Jaw chuck for micro drills as an alternative to collet chucks

In order not to think about how to make a collet chuck or clamp with your own hands, you can purchase a jaw chuck to equip your microdrill. This clamp is an analogue of the jaw chucks used to complete conventional electric drills, and works on a similar principle. When the movable holder on the body of such a device rotates, the cams with which it is equipped move and thereby ensure reliable fixation of the tool.

Miniature jaw chuck ensures rigid fixation of working attachments

A wide variety of inexpensive jaw clamps are available today to equip micro drills. The vast majority of their models are fixed on the drive motor shaft using a threaded hole on the side of the mounting part, into which a screw is screwed. Rotation of the cam clamp cage, depending on the specific model, can be done either manually or using a special key, which is necessarily present in the factory kit of this device.

Purchasing a jaw chuck is a good opportunity for little money to equip your power tool with a universal clamping device that is easy to use and provides reliable fixation of working attachments

The main thing you should pay attention to when choosing is the material from which the main working elements of the clamp are made. If you choose a chuck whose jaws are made of durable high-carbon steel, it will last much longer and will provide precise fixation of the tool being used.

To carry out drilling work on miniature workpieces, engraving machines, the so-called “dremels,” are usually used. The name comes from the name of the most popular manufacturer. This is a convenient hand tool, but its cost is usually high (especially for high-quality branded products).

The most common area of application is amateur modeling and production of printed circuit boards. As a rule, an industrial design is redundant for such work: some of its capabilities are not in demand. Therefore, home craftsmen often create instruments with their own hands.

Drill chuck

The versatility of use is emphasized by the range of diameters and lengths of interchangeable nozzles. In this case, the processing of the material can be performed not only in the translational direction, continuing the body. In addition to the “classic” chucks with a clamping key, there is an angled chuck.

Angle chuck for drill

Unlike others, more common and described everywhere, it is almost unknown. Provides flexible work in the truest sense - right up to drilling around a corner or into the frame.

All types of chucks are divided into regular (key, quick-release, etc.) and special (flexible, extension, etc.). The whole difference is in versatility.

When it becomes necessary to choose a chuck for a drill, the types offered on the market will completely satisfy any master. Regardless of which drill and how often it will be used, you should pay attention to the simplicity of the chuck design.

Classic drill chuck

The cartridge is “classic”. The drill is fixed using a cam method - the replaceable nozzle is clamped from several sides. These cams (collets, petals) move under the influence of the compression screw and hold the shank of the nozzle.

Lathe chuck: purpose, types and features of choice

Return to article list

It is difficult to imagine the rapid development of the metalworking complex without the constant improvement of machine tools. It determines the speed of sharpening parts, compliance with their geometry, and the quality of surface treatment.

To securely hold the workpiece, a lathe chuck is used to ensure the necessary clamping force and centering accuracy. This article addresses the main issues regarding the selection of devices:

This article will cover the following issues:

Lathe chucks are installed on universal and special machines and are used to fasten parts to the spindle axis. Thanks to their use, reliable fixation is achieved and the clamping force is increased with high torque. The part does not break off, maintains the correct position during operation, reducing the risk of cutter breakage and ensuring high speed of product production.

Chucks for lathes are made from hardened steel, less often cast iron, and differ from each other in design and purpose. In Russia, eight standards have been developed and approved that describe the requirements for these elements. For example, according to GOST 1654-86, there are 4 accuracy classes: A (extra high), B (high), P (increased) and N (normal).

All used lathe chucks are conventionally divided into two groups: jaw and collet. The first ones consist of several movable segments (cams), due to which the part is fixed.

They are used for most operations and differ from each other in design features and purpose.

The lathe chuck is also classified according to:

- number of cams (from two to six);

- features of fastening (on the external or internal surface);

- specifics of execution (solid, prefabricated or overhead cams);

- the drive used (manual or mechanical).

Each type of device has its own advantages, features of use and is designed for certain functions.

The 2-jaw chuck for a lathe is used for fastening complex shaped parts, non-cylindrical and asymmetrical workpieces. Their peculiarity lies in the ability to fix untreated surfaces in sponges, providing sufficient adhesion.

All parts of the product are made of steel; moving parts are subjected to heat treatment, which increases their strength characteristics and wear resistance. The dimensions are standardized: diameter varies from 125 to 400 mm. The disadvantages of devices of this type include a high risk of misalignment due to the wide gap between the guides.

Reducing time costs allows you to speed up the process, which is especially important when there is a large load, for example, on serial machines. The mechanized drive provides another important advantage: constant clamping force, due to which the part does not warp or fly out at any speed.

The mechanized drive provides another important advantage: the constancy of the clamping force, due to which the part does not warp or fly out at any speed. a - three-jaw chuck; b - four-jaw chuck

a - three-jaw chuck; b - four-jaw chuck.

The 3-jaw chuck for lathe can be either spiral or rack. Spiral structures were one of the first to appear and have been used for more than 100 years due to their simplicity and reliability.

Rapid failure is caused by the use of a fragile volute, dirt and metal shavings getting into the gaps.

Types of malfunction

Typical cases in which the chuck of a Metabo, DeWALT, etc. screwdriver jams:

- when trying to use a drill of the maximum permissible size, the cams are moved to the maximum, after which it is impossible to bring them together with the application of standard forces;

- It is not possible to remove a drill or bit clamped in the chuck - the cams do not move apart. Often, they are clamped unevenly, which impairs the fixation of the drill.

Less commonly, jamming of the jaws occurs during their free movement during compression or expansion - usually this is facilitated by particles of debris, scale, shavings, etc., trapped under the figured part of one of the cams.

Making a collet chuck for hand tools and machine tools

The simplest homemade collet chuck for hand tools can be created without using a lathe. If you need equipment for a machine, it will have to be machined from a workpiece and you cannot do it without special knowledge.

Method 1. The simplest wire collet

To equip a drill with low motor power, which will be used to work with wooden and plastic workpieces, a miniature collet coupling soldered from steel wire is suitable

It is important to consider that the resulting chuck can only be used for drills of the same diameter, and the diameter of the drill must correspond to the output shaft of the motor

Photo No. 2: The simplest collet clamp made of wire

For work you will need the following tools and materials:

- a cylindrical metal blank, the diameter of which coincides with the diameters of the output shaft of the motor and the drill;

- steel wire 1 mm thick;

- electric soldering iron;

- soldering flux or KFET.

The wire should be wound around a blank, forming a rigid spring. The turns of wire must be placed as close to each other as possible. The finished spring is soldered directly on the workpiece using flux or KFET.

The resulting collet coupling is put on the electric motor shaft, and a drill is inserted into the hole at the opposite end.

Method 2. Collet clamp from a screw

A collet chuck with similar characteristics can be made in another way. The product will consist of two parts connected by a screw. Fixation of the clamp on the shaft of the electric motor and the tool is ensured by cylindrical grooves on the internal surfaces of the equipment.

Photo No. 3: Blanks for making a collet clamp

To work you will need:

- 8 mm bolt or screw;

- closed nut M8;

- grinder with a metal disc;

- drill and drill bits 2 and 5 mm.

Photo No. 4: A collet chuck made from a screw mounted on an electric drill, in use

Drill a 3mm hole in the bolt leg. Make two even axial cuts crosswise with a grinder or a hacksaw. After this, drill a hole with a diameter of 2 mm in the closed nut exactly in the center. Extend it to 5mm. Round the edge of the bolt to create a cone. The finished collet chuck must be centered before use. Only in this case will it work correctly.

Method 3. Homemade collet chuck for a milling machine

A homemade collet chuck for a milling machine can be made on a lathe. For equipment you will need a steel blank (round timber with a diameter of 40 mm and a height of 70 mm). The work is carried out in two stages. First, the cartridge body is made, then the clamping nut.

Photo No. 5: Collet for a milling machine, turned on a lathe

Manufacturing of the cartridge body:

- Clamp the blank into the chuck with reverse jaws.

- Drill a through hole in it along the axis and bore it.

- Cut a M27 x 2 thread in the hole.

- Grind the outer surface of the blank.

- Trim the end that will support the base bearing surface on the spindle.

- Remove the resulting mandrel from the chuck and the three-jaw chuck from the machine and screw the mandrel onto the spindle until it stops.

- Bore the cylindrical and conical surfaces of the collet socket.

- Grind the end of the mandrel and cut a thread in it for the clamping nut.

Making a clamp nut:

- Clamp the workpiece into the reverse jaws of the three-jaw chuck.

- Drill a hole in it, bore the internal cavity.

- Grind the inner end bearing surface.

- Cut a counter thread in the nut.

- Screw the nut onto the chuck previously installed on the machine spindle.

The resulting equipment can be improved to make it easier to fix the tool. For this purpose, grooves are rolled on the side surfaces of the cartridge body and nut and grooves are made in the outer side surfaces.

Mounting methods

There are three ways to attach the clamping cylinder to the spindle:

• using thread; • using a fixing screw; • using a Morse cone.

The first method involves the presence of threads on two parts in contact.

The cylinder is screwed onto the shaft.

The screw is used as a contact amplifier between the sleeve and the shaft.

In this case, screwing also takes place, but the fixing component serves for additional fastening.

The screw is usually characterized by a left-hand thread and the presence of a “cross” head.

To see the element, you need to move your fists as far apart as possible.

The Morse taper is a variant that has been used for over a hundred years.

The surface of the shaft has a cone-shaped format, similar to the shape of the cartridge.

The matching parameters of both cones make it possible to reliably and quickly combine parts.

This option is used in many modern models (pneumatic, etc.).

Do-it-yourself drill for small jobs

The drill has long ceased to be an exclusively professional dental instrument. Today, a drill with a flexible shaft is actively used to perform small decorative work, grinding, polishing, and cutting various products.

At the same time, it should be taken into account that for high-quality work of the homemade product you will need a fairly powerful motor. So, an 18V motor from a screwdriver is perfect for powering drills. The easiest way would be to make an engraver from an old blender.

To make a drill you will need:

- Disconnect the top part of the blender from the working part;

- Using a utility knife, remove the rubber cover on the button and use a screwdriver to unscrew the bolts located under it;

- Using a screwdriver, from the side of the power cable, pry up the top cover of the case and carefully remove it;

- Remove the circuit connected to the power cable from the blender body;

- Remove the plastic part located above the rotator from the housing;

- Remove the plastic tip from the electric motor shaft;

- Measure the diameter of the shaft with a caliper (if you don’t have one, a ruler will also work for this purpose);

- Clean the electric motor housing from oil and degrease its surface using an alcohol wipe;

- Place a collet chuck of the appropriate size onto the shaft;

- Replace the power button with a push mechanism that controls both turning the device on and off;

- Assemble the blender.

Parts for making a drill can be found at a flea market.

The hand drill is ready! Such a tool will be powered via a power cable with a plug. You can power the tool with batteries, but then the batteries will have to be changed or charged from time to time.

How to choose a new cartridge

A screwdriver chuck is selected based on a number of aspects. When choosing a suitable part, you should be guided by the following recommendations:

• if bits have to be changed frequently, it is better to choose quick- or self-clamping cylinders; otherwise the work will go slower; • gear-rim design – the choice of those who strive for maximum cartridge reliability; if 100% fixation of the bit is a priority, it is better to purchase a key cartridge; • when choosing a part, it is necessary to take into account its characteristics; parameters are regulated by relevant GOSTs; the larger the clamping cone, the larger the number with which it is marked; • it is necessary to take into account the country of origin - the alphanumeric designations of foreign models differ from domestic ones.

If it is difficult to decide on the type of “clamp” on your own, it is better to seek advice from a specialist.

An incorrect choice is tantamount, at a minimum, to incorrect operation of the tool.

In the worst case, it is possible not only to re-spend on a new cylinder, but also to replace the entire screwdriver.

Areas of application for collet chucks

The main structural element of a chuck with a clamping type collet is a sleeve with spring petals, the number of which can vary. Thus, for clamping workpieces whose diameter does not exceed 3 mm, chucks with three petals are used, when processing parts with a diameter of up to 80 mm - with four petals, and over 80 mm - with six. To process parts of very small diameters, clamping chucks are used, the collets in which are moved apart using special springs. In addition, there are models of collet chucks that are equipped with replaceable inserts of various sizes, selected depending on the geometric parameters of the workpiece being processed.

Clamping collets are used not only for fixing the workpieces being processed, but also for fastening the tool used in them, which can be a cutter, drill or tap. The tool shank is fixed by the clamping elements of a replaceable collet, which is held in the inside of the chuck by a special nut. This device works according to the following principle: when a nut is screwed onto a collet clamp, which is made in the shape of a reverse cone, this element is pulled into the hole in the chuck, thereby ensuring tight and reliable compression of the tool shank installed in it.

Set of collets with nut and locking ring for Sparky router

Among the advantages of collet chucks for milling cutters, which have made them very popular and in demand in the modern market, the following should be highlighted:

- simplicity of design;

- ease of use;

- high reliability of fixation of workpieces and tool shank.

In addition, collet chucks ensure minimal runout of both the tool and the workpieces that are fixed in them. This is explained by the fact that the bodies of rotation installed in such a cartridge are perfectly centered. Convenience and ease of use are also ensured by the fact that you do not need to use a special key or other additional devices to operate it.

Chuck with ER20 collet for cutters with shank diameter 8 mm

Of course, like any technical device, collet chucks also have disadvantages. The most significant is that the diameter of the workpiece or tool shank for a milling cutter directly depends on the working diameter of the collet itself. Thus, for tools and workpieces of different diameters, it is necessary to select collets of different sizes.

One of the most notable areas of application of collet-type chucks is the equipment of longitudinal turning machines, where they are used to fix the workpiece. Such machines, as a rule, process workpieces of not too significant diameter, which makes it possible to use collet-type clamping devices to fix them. Meanwhile, the collet chucks used to equip such machines differ in their design from the collet chucks used on lathe equipment. Longitudinal turning machines are often equipped with two types of collets, one of which, as mentioned above, is used to fix the workpiece being processed, and the second is used to secure the shank of the tool being used.

Which way to unscrew the drill chuck?

Everyone probably remembers how to remove a cartridge from a Soviet drill. Modern electric models are not much different from the manual one.

The process of removing a chuck from an electric or hand tool begins with studying the documentation and markings. Any thread (regardless of the cutting side - left or right) is marked with an arrow and symbols.

Thread type - both metric and inch. Before applying physical force, you must ensure that the chosen direction is correct. There are frequent cases of normal breakdown and failure of this connection. Information is provided on the tool body and in the instructions.

The chuck rotates clockwise for drilling and tightening hardware. To ensure reliable fastening of the cartridge itself, the thread is usually made “left-handed”, left-handed. To unscrew it, you need to rotate it counterclockwise.

The thread size is indicated by letters. Type: M, metric, or UNF, inch. The numbers show diameter and pitch. The most commonly used thread is M14. It is very suitable for installing various adapters for the cartridge.

Types and features

Depending on the area of application and the design features of the mechanism, collet chucks are divided into several types:

- ER collets. With two clamping points and a through hole, the most commonly used type;

- for taps. With a square groove compensating the axis;

- through and blind. The former process parts of unlimited length, the latter are suitable for workpieces of limited size, for example, workpieces in which one end is sealed;

- with one and two clamping sections. The second type, compared to the first, fixes the part more reliably by holding it at two points on the axis.

Collet chuck clamps come in two types:

- clamping The bushing is made in the form of several springy petals corresponding to the size of the fastener. The three-lobe bushing is designed for processing workpieces with a diameter of up to 0.3 cm, four-lobe bushings - from 0.3 to 8 cm, six-lobe bushings - for parts more than 8 cm in diameter;

- servers. The steel collet is equipped with three longitudinal grooves, forming petals with converging ends. The well-springing design feature allows for easy installation and reliable holding of a workpiece of the required diameter in the chuck. During operation, the feed mechanism with the screwed collet begins to move, which contributes to an even closer approach of the petals.

The feeding type of cartridge is more reliable, but requires a special key for fixation. Clamping types are used in cases where frequent replacement of cutters during operation is necessary.

How to determine the fastening method

Before you figure out how to unscrew the chuck from a screwdriver, you need to determine the method of fixation.

A tool that uses a clamping device with a Morse taper fastening type may be marked B10, B12, B14, etc.

According to GOST, there can be 9 standard sizes - from B7 to B45.

The number indicates the size of the cone.

Next to it, in millimeters, the range of diameters of the shanks of fasteners that are suitable for fastening in this screwdriver is indicated.

The screwdriver chuck with a threaded fastening has a different marking.

On domestic models you can find the type designation 1.0-11 M12x1.25.

This marking is in metric format.

The numbers before the letter indicate the permissible shank size, the rest - the thread size.

Foreign screwdrivers use the inch designation.

For example, a part may be marked as follows: 2-13 mm ½-20 UNF.

Here the first numbers are the diameter of the bits, the fraction is the diameter of the thread in inches, 20 is the number of threads in each inch.

DIY hand drill: manufacturing instructions

A small electric drill is a must-have for anyone who makes electronic crafts or does delicate decorative work. This machine is ideal for performing small work on wood, plastic and metal, and drilling printed circuit boards.

The motor can be taken from a hair dryer or grinder. An electric motor from a VCR or a motor from an old cassette recorder are also suitable for making crafts.

To make an electric mini drill you need:

- Connect the cartridge to the motor. This is best done using cold welding. But you need to work quickly and carefully: the weld quickly hardens and becomes as strong as iron. If it fails, it will not be possible to redo the connection.

- Place the cartridge in the jar. For better fixation, the cartridge must be treated with hot glue.

- Make a hole in the second base for the switch. It’s better if the switch is small and keyboard-based.

The hand micro drill is ready! All that remains is to solder the wires from the motor and power to the switch, observing the polarity. To power the mini-drill, 9-12v batteries will be enough. Additionally, you can do reverse on a six-pin switch.

Which drill chuck is better?

The drill chuck plays the role of an adapter between the drill and the working tool. For any task or for each type of drill, you need to select the optimal chuck option. Working hours and workload are also important.

What is the most influential factor on the operation of a cartridge and what factors can cause it to fail? Replacing a cartridge in the field can be difficult if you don't have a spare.

- Quality of materials. The “Chinese” cartridge can fail during heavily loaded operations. Therefore, it is better to purchase high-quality models.

- If the drill or the chuck itself falls out, time is lost. When drilling at height, safety is at risk. In case of a loose conical fit with a loose fastening, measures must be taken in advance.

- Drill chuck runout. If this occurs, you should disassemble the drill chuck, check for contamination or adjust the fastenings. If bent, it usually cannot be repaired manually; it is best to replace it with a new one.

- Collets or jaws jamming. To rectify the situation, you will need to disassemble the cartridge (remove the cartridge itself if you know how and have already changed it). Cleaning, lubrication and assembly are carried out.

The most popular varieties besides the key one are: quick-clamping (or “bzp”) and self-clamping.

Device manufacturing algorithm

The collection takes place in 3 stages. Let's take a closer look at each of them.

Making a mini cartridge

In order to assemble a mini drill chuck, you need to purchase a collet - a special mechanism designed for clamping cylindrical objects. Next, you need to connect the motor to the contacts of the future battery, which will power the device during operation.

If your drill is spinning in the wrong direction, swap the wire contacts.

Finding a drill of the right size is not difficult. Insert the drill into the collet body and clamp tightly. Next, the finished nozzle must be installed on the motor body. The collet should fit tightly onto the motor shaft. Otherwise, you cannot avoid vibration. The chuck for a homemade mini drill is ready.

Attachments for a homemade mini drill

can be purchased at any hardware store. Before purchasing, make sure they match the diameter of the collet.

Preparing the body

As a housing for the future device, you can use either an antiperspirant container or a regular hollow tube of a suitable size. hollow tube as the body

.

it is necessary to cut off the bottom and insert a rubber or other plug in its place. If you are making a device from an antiperspirant body

. a hole must be drilled in the cover for the drill to exit.

Connecting the elements

The motor must be installed on the reverse side. If your motor is not the right size, choose another tube. The fit must be very tight to avoid vibration as the shaft rotates. After this, it is enough to tighten the bolts on the collet and connect the resulting device to the electrical network.

One of the main disadvantages of assembling a drill with your own hands from a motor is the lower power compared to a standard device and the low strength of the drill.

If your work requires a cutter, you can easily make one yourself from an old lighter.

To do this, remove the spinning drum from the lighter and place it on a bolt of a suitable size. Secure this with a nut and insert it into the collet hole. The cutter for surface treatment is ready!

If for some reason the cartridge does not fit in size

to the cylindrical shaft of the motor or coil, it is necessary to degrease it well and then attach it to hot glue. This will help to obtain a stable and durable structure.

Such a mini drill with purchased attachments can perform minor repairs on technical equipment, drilling plastic, thin metal, and making crafts.

The problem of consumption or lack of collet cartridges is especially familiar to jewelers. Specialists involved in the manufacture of printed circuit boards also face this problem.

Collet chucks can be created independently from available materials. However, there are some nuances that will be covered in detail in the article below.

It should be noted right away that a hastily made collet will not be dismountable. That is, strictly speaking, removing one drill from it and inserting another will not work. For this reason, the manufacturing method is more suitable for those who need to create a large number of identical holes.

So, to create a homemade collet chuck we will need:

- drill;

- blank;

- steel wire;

- soldering flux;

- hoop.

Initially, you should wind the steel wire around the blank in the form of a rigid spring (the half rings come as close to each other as possible). Next, the resulting structure must be thoroughly soldered.

Today, anyone can easily purchase a special cam for any type of drill. This can be done both in construction boutiques that offer equipment for sale, and on the Internet (at auctions such as Ebay or Amazon).

The price of such a device does not exceed sixty rubles. Purchasing a cam will forever save you from searching for suitable collets for using various drills.

Of course, it is better to purchase a cam made of high-carbon, durable steel. To tighten it, it is recommended to use a special wrench, which is included in the kit.

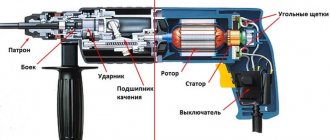

Screwdriver and its design features

You should start repairing a screwdriver yourself by becoming familiar with its design. The main element of a screwdriver is an electric motor. Screwdrivers come in both corded and cordless types. The use of a corded screwdriver is used less frequently, due to such a disadvantage as the need to connect the tool to a 220V network. Battery-type tools are more popular, as they allow you to carry out not only repair work at home, but also outside it.

The main components of a cordless screwdriver are:

- Frame. Typically, all screwdrivers are made of durable plastic.

- Start button. It is designed in such a way that the number of revolutions of the cartridge depends on the force of pressing it.

- Electric motor. Battery-powered tools use single-phase commutator-type and DC motors. The motor consists of a rotor, a stator in the form of magnets, and a brush assembly.

- Gearbox.

- Force regulator.

- Reverse switch.

- Battery. As a rule, it is removable and is often supplied with the product in duplicate.

- Cartridge. As a rule, quick-release chucks are used.

Some models are additionally equipped with LED backlights, as well as battery charging indicators. Returning to the problems with the screwdriver, it should be noted that any of the above elements can cause the tool to malfunction. What is needed for repairs? The first step is to find the cause of the breakdown, and then make the appropriate decision to eliminate it. The tool can be divided into two parts: electrical and mechanical. Initially, you need to find out what the problem is with the screwdriver not working: mechanical or electrical. This won’t be difficult to do, so let’s look at the breakdowns in more detail.

Mechanical faults

Mechanical malfunctions of screwdrivers can be identified by such a sign as the audibility of the operation of the electric motor. When you press the start button, you can hear signs of the electric motor running, but the tool chuck does not rotate or characteristic sounds of a malfunction are heard when rotating.

The design of the screwdriver is quite simple, but a significant drawback is that all the elements are almost 2-3 times smaller than those of an electric drill. Possible mechanical failures of a screwdriver include the following malfunctions:

- Cartridge failure. Despite the fact that quick-release chucks are more versatile and easier to use, their significant drawback is their low service life. It is impossible to repair the keyless chuck, so if the tool refuses to hold the drill or bit, the chuck should be removed and replaced with a new one. This is one of the most common malfunctions of the tool, but it does not require disassembling the screwdriver.

- Gearbox failure. The screwdrivers are equipped with a planetary type gearbox. Typically, in order to save money, manufacturers make gearbox gears from low-quality plastic or metal. This affects not only the power of the tool, but also its service life. If the engine runs when you press the “Start” button, but the cartridge does not rotate, then the problem lies precisely in the planetary gearbox. To find out the cause of its malfunction, you need to disassemble the tool and then determine the breakdown. If one gear fails, the gearbox should be replaced.

- Bearing wear. The bearing is located in the planetary gearbox, so it is replaced along with the gears.

- The force regulator is broken. This device in screwdrivers is used not only to increase or decrease the traction force of the tool, but also to increase safety. If during work the working attachment becomes jammed, then instead of turning the tool, the regulator will turn. Thus, the master will not get a dislocated arm, and the electric motor will be protected from high loads, from which it can burn out.

It should be noted that the small size of the mechanical part of the instrument somewhat complicates the process of instrument repair, so be sure to be careful when carrying out repair work.

Electrical faults

Unlike drills, screwdrivers operate primarily on batteries. This means that different electric motors are used in the design of these tools. It is not difficult to determine the malfunction of the electrical part of the screwdriver. If the battery is charged, but when you press the “Start” button you cannot hear the sound of the electric motor, then the cause is an electrical failure. Let's look at the main types of electrical faults in screwdrivers.

- Battery fault. Initially, you should pay attention to the battery. As a rule, screwdrivers use low-quality nickel-cadmium batteries. They have a significant drawback, which is the need to charge it only when it is completely dead. Such batteries cannot be recharged, as this shortens their service life. If one day the screwdriver refuses to function, then do not rush to disassemble it, make sure that the battery is functional and provides a charge. You can check by connecting a second battery. The battery charge can also be checked using a tester, which should show the appropriate voltage value.

- Charger fault. There is a special charger for charging the battery. If the battery is discharged even after you have charged it, you should check the integrity of the charger. Chargers usually have indicator lights for these purposes. If they are not there, then you need to use a multimeter.

- The power button is faulty. It is necessary to check the start button, since often the reason for its inoperability is oxidation of the contacts or dust. The tool should be disassembled and then the contacts should be cleaned. The buttons on screwdrivers usually have the function of regulating the speed of rotation of the chuck, for which a transistor is installed. If the tool works, but the speed control function is missing, then the transistor needs to be replaced.

- If the reverse function does not function, the breakdown can be corrected by cleaning the contacts of the polarity switch button.

- Motor malfunction. The electric motor is one of the most expensive structural elements of a screwdriver. If everything is checked and it is determined that the problem lies in the electric motor, then the cause should be found out. Most often, the problem occurs with brushes, which simply wear out over time. The brushes cannot be repaired, so they must be replaced. The armature should be replaced if a break is detected when testing its winding terminals. No one will rewind such a small rotor, so it’s easier to purchase a new unit. The stator of a permanent electric motor is presented in the form of 2-3 magnetic plates that do not fail.

Now you know the main signs and types of screwdriver malfunctions. To repair it, you don’t need to be a specialist, but just stock up on tools and free time.

Types and principles of operation of chucks

Collet chucks are used mainly when processing cold-rolled rods or other metal products that have an already machined surface.

Structurally, cartridges can be classified according to functionality:

- with a fixed mechanism;

- with retractable mechanism;

- with retractable mechanism.

Each design has its own characteristics. The feeding type is made in the form of a steel sleeve with 3 cuts forming petals that have a springing effect.

Type F

Collets type F - clamping the main spindle are used to secure the workpiece.

Type LN

Collets type LN - counter spindle are produced elongated, size E depends on the standard size.

Type R

Type R – are pull-type collets.

Type T

Type T - clamping.

Drawing No. 5 collet BF

Type BF

BF type feed collet - designed for bar feeding.

When installed on the machine, the feed collet is threaded onto the pipe with the help of which it is fed into the working area. It is necessary to take into account the design feature - the size and shape of the collet, which must necessarily correspond to the profile of the bar being processed.

In preparation for processing, the rod moves through the petals, which, due to their design features, tightly hold the workpiece. During processing, when feeding the workpiece, the adhesion force between the petals and the product increases due to rotation. The principle of operation of the clamping elements is based on strengthening the adhesion of the petals to the workpiece during rotation of the working mechanism. Bushings with 3 petals are used for processing products up to 3 mm, four – up to 80 mm, six – over 80 mm. Typically, collets have an angle at the apex of the cone equal to 30º.

Collets for shaft 2 mm (0.1-3 mm) for micro drill

When processing thin rods, collets equipped with springs are used to increase the clamping force of the jaws. When increasing the diameter of the workpiece being processed, designs are used that are equipped with special inserts selected according to the dimensions of the product. Collet clamps are also used when machining with a drill, cutter or tap. The sleeve is fixed in the chuck with a nut, and the cutting tool is fixed directly in the collet. When fixed with a nut, the internal volume of the hole where the workpiece is installed is reduced, thereby increasing the force holding the rod stationary.

Cartridges of this design also have their drawbacks. First of all, the requirement that the shanks of the tool used must match the characteristics of the collets used. At enterprises, the most widely used collets are the ER type, which constitute the largest number in the total volume of tools used.

When performing complex work on the manufacture of products, various collets are used, indicating all sizes and technology for performing work operations, but often it is necessary to combine equipment or make the necessary collet chuck with the required characteristics with your own hands.

Video review of a lathe collet chuck

Types of cartridges

More details about the types. Screwdriver clamping devices are divided into:

The first two types are similar.

The difference lies mainly in the fact that self-clamping models fix the products automatically.

If the tool has a locking mechanism, single-clutch cylinders can be used.

If there is no blocker, you will have to use a two-clutch type.

Elements with one coupling can be clamped with one hand.

To work with another type, the participation of both hands is required.

Quick- and self-clamping models are intended mainly for modern tools.

For example, for pneumatic screwdrivers.

Models with automatic clamping are convenient for those who need to quickly and often change different attachments.

Read also: Name the types of images of a part in a drawing

Key options are less convenient, but more reliable. They clamp better and are more resistant to shock loads.

If the cylinder will be used intensively, it is recommended to choose a screwdriver with a key.

Do-it-yourself flexible shaft for a drill

If you need to transfer the rotation of the motor of an engraver, drill or bur to an attachment, then you will need a flexible shaft. This device consists of a wire enclosed in flexible armor, twisted in several layers, and

can significantly expand the functionality of a rotary instrument. You can assemble the flexible shaft yourself.

For this you will need:

- Brass tube;

- Two M4 threaded bushings;

- Electrode shaft (diameter 5 mm) with M5 thread;

- Adapter from internal thread M5 and external thread M8 to 0.75;

- Mini quick-release chuck;

- Clamp made from an M12 bolt drilled along the axis;

- Protection for connection.

Assembling the flexible shaft. To do this, insert an electrode shaft into the brass tube and put M4 bushings on both sides of the tube. On one side of the tube we screw an adapter onto the sleeve, and onto it a mini-cartridge. On the back side of the tube we place a clamp, with which we connect the shaft from the electrode to the flexible one. For convenience, you can sand down the heads of the screws on the clamp. We put a special brass protection on the clamp and secure it with fasteners. We isolate the connection. The flexible shaft is ready! For convenience, a clamp with a plastic handle can be placed on the cartridge side.

Read also: Electric heating scheme in a private house