.

- Professional models - a suitcase with a handle for comfortable carrying, plastic or rubber-coated.

Inside contains a set of screwdrivers, replaceable heads or bits.

The larger the set, the more variations there are for different types of work, sizes and shapes of marks.

There are models supplemented with protective agents - anti-corrosion liquid, oil for lubricating metal elements, and a cleaning brush.

Rechargeable models are complemented by a charger and a replaceable battery. Household variations often do without these accessories - the buyer independently takes care of timely charging.

Types of handles

Screwdriver handles have also undergone considerable changes during the evolution of household and professional tools. They have become more comfortable, more powerful and stronger. And some have added complex elements with rotational mechanisms. In addition to the traditional types, there are also the following:

- Handle with heel. This type of screwdriver is characterized by the fact that the rod is located along the entire length of the tool and comes out from the reverse side. The concept of "heel" arose because the area that protrudes from the other side forms a thick projection that can be hit with a hammer. Used in dirty and rusty places where a screwdriver can be used as a chisel.

- Handle with ratchet. It works as an intermittent movement in one direction with a conversion of reciprocating rotational movement and a switch that allows you to change the direction of movement. Typically, such screwdrivers are produced with a set of various attachments, allowing the tool to be used on almost all types of fasteners.

- Swivel or T-shaped. Such a screwdriver is made in the shape of the letter T or with a hole in the upper part of the handle for additional leverage, which allows such a tool to tighten fasteners as tightly as possible.

Depending on the type of work, the inaccessibility of the fastening element, as well as the type of fastener itself, different types of attachments and sizes of screwdriver rods are used. From the miniature length of the rod, measured in millimeters, to the longest, several tens of centimeters. From a regular flat attachment to a hex ratchet. There is also a screwdriver with a flexible shaft for getting into hard-to-reach places.

What to look for when choosing a screwdriver?

In specialized stores, the selection of screwdrivers is so large that anyone would be confused. Sometimes sales consultants can come to your aid, but, unfortunately, they do not always recommend a truly high-quality product, so you should rely only on yourself. The only thing you can do directly in the store is to carefully examine the product; you will be able to evaluate how it will cope with its main task only after purchase, so be careful.

Pay attention first to the handle, hold the screwdriver in your hand. it should fit comfortably in your palm and not slip. The handle itself, no matter what material it is made of, must be made carefully. If it is rubber, it should not have pores or excess material at the junction. Then pay attention to the rod; some manufacturers apply markings indicating what material it is made of. The presence of such markings may imply factory quality.

The tip, as the most important part of the screwdriver, must be very durable. Look at its color, if it is darker than the rod, this indicates additional reinforcement, which is a clear advantage. Even little things like this can help you decide and choose the best product that will serve you for many years.

The article was written for the site.

Tags:Construction fasteners, Construction

Non-standard applications

It happens that you need to tighten something in a hard-to-reach place where only the shaft of a screwdriver can get through. And there is no special tool at hand that can hold the fastener. Then you have to resort to such a trick as magnetizing the tip. Then the bolt or screw will be easily held on the tip, which will allow you to deliver it and tighten it anywhere. The following steps will show you how to magnetize a screwdriver at home:

- Using a magnet. A powerful magnet, preferably neodymium, is suitable for this. The stronger the magnet, the better the magnetization effect. You can buy the necessary magnet at the market or at a hardware store. If you have old computer hard drives at home, you can use the magnets in them. For proper magnetization, it is necessary to clean the surface of the rod from contamination and dry the surface after processing. Then you need to take the magnet and move it along the shaft of the tool from the handle to the tip, you need to do this several times, then turn the tool a quarter turn and do the same with each side. You only need to move the magnet in one direction. If, after completing the procedure, the tool is not able to hold the fastener, then the entire process must be repeated again. In case of repeated failure, it is worth replacing the magnet with a more powerful one. A tool made of good steel can hold magnetic domains for up to several months. If the tool needs to be demagnetized, then you can carry out the same procedure, but in the direction from the tip to the handle, or knock the tool on the floor or wall, which will help destroy the magnetic domains.

- Using a battery. For this method, you will need a small cross-section electrical wire with a length of at least one meter and ends stripped on both sides. A 2.5 square wire with single insulation is best suited. The ends of the wire are stripped, and the remaining unstripped part is wound around the screwdriver rod, thus forming a kind of magnetic field. Then take a battery or crown with a power of 6 to 9 volts (no less and no more), to which the stripped ends of the wire are connected. There is no difference where to connect the negative and positive contacts. It is important to know that it usually takes half to one minute for the tool to become fully magnetized. After this time, the battery must be disconnected from the wires, the tool must be freed, and it must be checked on the fastener. If magnetization is unsuccessful, you can try to increase the number of skeins, placing them in two layers on top of each other. Increasing the battery power can also help, but you should be wary of electric shock or sparks, so all manipulations should be carried out with dielectric gloves.

- There are also several options for magnetizing the instrument, which would most likely be considered amateur. You can magnetize the instrument using a silk scarf or synthetic rag. If you carefully rub the tip with a similar cloth for a long time, then for some period of time, the screwdriver will be able to hold a small bolt or screw. If you don’t have anything on hand that can magnetize the tool, you can use a hammer or a heavy wrench. To do this, you need to position the tool with the tip facing north and hit the tip for a long time. Thus, the magnetic domains are aligned in the direction of the Earth's magnetic field.

What should the core be?

The rods come in square, round or hexagonal shapes . They also have different lengths , but whatever screwdriver you need, the hardness of its shaft according to GOST should be 47-52 HRC. This is an indicator of hardness at which optimal strength is maintained with internal viscosity, which prevents the destruction of the rod when twisted with great force. If its strength is less than 47 units, then during operation it will simply bend, and if it is more than 52 units, then it may burst. Rods, like tips, are made from chrome vanadium steel . To prevent the formation of corrosion, the rod is coated with a galvanized protective layer.

Pros of screwdrivers

The advantages of screwdrivers are based on the configuration and functionality. A convenient set of options does not always replace specific functions.

Basic advantages of options:

- electric models or battery type - increased operating speed;

- with reverse - support unscrewing of fasteners;

- ratchet - minimal load on hands;

- impact - cope with tight screws that a regular screwdriver cannot twist;

- indicator - the ability to determine the phase, search for live wires;

- dielectric - safe for electrical installation work, preferable when it is not possible to de-energize the room.

The advantages are usually combined. For example, a dielectric coating is combined with an indication option, and a battery is combined with reverse.

Markings and sizes [edit | edit code]

Wrenches and screwdrivers are marked T

or

TX

with slot number - 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 15, 20, 25, 27, 30, 40, 45, 50, 55, 60, 70, 80, 90, 100.

Torx Tamper Resistant wrenches and screwdrivers

after the main marking they are additionally designated

TR

.

For keys and screwdrivers with Torx Plus

The slot number is indicated first, and then, instead of

T

or

TX

, it is indicated by the letters

IP

.

Torx Plus Tamper Resistant wrenches and screwdrivers

after the main marking they are additionally designated

TS

.

The size is determined by the diameter of the circle described by the vertices of the tool sprocket (for version E - bolt).

Approximate dimensions and tightening torques [3]

| Number | Size | Torque | |

E Torx

| inches | mm | N•m | ||

| T1 | 0,031″ | 0,81 | 0,02 — 0,03 | |

| T2 | 0,036″ | 0,93 | 0,07 — 0,09 | |

| T3 | 0,046″ | 1,10 | 0,14 — 0,18 | |

| T4 | 0,050″ | 1,28 | 0,22 — 0,28 | |

| T5 | 0,055″ | 1,42 | 0,43 — 0,51 | |

| T5.5 [4] [5] [6] | ||||

| T6 | 0,066″ | 1,70 | 0,75 — 0,90 | |

| T7 | 0,078″ | 1,99 | 1,4 — 1,7 | |

| T8 | 0,090″ | 2,31 | 2,2 — 2,6 | |

| T9 | 0,098″ | 2,50 | 2,8 — 3,4 | |

| T10 | 0,107″ | 2,74 | 3,7 — 4,5 | |

| T15 | 0,128″ | 3,27 | 6,4 — 7,7 | |

| T20 | 0,151″ | 3,86 | 10,5 — 12,7 | E4 |

| T25 | 0,173″ | 4,43 | 15,9 — 19 | E5 |

| T27 | 0,195″ | 4,99 | 22,5 — 26,9 | |

| T30 | 0,216″ | 5,52 | 31,1 — 37,4 | E6 |

| T35 [7] [8] [9] | ||||

| T40 | 0,260″ | 6,65 | 54,1 — 65,1 | E8 |

| T45 | 0,306″ | 7,82 | 86 — 103,2 | |

| T47 [10] [11] | GM-Style | |||

| T50 | 0,346″ | 8,83 | 132 — 158 | E10 |

| T55 | 0,440″ | 11,22 | 218 — 256 | E12 |

| T60 | 0,519″ | 13,25 | 379 — 445 | E16 |

| T70 | 0,610″ | 15,51 | 630 — 700 | E18 |

| T80 | 0,690″ | 17,54 | 943 — 1048 | E20 |

| T90 | 0,784″ | 19,92 | 1334 — 1483 | |

| T100 | 0,871″ | 22,13 | 1843 — 2048 | E24 |

External Torx Spline Dimensions

| Number | Size [12] | Standard bolt [13] | ||

| inches | mm | SAE | metric | |

| E4 | 0,15″ | 3,8 | #6 | M3 |

| E5 | 0,18″ | 4,7 | #8 | M4 |

| E6 | 0,22″ | 5,6 | #10 | M5 |

| E7 | 0,24″ | 6,1 | ||

| E8 | 0,29″ | 7,4 | 1/4″ | M6 & M7 |

| E10 | 0,36″ | 9,3 | 5/16″ | M8 |

| E12 | 0,43″ | 11,1 | 3/8″ | M10 & M11 |

| E14 | 0,50″ | 12,8 | 7/16″ | M12 |

| E16 | 0,57″ | 14,7 | 1/2″ | |

| E18 | 0,65″ | 16,6 | 9/16″ | M14 |

| E20 | 0,72″ | 18,4 | 5/8″ | M16 |

| E24 | 0,87″ | 22,1 | 3/4″ | M18 & M20 |

| E28 | 7/8″ | M22 | ||

| E32 | 1″ | M24 & M27 | ||

| E36 | 1-1/8″ | M30 | ||

| E40 | 1-1/4″ | M33 | ||

| E44 | 1-3/8″ | M36 | ||

Screwdriver manufacturers

FIT

Budget tool supplier from China. The company itself is located in Canada. They offer a large selection of hand tools. The warranty is for power tools only and is equal to 1 year.

Gross

German brand, the tool is produced in China. They have impeccable quality, reliability and ergonomics that meet European standards for work at a professional level. Warranty – 1 year.

Hama

A German company that produces tools and accessories in various industries. They provide a huge selection (more than 17,000 items of goods). Warranty terms are not specified.

JONNESWAY

Manufacturer of professional tools from Taiwan. Products are made from high quality materials according to generally accepted standards. It is used in enterprises with high equipment requirements. Lifetime warranty on products.

Makita

A Japanese manufacturer specializing in household appliances and tools, manufactured in China. Quality and durability are confirmed by a lifetime guarantee and an international quality certificate.

Stanley

The company is based in the USA and the instruments are made in Taiwan. They specialize in hand tools for professionals and amateurs. The main qualities of the products are innovation and convenience. Manufacturer's standard warranty is 1 year.

STAYER

A young Russian manufacturer specializing in the production of budget tools, power equipment, and thermal equipment. The company's products are famous for their high quality and long service life. The warranty on tools is 5 years.

Wiha

World leader in the manufacture of premium hand tools. They produce more than 3,000 types of tools that are famous for their quality and functionality. Warranty – 2 years.

History [edit | edit code]

The spline was developed by Textron in 1967. The use of tight-fitting bolts and bolts of increased strength class allows increasing the load on the fasteners; accordingly, a slot was needed, which provides a higher tightening torque. However, the unpopularity of the Torx tool made it possible to use the slot also to protect devices from self-repair by the owners. As the tool became popular, Textron added a new type of spline as a vandal-resistant Torx option.

In 1990, when the patent expired, Textron developed a new standard, Torx Plus, which was even more reliable and also had a vandal-proof option.

Malfunctions

Screwdriver malfunctions in their basic form are limited to broken handles or dull metal slots.

- If the handle is replaceable, it is replaced with an analogue one. Models with solid handles must be recycled. However, craftsmen fix broken plastic by heating or using superglue.

In this case, the durability of the repaired handle is not guaranteed; the tool is no longer suitable for screwing in self-tapping screws and tight bolts.

- A dull screwdriver is sharpened using a grinder and a cutting wheel, a Dremel or a needle file. The last option is the most labor-intensive. Sharpening a screwdriver with a disc requires fixing it at an angle of 90 degrees to create correct bevels.

Self-repair is only possible if the battery is dead or the ratchet is clogged. If the mechanism becomes clogged, the tool is disassembled, cleaned of abrasives and lubricated for prevention.

Models with complex mechanics are more often subject to repair under service conditions.

Guarantee

Hand tools come with a warranty that ranges from 12 months to lifetime service.

- The need to exchange goods or return money arises if the purchased screwdriver turns out to be defective, deteriorated or broken due to the fault of the manufacturer.

- Refusal to receive warranty service occurs in case of non-compliance with the rules for using the tool or in case of mechanical damage.

The budget segment allows people not to contact service centers, but to buy a new tool.

Problems

Disadvantages that complicate operation are also associated with the set of functions. The fewer additional options a screwdriver has, the higher the chance that the tool will last a long time.

Problem areas:

- Rechargeable type - requires constant changing or charging of batteries. In conditions of major renovation of the premises, it quickly breaks down. More often this feature is found in Chinese technology, the quality of which does not always meet the needs of Russian conditions.

- Ratchets are sensitive to abrasives and dust. The mechanism fails when used in dusty areas or at a construction site.

- Drums are unsightly due to their metal casing; ergonomic models of this type are rare.

- Indicator - the main problem is the indicator light burns out, after which the model turns into a regular screwdriver. An audible indication requires changing batteries.

The current charge is not displayed on the case, so at the right time it is easy to find yourself without the corresponding functionality.

Models with reverse are not included in the list of problems, since the mechanism rarely fails. Dielectric variations are similar to ordinary ones, the only difference is in the coating, so their operation does not cause problems.

Operation of screwdrivers

To operate the OS correctly, you must adhere to several rules:

- In the marking of products, according to GOST, the type of slot is encrypted (see the chapter “Marking” above). The screwdriver must be used in full accordance with the type and size of the slot;

- It is better to store the tool in a suspended state. In this case, the tips will be protected from accidental damage;

- Clean instruments are stored in dry indoor conditions that do not provoke metal corrosion.

Self-production

You can make a screwdriver from any metal rod or nail. The rod is ground on a grinding machine on one side. Usually they make a tool with a tip for a straight slot.

Home craftsmen grind a head with an opening for replacement bits. It is welded to the end of the rod. The end of the rod on the other side is bent with a hook. You can use an old key for the blank. This is convenient because the tool can be carried on a key ring.

For a homemade cross OSH you will need a milling machine and a sharpener. The tip of the rod is milled, achieving a cruciform cross-section of the rod. Then the finished tip is ground into a cone shape.

An L-shaped fold is placed between the cut halves of a round block. Then both pieces are tightened with clamps. In another case, the bent end of the rod is placed in a mold and filled with epoxy resin. The handle is then ground down for comfortable hand grip.

The correct selection of slotted screwdrivers facilitates quick and efficient repair and installation of various devices and instruments with threaded connections. You can easily purchase suitable hand tools in the retail chain.