Home / Cast iron from gray, malleable, alloy cast iron to order.

The process of manufacturing various products, during which a material in a liquid state turns into a solid (casting formation), is called “casting”. Iron casting, which is a method of producing cast iron products, has become widespread in various fields of activity. In fact, in order to produce any part from this material, casting is the only way. Castings for stoves are in high demand: cast iron elements are used both to ensure their functionality and as decoration.

Functionality and features of cast iron

Cast iron, which is used for the production of castings (technological products and artistic elements), is divided into several types. Thus, there is high-strength cast iron (in some cases it acts as an alternative to steel), as well as gray, white and malleable cast iron. In addition, there are special grades of this material, but they are not used in cast iron foundries (their purpose is to use them as alloying additives in steel).

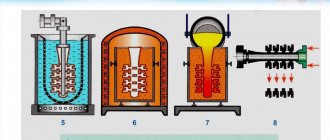

Various methods are used to create cast iron castings. Thus, one of the most common is casting in sand-clay mixtures. Cold-hardening mixtures (CMC) can also be used. The production process itself involves pouring material in a liquid state into hollow molds. After it has completely hardened, the resulting product is removed and subjected to the necessary mechanical processing.

CJSC "Special Machine Building Plant "Mayak" produces high-density cast iron casting using the cold casting method. Castings made by this method have an attractive appearance, there are no blockages or sinkholes. Deliveries are made to enterprises in the engineering, metallurgical, energy, and machine tool industries.

It should be noted that casting is a complex technological process, the results of which are influenced by many factors. Of course, it is impossible to obtain a high-quality product without high-tech equipment, but the level of qualifications of specialists and the availability of product quality control at each stage of production are also of utmost importance. In addition, only strict adherence to technology can eliminate the risk of voids (in cast iron casting this is considered the main disadvantage).

The main advantages of cast iron are practicality, strength, long service life and safety. The attractive appearance of the products is of no small importance for many customers. The affordable price of cast iron is also considered an advantage, which significantly reduces the final cost of the products.

The production of cast iron is in demand in many areas. Products are used in mechanical engineering and machine tool building, mining, construction industry, as well as to solve various problems in other industries. And, of course, there is an increased demand for artistic casting: along with strength and wear resistance, such products are distinguished by impeccable aesthetic characteristics. The method is suitable for creating stair railings, lanterns, gazebos and all kinds of small architectural forms.

Production of high-quality iron castings for machine tools and complex body iron castings

(frames, housings) by the casting method in the cold steel system particularly distinguishes our enterprise, especially considering that we have the ability to carry out complete machining of these products, taking into account all the requirements for accuracy and roughness. In the production of machine-made cast iron castings we mainly use the following alloys: SCh20, SCh25, SCh30, VC45, VC50, VC60. If necessary, it is possible to introduce alloying elements. Castings must undergo heat treatment to relieve internal stresses - artificial aging (the thermal section has large furnaces with dimensions of 7000x7000x14000mm). Without this heat treatment, during the operation of products, deformations may occur that exceed the requirements of the drawing in terms of possible deviations from flatness, parallelism and perpendicularity. 3D scanning can be used to control the dimensions of castings with complex configurations.

EXAMPLES OF OUR WORK (PHOTO GALLERY)

Casting iron at a factory

The main element in the alloy is iron. It always contains from 2.4 to 6.0% carbon, a constant small percentage of silicon, sulfur, phosphorus, magnesium. This is a low-ductility material and cannot be rolled or forged. Melting point is about 1200 °C. Possesses foundry quality. To obtain the desired designs, custom cast iron is required. Castings can be made in a wide variety of complex shapes. You can order a single copy or launch mass production.

Low prices for castings, availability of casting structures of any complexity and size, high strength and wear resistance of the material, and the possibility of recycling. These properties have become widely used in a variety of fields.

Grades and types of cast iron

Division is accepted depending on the form in which carbon is contained in the alloy.

- White: carbon in a bound state, like cementite. When broken, the fracture has a matte white color. This grade is brittle but resistant to corrosion and custom cast iron is mainly used for making piston rings, solid bases.

- Grey: Graphite is included in the composition in plate form. From these grades, cast iron is ordered according to GOST for the manufacture of various parts for the engineering industry.

- High Strength: Graphite is incorporated in the form of spheres. Precision casting is most often used in mechanical engineering, for the manufacture of pipelines in the oil and gas, food industries, where increased corrosion resistance is required.

- Chromium: alloyed with chromium, intended for use in alkaline, air, gas environments and at high temperatures.

- Heat-resistant cast iron: intended for the manufacture of castings and parts, the operating temperature of which can reach up to 1100º C. Manufactured in accordance with GOST 7769-82, which regulates the chemical composition, mechanical properties and modes, methods of heat treatment of heat-resistant cast iron.

The main areas of application of cast iron blanks:

- in heavy industry, metallurgy. The density of the alloy is 7.0 tons in 1 cubic meter. Metal platforms are often used to stabilize large equipment in workshops;

- In the machine tool industry, they practice the production of castings from high-strength cast iron for particularly critical parts. Massive platforms for installing processing machines help dampen vibrations and vibrations;

- The automotive industry practices the production of castings from high-strength cast iron for diesel crankshafts, brake pads, and cylinder blocks;

- in the oil industry. Oil is characterized by high chemical activity. This justifies the choice for pipes, ordering the production of casting fittings;

- High heat capacity is used in the manufacture of heating radiators. Dishes are also in high demand among housewives. The thick bottom of the pan distributes heat evenly, allowing food to heat and cook well;

- artistic casting. Cast iron casting, purchased upon request, is required for the manufacture of fences, enclosures, and the creation of works of art.

IRON CASTING AND BASIC PRODUCTION TECHNOLOGIES

Cast iron casting in sand-clay mixtures

- Dimensional accuracy class for cast iron according to GOST R 53464-2009: 9-14

- Surface roughness of cast iron castings according to GOST 2789-73 Ra = 80-100 microns

- The minimum wall thickness obtained when casting cast iron is 3 mm

- Weight of castings from 0.5 kg to 40 tons

Cast iron casting in liquid-glass mixtures (ZhSS) and cold-hardening mixtures (CHS)

- Dimensional accuracy class for cast iron according to GOST R 53464-2009: 8-13

- Surface roughness of cast iron castings according to GOST 2789-73 Ra = 40-100 microns

- The minimum wall thickness obtained when casting cast iron is 3 mm

- Weight of castings from 0.5 kg to 40 tons

Characteristics of our iron casting production

- Area of the main foundry: 18,000 sq. m;

- Production capacity of the iron casting workshop: 24,000 t/year;

- Manual parade ground: 2000 sq. m;

Furnaces used for heat treatment:

- 2 furnaces with a load of 25 tons have working dimensions: B=2500 mm, H=1850 mm, L=5500 mm

- 2 furnaces with a load of 100 tons, with working dimensions: B=7000 mm, H=7000 mm, L= 14000 mm

Production time, level of complexity, guarantee for cast iron

- We will produce model equipment in 3 days;

- Production time for finished castings is from 5 days;

- We can produce thin-walled body parts, complexity group 6;

- We carry out laboratory tests (controlled parameters: chemical composition, yield strength, tensile strength, impact strength), and at the customer’s request we provide the results of fluoroscopy, ultrasonic flaw detection, magnetoscopy.

Application of cast iron products

In addition to parts of mechanisms, machine tools, and cars, cast iron is used for the manufacture of artistic structures, fences, fences, monuments and busts. Products are made to order. Cast iron does not rust, withstands high temperatures well, therefore it is used for the manufacture of grates for furnaces, valves, dampers, and for the manufacture of heating boilers.

It is impossible not to mention Kasli and Kusa casting: a folk craft in the Southern Urals, artistic products made of cast iron with a three-century history.

Cast iron alloys used and cost of castings

- Gray cast iron GOST 1412-85: SCh10, SCh15, SCh20, SCh25, SCh30, SCh35 from 102 rubles/kg;

- High-strength cast iron according to GOST 7293-85: VC40, VC45, VC50, VC60 from 135 RUR/kg;

- Special types of cast iron, alloyed cast iron according to GOST 7769-82: ChH1, ChH16M2, ChH16 from 170 RUR/kg, ChH28N2, ChH28 from 360 RUR/kg, ChH32 from 380 RUR/kg, ChS5 from 125 RUR/kg, ChS5Sh, etc.;

- Anti-friction cast iron according to GOST 1585-85: AChS-1, AChS-3, AChS-5 from 142 rubles/kg, etc.

- It is possible to cast cast iron from the customer’s choice of grades

*** Prices are indicated for 1 kg of castings including VAT

Cylinder block casting process

Overview: Casting Molds and Related Casting Processes

Steel molds with sand cores

Steel molds Steel molds

Low pressure casting

Squeeze Casting

The table contains a short overview of the foundry processes used for aluminum casting and the corresponding casting molds. The following subsections describe specific foundry processes and explain their advantages and disadvantages.

Sand casting

Sand casting is a traditional mold casting technology with destructible (lost) sand molds. The molds used for a single casting are made, in principle, from quartz sand as the main material of the mold using binders. The production of molds is carried out by copying models made of wood, metal or plastic and makes it possible to obtain castings of complex shapes by detaching and separating the model and mold. After the castings harden, the sand molds are destroyed, and the sand cores, which serve to reach inaccessible and unworkable cavities, are shaken out or washed away. The commonly used sand casting plays a secondary role in mass production. The main area of application is the production of prototypes and small series. Cost-effective sand casting in the form of an automated core package system (CPS = core package system). The pure sand casting process (the mold and cores are made from sand) is done by free pouring or low pressure casting. Image 1 shows free pour sand casting.

Chill casting

During chill casting, liquid aluminum is poured into durable metal molds made of cast iron or heat-resistant steel. With this casting method, the design and freedom of its design depend, however, on whether the casting is made by free-moulding or low-pressure casting. Compared to sand casting, chill casting achieves better surface quality and greater dimensional accuracy of the castings.

Free casting

In free casting, the mold is filled solely under the influence of gravity acting on the metal at atmospheric pressure. Casting is done manually or on partially or fully automated casting machines. With this method there is quite a lot of design freedom, since it is possible to use sand cores (Fig. 3). In this way, rear cuts or cavities that cannot be achieved by machining are also possible. Thanks to the rapid, directional solidification of the melt using the free chill casting method, compared to sand casting, a thinner structure, higher strength, as well as unlimited possibilities for working with heat are achieved.

Low pressure die casting

When casting under low pressure, the melt at a relatively low excess pressure (for aluminum alloys - from 0.2 to 0.5 bar) rises into the mold and solidifies at this pressure. We are talking about pressure, in fact, about filling pressure , necessary in order for the liquid metal to be delivered in the casting machine to the top, into the mold. The filling pressure is maintained until solidification occurs, from the outermost point to the cut of the siphon sprue (the inlet of the mold). The almost ideal, directional solidification and filling of the mold without turbulence is therefore an essential basis for the high value of low-pressure castings. As with free casting in a chill mold, this method also uses sand cores, which provide sufficient scope for constructing the mold.

Where to order cast iron?

Services for the production of custom-made iron castings in Moscow and the Moscow region are offered by ZAO Mayak Special Machine Building Plant. Available production capabilities allow us to produce castings weighing up to 40 tons. In this case, various cast iron alloys are used to make castings. Also among the advantages of cooperation with JSC “Special Machine Building Plant “Mayak”:

- quality guarantees of manufactured products (all products comply with GOST requirements and undergo laboratory tests);

- the use of various technologies depending on the customer’s needs;

- minimum production time;

- professionalism and significant work experience, allowing you to solve problems of any level of complexity;

- favorable pricing policy.

Any questions? Employees of ZAO Special Machine Building Plant Mayak are ready to advise on all aspects of ordering castings.

Shaped casting

Cast iron products

Iron casting cost

The price for manufacturing a specific product is calculated individually. This includes the cost of creating drawings, sketches, models and molds. The cost of materials is also taken into account.

Services are provided without intermediaries and contractors, thanks to which we fully control the quality of work and offer competitive prices to clients.

Starting up equipment is a costly part of the entire process, so manufacturing a large batch or series of products is more profitable - the final cost of each part will be lower.

Start of iron foundry

People have never been particularly interested in the history of cast iron, although its importance is difficult to overestimate. Only a relatively narrow circle of specialists knows what role this seemingly inconspicuous material played in the development of productive forces in different eras, but everyone knows that cast iron and the steel produced from it in oxygen converters are the basis of modern engineering and technology.

Among structural materials, they certainly occupy the first place and will not give it up for a long time, despite the increasingly widespread use of light non-ferrous metals, polymers and ceramic materials.

Already today the number of iron-based alloys has exceeded 10 thousand.

Analyzing European languages in the field of iron foundry, sometimes you come to interesting observations. For example, a billet for further remelting is called “pig” in Russian and Ukrainian, that is, “pig”. Likewise, in English it is called “Pig Iron”, that is, literally “pig iron”. This was due to the fact that pig casting, unlike shaped casting, was trusted to students and journeymen, considering this type of casting to be the most primitive and unprestigious. In most European languages, the term for cast iron is derived from the root term for the base material of iron-carbon alloys, iron, and means “cast iron.”

So, in English, the term “Iron” - “iron” corresponds to the term “Cast Iron” - “cast iron”; in German, the term “Eisen” - “iron” corresponds to the designation “Gusseisen” - “cast iron”; in Swedish “jarn” means “iron”, “gjutjarn” means “cast iron”. The same is true in Turkish, Finnish, Modern Greek and other languages. However, in French the name of cast iron “fonte” is associated with the concept “fondre” - to melt, cast; in Russian, cast iron is denoted by the term “cast iron”, in Ukrainian it is clearly a derivative of the Russian “chavun”, which sound foreign (and in fact they are), and at first glance have nothing to do with the term “iron”.

How could it happen that the most characteristic difference between cast iron and other alloys - its production exclusively in a cast state - did not find a domestic designation, instead of which a foreign word began to be used. Where did the word “cast iron” come to us and what does it mean?

Cast iron as a foundry material was invented and mastered in China many centuries before the new era, as evidenced by the four-shot cast iron cannon cast in the fifth century BC. e. and cast iron castings that still exist, the largest of which is considered to be the “lion”, about 6 m high and 5.4 m long. According to literary data, the appearance of cast iron in China dates back at least to the 6th century. BC e. In contrast to these data, B.B. Gulyaev believes that casting iron was mastered only 600 years ago.

The vast Mongol Empire, which arose as a result of the predatory campaigns of Genghis Khan and his first successors, greatly facilitated familiarization with the cultural achievements of the Chinese, residents of Central Asia and Eastern Europe.

Comparison of the dates of the Tatar invasion and their establishment in Eastern Europe and the southeastern parts of Europe (the first half of the 13th century), as well as the dates of travel of the first European scout ambassadors to the Tatars - Plano de Carpini (1246), Ascelina (1247), Marco Polo and others, with the time of the “invention” of gunpowder (late 13th century) and cast iron (2nd half of the 14th century) by Europeans, clearly shows the mutual connection of these seemingly disparate and seemingly completely independent historical facts .

Ancient Rus' had direct connections with the Golden Horde, in the capital of which many Russians lived, who had separate trade and craft rows there and even a separate diocese, and was in more favorable conditions than Western countries for the development of Chinese and Khorezm achievements in the field of technology. Therefore, it is logical that the Russian word - cast iron - comes from the Tajik word “chuyan” (in Tatar “chuen”). This term for both Tajiks and Tatars was brought from outside, namely from the Chinese, for whom the term “chu” (“zhu”) corresponds to the verb “to cast”, and the term “gong” is equivalent to the name “foundry” (production). In Fig. Figure 1 shows two Chinese characters: the left one “zhu” means “to pour”, the right one “gong” means “to do, production”.

Rice. 1. Chinese characters

V. Yakovlev points out that in some languages the term for cast iron is also derived from the term assigned to iron, but in combination with different adjectives. Thus, in Chinese, the synonym for the word “cast iron” - (shengte) can be literally translated as “living iron” or as “raw”, “unfamiliar”, “unusual” iron. The same can be observed in Japanese, Danish, Hindi and other languages.

But in another group of languages the term for cast iron was not formed in the same way as in previous cases. These languages include Russian, Tajik, Turkmen, Kyrgyz, Afghan and, probably, a number of others. In terms of sound similarity, the Afghan term for cast iron is closest to the Russian word “cast iron”. In Afghani (cast iron) - and means cast iron. “Cast iron” in Turkmen and Kyrgyz is “choyun”, and in Tajik it is “chuyan”. One gets the impression that the Russian term “cast iron” is of Central Asian, not Chinese, origin. But this does not mean that the peoples of our country became acquainted with cast iron through the mediation of the peoples of Central Asia.

Confirmation that the Russians borrowed the name cast iron from the Tatars and Chinese through Central Asian merchants can be seen in the fact that in the census books of clerks Yuri Telepnev and Afanasy Fonvizin for the Tula and Kashira factories of 1645-1676 we have a confusion of unidentified technical terms “cast " and "cast iron" iron.

Herberstein testifies that in Rus', already under Vasily III, cast iron cannonballs were cast, and under Ivan the Terrible, cast iron bells and cannons were cast, which means that by this time iron foundry in Rus' already had a long-term practice and went through a period of development and establishment.

The Chinese origin of the word “cast iron” is also proven by Professor L. M. Marienbach. He believes that the Russian name for cast iron comes from the Chinese word "zhugong" (must be "zhutsauogong"), which in Russian means "foundry worker", or from the Chinese word "zhugendi" (must be "zhuchandi"), which -Russian means “cast”.

In both assumptions, Chinese words were selected that were close in sound similarity and denoted terms from the field of cast iron production. If we select words only by sound similarity, then in Chinese the word for a stick or staff sounds nothing more than “zhugun”. A direct connection in sound between the Chinese and Russian terms for cast iron cannot be detected. In addition to direct acquaintance with iron casting in the Great Bulgars and Sarai Berke, the Moscow government used the services of Western European specialists, and contrary to the opinion of V. Knabbe, cast iron in Rus' appeared not in the 17th century, but much earlier. Thus, the work describes that from the works of the famous ancient scientist Aristotle, it can be assumed that he knew cast iron 2300 years before the present day. Four centuries later, the Roman scientist Pliny the Elder reported that sometimes “iron, when melted, becomes liquid like water, and then breaks like a sponge.” These are already clear signs of cast iron. (Although in many sources these signs were interpreted differently.)

The outstanding Russian foundry worker N.N. Rubtsov directly writes: “Be that as it may, we have several cast iron castings dating back to the 5th-6th centuries. BC e. In museums there are many examples of cast iron dating back to a period more than a thousand years before the Middle Ages, which is considered the time of the discovery of cast iron.”

Cast iron casting was widespread BC. e. in China, irrefutable evidence of which is the cast iron castings that still exist to this day. The largest of these is a cast iron lion, about 6 m high and more than 5 m long, which stands near the Tian-jin-Pukou railway near Chien-zhou and is probably the largest of the cast-iron statues, the casting is dated 974 AD. e. About the same monument, A. M. Petrichenko and E. A. Sukhodolskaya write that they themselves examined this unique casting in detail and were convinced that the form of the Lion Tsar was poured in one go (or with short breaks, during which the cast iron in the mold did not had time to harden).

According to literary data, the appearance of cast iron in China dates back at least to the 6th century. BC e. It is interesting to note that the Scythians, who inhabited the territory of our country from the 8th century BC. e until the end of the 2nd century AD. e. There was no cast iron. The Scythians did not go beyond bronze in metallurgy and casting.

According to the American magazine Modern Casting, 600 BC. e. In China, the first iron casting was cast - a tripod (weighing 600 pounds), and in 233 BC. e. The first cast iron shares were cast there.

It is known that the inhabitants of Fergana in the 2nd century. BC e. learned from fugitives from the Chinese troops how to cast iron. In 115 BC. e. The Chinese government monopolized the entire iron industry; there are numerous indications that one of the main incomes from the use of iron was the manufacture of vats for evaporating salt from sea water and, as far as one can go back centuries, these vats were always made of cast iron.

Of all the countries known in the ancient world, only in China was iron reduced from ore with coal, and in all others with charcoal.

The ore used contained from 0.5 to 1% P, so that the pig iron obtained from this ore should not contain more than 1% P. The castings contained from 5 to 7% P, with an additional amount being obtained from coal. Thus, the Chinese learned to produce an alloy close to phosphide eutectic, that is, a metal with a melting point approximately 100° lower than bronze. This explains the relatively wide distribution of cast iron castings in China in bygone times and the, at first glance, surprising fact that neither India, nor Greece, nor Fergana, nor Russia, conquered by Batu, who had the opportunity to get acquainted with the Chinese experience, could develop This is production at home, since they did not have suitable raw materials. Therefore, the development of iron foundry production began again in the Middle Ages, when 1) the invention of more powerful blowing devices made it possible to move to higher furnaces for the production of iron, in which cast iron was obtained due to the carburization of reduced iron, at first unexpectedly for the metallurgists of that time; 2) when the demand for cast iron cannonballs and then for cast iron cannons created a stable demand and, therefore, a solid economic basis for young production.

Interesting data is provided by A. M. Petrichenko, a great expert in artistic and coin casting, who writes that an exception to the rules of the world monetary system should be recognized as the casting and participation in the monetary circulation of China of cast iron coins, which were widely used during the period of the Pentaterum (907-960 AD). . BC) and especially during the Song era (960-1279 AD). In some regions, in order to save copper, only cast iron coins were in circulation, but there was also a ban on their export abroad.

In foreign and domestic literature, the prevailing opinion is that the reason for the emergence of iron casting in China was the presence of high-phosphorus ores and the use of special phosphorus additives by ancient Chinese foundries.

Even a short excursion into the history of metallurgy in China is enough to convince us that this is not the only and not the main reason for the early appearance of cast iron in China. The main reason that the Chinese were the first in the world and more than 1500 years earlier than the Europeans to learn how to mine ores, smelt iron and make iron castings is the remarkable success of the Chinese in the field of bronze smelting and the construction of furnaces at the time of the advent of iron.

Some researchers attribute the first castings to the Warring States period, while others reasonably believe that the Chinese knew how to make cast iron castings back in the Spring and Autumn era (722-481 BC). In fact, China began its Iron Age, as Li Heng-de testifies, not by mining raw iron and forging products from it, but by smelting cast iron and making iron castings. This is one of the features of the original development of Chinese foundry production. If there is still no convincing evidence about the use of forged iron products in the “Spring and Autumn” era, then there is a lot of completely reliable data about the production of cast iron castings during this period.

In China, already in 513 (BC), a large cast-iron ritual vessel was made, on which one of the codes of the then laws (a kind of criminal code) was cast. But the first cast iron castings were primarily implements and tools for agricultural purposes. The ancient chronicles of China provide irrefutable evidence of the use of iron (cast iron) agricultural tools back in the 7th century. BC e., which led to a sharp increase in field yields.

A. M. Petrichenko directly points out that the Chinese, more than 1500 years earlier than the Europeans, learned to smelt cast iron and make complex cast iron castings. By the period of the “Warring States” (403-221 BC), i.e. by the time of the appearance of cast iron die casting in China, Chinese foundry workers had perfected the technique of smelting cast iron. By this time they had reached a high level in the manufacture of foundry molds. Moreover, to produce cast money and other castings, the foundry workers of that time used mainly semi-permanent fireclay molds. The halves of such forms were made using metal (bronze) models or molds. Of course, casting iron money was a very progressive process for several reasons.

Firstly, cast iron is not a noble metal, resistant to abrasion, this scourge of metal money made from precious metals.

Secondly, cast iron is not in short supply, which made it possible to clearly implement the law of metallic money, almost unchanged over the centuries: the value of the metal of a coin should be lower than its face value (however, in the history of metallic money there were exceptions).

Thirdly, the state monopoly on iron casting that existed in China excluded counterfeiting by definition.

Fourthly, it is unlikely that cast iron can be smelted from ore at home by a person who does not master the art of metallurgy, who does not have prepared ore, fluxes and reducing agents, the recipe of which was almost always kept secret and passed on from father to son.

China is the country of the oldest foundry literature. Apparently, the first book on casting technology was the book “Kao Gong Di”, widely known in China, written more than 2000 years ago. This book outlines not only methods for producing castings, but also a detailed description of alloys for various products (swords, bells, household utensils, etc.), their composition and melting methods. Similar information about various casting methods is available in later sources.

More than four hundred years ago, Song Ying-hsing's book "Original Inventions" was first published, which gives brief descriptions of many of the most characteristic casting processes that have survived from ancient times. This book is well illustrated; it has been reprinted many times.

It is interesting to note that in our country, on the territory of the Odessa region, near the village. Nikolaevka, Belyaevsky district, in 1964, A.I. Melyukova found three fragments of cast iron boilers, which are the most ancient cast iron products not only in Ukraine, but throughout the entire European part of the former USSR. The fragments were found at a settlement of the Greco-barbarian type in undisturbed layers in different places and at a significant depth - 0.7-1 m. This layer contained a large number of products of the ancient era, reliably dated to the 4th-3rd centuries. BC e. The fragments, like any deformed cast iron, had an irregular shape measuring 94x140-110x160 and 95x130 mm, with a wall thickness of 3-7 mm. Etching revealed in all sections the cast structure of hypereutectic white cast iron with the structure of ledeburite, primary cementite and a small amount of graphite. The authors explain the reason for the chilling of cast iron by the low silicon content, and the almost complete absence of manganese indicates that the cast iron was smelted without the use of fluxes.

Chemical and spectral analyzes proved that the fragments belonged to the same boiler and were made of ore, apparently a type of brown iron ore, which was often used by ancient metallurgists to obtain iron.

It should be noted that, as an independent branch of industry, foundry separated from metallurgical production only at the end of the 19th - beginning of the 20th centuries with the advent of small furnaces (cupola furnaces) capable of melting metal, providing sufficient overheating and providing molten cast iron with sufficient fluidity and other casting properties. It was then that when casting cast iron they stopped using only the metal of the first melt, and cast iron itself became a widespread structural material. But the foundation for this was laid by the ancient masters of China, Uzbekistan, and Volga Bulgaria.

conclusions

1. Cast iron casting was widespread BC. e. in China, irrefutable evidence of which is the cast iron castings and cast iron molds that still exist to this day.

2. Scythian tribes that inhabited the territory of our country from the 8th century BC. e. until the end of the 2nd century AD. e., they didn’t know iron casting.

3. Ancient chronicles of China provide irrefutable evidence of the use of iron (cast iron) agricultural tools back in the 7th century. BC e.

4. In fact, China began its Iron Age not by mining raw iron and forging products from it, but by smelting cast iron and making cast iron castings. This is one of the features of the original development of Chinese foundry production.

5. The main reason that the Chinese were the first in the world and more than 1500 years earlier than the Europeans to learn how to mine ores, smelt iron and make iron castings is the remarkable success of the Chinese in the field of bronze smelting and the construction of furnaces by the time iron appeared.

rusnauka.com

Iron casting technology

The technology of cast iron casting was first mastered in China around the 10th century AD; in Europe it was first mentioned in the 14th century as a material for the production of cannons. In Russia, the first “iron casting suitable for making cannons” dates back to the era of Ivan IV Rurikovich. The heyday of the cast iron era came in the 19th and 20th centuries. At this time, bridges and pipelines, lanterns and fences, elements of architectural decor and load-bearing structures of buildings were made from it. In addition, rails, parts of machine tools, and engines were cast from the same material. Separately, it is worth mentioning cast iron cookware, irons and heating appliances.

Cast iron castings

Cast iron castings come in different sizes - from small parts to multi-meter beds of large machine tools. Their configuration can also be very diverse - from simple bushings to sophisticated cast grilles and gates.

Iron castings are also divided into:

- by purpose - general and special, such as anti-friction, heat-resistant, etc.

- according to the structure of the material - ferritic, perritic and mixed

- According to the type of graphite contained - into spherical, lamellar, flake and vermicular

- According to carbon content - white, gray and bleached

In metallurgical science, there are other classifications of cast iron castings.

Foundry production of gray cast iron castings, mechanical processing

One of the most famous types of alloy is the so-called gray cast iron.

In addition to the traditional main components - iron and carbon - it also contains plate-shaped graphite. Thanks to it, the fractured material acquires a characteristic gray color. The carbon content in this cast iron reaches a minimum of 2.4, maximum of 4.2%. It is the inclusion volume that determines the mechanical characteristics of the alloy, which the cast iron foundry must take into account. Due to its high fluidity, gray cast iron is suitable for casting products of complex shapes. It is relatively cheap and has an aesthetic appearance. Low wear allows it to be used in the assembly of components and mechanisms. But the material also has the disadvantage of low bending strength, and therefore increased fragility. True, this minus is compensated by high compressive strength.

The brittleness of the alloy places increased demands on its mechanical processing. For a long time, welding was considered impossible for gray cast iron. However, technologies have emerged that still make it possible to make permanent welded joints from it. This becomes possible if the workpiece is preheated.

Classification of cast irons

Types of cast iron are classified according to different parameters. Taking into account the purpose and chemical composition, cast irons are distinguished:

- high-strength, capable of replacing steel. Made from gray cast iron and special additives;

- malleable. They are obtained from white cast iron through a heat treatment process. They have high ductility, resistance to stretching and impact loads;

- alloyed. Contains nickel, titanium, sulfur, chromium. They are distinguished by strength and durability. Used to make machine parts;

- special. Contain increased amounts of manganese and silicon. Used for melting steel and removing harmful impurities.

Cast iron foundry