The most widespread among professional builders in Russia are Bosch rotary hammers, and among amateurs the household models Bosch 2-20, 2-24, 2-26. Rotary hammers not only work well, but are also easy to repair. You can easily find any broken part on them.

The designs of the described rotary hammers are based on the same principle: transmitting torque from the rotor to the shaft of the impact block barrel while simultaneously transmitting a translational impulse to the working tool.

Structurally, hammer drills are made according to the same design, but individual components or parts have their own characteristics.

If you know the specific differences between the models of the described Bosch rotary hammers, then disassembling and repairing them yourself will not be difficult.

Along with the originals, there are a large number of counterfeit tools on the Russian market, including Bosch rotary hammers. Below we describe the design features of the models and how to disassemble and repair them yourself.

The operating principle of rotary hammers is the same, but the design features differ.

The main parts used in the listed models of Bosch rotary hammers are interchangeable. This applies to the mechanical and electrical components.

But there are units made that differ in the parts used.

To repair a Bosch 2-20, 2-24, 2-26 rotary hammer, you need to know these differences. Knowledge of the design features of each rotary hammer facilitates the repair process, finding breakdowns and eliminating them.

The designs of Bosch rotary hammers are so simple that they allow you to perform simple repairs, practically with your own hands, and replace any part without contacting service departments. You must have assembly skills, have basic knowledge of electrical engineering and understand the principle of operation of a rotary hammer.

The main differences in the designs of Bosch rotary hammers

When repairing a Bosch rotary hammer, you cannot do without an electrical diagram and a disassembly diagram for the tool of the model you are going to repair.

The electrical circuits of Bosch 2-20, 2-24, 2-26 rotary hammers are almost the same. Although there are some unprincipled differences.

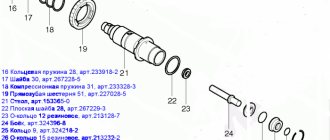

But mechanical blocks are equipped with parts that differ structurally from each other. The main differences are concentrated in two units: the intermediate shaft and the barrel shaft of the shock block.

The greatest differences are presented in the design of the intermediate shaft, the “drunk bearing” assembly, and the mode switch. Unprincipled features are present in the design of the barrel of the striker block, firing pin, and striker.

Let's start with the Bosch 2-20 rotary hammer.

Diagram and design of the Bosch 2-20 rotary hammer

Repairing a Bosch 2-20 rotary hammer is not possible without knowledge of the design of the tool being repaired.

The operating principle of the Bosch 2-20 rotary hammer is based on the transmission of torque from the rotor shaft pos. 3 to the impact block shaft pos. 22 through the intermediate shaft pos. 824, while simultaneously transmitting longitudinal impulse to the working tool.

Rotor pos. 3 transmits torque to the helical gear of the intermediate shaft pos. 824.

The helical gear is mounted on the intermediate shaft and transmits rotational torque to the shaft. A fixed bearing is attached to the shaft, receiving rotational torque through the clutch. Due to its design, the drunk bearing transmits translational motion to the barrel cylinder of the impact mechanism.

Design of the intermediate shaft of the Bosch 2-20 rotary hammer

The intermediate shaft of a Bosch 2-20 hammer drill consists of a rolling bearing assembly (drunk bearing), a clutch, a large helical gear, and a small spur gear.

Most often, breakdowns manifest themselves in wear of the clutch splines, which leads to the loss of rotation of the hammer drill chuck in the presence of a shock pulse.

It can be corrected by replacing the clutch or restoring the teeth of the clutch parts.

What malfunctions do Bosch rotary hammers have and how to fix them yourself

Nothing lasts forever. And the most reliable Bosch rotary hammers begin to break over time. But any malfunction can be repaired with your own hands if you have detailed instructions for performing repair work. Below we offer you a guide to troubleshooting Bosch rotary hammers and a method for eliminating them.

- Mechanical malfunctions of the Bosch rotary hammer The rotary hammer stops chiseling, but drills

- The hammer drill has stopped drilling, but is chiseling

- Let's consider options in which the hammer drill does not hammer, but drills

- Let's consider options in which the hammer drills but does not chisel

- Let's consider options in which the hammer drill does not drill or chisel

The main causes of breakdowns are:

- careless work with the tool;

- improper storage of the hammer drill;

- heavy loads when working on working parts when chiseling or drilling;

- tool overheating;

- long work without a break;

- failure to comply with maintenance schedules.

Conventionally, faults can be divided into mechanical and electrical.

Next, we will consider faults according to their affiliation, dividing them into mechanical and electrical faults.

When mechanical malfunctions occur in the operation of the tool, an extraneous unpleasant sound appears, sparking intensifies in the collector area, a burning smell appears, the tool heats up excessively, its power drops depending on the duration of operation and the impact on the material.

We will look at all the faults in the diagram of the Bosch 2-26 rotary hammer. Other models, such as Bosch 2-20, 2-24, differ in the design of the intermediate shaft and the installation of various bearings.

The hammer drill stops hammering, but drills

The hammer drill does not hammer under load or in idle mode for the following reasons:

- the rubber rings of the striker, striker, and piston are worn out;

- the rolling bearing race has collapsed;

- the cylinder and the firing pin of the percussion mechanism were destroyed;

- cut off the splines of the clutch mounted on the intermediate shaft;

The hammer drill has stopped drilling, but is chiseling

The main reasons why a rotary hammer hammers but does not drill are:

- the force of the conical spring pressing the clutch has weakened;

- the locking roller does not fix the large barrel shaft gear;

- does not hold the tool locking mechanism in the barrel;

- The hammer drill does not chisel or drill.

The main reasons why a hammer drill does not chisel or drill are:

- sheared teeth on the small rotor gear or on the large intermediate shaft gear;

- The rotary hammer electric motor does not work;

- there is no power to the hammer drill motor.

Now let's talk about everything in order

Wear of rubber rings on the striker, striker, piston.

This reason appears gradually as the rubber rings wear out. At first the blow weakens, then disappears altogether.

The malfunction is eliminated by replacing the indicated rubber rings with new ones.

For any repair of rotary hammers or their components, all rubber products must be replaced.

If the drunk bearing pos. 830 is destroyed, the rotational movement of the intermediate shaft cannot be converted into the translational movement of the cylinder in the impact mechanism.

Eliminated by completely replacing the rolling bearing.

The cylinder, firing pin, and firing pin of the firing mechanism were destroyed

There are cases when the striker in the cylinder, pos. 26, gets stuck, which leads to destruction of the cylinder and the impossibility of creating air pressure in the barrel of the striker mechanism. And the second reason: destruction or breakage of the striker pos. 28, leading to distortion of the part and the impossibility of transmitting the shock impulse. Breakdowns are eliminated by completely replacing failed parts.

The splines of the clutch, pos. 67, mounted on the intermediate shaft, were cut off

The malfunction can be eliminated by repairing the clutch or completely replacing it. When making repairs, the worn teeth on the clutch are filed down. To correct this defect, a round needle file and a drill are used. The coupling is clamped in the hand, and the tooth profiles are straightened using a drill with an appropriate file. The splines on the intermediate shaft are modified in the same way.

The force of the conical spring pressing the clutch has weakened

When the pressure force of the spring pos. 50 decreases, the clutch slips on the intermediate shaft without transmitting rotation from the small spur gear to the large gear pos. 22 of the barrel shaft pos. 821 of the impact mechanism. By the way, on different Bosch models, clutches are designed differently.

The locking roller does not lock the large barrel shaft gear

The large gear, pos. 22, is attached to the barrel shaft, pos. 01, with a roller, pos. 88, pressed against the shaft collar with a conical spring, pos. 80, and secured with a retaining ring, pos. 85.

The reason may be a weakening of the force of the conical spring pos. 80, destruction of the locking ring pos. 85, or loss of the fixing roller pos. 88.

The mechanism for fixing the tool in the drill barrel does not hold the drill

Bosch rotary hammers use two types of chucks: SDS-plus and SDS-max. The difference is in the design of the locking mechanism.

The reason is the wear of the antennae of the chuck raster bushing, which makes it impossible to transmit the shock pulse to the working tool of the hammer drill.

Sheared teeth on the small rotor gear

The gears rotate and the teeth on one of them, usually the small one, are cut off.

When the working tool jams and the clutch does not work properly, the gear teeth on the hammer drill shaft and the intermediate shaft wear out or are completely destroyed.

In this case, the rotor or large gear of the intermediate shaft is completely changed.

Hammer drill motor does not work

The reasons for a non-working electric motor may be:

- short circuit in the rotor, stator;

- destruction of carbon electric brushes;

- loosening of the brush holders;

- burnout of lamellas on the rotor commutator;

- breakage of the rotor or stator windings.

The listed malfunctions are eliminated by repair (manually rewinding the windings, replacing the commutator and desoldering the winding leads) or replacing the rotor, stator, and carbon electric brushes with new ones. The majority of malfunctions in the electrical part of the Bosch 2-26 rotary hammer are confirmed by increasing sparking in the collector area.

The length of serviceable electric brushes cannot be less than 8 mm. When replacing one brush, the second should change automatically.

The rotor or stator windings can be rewound yourself at home.

No power to the electric motor of the Bosch rotary hammer

The cause of this malfunction is a break in the wire supplying power to the electric motor. Most often, a break occurs at the point where the cable enters the hammer drill. The wire should be replaced with a new one or repaired.

The malfunction can be determined using a tester. If there is no tester, the fault can be found using the power phase and a screwdriver with a neon indicator lamp.

Connecting the power wires one by one, at the other end, using a neon screwdriver, determine the presence or absence of a phase.

The power button for the hammer drill does not work. Determined by a short circuit tester.

Most often, the failure of the punch button is caused by a short circuit of the filter capacitor. It is best to replace the button with a new one.

Design features of the Bosch 2-24 rotary hammer

It is best to start repairing a Bosch 2-24 rotary hammer by becoming familiar with the circuit and design features of the tool being adjusted. The operating principle of the Bosch 2-24 rotary hammer is similar to the operating principle of the Bosch 2-20 rotary hammer.

The torque is transmitted to the tool mounting shaft, simultaneously with the transmission of the shock impulse. The hammer drill has three operating modes: drilling with impact, drilling without impact, impact.

The helical gear of the rotor pos. 803 transmits torque to the helical gear of the intermediate shaft pos. 826.

Design of the intermediate shaft of the Bosch 2-24 rotary hammer

The intermediate shaft of a Bosch 2-24 rotary hammer consists of a rolling bearing assembly, pos. 830, a clutch, pos. 823, and a switching part, pos. 44. Most often, the clutch fails. The teeth in it wear out. Repair of the coupling consists of correcting the profile of the engagement tooth in the coupling and on the intermediate shaft.

Impact mechanism barrel shaft design

The barrel shaft of the impact block is designed to transmit a rotational impulse with simultaneous movement of the striker.

Rotation is transmitted from the spur gear of the intermediate shaft to the large spur gear pos. 22 of the barrel shaft pos. 821.

The reciprocating motion is transmitted through the driven bearing pos. 830, the impact piston pos. 26, the striker pos. 27, the impact bolt pos. 28 to the drill fixed in the chuck pos. 756.

The design is a shaft, hollow on one side. Parts are installed on the shaft on both sides.

From the side of the cartridge mounting, a spur gear, pos. 22, is installed on the shaft and fixed on the shaft using a roller, pos. 88, and pressed against the shaft collar with a spring, pos. 80. The spring itself is fixed with a locking ring pos. 85.

The following is inserted into the cavity of the impact block barrel shaft: the assembled impact bolt pos. 28 and the impact piston. The striker pos. 27 is inserted into the impact piston pos. 26 with a new rubber ring pos. 73 placed on it. All rubber products are lubricated with the recommended lubricant.

Malfunctions of the hammer shaft shaft

Due to the weakening of the spring force and the locking roller falling out, the gear may rotate on the shaft. This manifests itself in the disappearance of the torque with the presence of a shock pulse.

The rotary hammer hammers, but does not drill.

When rubber products (sealing rings) wear out, the hammer drill stops working in the “Slotting” mode. This happens gradually. The impact force weakens as the rubber rings wear. The thing is that from the drunk bearing the movement is transferred to the impact piston pos. 26, in which the striker pos. 27 creates air pressure and acts on the impact bolt pos. 28.

The hammer drills, but does not chisel.

If you apply a lot of force when operating a hammer drill, this can lead to the destruction of the impact bolt and jamming of the striker in the impact piston. Such malfunctions can only be eliminated by completely replacing the failed part. Learn more about troubleshooting a Bosch rotary hammer.

Uncharacteristic malfunction of the Bosch rotary hammer

Bosch rotary hammers are very reliable. But there are malfunctions that are practically not encountered in practice. Below is one of them.

Bosch rotary hammer drills, but does not chisel

If the hammer drill has stopped hammering, but still allows you to drill, the most likely reason may be the destruction of a “drunk bearing”. This malfunction does not occur often and is not easy to find.

To fix it, you don’t need to go to a repair shop. Any person with the slightest knowledge of mechanics can fix such a malfunction.

New drunken bearing

First you need to disassemble the Bosch hammer drill down to the intermediate shaft. The disassembly procedure is given above.

By removing the intermediate shaft, you will get to the “drunk bearing”. The destruction of a rolling bearing is indicated by a broken race, scattered balls, or pieces of the race.

You take out the bearing, remove dirt and all parts of the destroyed mechanism.

You buy a new “drunk bearing”, and, having lubricated all the parts with new grease, replace and reassemble in the reverse order of the disassembly steps.

Design features of the Bosch 2-26 rotary hammer

Repair of a Bosch 2-26 rotary hammer should begin with familiarization with the design features of the tool being adjusted. The operating principle of the Bosch 2-24 rotary hammer is similar to the operating principle of the Bosch 2-26 rotary hammer.

Rotation is transmitted from the rotor shaft, through the intermediate shaft, to the shaft of the impact barrel. At the same time, a bearing mounted on the intermediate shaft transmits reciprocating motion to the impact piston.

The hammer drill has three operating modes: drilling with impact, drilling without impact, impact.

The helical gear of the rotor pos. 803 transmits torque to the helical gear of the intermediate shaft pos. 823.

The intermediate shaft is similar to the shaft in the design of the Bosch 2-24 rotary hammer and is interchangeable with parts included in the intermediate shaft of the Bosch 2-24, 2-26 rotary hammers. Instructions for disassembling a Bosch rotary hammer.

Impact mechanism barrel shaft design

The barrel shaft of the impact block is similar in design to the barrel shaft of the Bosch 2-24 rotary hammer. Breakdowns are caused by malfunctions of the same parts as in the Bosch 2-24 rotary hammer.

Features of the Bosch 2-26 rotary hammer shaft are that the driven large spur gear, pos. 22, is fixed on the shaft with three pins, pos. 37, in contrast to the locking roller in the Bosch 2-26 rotary hammer.

When disassembling the barrel shaft of the impact block of the Bosch 2-26 hammer drill, pay attention to the method of fixing the gear. Before removing the gear, three pins must be removed. The procedure for correctly assembling a Bosch rotary hammer.

Disassembling the hammer drill and removing the cartridge

To repair a rotary hammer, you first need to disassemble it correctly. And we start doing this by disassembling the cartridge.

- Remove the rubber tip and retaining ring;

- Remove the washer and conical spring;

- We take out the side balls (preferably using a magnet);

- We put the operating mode lever in a position equivalent to the maximum and remove the switch handle. We fix the position;

- Remove the rear cover on the handle and the engine brush;

- Unscrew the 4 screws near the drill to remove the front cover;

- We take out the barrel and shaft, and using a screwdriver, remove the bracket and bearing;

- Open the back cover and remove the reverse switch;

- We remove the rotor by unscrewing the fasteners and disconnecting the terminals from the starter, which also needs to be removed by removing the protective casing.

Important! When disassembling, be extremely careful about where and when you remove certain parts. Fold them so that you never lose them. This determines whether you put the tool back or not.

Conclusions:

• Knowing the differences between the above models of Bosch rotary hammers will allow you to quickly disassemble the tool and replace faulty parts. To do this, you do not need to contact customer service.

• Structurally, Bosch rotary hammers are so simple that they allow you to carry out repairs of almost any complexity.

• All you need is desire and basic knowledge of mechanics.

It happens that you come across counterfeit models of Bosch hammer drills. Read more about this.