04/30/2021 Author: VT-METALL

Issues discussed in the material:

- Operating principle of semi-automatic machine

- Pros and cons of semi-automatic welding

- Equipment for semi-automatic welding

- Semi-automatic welding without gas

- Semi-automatic gas welding

- Which semi-automatic welding method is better?

- Criteria for selecting a welding machine

Which semi-automatic welding is better - with or without gas? It is quite difficult to answer these questions. Each technology has its own advantages and disadvantages, so one or another method is better to use depending on the specific situation.

In general, semi-automatic welding, using any of the methods, is today one of the most popular types of metalworking. But in order to properly take advantage of its benefits, you need to have an idea of the technological nuances of each method.

Semi-automatic welding is

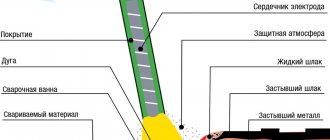

A type of arc welding, during which the welding process occurs due to the simultaneous automatic supply of the electrode wire with the influence of a shielding gas on it.

The shielding gas used during welding completely protects the heated and molten base and electrode materials from exposure to air, which both slows down the welding process and can completely stop it.

Next, we will look at the basic principles of working with a semi-automatic machine, the selection and preparation of this type of tool.

What you need for MIG welding of stainless steel

- MIG welding machine with feeder;

- welding torch with nozzle, mouthpiece and sleeve with connector;

- shielding gas cylinder;

- pressure regulator;

- gas hose for transferring gas from the reducer to the device;

- cable and ground clamp;

- stainless steel welding wire.

It is important that the welding wire is sufficiently alloyed, otherwise the weld will quickly begin to rust. The higher the content of alloying elements in the workpiece metal itself, the higher the percentage of additives should be in the electrode.

A good option is BARSVELD wire 308LSi, which contains 8% nickel and 18% chromium, therefore it perfectly replenishes burnt-out elements, protecting the seam from corrosion. Due to silicon, the weld is of increased strength. The wire is suitable for semi-automatic welding of stainless steel when laying pipelines in the oil industry, in the manufacture of containers, and in mechanical engineering.

Operating principle of semi-automatic machine

Semi-automatic welding machines are mostly simple equipment. Its main parts are an adjustable direct current source, which supplies the welding voltage, as well as a special mechanism designed to feed the welding wire into the welding arc zone, and the feed is performed at an adjustable speed.

The arc has reliable protection thanks to the gas flow created by the burner, where it enters from a cylinder with the same gas. The electrode feed speed and welding voltage are adjusted simultaneously.

As already mentioned, the welding wire must be fed into the arc zone at a strictly defined speed. Only in this case will the welding process proceed stably. Otherwise, at the slightest break in the wire feed, the arc breaks, and this leads not only to a decrease in the quality of the weld, but also to other more serious consequences, which include, first of all, burn-through of the seam, melting of the electrode tip and other failures and defects.

For high-quality feeding, it is necessary to check the drive rollers before work. It is necessary that the feed roller has a V-shaped groove, the size of which must match the size of the wire, and that this groove is in good condition, that is, not worn out.

Often when people experience poor feed, they will increase the clamping force on the drive rolls, which can only make the feed worse as the wire can become deformed. In addition, the burner guide channel can be damaged for the same reason.

During operation, the welding wire passes through the torch through a guide channel, which over time tends to become dirty and wear out. As a result, the resistance of the electrode feed increases, until the wire stops completely.

This should not be allowed; it is better to notice these changes in time and replace the guide channel with a new one, installing which you need to be very careful, since if its length, external and internal diameters do not match, serious feeding problems may arise. In other words, the whole point of replacement is lost and normal welding is still not possible.

In order to reduce wire contamination, as well as premature wear of the guide channel, it is better to choose a semi-automatic machine with a closed feed mechanism. This approach to wire feeding significantly better protects it from dust, moisture, oxidation, etc.

Now a few words about the contact tip of the torch, through which the actual welding current is supplied to the electrode (welding wire). It is clear that for high-quality welding, the wire must have high-quality and reliable contact with this tip. It is necessary to monitor the degree of wear of this part of the semi-automatic welding machine in order to replace it in a timely manner.

All these seemingly little things are of great importance for high-quality welding performed using a semi-automatic machine. Good condition of equipment is the key to success, and poor care of it is the first and surest step to the occurrence of all kinds of malfunctions.

Rules for working with a semi-automatic machine

We list a number of requirements, or rather rules, that should not be neglected when using an automatic welding machine:

- Before starting to operate the semi-automatic welding machine, you should carefully study the operating instructions;

- when welding, you need to ensure strict polarity - “plus” should be on the torch, and “minus” should be on the part being welded;

- To avoid unpleasant situations associated with human injury, when threading wire into the torch, you should not point the nozzle at yourself or other people. Here you need to be very careful, because the end of the wire can pierce your palm or other part of the body;

- It is strictly forbidden to move the semiautomatic device during operation by pulling it by the burner or cable; there are handles for this;

- in order not to damage the eyes and other parts of the face, you should work with a semi-automatic welding machine only in a special protective mask that has a light filter, the marking of which must correspond to the current range used in welding, and for additional protection you should use glasses with glass lenses, since glass does not transmit ultraviolet radiation;

- for long and trouble-free operation of the device, it is necessary to clean all its insides from dirt and dust twice a year;

- if, during an external inspection of the device, damage was discovered in the cable or burner sleeve, they must be immediately eliminated using insulating tape or heat-shrink tubing, and it is better to replace worn parts with new ones;

- the shape of the groove must clearly correspond to the electrode material: V-shaped smooth is used for solid steel wire, V-shaped with notches for flux-cored wire, U-shaped for alloys and soft metals;

- during operation, it is prohibited to touch the live parts of the semi-automatic welding machine, as well as to work with its covers removed;

- the room in which welding is performed must be well ventilated, since aerosols released during work are extremely harmful;

- Fire safety rules should be strictly observed;

- We must not forget that during welding the welding seam heats up to very high temperatures, so it is strictly forbidden to touch these places;

- It’s no secret that a semi-automatic machine, like any welding machine, is a source of electromagnetic radiation, which has an extremely harmful effect on human health. Not all people can work in such conditions, so you must first undergo a medical examination;

- It is strictly forbidden to weld vessels and pipelines together with liquids, as well as vessels in which flammable and flammable liquids were previously stored;

- do not overload the semi-automatic machine, work only under the conditions specified in the operating instructions, since this, firstly, is dangerous to the health of the operator, and, secondly, reduces the service life of the semi-automatic machine itself;

- since a person is a carrier of static electricity, touching the elements of the electronic board is strictly prohibited, in this case they may breakdown;

- The lid of the feed mechanism niche must be tightly and securely closed during operation so as not to become a source of injury to the operator;

- welding should not be performed in a continuous mode, it should be alternated with regulated breaks, the duration of which and the intervals between them should be selected in accordance with the manufacturers' recommendations;

- while operating the semi-automatic welding machine, it is strictly forbidden to switch the stages of the transformer installed on the welding power source;

- all welding work should be performed only in clothing specially designed for this purpose, in addition, clothing must be completely dry in order to protect yourself from possible electric shock;

- The flow rate of the shielding gas, which can be argon, helium, carbon dioxide or mixtures thereof, must be calculated optimally, since it forms a protective environment in the arc zone; in addition, the gas must be selected in accordance with the type of material being welded, as well as its thickness. The cylinder must be secured horizontally and securely enough.

Semi-automatic welding without gas

Among the vast number of types of welding, welding without the use of gas is becoming the most promising and in demand.

Semi-automatic welding of this type is carried out using flux-cored wire or, as experts call it, flux-cored welding wire.

Flux-cored wire is a steel tube, but inside this tube there is a special powder - welding flux, similar to the coating of conventional electrodes.

By exposing the flux-cored wire to high temperature, the flux is burned, which provides a protective gas cloud at the welding site. The process itself is very similar to conventional electrode welding.

The main advantage of this method is the absence of the need to carry gas cylinders with you, a huge selection of materials with different types of chemical compositions, with the help of which you can form the necessary arc properties and change the characteristics of the seam.

Since semi-automatic welding is similar to conventional electrode welding, slag from the burnt flux gets into the welding zone, so it is necessary to ensure sealing of the welding surface. To do this, you need to put a few more new ones on top of the finished seam.

Flux-cored wire has low rigidity, so it must be fed to the welding zone with a slight increased pressure; bends in the semi-automatic welding hose are simply unacceptable.

It is extremely necessary to observe the polarity conditions of the phase wire and the “ground”

On the left you see the polarity of welding without using gas, and on the right with using gas when welding.

In order to start the process, you need to connect the power source in the following way: minus to the torch holder, and plus to the surface to be welded. In the case of welding using shielding gas, the connection occurs in the reverse order.

This method of power connection provides a high temperature for melting the flux and the formation of a protective gas environment.

The main advantages of gasless welding:

- Easy welding process

- No need for a gas cylinder

- Fast speed of work

Refueling and consumption

In order for the welding operation to proceed quickly and without errors, you need to correctly thread the wire into the machine. This is done as follows:

- Usually welders buy one or more wire spools at a time. After unwinding a small piece, straighten the outermost 10 centimeters using wire cutters;

- then you should examine whether there are any traces of corrosion or contamination on the wire surface. If everything is fine, then you need to advance the wire thread a few centimeters into the so-called liner (this is a tube in the area of the device sleeve);

- Now you need to turn on the semi-automatic welding machine and start working, not forgetting to make sure that the bends of the sleeve are not too strong and sharp. Because of this, the wire may well get stuck and break in it.

It is equally important during welding or in advance to find out at least the approximate consumption of welding wire. N

and the consumption rate is influenced by such parameters as the chemical composition of the metal, the thickness of the wire itself, and the technical characteristics of the welding machine.

In many cases, it is believed that the weight of the wire should be equal to 1.5% of the weight of the parts being welded. And the weight of the deposited material is always 6-10% less than the weight of the wire (this 6-10% “eats” the waste).

Open sources also indicate that the consumption of flux-cored wire per second during semi-automatic welding can range from 3 to 25 cm. Obviously, much will depend on the speed of the master welder.

Semiautomatic welding machine for gas environment

Semi-automatic welding machine designed to work in a protective gas environment is a new type of welding that is gaining popularity. Over the past 20 years, the use of this type of welding has reached a large scale.

This type of welding involves two types of work:

MIG (Metal Insert Gas) - welding occurs under the influence of an inert gas, for example argon, as well as other types of gas mixtures.

MAG (Metal Active Gas) is a process of welding metal using an active gas, for example carbon dioxide.

The use of gas cylinders does not allow mobile welding in any conditions, however, when used stationary, this type of welding is the best and has no analogues.

The welding process is carried out by feeding electrode wire, which contains silicon and manganese, into the welding zone together with carbon dioxide.

This creates a protective environment for the electrode and welding surface from the effects of the environment.

The advantage of this welding is the ability to control the process; also the advantages of welding in a gas environment include saving time, because when gasless welding it is necessary to change the electrodes and clean the welding seams from slag.

The quality of work using a protective gas environment is much superior to gasless welding, but there are small nuances here too.

Let's look at them using the example of seam quality. When using CO2 active gas, the seam will have a scaly appearance and burrs, i.e. effect of stuck balls. At the same time, when using a mixture of argon gases in the amount of 80% and carbon dioxide 20%, respectively, the seam has a smooth and even surface that does not require additional processing.

In recent years, for the operation of semi-automatic welding machines, the use of inverter types of power sources instead of an alternating current source has become widespread. This is due to such advantages as:

- Light weight of the device

- Smooth voltage regulation, which means safe work performance

- Low load on the electrical network, which in turn leads to uninterrupted operation of other electrically consuming devices in the room.

Types of welding wire

Welding wire is manufactured for semi-automatic machines in the form of coils, which makes it possible to establish a continuous supply of the electrode to the working area. Such electrodes for semiautomatic devices are classified in several ways. There are solid, powder and activated consumables. This typology includes any consumables for a semi-automatic machine: steel, brass, aluminum wires and other types for a semi-automatic machine.

The main composition of metal flux-cored wire for a semi-automatic machine is a tubular electrode consisting of an outer metal shell with a core made of powdered materials. The metal shell can be cobalt, nickel, iron or stainless steel. The shell conducts electrical current during the welding connection process. The internal powder composition of metal flux-cored wire for semi-automatic machines consists of both elemental and alloyed (stainless) powders such as nickel, cobalt, chromium, tungsten, molybdenum and manganese.

Cored wire

During the electrode manufacturing process, metal strips enter the mill to form an outer metal shell for the powder core. Using a specialized feeding process, the powder enters the casing in exactly the required volume. The consumable material is rolled into a tubular shape and then stretched to a final size ranging from 0.45 to 0.125 diameter.

Some of the advantages of using semi-automatic metal cored welding wires are that under certain conditions (for example for aluminum) higher deposition rates, excellent sidewall adhesion, slag recovery, vapor reduction and application for special alloys can be obtained.

The outer metal sheath of the semi-automatic flux-cored wire conducts electric current for welding. The internal components of metal cored wire consist primarily of alloys, manganese, silicon, and in some cases nickel, chromium and molybdenum, as well as very small amounts of arc stabilizers such as sodium and potassium, with the balance being iron powder. The electrodes make it possible to have alloy compositions used for specific applications in smaller batches than conventional large solid wire electrodes.

Many alloy compositions using chromium, nickel and molybdenum are now available, including austenitic and ferritic stainless steel alloys. An electrode made of metal powders practically does not form slag-forming components in the internal filling of the wire. Similar to solid MIG wire, welds made from metal cored wire will only have small islands of silica from the deoxidized products that appear on the surface of the weld.

Electrode wire for semi-automatic machine is used for connection when protecting carbon dioxide. Such consumables consist of 93% shell, and the rest is powder. The activated version is represented by SV08G2S as the most popular in use, which is produced using alkali metals with a high degree of ionization.

Electrode wire SV08G2S

Such components will increase the stability of the electric arc. Also, this type of wire is more tolerant of mechanical damage. Also, the low thermal conductivity of alkaline elements allows heat to be retained in the welded zone.

How to choose a welding machine

Like any equipment, the welding machine has its own design and it consists of:

- Burner, differing in type of power and cooling methods

- Wire feed mechanism. It includes feeding method, speed regulation and number of pinch rollers

- Hose that varies in diameter

- A gas reducer, which must have two pressure gauges.

When choosing a semi-automatic welding machine, you should take into account the thickness of the metal that will be exposed to welding, the length of the seam the machine produces, as well as the conditions for performing welding work.

Before purchasing, you need to clarify all the above parameters, as this will help you choose the device that is right for you.

It is necessary to select a welding machine using the following method:

- The choice begins with clarifying the tasks for which the device is purchased

- When choosing, pay attention to the quality of the welding machine, read information about the manufacturer and study reviews about it and the machine. Also pay attention to the cost, which cannot be lower than average.

- If you choose a low-power device, then you should take into account that it is capable of processing only small surfaces.

- At the place of purchase, find out the specifics of the warranty, the availability of service centers and the availability of consumables and spare parts for the device, such as conductive tips, torch nozzles, insulating sleeves, feed spirals and rollers.

Preparing the welding machine for work

Like any type of activity, carrying out welding work requires compliance with the rules of preparation for the process, this will ensure the safety and quality of the process itself.

Before starting work, you need to prepare the welding surface to avoid the appearance of pores. To do this, you need to remove dust, debris, dirt, moisture, oil, as well as rust up to 30 mm from the edge of the gap from the surface.

The surface can be cleaned with a metal brush, a steel brush for metal, rags, or a sandblaster, then it must be degreased and etched.

It is also necessary to prepare the welding machine; for this, the following preparation steps must be followed:

- Check the grounding of the device. Any cooking equipment must be checked for connection to the grounding conductor. Missing or malfunctioning jeopardizes the safety of the welding process.

- Checking the network voltage. Many devices are sensitive to power surges and may fail. Therefore, the voltage in the network must be stable.

- Select the welding machine mode. Modern semi-automatic machines have many welding modes and its adjustment. With their help, you can adjust the welding to the material being welded and the nature of the welding.

- Before starting work, you need to adjust the diameter of the tip; it should be several millimeters larger than the size of the wire.

- Check the adjustment of the tip and feed mechanism. If these elements are upset and configured incorrectly, this can lead to operational errors or damage to the material being welded.

- Checking the quality of the wire. It should be smooth without burrs, dents and various kinds of scratches.

What is MIG/MAG

The wire has such qualities as flexibility and thinness. And its use allows you to reduce the spattering of molten metal, increase the size of the weld pool and the depth of welding. Using semi-automatic wire machines, you can weld different grades of steel, non-ferrous metals, and other materials.

Modern wire welding machines use MIG/MAG technology. What do these English abbreviations mean? MIG is Metal Inert Gas and MAG is Metal Action Gas.

That is, what kind of gas is used in the welding process is of key importance here. If it is inert helium, then the technology should be called MIG, and if welding is carried out with CO2 gas, which is classified as active, then MAG.

The welding process with machines that support MIG/MAG technology is quite simple. Even craftsmen without serious experience in the profession can achieve decent seam quality and a good level of productivity.

With a semi-automatic welding machine it is possible to work spotwise and create continuous seams up to 40 meters long. Anyone today can purchase one of these devices in specialized stores, and it will definitely come in handy in the household.

In the design of a semi-automatic wire welding machine, three main elements can be distinguished: a transformer (or inverter) that generates an electric arc; a conveyor responsible for feeding the wire electrode; and a control unit, whose main task is to synchronize all processes.