An angle grinder is considered a very dangerous piece of equipment, so it is important to know in advance how to correctly cut metal with a grinder in order to avoid injuries and cope well with the task. You need to ensure that safety measures are observed during work and use personal protective equipment: use a respirator, wear protective gloves or mittens, goggles, etc.

Cutting equipment must be used strictly for its intended purpose; work is carried out using special metal wheels. It is strictly not recommended to remove the protective cover. How to work correctly with an angle grinder, watch the video:

You cannot start cutting metal with a grinder without obtaining the appropriate knowledge and certain abilities. The most important threat is the possibility of the cutting wheel jamming in the cutting zone and its subsequent destruction. When carrying out work, the grinder must be held firmly with 2 hands. You must carry out the cutting strictly on your own. The depth of the cut is determined by the diameter of the disc.

Cutting an iron angle has certain aspects:

- It is easier to cut a large corner (more than 60 mm) together with a partner. In a workshop setting, the workpiece is clamped in a bench vice or secured with clamps on a fixed base. The corner is laid on the surface of the supporting structure (table, box, etc.) so that the cut edge hangs down, and its other part lies completely on the support. In this case, the assistant must press the workpiece and pull it slightly away from himself to prevent the disc from biting. Cutting begins from the edge, moving towards the rib.

- Cutting corners with the smallest dimensions (up to 60 mm) can be carried out without the help of third parties. The material to be cut is laid out supported on both shelves (edge up). The detachable part must be suspended and not touch the ground or floor. The remaining part is pressed down with the left foot (in the absence of rigid fixation), to be able to hold the grinder with both hands. Cutting should begin from the edge, evenly going down and going deeper into the areas of the corner.

What products can be cut with a laser?

A fairly large number of products differing in thickness, design, and size are subjected to laser cutting.

First of all, this is sheet material intended for further processing. Stainless steel sheets are pre-fitted to the size of the machine tabletop and checked for uniform thickness. Using a laser, you can perform primary, external decorative or customization processing of a part.

Also, you can cut or adjust finished products in thickness and width. This procedure can help you out if size discrepancies appear on finished parts.

Hydroactive method

Laser cutting and engraving: services, products, materials

The action consists of supplying liquid through a sapphire, diamond or ruby nozzle 1/10 mm wide. The output stream is accelerated to three times the speed of sound, after which the fine, concentrated stream is capable of cutting tough materials, including stainless steel. Pure water is used for soft workpieces; for harder workpieces, abrasive elements (sand) are added.

The speed of modern installations is high, so they successfully compete with laser and plasma devices. For example, Dekart W2040 L reduces up to 8 m of metal per minute (depending on thickness); in the case of stainless steel this figure is usually 2-3 m/min.

Interesting fact: in the West, studies were conducted to determine the effectiveness of waterjet and laser machines. For this, dozens of plates, each 0.3 mm thick, were cut out. It turned out that for bags up to 6 mm thick the laser is more effective, and for bags over 6 mm thick. Hydraulic accumulator.

Advantages of the method:

- Stainless steel does not heat up during operation;

- The likelihood of workpiece deformation is reduced;

- High cutting quality;

- Lowest material losses

- Speed of work;

- Minimal process error (cut width is 10 times thinner than arc cutting).

Flaws:

- High cost of equipment (a conventional waterjet machine will cost the user 3 million rubles or more);

- Rapid wear of working parts.

Cutting stainless steel with a water jet is considered a promising processing method.

Plasma cutting

The technique was developed about half a century ago and immediately eliminated the disadvantages of gas-arc equipment.

The principle of operation is partly similar to that previously discussed - a compressed electric arc intensively melts the stainless steel along the cut line, and the remaining liquid metal (“splashes”) is removed from the surface by a fast plasma flow. The speed of the operation is impressive - the plasma has a temperature of 15-20 thousand degrees (versus 1800 degrees for a conventional arc), so the productivity of work is several times higher. Plasma cutting of stainless steel is recognized as the best processing option. It does not require gas cylinders, additional chemicals, or special fire safety requirements for the premises. To operate, you only need electricity, air and inexpensive consumables - electrodes and nozzles. This makes plasma the most cost-effective method for cutting stainless steel.

The technique has only one drawback - the cut edge is not very smooth, requiring additional processing. However, the surface quality along the cut line is much higher than with arc machining.

The higher the thermal conductivity of the material, the thinner the part the plasma processes. For example, the permissible thickness of copper should be lower than the maximum thickness of stainless steel, all other cutting conditions being equal.

When processing workpieces thicker than 200 mm, it is recommended to use gas-arc cutting.

Which drill is better to use

- Any tool that contains cobalt in its alloy. The higher the percentage of this component, the better. Cobalt products differ from ordinary ones in a yellowish tint. Do not confuse the cobalt alloy with the application of this metal only to the outer part of the drill by electroplating. In the latter case, it will not be possible to drill through stainless steel.

- Expensive specialized tool. Such pobedit drills can drill through stainless steel, not just concrete. They have a certain sharpening angle.

- For thin stainless steel, you can use a feather-shaped drill bit for ceramic tiles. This is not the best option, but it will help to drill the workpiece once.

Application of cobalt drill

How to drill through stainless steel. Tips for choosing a drill for stainless steel

Of the old Soviet drills for stainless steel, the most suitable tool would be the one with the brand R6M5K5. This type of equipment contains up to 5% cobalt in the alloy. Due to this element, the tool acquires high strength, and the heating temperature can reach 135 degrees Celsius, which does not entail destruction of the material. Products of this quality can only be found in markets where old Soviet equipment is sold, and even then not always. An alternative to a domestically produced cobalt drill is a foreign analogue under the HSS-Co brand.

How to choose the right cutting disc

You definitely need to pay attention to the expiration date (it is stamped on the rim of the sleeve), since bakelite resins are used as a binder in such products, which dry out over time and lose their elasticity. You also need to understand that metal cutting discs of the same type, but from different manufacturers, behave differently during operation. Therefore, in order to avoid surprises, in addition to analyzing standard data, you must definitely look for additional information in customer reviews, on specialized forums, etc. The video below explains how several almost identical disks from different brands differ.

Laser cutting of stainless steel in Moscow

How to cut gypsum board sheets

The Metal Products to Order organization provides services for profile, decorative and finishing cutting of stainless steel using the most modern and precise technology: laser. The company has been on the market for a long time and has managed to demonstrate itself as a reliable and responsible partner. We carry out laser cutting of stainless steel in Moscow and the Moscow region, as well as in Lyubertsy

The company has at its disposal a large number of machines and equipment designed for processing metals of various types, including a large number of varieties of stainless steel in shape and thickness.

How to calculate the consumption of a cutting disc

The main disadvantage of this method is the problem of non-repeatability of the parameters of cutting wheels of the same type purchased by users on the modern Russian market. Therefore, it is best to adopt your own standard for each batch of purchased disks by carrying out test cutting with several of them on certain types of metal workpieces (sheet, pipe, fittings, etc.). In this way, over time, you can accumulate a sufficient database, analyze patterns and develop your own standards with correction factors.

There is often a statement that stone cutting wheels can be used to cut non-ferrous metals without any problems. What do you think about this? Please share your opinion in the comments.

Source of the article: https://wikimetall.ru/oborudovanie/otreznoj-disk-po-metallu.html

Cutting cast iron with a grinder

Cast iron is a rather fragile metal, but very durable, so it is recommended to use diamond-coated discs for cutting it. You can cut cast iron with simple metal discs, but they are much less durable. You can cut this material with a grinder only in a straight line. Any attempt to make a figured cut can lead to jamming of the cutting wheel. As a result, under heavy loads, the abrasive element is destroyed and its parts flying out at high speed can seriously injure people nearby. But it’s better to cut cast iron with a saw, as in the video:

A grinder for working with metal is the best solution. This versatile tool allows you to use it not only for cutting, but also for polishing, stripping, grinding metal and many other operations.

Cut a 1.5 mm stainless steel circle. Bulgarian

If the correct metal cutting technology is followed, the separated piece will fall down under its own weight, thereby increasing the width of the cutting zone. The possibility of disk jamming is reduced to zero.

To cut pipes with a grinder, it is recommended to use cutting wheels less than 1 mm wide, otherwise the cut will be more difficult, and there will also be a lot of sparks and flying hot particles.

The development of the work is as follows:

- The pipe is secured in a vice or secured using another method. In this case, the cut part should hang down. It is not allowed to place the workpiece between two supports and make a cut in the center, since the cutting blade will jam (due to sagging pipe).

- Markings are applied using a strip of paper and masking tape. The ends of the tape must meet very precisely. Home craftsmen advise lowering the pipe into the liquid at the required angle, and then marking a cutting line along the boundary between dry and wet.

- The cut should be made from the highest part of the pipe, evenly lowering the grinder lower. The cutting disc should go along the very edge of the glued strip.

A pipe of huge diameter is cut slightly differently, since the working part of the circle does not do it at once. The wall is cut sector by sector, and the pipe is turned to the appropriate side.

To cut aluminum with a grinder, a different type of disc is used, since it is a soft metal and the cutting tool gets stuck there. There are special cutting discs for aluminum and copper.

You should not try to make a cut in one pass, as hardening will form on the teeth of the cutting tool and it will become pinched in the material. The cut is made carefully, without cutting through the metal all the way. It is necessary to go through one place a couple of times and not even allow distortions. The process is quite leisurely, and the quality of the cut will be low. When cutting thick workpieces, experts advise dripping kerosene into the cutting area. It is better to work with aluminum with a hand router, which allows you to make figured cutting and make holes. You can, well:

The main stages of the heating process

To harden stainless steel, it is advisable to know its exact grade, or at least which type of carbon it belongs to (more or less than 0.4%)

This is very important, because in order to properly harden the product, after the hardening itself it must also be released. The brand of factory stainless steel can be found out from the seller of the workpiece, who can also advise on how best to harden it

If some old thing is used as the starting material, then the Internet will come to the rescue with tables of products and grades of steel from which they are made.

In general, the full heat treatment cycle of a stainless steel part includes the following steps:

- Preparation of equipment, tools and materials. This includes checking the fuel (coal or gas), which should be sufficient for the entire heating cycle. After all, in order to qualitatively harden stainless steel, it should be heated smoothly and without interruptions.

- Warming up the forge or stove. If gas-flame heating is used to harden the part, a stainless steel workpiece is installed and the gas burner is turned on.

- Placement of the workpiece. Often it is necessary to harden only some part of the future product, so it should be placed so that this part is in the maximum temperature zone.

- Heating to the required temperature. The product is kept in a high-temperature zone, controlling its heating by color. In order to harden chromium stainless steel, it must be heated to 1050 ºC. This corresponds to a color that is defined in the tables as orange or dark yellow.

- Cooling. After the heated metal has acquired the required color, the part is cooled by immersing it in a container with mineral oil. It can ignite, so keep a piece of thick cloth next to the container.

- Cleaning. After cooling in oil, the stainless steel should be thoroughly cleaned. In case of severe contamination, a solvent can be used.

- Vacation. To harden your part “according to science”, after heating and cooling it should be released. For steels with a carbon content of 0.4% or more, the tempering temperature is 200÷250 ºC (see table below), so it is enough to place them in a regular kitchen oven for a couple of hours. With a lower carbon content, the tempering temperature is much higher, up to 700÷750 ºC, and it is carried out with gradual cooling in air or in dry sand.

Tricks for drilling stainless steel

As can be seen from the article, the process of drilling stainless steel is quite labor-intensive and requires certain skills and training.

We have prepared some useful tips on how to drill through stainless steel:

- When drilling, metal shavings should be long and come out in uniform sections; small, dark-colored shavings indicate that the rotation speed is incorrectly selected, and that the cutting edges of the drill are excessively heated.

- If you don’t have a prepared lubricant on hand, you can use regular vegetable or olive oil; pork fat or lard are also excellent.

- To work with thin sheet stainless steel, you can use a special drill bit for porcelain tiles.

- It is advisable to carry out the drilling process at a low speed of rotation of the cutting tool, and if the drill does not have a speed control function, drill by briefly turning it on and off for 2-3 seconds.

- If a cobalt drill is not available, you can use a pobedit tool with sharpening the cutting edges at 135 degrees.

- Before starting the drilling process, the workpiece should be punched, which will facilitate centering the drill.

- When drilling a workpiece of increased thickness, you can preheat the treatment area using a gas burner; when cooling, the heating can be repeated periodically.

- When processing thin stainless steel parts (up to 1 millimeter), you can use a high-quality wood drill bit; experience shows that the holes are smooth and of precise dimensions.

Methods for cutting stainless steel

The material in question belongs to alloy types of steel, which are not afraid of contamination and exposure to liquids, since they do not become rusty. The composition of the steel is complemented by a high content of chromium, as well as hardeners - titanium, tungsten, iron molybdenides. Thanks to this, on the one hand, the durability of the metal is achieved by increasing strength; on the other hand, it complicates the cutting process. However, there are several ways to qualitatively divide metal into small pieces.

There are two cutting groups:

- mechanical (the workpiece is cut with a sharp hand tool);

- thermal (due to exposure of the metal to high temperatures, leading to its melting).

The advantage of the first method is that the master will not need expensive equipment. The disadvantage is the need for physical force and a lot of time. Therefore, thermal cutting methods are becoming very popular today.

These include:

- gas arc cutting;

- by electrical erosion;

- waterjet;

- laser;

- plasma.

The features of each type of material processing are discussed below.

Oxygen cutting

Better known as “gas arc cutting”. As in other cases, processing involves the use of special equipment. Its working part - the arc - comes into contact with the workpiece, after which deformation of the cut layer occurs.

Arc cutting is performed with consumable and non-consumable electrodes. The first includes steel, the second - graphite. To increase the efficiency of work, air (air-arc cutting) or oxygen (oxygen-arc cutting) is supplied to the arc zone.

The advantages of the method are the availability of equipment and the low cost of it (or work). But there are more shortcomings. Among them:

- violation of the integrity of the metal;

- poor cut quality;

- low productivity.

The process of arc cutting stainless steel is now considered obsolete as more efficient methods have replaced it.

Preparation and finishing

The quality of welding of stainless steel, like any other metals, depends on the preparation of the welding zone. The metal must be thoroughly cleaned of grease, dust and dirt, washed with acetone or high-octane gasoline and dried. Use a wire brush to clean the edges of the parts to a characteristic shine.

Welding stainless steel has its own characteristics - a high coefficient of thermal expansion can cause cold cracks to appear if the parts are moved very tightly. It is necessary to leave a small gap between them, the width of which is determined from the reference book or the experience of the welder.

Before cleaning a weld on stainless steel, you must carefully inspect it for cracks or other visible defects. For domestic welding, there is no need to use flaw detection equipment, but for industrial welding, it must be used without fail.

Acid pickling is carried out on all grades of steel using hydrochloric and sulfuric acids. After processing the seam, it is necessary to rinse the work area with clean water. At home, acid etching is rarely done; the mechanical method is more common.

Mechanical processing is carried out by cleaning with a metal brush and processing with fine-grained sandpaper. If possible, sandblast. After mechanical treatment, a passivating solution should be applied to the seam.

Grinding and polishing of the seam area and the entire surface of the product is carried out using polishing and grinding wheels with various types of surface. The tools used are a grinder or vibrating sanders.

Mechanical methods

- Bulgarian. A working method, but the stainless steel should not heat up. To do this, water the cut area. An increase in disk life will also be achieved.

- Metal scissors. The method is only suitable for very thin stainless steel sheets (0.5-1 mm).

- Circular saw for metal. Instead of a toothed disk, a cutting abrasive disk is installed (as on an angle grinder), and some kind of stop is placed on the sheet to be cut. The downside is the impressive consumption of the wheel, and if the adjustment is incorrect, the workpiece is pulled to the side and the cut is disrupted.

Treated stainless steel sheets can be bent, stamped, polished, painted, welded, etc. There are many ways to divide large workpieces into small ones, and it is up to you to decide which one is more effective. The best option for home use is an angle grinder; for industrial use, cutting stainless steel with a laser or plasma is acceptable.

If you know other ways to process alloy steel or notice an inaccuracy in the description, please share the information with readers.

Types of cutting discs for metal

The technical characteristics of cutting wheels (or otherwise disks) for working on metal are regulated by GOST R 57978-2017, which provides for two types of this tool: flat (ISO 41) and with a recessed center (ISO 42). The same GOST establishes size ranges and other standardized parameters for both types. Structurally, a metal cutting disc is a sandwich-type structure consisting of alternating layers of reinforcing mesh and cutting composite into which a metal sleeve is pressed (see figure below).

How does the stainless steel cutting process work?

Laser cutting of stainless steel is a complex technological process that requires a correct, and most importantly, structured approach. The cutting process begins with drawing up a drawing, first in paper form, then in computerized

When modeling cuts and slits, it is important to consider the cutting thickness: the width of the light beam coming from the laser. Also, do not forget the possibility of adjusting this parameter: the narrower the spot, the faster the metal will be cut.

Even at the modeling stage, it is necessary to take into account the maximum cutting area of the equipment used: all CNC machines have a strict size limit, and it is simply impossible to cut a part that is not included in this range.

Then the finished file is sent to the main operator of the machine: depending on the goals set, he configures the equipment according to ready-made instructions and puts the CNC into operating mode.

Depending on the thickness of the material being processed, the laser output power is adjusted. At the same time, the cutting speed must be maintained: otherwise, the laser may not have time to make a cut in the required place.

Circular cutting for stainless steel

The methods listed above are unlikely to be suitable for a person with ordinary needs and a small amount of work with stainless steel. Returning to the beginning of the article, we come to the conclusion that it is advisable to use angle grinders (popularly called “grinders”) for cutting the capricious alloy. There are certain subtleties and little things that can carry out cutting at a level no worse than the factory one. To do this, use a special cutting wheel for stainless steel

.

Its main difference from a regular circle is the structural differences that contribute to additional heat removal from the cutting site. In addition to this factor, a component component is added. The grains and abrasives are selected so that stainless steel discs

can cope with a more durable and mechanically resistant anti-corrosion alloy.

Many of the wheel manufacturers provide a large niche in their own product line for stainless steel wheels and steel blades for circular saws

. Among the most famous are Luga Abrasive, 3M, Metabo, Cibo, Klingspor, Hilti and a number of others. Comparative tests of these cutting tools are carried out using a standard procedure for cutting a sheet of stainless steel metal, 3 mm thick. Using the same angle grinder, measure the width of the cut (to analyze the lateral runout) and the remaining diameter of the circle after a series of cuts. By linking the results obtained to the weighted average price of a particular circle on the market and in the store, everyone will decide on the choice of a suitable product to achieve their intended goals.

There are many “test drives” of cutting wheels for stainless steel posted on the World Wide Web. As a rule, their analysis indicates a direct dependence of quality on the price of the product. A good product will not be sold cheap. Thus, Cibo Top, Hilti Universal Premium, Bosch Expert, well-known wheels on the market, occupy high places in test ratings, showing twice the performance with a price priority of no more than 20-30% compared to competitors. By adding less disc runout, you can reduce the costs of subsequent operations to fine-tune the cut to an ideal state.

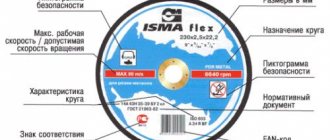

Markings of circles for cutting metal

The photo above shows a metal cutting disc from the Luga Abrasive Plant, marked in accordance with state standards. The following fields are indicated by numbers:

- Construction type (ISO 41, flat).

- Geometric characteristics (diameter, thickness, mounting hole). Below, under the red stripe, they are indicated in inches.

- Physical characteristics: type of abrasive (A – electrocorundum); grain size; degree of hardness (Latin T - very hard); bond type (BF – reinforced bakelite).

- Maximum rotation speed.

- Maximum permissible peripheral speed.

- What material is it intended for?

- Safety pictograms.

- Link to regulatory documents.

- Manufacturer's logo.

In addition, GOST P 52588-2011 and international standards oblige manufacturers to apply color markings to their products in the form of a continuous horizontal stripe with a width of 5 to 20 mm, indicating the maximum peripheral speed. For metal cutting discs, this is usually a red stripe corresponding to 80 m/sec (see photo above). Some manufacturers additionally mark their products with color fields in accordance with the group of materials (metals, stone, ceramics, etc.) for which a particular type of wheel is intended for cutting. Such markings in the ANSI and ISO systems only partially coincide, so it is better to focus on signs in the form of inscriptions and pictograms.

The best way to cut stainless steel

Today, throughout the world there is a gradual, smooth technological progress characteristic of all areas of human activity. It was he who made people believe in miracles and make into reality what previously seemed like a wild and impossible fantasy.

This phenomenon also applies to such areas as industry, where, nowadays, you can see a full range of lasers, plasma tools, and even devices capable of cutting the toughest materials using water.

However, one cannot help but say that their use is completely justified and allows one to achieve high results in a process such as cutting stainless steel, which previously seemed impossible.

What is stainless steel? Today, people know special types of steel, one of which is stainless steel. It has a number of advantages over conventional steel, namely:

High resistance to corrosion processes Attractive appearance Increased wear resistance Resistance to high temperatures.

However, in addition to the advantages, there are also a number of difficulties that arise during the cutting process.

The thing is that stainless steel is extremely difficult to cut using conventional methods without damaging its structure or spoiling its brilliant appearance. In this regard, the following began to be actively used for cutting stainless steel:

- Gas arc cutting

- Plasma cutting

- Laser cutting

- cutting

- Waterjet cutting.

Gas arc cutting of stainless steel

When talking about types of stainless steel cutting, we cannot ignore gas-arc cutting. This type of processing of a steel sheet is carried out by melting the metal in the place where it is necessary to make a cut.

In this case, simultaneously with melting, it is necessary to remove all the resulting oxygen, the presence of which in the metal composition negatively affects the strength. The advantages of this type of stainless steel cutting include the availability of this procedure and its low cost.

Alas, there are many more shortcomings that make this process irrelevant.

Among them:

- High probability of damage to the metal structure

- Extremely poor quality of side cuts

- Uneven cutting lines.

Plasma cutting

In order to achieve better results than in the first case, it is necessary to use plasma cutting. This type of cutting is based on the use of tungsten electrodes, which form plasma based on high-temperature gases.

Plasma cutting, due to its high temperatures, has a high penetrating ability, cutting through layers of stainless steel and removing from there all the by-products that have accumulated during the cutting process.

Perhaps the disadvantages of such processing of stainless steel include the impossibility of cutting layers of metal with a thickness exceeding the 30 mm mark, as well as the need for subsequent mechanical processing of the edges to give them the desired appearance.

Laser cutting stainless steel

Another, no less interesting type of cutting is laser, which is the most advanced processing technology among all available to mankind. It is the laser beam, consisting of highly concentrated particles, that is capable of cutting stainless steel with extreme precision, but at extremely low speed.

Stainless steel cutting

The least interesting of all the above types of cutting is stainless steel cutting. This process is the processing of a sheet of metal through directed mechanical action. It is used only in exceptional cases, to obtain parts of simple shape and small thickness.

Waterjet cutting

Last on the list, but far from least important, is waterjet cutting of stainless metals. From the name it is already clear that the metal is exposed to concentrated water flows, which contain an abrasive solution. Thus, with a jet speed of 1000 meters per second, it is possible to cut any sheet of steel up to 100 mm thick in record time.

Despite these significant advantages, even waterjet cutting is not perfect. The only drawback that repels customers and significantly hinders the development of this technology is the high price for this type of service.

To summarize, by choosing the most suitable processing method in a given situation, you can achieve the desired results without going beyond your budget and time constraints!

How does a laser cut stainless steel?

First, a little about the process itself. We won’t go into technical details - this is not a textbook for carvers, but a review article for customers.

How can intangible light cut through solid metal? It's a matter of heating. The concentrated laser beam heats the area it is aimed at to extreme temperatures. Most laser systems melt metal. Some don’t just melt, but evaporate. This is a huge temperature, as you understand.

But in principle, for work it is enough that the metal is simply melted. A powerful gas jet directed into the cutting zone blows out the resulting melt, leaving a smooth edge. Plus, the gas jet cools the cut

It is important. Thanks to this, parts that have undergone laser cutting do not have thermal deformations - all the melting energy is concentrated in the right place, and the rest of the part heats up weakly

At the same time, to cut stainless steel, just air is not enough - in a good way, you need nitrogen. Nitrogen displaces oxygen from the cutting zone, which could participate in a thermal reaction and spoil the metal.

The point is this. Now let's look at the types of tasks for which you should NOT use laser cutting.

Coolants and lubricants

For drilling holes in stainless steel, there are more effective lubricating solutions that can be prepared at home. This applies, for example, to a solution based on sulfur and fatty acids. Cooking method:

- Laundry soap is ground by rubbing on a medium grater.

- The resulting material is dissolved in a container with hot water until it becomes a saturated soap composition.

- Take technical hydrochloric acid and slowly pour it into the same container. As a result of the chemical reaction, fatty acids will rise to the upper layers of the solution.

- After the process is completed, cold water is poured in to solidify the fatty acids, then they are mechanically separated from the total mass.

- Sulfur and lubricant are mixed in a ratio of 1:6.

How much does a plasma cutter cost?

Plasma cutters

| Cutting thickness | Voltage | Price |

| 60 mm | 380 V | In stock: Little211,000 rub. |

| Promotion! Aurora PRO AIRFORCE 100M Free shipping | ||

| 40 mm | 380 V | In stock: Many RUB 96,700 Cashback: RUB 4,835 |

| Aurora Jet 40 Free shipping | ||

Interesting materials:

How to preserve autumn seedlings until spring? How to preserve autumn grape seedlings until spring? How to keep petunia in a pot until spring? How to preserve petunia at home in winter? How to preserve a peony before planting in the ground? How to save peonies before planting? How to save peonies until spring? How to preserve peonies at home? How to preserve peonies in winter at home? How to preserve peony planting material until spring?

At home

In order to answer the question: how to weld stainless steel at home, you should familiarize yourself with the following information.

For beginners and home welders, the best option for welding work is electric welding using an inverter. A welding machine of this type has a compact size and operates from a standard 220 V power source.

In addition to the apparatus, the performer will need electrodes: special for stainless steel or regular ones. Welding is carried out on a thoroughly cleaned surface. The connection is made with direct current, the value depends on the thickness of the metal and varies from 40-150 A.

Video

The video popularly explains how to do this.

Let us repeat, to select brands of stainless steel electrodes, go to the appropriate section. Questions about welding thin stainless steel, pipes, and black steel are discussed here.

All of the above methods will help you understand what you can use to cook stainless steel in each specific situation. Depending on the grade of corrosion-resistant steel, the contractor selects the optimal welding mode. The correct parameters guarantee the safety of the welding process for the performer and ensure the required quality of the weld.

Each welder will decide for himself what is the best way to weld stainless steel after reading the listed data.

What are the advantages of laser cutting of stainless steel?

In other cases, when it comes to working with stainless steel sheets of moderate thickness, laser cutting has serious advantages over competing technologies - chopping and plasma cutting.

Exact match to the project

Firstly, the laser is aimed with an accuracy of tenths of a millimeter

For cutting roofing sheets, it doesn’t matter. But for instrument making it’s a must

Here the laser outperforms cutting and plasma - both of these technologies provide less accuracy.

Secondly, the laser consistently produces the same contour from cut to cut. Every detail will strictly correspond to the laid down program. Coordinate punching machines, in principle, are just as stable, albeit with less accuracy - but a plasma arc, for example, is unstable and allows fluctuations.

Laser produces high-quality edges

Again - perhaps this would not be important for roofing sheets

But for delicate and precise work it is important. The only drawback to laser cutting edges is a slight taper when working with thick steel.

In the range of several millimeters - that is, at the most popular thicknesses - this taper does not appear at all. When cutting stainless steel 10 millimeters thick, it may already appear. The slope of the edges will be around 0.5 degrees, the hole will widen slightly towards the bottom. Strictly speaking, it is impossible to notice this with the naked eye, and it will not affect most operations with this hole. However, it is worth keeping this in mind.

Chopping gives rough edges - that's what chopping is for. Plasma too: burns, scale. Plus taper - but this time with expansion upward and much more noticeable - from 3 to 10 degrees. That is, even with a metal thickness of 20 millimeters, the difference between the upper and lower diameter of the hole can reach up to 1 millimeter.

Here's what we offer:

Production of parts for medical equipment

Minimum human factor - minimum defects

Laser cutting machines use numerical control. The laser beam moves clearly along a given path and at a given speed. If the initial calculations are made correctly, the processing will be of equal quality along the entire length of the cut. Regardless of how many parts are in the batch, the robot never gets distracted or sneezes. Therefore, the cut is always the same, and there are no defects at the cutting stage.

Fine cuts and complex contours available

The laser can make thin holes—thinner than other cutting methods. With a plasma arc, for example, you can cut a hole with a diameter of at least 4 millimeters, and even wider for thick steel. The laser cuts holes equal to the thickness of the metal, from 1 millimeter.

Plus, for complex shapes, the laser clearly cuts corners without rounding them, like plasma.

No scratches or thermal deformation

There is no physical impact on the workpiece, and the thermal impact occurs in a minimal area - in fact, in the cutting zone. For comparison, when working with coordinate punching machines, the part must be rigidly fixed - hence the scratches. And the plasma heats up the entire workpiece, leaving thermal deformations.

Quick launch into production

This advantage is typical for both laser and plasma. A jig punch machine may have problems with this if the part has holes that differ from the standard ones. In this case, you will have to produce punches specifically for it.

To start the laser and plasma operation, it is enough to create a cutting program and start the machine.

And here is an example of a case produced by Metal-Case:

Body frame made of rectangular stainless steel pipes

The laser has a thin cut, unlike plasma. Accordingly, it is often possible to cut more parts from one sheet of metal with a laser. In small batches this may not seem serious - but in large batches it turns out to be an important advantage.

Drilling a sink

The question often arises about how to drill a hole in a stainless steel sink. It is important to understand here that the sink should first be dismantled so as not to damage the plumbing elements and the bedside table. Then the sink needs to be installed on a flat horizontal surface. Next, the location of the future hole is marked and it is cored. If the hole is intended for installing a faucet and has a large diameter, then it is better to use a conical step drill, since the metal of the sink body is thin-walled.

If you are in doubt about how to drill stainless steel with a drill, then there are no big features from the technology described above. The main thing is to use the correct drill and ensure that it is well centered. Use a drill with speed control, set the torque to a position close to the maximum. A hand drill can help produce holes with a diameter of up to 10 - 12 millimeters.

What are the limitations of laser cutting stainless steel?

Maximum thickness of stainless steel for laser cutting

Lasers cut thin sheet metal efficiently and cheaply.

- Of course, not as cheap as guillotine cutting - but guillotine cutting does not allow for fine work and produces mediocre edges of parts that require additional processing.

- However, it is quite comparable to plasma cutting, the second competing technology.

As the thickness of the metal increases, the cost of laser cutting increases. However, like the cost of any other type of cutting. The question here is the dynamics of this increase. As the thickness of the sheet increases, there comes a time when a high-quality cut requires too much energy - and it simply becomes unprofitable.

- With a sheet thickness of up to 20 millimeters, the use of a laser is justified - not much energy is required, the laser is relatively cheap.

- From 20 to 40 millimeters, laser use is no longer recommended. Plasma cutting will be more profitable. But plasma has less accuracy, produces shape deviations from part to part - and also has a relatively low quality of edges compared to laser. And if accuracy and quality are fundamental for a specific order, choosing a laser within this range of thicknesses is still possible.

- But with a thickness above 40 millimeters, even high quality does not justify the increase in the price of laser cutting. It will be cheaper to cut with plasma and mechanically process all the edges whose quality you are not satisfied with.

In fact, most of the orders for laser cutting of stainless steel in instrument making are not even 20 millimeters, but 10 – and then with a margin. However, in principle, this property of the laser is worth keeping in mind.

Flat cutting VS volumetric cutting

Important point. For obvious reasons, it is easy for a laser to cope with sheet metal - the cutting head moves above it along two axes X and Y, deviations from the vertical are possible, but are generally not used. Volumetric laser cutting is more difficult.

Until recently, it was practically impossible on an industrial scale - there were no suitable lasers. Now there are lasers built on fiber technology. Some machines based on it can perform volumetric cutting, cutting off unnecessary things from the metal “blank”. However, this method is still rare.

So now laser cutting is actively used only in sheet metal production. Then these flat developments can be folded into housings on bending machines and welded - this is not a problem. However, not every part can be made in this way. So complex volumetric parts, as before, are manufactured:

- or by casting method,

- or on milling machines.

Yes, of course - casting takes a long time to put into production, and milling produces a fierce, frantic consumption of metal. We can expect that 3D laser cutting machines will become more common in the future and will replace milling. But for now the situation is as follows, and volumetric parts are the main limitation when laser cutting stainless steel.

Production cutting methods

The components of stainless steel give it advantages over unalloyed or low-alloy steels. But they, at the same time, serve as a reason for the loss in some design features. This applies to cutting and cutting metal. Ferrous metal can be cut in a garage using an ordinary grinder or metal saw.

It is somewhat difficult to do the same with stainless steel. The likelihood of changing the structure and damaging the decorative surface remains at a high level and depends on what you use

to cut stainless steel

. In production, the following methods are used for cutting this type of sheet:

- Cutting and cutting using GDA (gas arc cutting apparatus)

- + availability of the method;

- + low cost of equipment and the process itself;

- - poor quality and unevenness along the edge of the seam - additional processing;

- — risk of changes in the metal structure.

- Application of plasma cutting of metal

- + high speed of the process;

- + removal of slag and harmful phases from the cutting area;

- — available thickness no more than 30 mm;

- — subsequent mechanical processing.

- Cutting on a laser radiation installation

- + high accuracy;

- + the coefficient of material utilization during cutting tends to 1;

- + absence of transformations in the structure;

- + no need for additional processing;

- — high cost of equipment;

- — the need for highly qualified personnel.

- Metal cutting.

- + low cost of the process, does not require additional investments and costs;

- - is rather an exception for stainless steels, used for one-time work and parts of a non-critical group.

- Waterjet cutting.

- + cutting speed can reach 1 km/sec;

- + the shape and spatial orientation of the cut is not limited;

- — high cost of equipment, its maintenance and depreciation.

Cutting stainless steel pipes

Oxygen cutting of stainless steel pipes is ordered not only by representatives of state enterprises and companies, but also by private individuals. Stainless steel pipes are in demand not only to achieve production goals, but also to solve economic problems. Stainless steel pipes vary in shape, cross-sectional diameter, and wall thickness. Their labeling, chemical composition, requirements for packaging and transportation are described in GOST 9940 - 81; 9941 – 81; 14162 – 79.

The main purpose of stainless steel pipes is the installation of pipelines for various purposes. In the food and pharmaceutical industries they are valued for their high degree of hygiene; for the chemical and oil and gas industries, their resistance to aggressive environments is important. When choosing a material for installing utility networks, take into account the high degree of resistance to corrosion. Using oxygen cutting, pipes of the required size are obtained that do not have oxides along the edges of the workpiece.