Types of crushers and their applications.

In many cases, customers need equipment that can crush and process all types of plastic. In reality, such a task is practically impossible, because polymer materials differ in a number of parameters: structure, shape, dimensions and other properties.

Shredding equipment is used by various manufacturing plants for recycling plastics. This makes it possible in the future to create products from old plastic that are almost as good as newly created polymers.

Devices for shredding plastic waste are divided according to their purpose into the following:

- polymer film shredders, which are equipped with special knives;

- shredders for thin plastics and various bottles;

- installations for crushing large products.

Also, rotors for crushing plastic are divided according to design:

- Guillotine cut

- Oblique cut

- Dovetail

- Cascade type

- Spaced rotor

There are also washing crushers, in which the material is washed during grinding. Water intensively cools the rotor and helps the polymer exit the chamber.

Shredders operate on the following principle: plastic is shredded by knives mounted on a rotating rotor.

Shredders come in the following types:

- single-shaft (toothed);

- twin-shaft (disc).

Do-it-yourself plastic crusher - drawing up a project and assembling homemade equipment

Plastic processing is one of the freest niches for doing business in Russia.

However, the issue of opening it most often depends on the cost of the equipment.

Entrepreneurs often start not with a full processing cycle with finished granulate at the output, but with the collection and grinding of polymer waste.

Even in this case, purchasing a shredder and/or crusher may not be affordable . One of the most discussed solutions to the problem is making your own shredder.

Such projects are quite feasible if two “constant quantities” are known - raw materials and product.

Next, we will talk about how to make a shredder and how to avoid gross mistakes when designing and making your own plastic crusher.

What is the difference between a shredder and a polymer crusher?

Both types of equipment perform the same task - crushing.

When processing plastics, this process is usually divided into two stages :

- coarse grinding - shredders are used for this;

- obtaining fine crumbs - a crusher is used for this.

The operating principle and kinematics of both units are most often the same, and they differ only in some details, for example, the size of the sieve cell, the overlap of the knives and the configuration of the cutting edges.

The process is divided into two stages in order to increase productivity and optimize energy costs.

Shredder design for plastics

When choosing the design of a plastic shredder, you should pay attention to the proposals of equipment manufacturers.

It is better to take other people’s work as a basis for a project and have certain guidelines than to reinvent the wheel and end up with a non-working model.

The most popular are single- and double-shaft rotary shredders.

Single shaft shredders are used for the initial shredding of most varieties of polymers .

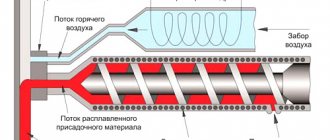

It consists of a rotor on which movable knives (2) are fixed and a housing with fixed or stator knives (1). The raw materials are fed through the loading window from above, and the finished crumbs are poured under their own weight through the calibrating sieve (3).

The shredding process involves repeated cutting and continues until all the plastic has gone into the receiving hopper.

The configuration of the rotary knives is selected depending on the material being processed:

- Dovetail and inclined – for processing film materials, PET containers and other soft waste.

- Straight – for crushing sprues, boxes, thick-walled blow moldings, PET bottle caps. Such knives are often made in the form of separate segments, which are arranged in cascades. Segmentation is performed to reduce shock loads on the drive, reduce noise and vibration.

Stator knives for single-shaft polymer crushers are made solid (type P).

Twin-shaft

The rotor and stator knives on such crushers are arranged in a checkerboard pattern, and the shafts rotate in counter directions.

Low-productivity machines with a small working chamber are made with a single drive ; the teeth on the rotary knives are used to capture and crush waste.

Grinding is also performed on the side surfaces (as in disc shears).

Where can I get the drawings?

You need to understand that manufacturers of equipment for shredders and crushers will not make drawings publicly available .

The easiest way to get diagrams for a homemade shredder or crusher is in two ways:

- Read forums on the topic , like this one. The likelihood of finding accurate and detailed drawings of plastic shredders is very low. Often, resource users recycle some unclaimed equipment from a related industry, for example, a lopper. And if a crusher is made from scratch, few people care about documenting all stages of production. Nevertheless, it’s worth reading the forums: analyzing discussions and other people’s design mistakes will help you make a more advanced plastic shredder with your own hands.

- Take measurements from the existing shredder. It will not be possible to obtain complete information, since the owner will not allow you to disassemble a working machine. But even a visual assessment will help in making your own homemade crusher.

Many attempts to make a crusher on their own reach a dead end due to the fact that the designer tries to attach to an existing unit . For example, “fit” all the elements to a worm gearbox found in the garage.

An attempt to reduce the cost of a design using secondary parts, as a rule, leads to mistakes.

It is better to start production with a clear definition of the tasks of the shredder, that is, you need to know the type and quantity of raw materials being processed, and the size of the output fraction.

Price for crushers

The sale of equipment in our company is carried out at factory prices, because we ourselves are manufacturers of such units.

Product prices vary greatly. It all depends on the type of device, the complexity of production and the materials used.

Information on the cost of equipment can be found by clicking on “Calculate price” and filling out a simple form on our website.

The product cards indicate the production time of the equipment, as well as other characteristics: design, raw materials, power.

Crushers for plastics, crushers for plastics

Ningbo Huare Machinery produces quality plastic impact crushers that are designed to crush sprues, defective products and other waste from plastic products manufacturing. Also, in some cases, these crushers are used for crushing rubber, paper, cardboard, and wood. The company produces a wide range of rotary crushers for plastic, which are capable of solving a wide range of problems.

Depending on the type of blades and power, Huare shredders are used for crushing sprues, canisters, PET bottles, preforms, vegetable boxes, household appliance housings, polymer films, bags, etc.

Principle of operation. Inside the crushing chamber there is a rotor with movable knives, as well as a stator with two fixed knives. The processed polymer waste is fed through the loading window of the crusher into the crushing chamber, where it is crushed using stator and rotating rotor knives. At the bottom of the crushing chamber there is a sieve with holes of the same size. As soon as the size of the crushed particles becomes smaller than the diameter, the particles fall into the receiving container. Unloading of crushed material from the receiving container is done manually or using pneumatic unloading (optional).

The most popular Huare HSS models are always in stock at our warehouse in Moscow, so you can buy a plastic crusher very quickly. Our specialists have extensive experience and will help you choose a plastic crusher based on your needs at the lowest price.

Universal series HSS

Crusher HNS

Attached crusher HFS

For cans and barrels HTS series

Machine for sharpening crusher knives

Our company also offers Italian highly efficient crushers manufactured by CMG, designed for crushing plastic products and production waste (molding and blow molding products, rejects, thermoforming waste, sheets, sprues, boxes, panels, caps, PET bottles, profiles and film, extruded foams, fibers and composite materials) into recycled materials. With the help of crushers and industrial mills it is possible to crush any engineering plastic ABS, PA, PBT, PC, POM, PE, PP, etc., as well as film, foil and paper. They make it possible to obtain grains of the desired geometry and size, followed by dosing crushed grains and mixing them with the primary material. Productivity from 10 to 2000 kg/h.

CMG crushers N17 series

CMG crushers N25 series

CMG crusher S30 series

CMG crushers N40 series

CMG crushers N45 series

CMG crushers N60 series

Operating principles of an impact crusher for polymers and other waste

The material to be processed is loaded into the hopper of the CMG crusher and crushed during the operation of the stator and rotor knives. A sieve with cells of the required size (diameter) is installed at the bottom of the crushing hopper. When the crushed granules become smaller than the diameter of the sieve cells, they are poured into a special hopper. In addition to standard configurations, CMG can manufacture and offer to buy a plastic crusher according to the specifications, productivity requirements and material characteristics received from the Customer.

Distinctive features of CMG polymer crushers

CMG plastic crushers have a rigid design. The large mass of the structure itself and the mass of the rotor ensure smooth operation under high load conditions and have a positive effect on the life of the knives. The gentle angles of the blades smooth out peak loads and guarantee ideal dynamics. As a result, the material is not damaged thermally, has sharp edges, has high uniformity and low dust content.

These properties are of great importance for a smooth crushing process. When using CMG crushers with their proprietary knives, there is no blocking of the rotating parts of the crusher due to uneven crushing of the material and the formation of a jam of material grains in the hopper due to the fact that the particles do not have breaks and dust is not generated during processing.

Thanks to its large mass, proprietary knives and special bearing design, the CMG plastic crusher has high productivity combined with low energy consumption and a long service life.

CMG crusher rotor design

The rotor inside the crusher is made of a solid, solid piece of metal. It has a lot of weight and, therefore, a high torque. The rotor has no imbalance. There are no welds on it that could prevent it from being cleaned. The rotor has inclined surfaces, so simple straight knives are used. The CMG film crusher has a fixed position of rotary knives. Only stator knives can be adjusted. This provides a number of advantages, because

Advantages of the MSK Polymer company

- We produce only high-quality equipment, providing a 12-month warranty, as well as further maintenance.

- We take an individual approach to each order, developing equipment specifically for your raw materials.

- Delivery is carried out anywhere in the Russian Federation.

- We work not only on full, but also partial payment.

- Turnkey installation is carried out.

Our company carefully analyzed this market segment, which allowed us to select the most acceptable pricing policy that reflects the quality of our work.

Free advisory support is provided for all of our products.

Types and classification of crushers

Among the crushers there are universal ones, for example, Molot, SPW 720 (for all solid and dry types of waste). There are universal plastic ones, for example, XFS-250 is designed for polymer films, bottles, and small plastic waste. S-DR-600 is primarily a crusher for PET bottles.

XFS series plastic crushers with rebar knives

Famous series of plastic crushers:

- XFS;

- SPW;

- AMD;

- C-DR.

There are two main divisions of equipment - by purpose and design. To shred film (nylon, acrylic, polyethylene, etc.) you will need V-shaped knives that work like scissors. For plastics, the crusher is equipped with cascade cutters. The peculiarity of the profile crusher for bottles is that it achieves maximum productivity only when fully loaded. Installations for crushing large-sized products - equipment casings, etc. - are sold separately. These are the RFS, HNS, HZS series.

By design, the division is into:

- jaws equipped with steel plates for sealing plastic;

- hammer, where the plastic is crushed by hammer blows on the rotor hinges;

- conical, grinding is carried out between two cones;

- rotary.

Impact crusher for foam plastic

The most common shredders are rotary. They achieved popularity due to efficiency and variability. In rotary crushers, high productivity is achieved by maximum loading. Thus, in high-speed crushers for thin-walled material with a power above 10 kW/h, the operating speed reaches 100 liters per second. Equipment for thick-walled plastic operates at a speed of 15 l/s and consumes less than 10 kilowatts per hour.

Impact crusher for plastic

Crushers can be double-rotor or single-rotor, with or without a grate. The grate is used as a hammer grinder. The rotary chopper requires careful maintenance during operation. Otherwise, the blades will quickly become dull and the rotor mechanism will become unusable. High-strength materials should not be loaded into it.

Advantages:

- two types of crushing – primary and final;

- high performance with low power consumption;

- uniformity of crushing.