Causes of the defect does not clamp the bit

Based on the experience of our service engineers, we can identify the following reasons:

- Untimely prevention and cleaning of the device

- Lack of protection against power outages

- Replacing Consumable Accessories

- Not carefully studying the user manual or ignoring the manufacturer's advice.

- Not careful use

Bring your equipment to our service centers or call the technicians to your home and we will repair it and provide a guarantee. Afterwards, the faulty device will work at 100 percent (full). Addresses of Umedia services in all districts of St. Petersburg.

Recent comments

- admin to the entry of top domestic motor oils

- Marat to the entry of top domestic motor oils

- admin to the entry of top domestic motor oils

- Alexey Orekhov on top domestic motor oils

- admin to the post what is better to listen to while running

© 2022. Product rating - TOP 10.

All rights reserved. Attention! The information published on the site is for informational purposes only and does not constitute a recommendation for use. The Materials may contain information intended for users over 18 years of age. 18+

This site collects, stores and organizes cookies to improve the functionality of the site. By continuing to use it, you consent to the processing of these files.

Where can I get it repaired in St. Petersburg?

Location: In the shopping center Trading yard Archimedes, 1st floor, room 7A. Nearest addresses - Metro: Politekhnicheskaya, Ploshchad Muzhestva; Avenues: Sciences, Civil Invictus, Northern; Streets: Vernost, Butlerova, Gzhatskaya, Favorskogo, Karpinskogo. .

Metro station:

Academic

—> Working hours:

from 10.30 to 20.00

Location: On the 2nd floor in the Morskoy shopping center. Nearest addresses - Metro: Vasileostrovskaya, Primorskaya; Avenues: Morskaya Embankment, Vasileostrovsky; Streets: Korablestroiteley, Nalichnaya, Uralskaya. .

Metro station:

Primorskaya

—> Working hours:

from 10.00 to 20.00 (7 days a week)

Location: Entrance from the parking lot. 6 steps up. Nearest addresses - Metro: Kupchino, Zvezdnaya; Avenues: Vitebsky, Slavy, Danube; Addresses: Sofia, Bukharestskaya, Malaya Balkanskaya, Oleko Dundicha, Budapestskaya, Kupchinskaya. .

Metro station:

Kupchino

—> Working hours:

Weekdays: from 10:00 to 20:00; Sat, Sun: from 10:00 to 18:00

Location: In shopping center Paktor (Bada Bum). 5 minutes from Ozerki metro station. Siqueiros, Yesenina, Vyborg highway, Thorez Avenue. .

Metro station:

Ozerki

—> Working hours:

Mon-Fri: from 10:00 to 20:00, Sat-Sun: from 10:00 to 19:00

Location: On the ground floor, section 015. Nearest addresses - Avenues: Bogatyrsky, Ispytatelei, Sizova, Streets: Tupolevskaya, Gakkelevskaya, Baikonurskaya, Staroderevenskaya. .

Metro station:

Pionerskaya

—> Working hours:

from 11:00 to 21:00 (Sat-Sun until 19:00)

Location: Entrance from Saperny Lane. Nearest addresses - Avenues: Liteiny, Suvorovsky, Nevsky, Ligovsky; Streets: Zhukovsky, Nekrasova, Vosstaniya, Radishcheva, Mayakovsky. .

Metro station:

Chernyshevskaya

—> Working hours:

Weekdays: from 10:00 to 20:00; Saturday: 10:00 – 19:00; Sun: 11:00 – 18:00

Location: On the 2nd floor of the Yugo-Zapad shopping center near Media Markt. Nearest addresses: Metro Kirovsky Zavod, Avtovo; Leninsky Avenue, Stachek; street Marshal Kazakov, Marshal Zakharov, Valor. .

Metro station:

Kirov plant

—> Working hours:

from 10.00 to 20.00 (7 days a week)

Location: On the 2nd floor in the Rzhevka shopping center, room No. 2-07b. Nearest addresses - Avenues: Irinovsky, Kosygina, Industrialny, Nastavnikov; Streets: Communes, Progressives, Enthusiasts, Shockers. .

Metro station:

Bolsheviks

—> Working hours:

from 11.00 to 20.00 (7 days a week)

Location: How to get there? Magnit store, checkout area, Umedia Serivis sign. Nearest addresses - Metro: Ploschad Muzhestva, Vyborgskaya, Chernaya Rechka; Avenues: Lesnoy, 1st Murinsky, Polyustrovsky, Bolshoi Sampsonievsky; Streets: Kantemirovskaya, Kharchenko, Litovskaya, Vyborgskaya. .

Metro station:

Lesnaya

—> Working hours:

from 10:00 to 20:00 (7 days a week)

Location: Entrance to the ground floor, near Magnit. Nearest addresses - Avenues: Severny, Prosveshcheniya, Lunacharsky; Streets: Kirishskaya, Toksovskaya, Luzhskaya, Ushinskogo, Kirishskaya. .

Metro station:

Civil Prospect

—> Working hours:

from 10.00 to 20.00 (7 days a week)

Location: on the 2nd floor. Neighbors FIX-PRICE. Nearest addresses - Metro: Bukharestskaya, Mezhdunarodnaya; Avenues: Slavy, Vitebsk; Addresses: Sofia, Salova, Bela Kuna, Fucik, Budapest, Paris, Turku. .

Metro station:

International

—> Working hours:

from 10.00 to 20.00

Location: Two end entrances to the Magnit Cosmetic Store. Nearest addresses - Avenues: Novgorodsky, Vitebsky, Moskovsky Streets: Shkolnaya, Pushkinskaya, Okulovskaya.

Metro station:

Shushary

—> Working hours:

Mon-Fri: from 10.00 to 20.00; Sat: from 11.00 to 19.00; Sun: closed

Location: In the Cosmos shopping center, 2nd floor. Nearest addresses - Avenues: Kolomyazhsky, Bogatyrsky, Ispytatelei, Korolev; Streets: Parashutnaya, Gakkelevskaya, Staroderevenskaya, Planernaya, Sharova, Dolgoozernaya. .

Metro station:

Komendantsky Avenue

—> Working hours:

from 10:00 to 20:00 (7 days a week)

Location: Second floor of the Pyaterochka store. Nearest addresses - Avenues: Levashovsky, Chkalovsky, Petrovsky, Dobrolyubova, Kamennoostrovsky; Streets: Zhdanovskaya, Bolshaya Pushkinskaya, Bolshaya Zelenina, Lenina. .

Metro station:

Chkalovskaya

—> Working hours:

Mon-Fri from 10:00 to 20:00, Sat-Sun from 11:00 to 19:00

Location: On the 1st floor in the Plovdiv shopping center, near the cash register area. Nearest addresses - Metro: Park Pobedy, Mezhdunarodnaya, Moskovskaya; Avenues: Vitebsky, Cosmonauts; Streets: Tipanova, Titova, Baseinaya. .

Metro station:

Moscow

—> Working hours:

from 10.00 to 20.00 (7 days a week)

Location: Front entrance from Valor. Nearest addresses - Avenues: Leninsky, Kuznetsova, Geroev, Peterhofskoe highway; Streets: Valor, Marshal Kazakov, Marshal Zakharov, .

Metro station:

Leninsky Prospekt

—> Working hours:

Mon-Fri: from 10.00 to 20.00; Sat: from 11.00 to 18.00; Sun: closed

Location: On the 2nd floor of the Termin shopping center. Nearest addresses - Metro: Dybenko, Bolshevikov; Avenues: Dalnevostochny, Podvoisky, Iskrovsky, Tovarishchesky; Streets: Dybenko, Antonova Ovseenko, Oktyabrskaya embankment, Podvoisky. .

Metro station:

Dybenko

—> Working hours:

from 10.00 to 20.00 (7 days a week)

strawberry

The garden strawberry (or simply strawberry Fragaria ? ananassa) is a widely grown hybrid species of the genus Fragaria (collectively known as the strawberries)

A banana is an edible fruit, botanically a berry, produced by several kinds of large herbaceous flowering plants in the genus Musa.

The apple tree (Malus domestica) is a deciduous tree in the rose family best known for its sweet, pomaceous fruit, the apple. It is cultivated worldwide as a fruit tree, and is the most widely grown species in the genus Malus.

The orange (specifically, the sweet orange) is the fruit of the citrus species Citrus ? sinensis in the family Rutaceae.

Source: remont3.ru

How to remove and repair a screwdriver chuck with your own hands

Today, many people use a tool such as a screwdriver, so it is not surprising that there is a high demand for them. Very often the device breaks down, and the buyer rushes to a repair shop, paying money for repairs. You don’t always want to do this, of course, so in our article we will help you become more familiar with the design of a screwdriver. You can deal with some problems on your own.

We will look at various cases of screwdriver breakdowns, namely: we will deal with the most common breakdowns of such an important part of the tool as the chuck.

Hard case

Well, it happens that the cartridge does not want to turn away, which means the drill cannot be pulled out of it. This should not happen on working cartridges, so if under any circumstances the cartridge does not spin up, this may indicate a malfunction.

Usually this does not happen abruptly - the cartridge begins to jam before it is clamped so that it does not turn around.

In such a situation, you can resort to two methods. I would like to immediately make a reservation that the cartridge will need to be changed after this. In this case, the drill needs to be removed in order to save the drill , and also to make it possible to remove the faulty chuck from the screwdriver. This cannot be done with a stuck drill.

- The first method is quite humane. You need to hold the drill in a vice and try to turn the entire screwdriver around it. You can spray WD-40 into the cartridge to make the task easier. It will be possible to turn the entire screwdriver with the chuck only if its design is such that the chuck is rigidly coupled to the screwdriver and cannot be turned except by pressing the start button. However, not all models provide this; therefore, you can rotate the cartridge using a gas wrench - the plastic part of it will deteriorate. If the drill gives in, then you need to rotate the chuck back and forth and gradually pull it off the drill.

- If the drill does not give in, then you will have to resort to the “vandal” method. We take a grinder and simply cut the cartridge. You just need to cut so as not to damage the screwdriver spindle and the drill itself, if you need it intact. Not a single drill .

These are the ways to remove a drill from a screwdriver. If this is your second case, then I’m sorry, but I don’t know a more humane way and I don’t think there is one. At least that's how I got the drills out. And this is where I end this article - see you next time!

Screwdriver chuck: description, function

The cartridge is a metal cylinder with a cavity inside, equipped with a ring and a control sleeve. It is fixed to the shaft. With its help, the drill or grinding attachment is securely fixed in it for further work. The fixation of the working part of the tool (drill) is ensured by the thread. The drill is tightened in two ways. The first method is to tighten it with a special wrench; in the second method, the drill is tightened when the chuck is rotated in the direction opposite to the axis of rotation of the drill.

How to disassemble a screwdriver chuck

Despite the fact that today there are many models of screwdrivers on the market, they have the same general approach to removing such an element as a cartridge. Now we will briefly describe it.

In order to unscrew it, you need to remove the screw securing it to the shaft. It is located inside the cartridge; the screw should be rotated clockwise. After you have unscrewed the screw, you should jerk the cartridge in the opposite direction.

Attention! If you try to unscrew it manually, you must set the drill to second speed if it is two-speed. When purchasing a tool, it is advisable to lubricate the screw with machine oil. In some cases, when this element does not want to give in, then you should put the tool on first speed, hold it in your palm, and turn the reverse to the left. The cartridge should come off the thread easily.

How to replace a screwdriver chuck

It will not be easy for an untrained user to replace it, since without the help of a special tool you will not be able to do it with your bare hands. There are two ways in which it can be removed, and we will consider them further in our article. In order to change it, you should pay attention to the actions that we described in the article above. Dismantling is performed with the following tools:

- A hex key is usually a 10mm L-shaped metal rod. Its short part should be fixed in the chuck, the long part should be rested against something, for example, a table. We turn the cartridge, and then remove it by turning the key.

We looked at the dismantling method using a key. The method to remove the element manually is described above.

Repair methods

Experts recommend, regardless of the reason why the screwdriver jams, what to do first: introduce universal lubricant such as WD-40 into the internal cavity of the chuck, including the surface of the jaws. After 10-15 minutes, use a rubber hammer (or a regular one, through a gasket) to tap the cartridge and jaws with moderate force.

If the bit is jammed in the chuck of a Bosch, Texas, Praktika, etc. screwdriver, then (after lubrication) the use of two adjustable wrenches effectively solves the problem. One clamps the base of the cartridge, the other carefully rotates its upper part. To avoid damage to the surface and the unit itself, soft but dense pads such as leather should be used.

If your efforts lead to nothing, workshop specialists will be able to restore the functionality of the tool with minimal financial costs and extremely quickly.

Having various technical devices at home is simply necessary. We are talking about tools such as a drill and a screwdriver. They are indispensable when performing various small household jobs. But like any equipment, they can also have malfunctions and break down. For example, in a screwdriver, one of the most unstable parts is the chuck. In this article we will look at how to remove and replace the cartridge in this device.

DIY screwdriver chuck repair

This is a moving element of the tool, which consists of many rubbing parts. During operation, it is subject to wear resulting from the action of friction forces, impact forces and other factors. The chuck's runout and excessive play can frighten an inexperienced craftsman. In some cases, it is not always possible to allocate the time or finances to contact a repair shop. Therefore, we will look at how you can do it yourself when repairing various tool malfunctions.

Repairing a screwdriver with your own hands when the chuck is loose

A small play within 1 mm usually does not create visible problems during operation. If the value is larger, you should pay attention to the condition of the gearbox. So, the procedure is as follows:

- Unscrew the bolts securing the top cover of the tool. Let's take it off.

- Unscrew the electric motor from the gearbox. We inspect the fastenings.

- Let's disassemble the gearbox. Often the cause of failure is a malfunction of the bushing located inside. It is possible to remove the bushing using the steps described at the beginning of the article (see how to remove the cartridge manually). The bushing is easily pressed out by hand.

- We are replacing the bushing. Then we assemble everything in the following sequence: bushing, shaft, bushing bearings, retaining ring. Lubricate the rubbing parts.

- After this, we assemble the gearbox in reverse order. We attach it to the electric motor.

- Assembling the screwdriver body.

Repairing a screwdriver with your own hands when the chuck runs out

The main culprit for this problem is the screwdriver gearbox. To make sure of this, you need to remove it by dismantling it in the above manner. This particular breakdown may indicate several problems in the gearbox, which we will indicate below. The reason may be:

- violation of the gearbox shaft geometry;

- production of gears;

- malfunction of the shaft support bearing;

- wear of the pins securing the satellites of the planetary gear.

The above parts are produced only in factories, so you won’t be able to make them yourself. All you have to do is purchase them and replace the broken ones.

For newbies

So, let's start with the simplest case - with inexperienced users. Screwdrivers have something called a torque regulator. It looks like a scale around the front of the screwdriver, which is right behind the chuck. There are numbers on it from 1 to 10, 15, 20 or even more - different for different models - and the last position on it is indicated in the form of a drill. If you rotate this regulator and set it opposite the special mark so that one of the numbers is next to it, then when a certain torque is reached, the cartridge will no longer rotate, but will begin to click. If you put it on a “drill”, then the screwdriver will try to twist with all its might, as much as the engine power allows it.

However, it is worth noting that with two-speed screwdrivers, at the second speed, even in the “drill” position, if the torque reaches a certain value, then a protective system is triggered, which simply turns off the current supply. At the very first speed, the screwdriver will also try to turn “to the last.”

And a beginner can start drilling or screwing screws, for example, when the torque regulator is set to one of the numbers, or the screwdriver is set to the second speed (and it is recommended to drill at it).

The drill can be clamped quite tightly, and as a result, when you start to release the drill or bit in the standard way (by turning on the reverse, holding the chuck and pressing the start button), either the torque limiter or the protective system may work.

Therefore, in such a situation, you just need to put the screwdriver at first speed and set the torque regulator to the “ drill ” position. On single-speed models, you only need to set the torque regulator to the “drill” position. Well, then again we unscrew it in the standard way.

Drill stuck in chuck drill drill stuck

Screwdriver chuck thread

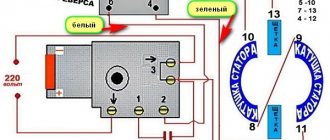

Structurally, this movable element is fixed in the tool body in three ways:

- Fastening using Morse taper.

- Carving.

- Securing the set screw.

Fastening using a Morse cone has been known for a long time and consists of the following. The shaft has the shape of a cone, repeating the contours of the surface inside the cartridge - the same cone. By combining them in a certain way, a reliable connection is obtained.

Connecting the shaft to the chuck using a threaded connection consists of having a thread at the end of the shaft onto which a chuck with the same thread can be freely screwed.

The fixing screw is most often used as an additional fastener. Its head has notches for a Phillips screwdriver, as well as a left-hand thread. You can see this screw by unscrewing the cams that cover it.

To find out what kind of mount your tool has, you need to carefully inspect the body of the tool. Each type of fastening has its own designation. For example, this: 1–6 B 10 will mean that the cartridge is secured using a Morse taper of size B10, and nozzles with a shank diameter of 1 to 6 mm can be used for it. If you have the following entry: 1.0–11 M 12 x 1.25, you will know that you should use nozzles with shanks from 1 to 11 mm; the metric thread has a cross-section of 12 x 1.5 mm. Foreign manufacturers use indicators in inches, for example, 1.0–11 ½ – 20 UNF.

In this article, we examined the main problems that arise during the operation of the tool, and paid attention to such a critical component in the design of a screwdriver as the chuck. At the same time, we figured out how it is attached to the design of the screwdriver, gave some tips on how to repair it yourself, and also tried to outline ways to solve repair problems.

Source: pro-instrument.com

Features of removing bits when they jam on screwdrivers from different manufacturers

Basically, all models of screwdrivers are quite similar, so the methods for removing a bit when jammed are similar.

- Bosch. In Bosch screwdrivers, you can get the bit using two keys after pre-lubricating the chuck.

- Makita. The tools of this company are reliable and have a long service life. The bit jamming occurs, as a rule, as a result of debris getting into the chuck. In this case, you can solve the problem by pouring lubricants into the inside of the cartridge. If there is no result, other methods are used.

- Interskol. Products manufactured under this brand work well and last a long time and rarely break down. It is easy to remove a jammed bit using the methods described.

- Other manufacturers. There are many instruments on sale from different brands - Metabo, Whirlwind, DeWALT, Diold, Caliber, Hammer. There are as many ways to remove the bat when a problem occurs as with other models. It is permissible to try all methods to cope with the problem.

The role of the chuck in reliable fastening of the drill

Clamping drill chucks for household drills are available in three modifications:

The body of the key jaw chuck is made in the form of a hollow hardened cylindrical sleeve (collet), on the outer surface of which a rotating adjusting collar is installed. On one side the cylinder is mounted on the drive shaft of the drill, and on the other side there are cams (petals) for attaching cutting tools (drills, taps, reamers, etc.). When the adjusting ring rotates, the steel cams move along guides using special threads. If they come close to each other, the drill is clamped. If they diverge from each other, the tool is released. The approaching and moving away of the cams depends on the direction of rotation of the holder. Reliable fixation of the drill is ensured by tightening the chuck holder with great force. To do this, use a special key or a quick-clamping - on quick-release chucks - clutch.

The key helps to firmly clamp the drill and easily unscrew the adjusting collar. Drills of various diameters with a cylindrical shank are fixed in jaw chucks. Most often, household electric drill chucks are designed for drills with a diameter of 0.8 to 10 mm or 1.5 to 13 mm.

Why and when do you need to change?

The clamping device must ensure drilling of holes with acceptable accuracy. But over time, the seats on the shaft and cams wear out, and the cartridge begins to beat. That is, the working area of the drill begins to move from side to side when rotating, and the hole is drilled with deviations both in location and in diameter. Wear on the cams does not allow the drills to be securely fastened, and they stop under load. There is only one way out - replace the worn cartridge with a new one.

Causes and types of malfunction

Incorrect operation of the fastening mechanism, when the screwdriver does not clamp the bit well, may be caused by wear of one or more of its elements. On the outside of the cams there are teeth that engage the rotary gear and, when twisted, move up along a conical guide, clamping the drill shank. When grinding teeth on the cams or gear, the clamping force becomes insufficient to hold the bit securely.

There is an option when the cams, although they do not converge completely, can provide the required amount of pressure up to a certain diameter. Then a temporary solution is possible. Wire is wound onto the shank of the bit (the best material is copper), increasing the diameter and thus tightly tightening the improvised structure. These are extreme measures that allow you to realize the capabilities of the tool only in case of extreme necessity.

How to replace the chuck in a drill with your own hands?

To attach the chuck to the drive shaft of the drill, a threaded connection or Morse taper is used. A visual inspection of an electric drill will not always help indicate how to secure the drill chuck. This can be indicated by the marking on the cartridge: it is stamped on its surface.

Replacing the conical type of part

The standard size of the Morse cone (according to GOST 9953–82) consists of 9 values: from B7 to B45. The larger the number after the letter B, the larger the diameter of the cone.

Thus, having found the marking “B” on the surface of the cartridge, we can conclude that this is a device with a conical mounting base. With this method of attachment, the cartridge can be easily removed. It is enough to use a drift and a plumber's hammer.

Video: how to remove a chuck with a cone from an electric drill?

Replacing the reversible threaded chuck

To secure the drill clamp to an electric household drill using a threaded joint, two types of threads are used:

- inch (for foreign models);

- metric (from Russian manufacturers).

The following marking is applied to the surface of the threaded clamping chuck body: 1.5–13 1/2 – 20UNF or 1.5–13 M12x1.25.

The reversible threaded cartridge for fixation has a screw with a left-hand thread. You need to know this nuance when removing a broken cartridge. In order to get to the screw head, it is necessary to recess the cams into the collet completely. As soon as the head of the screw is visible, use a hardened Phillips screwdriver to unscrew it to the right clockwise. Then hold the hex key in your fists and hit it sharply in a counterclockwise direction. After the cartridge is torn from its place, it can be easily unscrewed.

Video: how to remove a chuck from a reverse drill or screwdriver?

On other models there are other options for mounting the cartridge on the thread. In some cases, the cartridge is twisted entirely from the threaded end of the shaft. In other cases, the screw can be fixed with a special thin key using a narrow groove. The main difficulty is to move the cartridge from its place when unscrewing. Sometimes this is very difficult to do. In any case, to remove the cartridge you need: a mechanic's tool, the necessary skill and patience.

Drill design - what do you need to know about the tool?

Convenience and ease of implementation ensured the popularity of the cam mechanism. But it is not without its shortcomings. One there is the difficulty in working with small drills. A short product may simply fall inside. You can still secure it by placing the drill in a horizontal position, but you cannot put too much pressure on its surface while working. If another drill was inserted into the drill, there is an option to remove it by turning the adjusting ring in the appropriate direction. This can be done manually from time to time; for this purpose there is no special key that acts as a lever, increasing the force. When tightening a drill without a key, it is also not recommended - the larger the diameter of the drill, the more securely the fastening must be made.

READ Mulching vs.

Disassembling a drill chuck with a quick-release nut

To clean the jaws and lubricate the moving parts and threads of the cartridge, it must be disassembled. Disassembly is necessary to repair and replace failed parts. Here is a short list and sequence of operations for disassembling the jaw chuck:

- The removed cartridge with the conical part up, lined with wooden spacers, is clamped by the coupling in a vice.

- Use a gas wrench to carefully unscrew the notched nut.

- The bearing is pulled out. The puck comes out.

- The cartridge is removed from the vice.

- The adjusting sleeve is twisted from the base by hand. If it does not give in (jammed), then the cartridge turns over and is again compressed by the clutch in a vice. A little machine oil is poured onto the threaded part of the coupling and base. Then, using a gas wrench, the base is skillfully unscrewed from the coupling.

- If there is a retaining ring or nut at the bottom, they are removed.

- The cams are pulled out of the guide rings and removed from the base cone.

- All parts of the drill chuck are carefully inspected. If worn, deformed or broken parts are identified, they are rejected and replaced.

- The jaw chuck is assembled in the reverse order. At the same time, all moving parts are lubricated with a special grease. It is best to use the lubricant recommended by the manufacturer.

The procedure for disassembling cartridges of other models may be different. It depends on the type of chuck, its design and the manufacturer of the drill. To disassemble the drill chuck yourself, you need to fulfill three conditions:

- have the necessary set of tools available;

- have plumbing skills;

- to be a person with a stable, balanced psyche.

How to change a drill bit in a drill - we can do it ourselves!

It is not always possible to remove a drill from the chuck using the usual method - as a result of heavy load or improper fixation, it can jam the chuck. How to remove a drill from a drill without damaging the fastener and tool itself? First, try to cool the cartridge well. From time to time this is enough for the cams to release the drill a little and you can remove it.

The most proven method for removing a stuck tool is to tap the cams. To do this, the free end of the drill is fixed in a vice, a wooden strip is applied to the chuck, through which tapping is carried out. Such vibration can cause the chuck to loosen its grip and release the tool. This method will be needed by both owners of traditional fasteners and those with quick-release fasteners. From time to time, extraction becomes possible after lubricating the drill with machine oil or the popular WD-40 lubricant.

The latter method is better, since due to the spray the substance will quickly reach the suitable points of contact between the drill and the chuck. In any case, after lubrication it will be necessary to wait a little for the substance to penetrate deeper. From time to time, in particularly difficult cases, the problem is resolved only after dipping the entire cartridge into machine or vegetable oil. If you don’t have either one or the other at hand, you can make a “bath” for your drill from gasoline. It is necessary to keep the cartridge in water for at least an hour. By combining methods, you will be able to get out a jammed drill even faster.

Possible problems with the chuck when operating a drill: causes, descriptions and ways to solve them

To avoid problems with a drill, you need to be able to operate it correctly. A drill is a universal tool; it can be used to drill wood and metal, plastic and tile, stone and glass, concrete and brick. In everyday life, a rotary impact drill of medium power is usually used. It is equipped with a chuck of the SDS system, which was invented by BOSH. The SDS chuck is not particularly accurate, but is ideal for drilling concrete, stone, and brick. That is, those building materials where drilling is necessary with impact.

For more precise drilling of metal and wood parts, it has a special adapter for attaching a jaw key chuck or a keyless chuck. A drill cannot be used for milling work. The drill chuck is not designed for side loads and will quickly fail. Of great importance is:

- correct choice of drill;

- correct sharpening of the cutting part of the drill;

- mandatory marking of the center of the holes using a core.

You need to skillfully select the desired speed, feed, operating mode depending on the workpiece material. All these factors directly affect the reliable operation of the drill chuck.

The part falls off

Does the cartridge fly off? This problem occurs quite often even on new drills with a cone-shaped jaw chuck when drilling a deep hole. You need to lift the drill to free it from the chips, and at this moment the chuck flies off the cone. The situation can be corrected by increasing the tension in the cone joint. To do this, the cartridge is heated in oil or oven to a temperature of 110 degrees and placed on a cold drill mandrel.

Clamping jaws jammed

Drill work always takes place in dirty conditions. This is dust, dirt, shavings, sawdust and other small debris. If this debris gets inside the chuck, it can cause the threaded connections, particularly the jaws, to jam. There is only one way out here. Requires disassembly of the cartridge, cleaning and rinsing of moving parts. Before assembly, all moving parts are lubricated with lithol. Especially a lot of waste is poured into the chuck when drilling ceiling surfaces. Here you can think about protecting the cartridge with half a small rubber ball.

Chuck runout can be caused by various reasons. For example, the Morse seat cone is worn out. This can be checked using paint. An even layer is applied to the cone and the cartridge is inserted. Then the mark he left on the cone is removed and studied. Another reason could be uneven wear on the cams. In this case, they need to be changed. But more often they replace a broken cartridge with a new clamping device.

In the right hands, a household drill can work wonders. With its help, holes are drilled in durable and soft materials. The chuck is an important component of a drilling machine. It is this that ensures the reliability of drill fastening and drilling accuracy. Therefore, it is very important for a home craftsman to be able to independently carry out minor repairs and replacement of this part of the device.

Source: 100uslug.com

A bit is stuck in a screwdriver, what should I do?

Any screwdriver user has encountered a problem such as the chuck jamming. It is constantly exposed to vibrations, dynamic and shock waves. Metal shavings, small mechanical particles, and dust get into the screwdriver This article will talk about how to open a jammed screwdriver chuck.

The chuck is the fastener where the drill is fixed. Typically, standard drills are equipped with a cam type.

Cases when the screwdriver fastener jams:

- The cams do not move, and it is impossible to remove a clenched drill or bit. During this, the cams are compressed unevenly, which makes it difficult to secure the drill.

- When using a drill that is too large, the cams are expanded to the maximum, as a result of which it is not possible to bring them together by applying great force.

In rare cases, the jaws jam while they move freely when unclenching or compressing - in most cases this is caused by particles of debris, shavings, okalina and others that have fallen under the figured part of one of the cams.

Professionals advise, first of all, to fill the inside of the cartridge, which includes the surface of the cams, with universal lubricant such as WD-40. This is recommended for any cause of jamming. After ten to fifteen minutes, tap it and the cams with moderate force with a regular hammer through the gasket or rubber.

From such vibration he will loosen his grip and free the instrument. If necessary, after introducing universal lubricant, the cartridge can be warmed up a little with a hairdryer. In addition to WD-40 lubricant, you can also use machine oil.

One way or another, it takes time for the liquid to penetrate deep enough inside, where the point of contact with the drill is located. This method is suitable for owners of both standard fasteners and quick-release fasteners.

If the bit jams, then after lubrication the problem is quickly solved by using 2 adjustable wrenches.

With the help of one, the base of the cartridge is compressed, and with the other, its upper part is carefully rotated. To avoid damaging the surface and the assembly itself, it is recommended to use soft and dense pads like leather.

In addition, in order to open the cartridge, it is necessary for it to cool. In some cases, this action alone is enough for the cams to release the drill and it can be removed.

The last method is to completely immerse the drill in machine or vegetable oil for one hour. If it is not available, you can use gasoline. By combining the above methods, you will be able to get it much faster.

If the problem cannot be solved on your own, you should seek the help of competent workshop specialists who will fix the problem in a short time.

And what methods do you know for clearing a jammed cartridge from a screwdriver?

Did you like the article? Subscribe to us in Yandex Zen. By subscribing, you will be aware of all the most interesting news. Go and subscribe.

Any screwdriver user has encountered a problem such as the chuck jamming. It is constantly exposed to vibrations, dynamic and shock waves. Metal shavings, small mechanical particles, and dust get into the screwdriver This article will talk about how to open a jammed screwdriver chuck.

The chuck is the fastener where the drill is fixed. Typically, standard drills are equipped with a cam type.

Cases when the screwdriver fastener jams:

- The cams do not move, and it is impossible to remove a clenched drill or bit. During this, the cams are compressed unevenly, which makes it difficult to secure the drill.

- When using a drill that is too large, the cams are expanded to the maximum, as a result of which it is not possible to bring them together by applying great force.

In rare cases, the jaws jam while they move freely when unclenching or compressing - in most cases this is caused by particles of debris, shavings, okalina and others that have fallen under the figured part of one of the cams.

Professionals advise, first of all, to fill the inside of the cartridge, which includes the surface of the cams, with universal lubricant such as WD-40. This is recommended for any cause of jamming. After ten to fifteen minutes, tap it and the cams with moderate force with a regular hammer through the gasket or rubber.

From such vibration he will loosen his grip and free the instrument. If necessary, after introducing universal lubricant, the cartridge can be warmed up a little with a hairdryer. In addition to WD-40 lubricant, you can also use machine oil.

One way or another, it takes time for the liquid to penetrate deep enough inside, where the point of contact with the drill is located. This method is suitable for owners of both standard fasteners and quick-release fasteners.

If the bit jams, then after lubrication the problem is quickly solved by using 2 adjustable wrenches.

With the help of one, the base of the cartridge is compressed, and with the other, its upper part is carefully rotated. To avoid damaging the surface and the assembly itself, it is recommended to use soft and dense pads like leather.

In addition, in order to open the cartridge, it is necessary for it to cool. In some cases, this action alone is enough for the cams to release the drill and it can be removed.

The last method is to completely immerse the drill in machine or vegetable oil for one hour. If it is not available, you can use gasoline. By combining the above methods, you will be able to get it much faster.

READ How to Insert Line into a Petrol Trimmer

If the problem cannot be solved on your own, you should seek the help of competent workshop specialists who will fix the problem in a short time.

What methods do you know for clearing a jammed cartridge from a screwdriver?

Did you like the article? Subscribe to us in Yandex Zen. By subscribing, you will be aware of all the most interesting news. Go and subscribe.

Every active tool user has encountered a situation where the clamping mechanism of an Interskol screwdriver chuck jams. Makita or any other brand. This structurally simple, but functionally significant unit is subject to serious dynamic, vibration and shock loads. Dust, metal shavings and other small mechanical fractions also penetrate into it - all these factors lead, if not to fatal breakdowns, then to periodic malfunctions of the mechanism.