Modeling and manufacturing of an auger screw using CAD/CAM technologies from Delcam plc

Alexey Martyushev, A.A. Oreshkin

Currently, blanks are processed mainly in small-scale production, sometimes in large-scale production and, partly, on automatic lines, with the share of main time exceeding the share of auxiliary time. This is due to the rationalization of tooling and clamping equipment, the development over the past 10-20 years of automatic tool and workpiece changers, as well as the introduction of modern control and manipulation systems. Currently, this is also facilitated by the development of systems for preparing control programs and CAD/CAM systems.

Thus, the possibilities for reducing auxiliary time are steadily narrowing, which leads to the need to solve the problem of further increasing processing productivity by reducing the main time by significantly increasing the cutting speed and feeds, as well as a corresponding increase in the volume of chips removed.

The authors were tasked with modeling the “Auger Screw” product and developing control programs for CNC machines for processing it. Initially, the customer provided a drawing of the part in GIF format. The drawing contained a theoretical development of the outer diameter, a general view of the part itself, as well as several views and sections that allow a better understanding of the part.

The work begins with the creation of a mathematical three-dimensional model of the future product. This requires a CAD system that allows you to create complex surfaces.

Screw calculation (turning of turns)

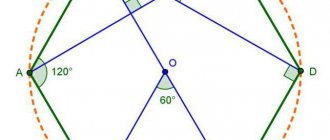

The surface of the screw turns made from sheet blanks is close to the surface of a straight annular helicoid (or, in other words, a screw conoid).

Strictly mathematically, the surface of a helicoid cannot be turned into a plane. This also means the opposite - . . theoretically, it is impossible to obtain a helicoid turn from a flat workpiece. But in practice, everyone often makes the working surfaces of screws from metal sheets! When deformed into a coil, a sheet blank is subjected not only to bending, but also to stretching and compression (forming). In this case, the initial thickness of the workpiece sheet changes locally! The classical theory of surfaces, of course, does not imply deformation stretching or compression of objects of study.

Next, we consider the approximate calculation of the development of a screw turn in the form of a sector of a concentric ring, which is widely used in practice, with a simple derivation of all formulas of the algorithm. A small program implemented in Excel is designed to help you quickly and conveniently calculate the auger (more precisely, the development of the auger turn).

Products of foreign colleagues

Imported ice axes can easily bite into any ice, are made of good materials, are of good build quality, and have less weight. Among the leaders of the domestic market are the Swedes and Finns. Swedish products have a different direction of rotation - clockwise, which you have to get used to.

What disadvantages are noted when operating in Russia:

Which is better: heated floors or radiators?

Warm floorBatteries

- significant cost of the product;

- sharpening blades is quite problematic, and sometimes impossible;

- walking on ice with sandy patches, the edges quickly become dull;

- the price of foreign knives is sometimes comparable to the cost of a domestic ice drill.

Swedish Mora are distributed throughout the world. The company produces 26 models, which differ in diameter, color, height of the screw part, dimensions, and folding system. The knives are hemispherical with complex arched blades.

Calculation in Excel of the development of a screw turn.

The length of the outer helix of the screw turn according to the Pythagorean theorem:

L=(( π * D ) 2 + t 2 ) 0.5 (1)

Similarly, the length of the internal helix of the auger turn:

l =(( π * d ) 2 + t 2 ) 0.5 (2)

a =( D - d )/2 (3)

Let's move on to consider the development of the auger turn.

The following three formulas reflect the relationship between spatial coil and flat sweep. (Angles in calculations are in radians!)

The length of the outer arc of the workpiece must be equal to the length of the outer helix of the turn:

L = α * D /2 (4)

The length of the internal arc of the workpiece must be equal to the length of the internal helix of the screw turn:

l = α * d /2 (5)

The width of the annular sector of the workpiece must be equal to the height of the screw turn:

a =( D - d )/2 (6)

Let us subtract equation (5) from expression (4), replace part of the expression with dependence (6) and express the angle of the annular body of the development:

L - l = α *( D - d )/2= α * a

α =( L - l )/ a (7)

Knowing the angle α from expressions (4) and (5), we find the diameters of the scan:

D =2* L / α (8)

d =2* l / α (9)

β =2* π — α (10)

Size of cutouts along the outer and inner diameters of the reamer:

B = D*sin ( β/2) (11)

b = d * sin ( β /2) (12)

In conclusion, for reference, let’s calculate the mass of the auger turn blank:

G = s *( π /4)*( D 2 - d 2 )/(2* π )* α * ρ (13)

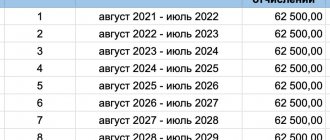

The screenshot below shows an example of a calculation in Excel that implements the simple algorithm considered.

Preparatory stage

Before you begin assembling the auger structure, you need to prepare a working tool . This list includes:

- sheet steel;

- car springs;

- file;

- special vice for fixing workpieces;

- hammer;

- cardboard and marker;

- grinder and wheels for it;

- fasteners; roulette;

- pipes of different lengths.

In addition, you will need a welding machine and safety glasses to reduce the risk of sparks getting into your eyes while working.

As for the pipe material, it is better to select steel elements that have increased corrosion resistance. If you take a cheap option, then after some time rust will appear on the surface.

If everything is prepared, then you can start working. To make a screw with your own hands, you must perform the following steps:

- first make a project, and then a template on thick cardboard;

- take a hollow steel pipe, this material must withstand severe mechanical stress;

- make coils from a flexible steel sheet and use a welding machine to weld the feathers to the pipe - you get a kind of spring.

If a screw is required to work with bulk material, then the turns must be arranged continuously. Otherwise, the desired effect will not be achieved. If everything is done correctly, you will get an effective tool that will have the following positive qualities:

- compact size;

- high performance;

- long service life;

- easy to use;

- rapid deepening and raising of the earth.

But all these characteristics can be obtained only if you strictly follow the installation instructions. Even a beginner can install some homemade devices.

Notes.

Let me remind you that the calculation of the auger turn is an approximate one! Attempts to improve it most often have neither theoretical nor practical meaning, since the accuracy of the surface of the coil depends on the method of its shaping.

If it is necessary to obtain high accuracy, the dimensions of the workpiece development can be adjusted for each specific case individually based on the results of experimental measurements. Sometimes it is rational to introduce additional mechanical processing of diameters on a lathe after forming and welding.

What is the accuracy of the scan obtained using the presented program?

A coil of a helical conoid with the parameters specified as initial data (see screenshot above) has a mass of 191 grams according to simulation data in one of the CAD programs. The mass of the unrolled coil according to the Excel program is almost 197 grams. The difference is 3%. Sweep more! Perhaps the diameters should be reduced? Don't rush to draw conclusions. If the thickness of the sheet in the example under consideration is only 0.05 mm less, the masses of the workpiece and the theoretical coil will become equal.

Products of Russian industry

Domestic mechanisms. They have a budget price, replaceable blades are interchangeable on many models, and the knives are easy to sharpen. However, there are some drawbacks:

- the coloring of the ice auger elements is not always at the proper level;

- knives are often made of low-quality materials that can quickly become dull;

- drilling holes in ice is much more difficult than with imported mechanisms;

- blade mounting screws require constant monitoring, as they tend to get loose and get lost;

- When unfolded there is some play.

Despite all their shortcomings and shortcomings, domestic products are very popular, and they are purchased not out of a sense of patriotism, but because they cope with the tasks assigned to them. Our article “How to work with an ice auger and not damage its elements” is devoted to how to handle them correctly.

Auger turn calculator

The calculation of the characteristics of a screw auger is determined by the properties of the material being moved and the productivity of the conveyor.

Production time – 5 working days Delivery (pickup or transport company: Business Lines)

Based on the customer’s initial information, an assembly drawing and screw detailing elements are developed

Using the calculator, you can perform the most accurate calculation of the auger

online

. The functionality of the program will give the full theoretical performance for a given type of design, shaft diameter, inclination angle, spiral rotation speed, and material filling factor of the conveyor. The last characteristic depends on the scope of use of the conveyor. The power and type of drive are also determined by the properties of the transported substances and specific production tasks.

Auger calculation calculator

provides only estimated data; for a detailed empirical calculation, we recommend contacting engineers with practical experience in the development and operation of screw products.

When contacting our company, the customer is guaranteed to receive a free consultation from a specialized specialist! Based on the initial information provided by the client, assembly drawings and detailing elements of the finished structure are developed. On our website you can buy screw turns (custom made) made to meet the needs of a specific project.

Source of the article: https://promvektor31.ru/raschet-shneka/

General information about the device and areas of application

When considering a screw, it should be taken into account that it is a type of screw, which is characterized by an increased area of turns. The features of such a detail are the following:

Despite the rather complex shape, to reduce the cost of the product, it is made by hand. A home-made version will be able to withstand long-term operation, however, errors made during calculations and manufacturing of the part can cause the screw to be completely unsuitable for use.

Calculation of the screw for the pump

A brief theory is presented and an example is given of calculating the geometric and hydrodynamic parameters of a centrifugal screw pump, as well as its energy and cavitation characteristics.

For students of the Faculty of “Engines and Power Plants of Aerospace Aircraft” performing coursework and diploma design, as well as for engineers involved in the calculation and design of high-speed screw centrifugal pumps. Size: 1.24 MB Format: djvu Download the book from yadi.sk Link not working? Write about it in the comments.

Conventions. Indexes.

1. Determination of angular velocity and basic parameters of the pump. 1.1. Device and main parameters. 1.2. Initial data for calculation. 1.3. Determination of angular speed and screw diameters. 1.4. Determination of the dimensions of the entrance to the centrifugal wheel. 1.5. Determination of the outer diameter of the wheel. 1.6. The joint work of the centrifugal wheel and the auger. Determination of auger pitch. 1.7. Auger profiling. 1.8. Selection and determination of inlet dimensions. 1.9. Verification cavitation calculation. 1.10. Calculation of a centrifugal wheel. 1.11. Profiling of centrifugal wheel blades. 1.12. Profiling of double-curvature blades using the conformal mapping method. 1.13. Calculation of drainage devices.

Complex option

This method of manufacturing a screw will allow you to assemble a high-quality and accurate device that will serve for a long time. First, calculations and drawings are made, then measurements are made. It is also worth preparing tools and suitable material in advance, and only then start assembling a homemade drill.

Step-by-step instructions for installing a screw mixer are as follows:

Actually, this is where the work is finished. All that remains is to make a handle and an extension cord. The first one can be made of plastic, it will be more convenient, but the last part can be made from any suitable pipe.

Auger calculation - calculator

The auger productivity calculator gives its full theoretical productivity, at the specified coefficient of filling the conveyor with material.

The theoretical performance of a screw in a horizontal position depends not only on the given diameters and rotation speed, but also on the angle of inclination, the nature of the material supplied to the conveyor and many other factors.

Where can I get the source data? What to start from?

Shaft speed

We recommend using the tabular data provided on the design page of our augers at the link: designs and photographs.

Typical diameters and fill factor

The selected dependencies on the scope of application of the conveyor are shown in the table of the second section on the main page of our website. Please note that you should not strive to select the smallest possible diameter of the conveyor. This leads to increased wear of its rubbing parts in contact with the product.

Theoretical calculations of auger performance are an estimate. For an unambiguous calculation of a real screw conveyor, it is necessary to take into account a number of empirical factors that cannot be presented in the form of tabular data. These values are selected based on experience in using conveyors for a particular task, taking into account its location, loading conditions and properties of the transported material. First of all, this concerns the choice of the required type of drive and its power. Secondly, when calculating the screw, it is necessary to take into account the safety factors and unloading of the spiral. Therefore, the choice of empirical coefficients for serious projects should be made by engineers with experience in operating augers.

Source of the article: https://ukrtehnoservis.com/raschet-shnekov/

Easy way

There is a very simple way to quickly assemble a homemade auger with two blades. These elements will fit perfectly into the ground. The only negative is that it can only be used at shallow depths, no more than 10 m.

The screw is manufactured using the following technology:

In this case, the drilling structure will make longer strokes, which means that working with the tool will be easier and faster. At this point the auger is ready.

From blade to screw system

As we have already said, there are a large number of drills on sale from both domestic and foreign manufacturers in various price segments. Therefore, developing an ice drill auger with your own hands is not entirely practical. However, there are craftsmen who show miracles of ingenuity.

Of course, with the proper skills and the necessary equipment, you can make a structure, but no one can guarantee how efficient it will be. We wrote about the general principles of manufacturing in the article “How to make an ice screw from improvised means.”

When making a homemade ice screw, you can copy the dimensions from the original. A spiral of fabric is welded onto a metal tube. One way to make an auger is to cut metal rings and spread the ends up and down.

The end of one ring is welded to the beginning of the next, and so on until the auger of the required height is obtained.

Another option for a homemade drill is a modification in the form of a shovel. A hemispherical blade is welded onto a steel tube with a brace in the upper part (it can be taken from a broken ice drill). The blade is sharpened on one side only.

Of course, its characteristics will be inferior to auger models, but a hole can be made in the ice.