Aluminum and aluminum alloys are often used in production and in everyday life. This material is different in that. Which is light in weight, resistant to corrosion, and also has an aesthetically attractive appearance. In addition to these qualities, the metal also has one drawback, which creates some difficulties during processing. Aluminum is a fairly soft metal, so when cutting it is important to know what tools can be used to work with it and what kind of aluminum cutting disc is needed.

Choosing aluminum wheels for an angle grinder

When making independent repairs in an apartment or house, most people are often faced with the need to cut various types of metal structures. In order to accurately carry out these works, it is necessary not only to select and buy the tool itself, but also to choose the right cutting wheel. After all, not every metal can be cut quickly and evenly with a universal nozzle. Choosing aluminum wheels for an angle grinder correctly.

What and how to cut aluminum products correctly

Such circles are similar to those that are used for circular cutting, and soft metals are processed through soldering.

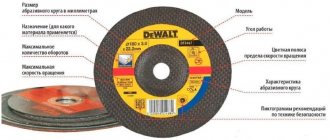

In order to choose the right cutting wheel for processing aluminum, it is important to look not only at the design of the product, but also its dimensions and thickness. The quality and convenience of work depends on the correct choice of cutting wheel.

It is worth understanding that not only the operating time, but also the quality of the processed material depends on the correct choice of tool.

Aluminum products are used in various fields of industry and agricultural activities. Aluminum products are used to make greenhouses, vineyards, support structures and much more. The right tool for the job will ensure convenience and comfort when processing and cutting aluminum.

Features of aluminum processing

Cutting soft metals raises many questions among ordinary people. In particular - aluminum. To process such material, there is a wide variety of sawing attachments that have different diameters. They also produce wheels for grinding aluminum. The description of cutting wheels for an angle grinder must begin with their sizes. Thus, the outer diameter of such products varies from 125 mm to 230 mm. The thickness of the cutting attachments ranges from 1 to 3.2 mm. As a rule, a larger disc diameter corresponds to a larger width. As for circles of small diameter, their thickness can be any, depending on the purpose.

If we talk about aluminum, then for its processing we use circles with a thickness of about 1 mm. This choice is explained by the fusibility of this metal. When working with a thick nozzle, aluminum becomes viscous from friction and begins to clog the abrasive wheel with its particles. In such a situation, the disc simply stops cutting.

As for the configuration and coating of the cutting part, most often wheels for aluminum have a fine diamond coating and a cutting edge in the form of several sectors. Essentially, this is a saw blade for concrete. It is convenient for them to carry out work on cutting aluminum structures. For example, cutting a profile. The diameter of such a disk has a minimum value, that is, 12.5 cm.

Circles with a maximum diameter of 23 cm are most often multifunctional and cut not only metals, but also concrete, plastic pipes and even wood with nails.

It must be said that it is almost impossible to understand the exact purpose of such an attachment just by appearance. Therefore, when purchasing, it is best to consult with the seller or study the characteristics indicated on the disc itself.

How to properly cut a metal corner with a grinder

You cannot start cutting metal with a grinder without obtaining the appropriate knowledge and some skills. The most important danger is the possibility of the cutting wheel jamming in the cutting zone and its subsequent destruction. When carrying out work, the grinder must be held firmly with both hands. You need to carry out the cutting strictly from yourself. The depth of the cut is determined by the diameter of the disc.

Cutting a metal corner has some nuances:

- It is easier to cut a large corner (more than 60 mm) together with a partner. In a workshop, the workpiece is clamped in a bench vice or fixed with clamps on a fixed base. The corner is laid on the surface of the supporting structure (table, box, etc.) so that the cut edge hangs down, and its other part lies completely on the surface of the support. An assistant should press the workpiece and slightly pull it away from you to prevent the disc from biting. Cutting begins from the edge, moving towards the rib.

- Cutting corners with smaller dimensions (up to 60 mm) can be carried out without the help of outsiders. The material to be cut is laid out supported on both shelves (edge up). The detachable part must be suspended and not touch the ground or floor. The remaining part is pressed down with the left foot (in the absence of rigid fixation) in order to hold the grinder with both hands. Cutting should begin from the edge, gradually going down and going deeper into the areas of the corner.

If the correct metal cutting technology is followed, the separated fragment will fall down under its own weight, thereby increasing the width of the cutting zone. The likelihood of disk jamming is minimized.

Selecting a grinding wheel

On the construction market you can see a wide variety of special wheels for various types of grinding and polishing with an angle grinder. Such nozzles are distinguished primarily by the type of coating:

- from sandpaper;

- from a sponge;

- fabric;

- with felt.

In addition to the abrasive coating on the wheel, various pastes with abrasive inclusions are used for grinding metal surfaces. Their use depends on how smooth the surface is planned to be. In order to perform rough sanding of aluminum, craftsmen use sanding attachments with large grains. The structure of the grinding wheel should not be dense (with a small number of grains per unit volume of the attachment). Such work results in a rather rough surface that requires cleaner grinding and polishing.

For fine and precise sanding, sponge wheels are suitable and can be used together with fine-grained pastes. After them, you can polish using replaceable felt or fabric covers, which are attached to a special attachment for an angle grinder. In this case, a paste with minimal grain sizes is used. When choosing a nozzle, the manufacturer's brand is also important. Products, the quality of which there is no doubt, are produced mainly by well-known companies, such as:

If the manufacturer is little known, then there is always the risk of purchasing a low-quality product with poor reinforcement or even without it. Working with such attachments is hazardous to health.

Why should you contact us?

We treat all clients with respect and carry out tasks of any size equally scrupulously.

Our production facilities allow us to process various materials:

- non-ferrous metals;

- cast iron;

- stainless steel.

In order to bring the workpiece closer to the sketch submitted by the customer, our specialists use universal equipment designed for jewelry sharpening of tools for particularly complex operations. In our production workshops, metal becomes a plastic material from which any workpiece can be made.

The advantage of contacting our specialists is their compliance with GOST and all technological standards. Strict quality control is carried out at every stage of work, so we guarantee our customers a conscientiously completed product.

Thanks to the experience of our craftsmen, the output is an exemplary product that meets the most demanding requirements. At the same time, we start from a strong material base and focus on innovative technological developments.

We work with customers from all regions of Russia. If you want to place an order for metalworking, our managers are ready to listen to all the conditions. If necessary, the client is provided with free specialized consultation.

Cutting Features

In addition to choosing a wheel, when working with soft metals, it is necessary to take into account their characteristics and features. Through cuts in aluminum structures are not made in one go. This is explained by the formation of hardening on the cutting teeth. Because of them, the nozzle gets stuck in the slot. Therefore, the work is performed in several approaches. In this case, the wheel must not be allowed to skew, which is most important for working with disks with a maximum diameter of 230 mm.

If the thickness of the aluminum is significant, you can sprinkle a small amount of kerosene on the cutting area. But you shouldn’t expect high quality cutting.

Why is it dangerous to cut aluminum with a grinder?

Cutting aluminum is not only difficult, but also NOT safe! Especially when using a high-power grinder. Due to the viscosity of aluminum, the disc will get stuck, and the tool will try to pull out of your hands.

And this will NOT happen immediately, but only when the cut reaches a certain depth. And this may come as a surprise to an inexperienced tool user. And in general, cutting with a disk stuck in the metal will not be easy.

A short story about how I had to cut an aluminum tank. And what came of it

One of my friends once had some work done and needed to cut an aluminum tank with a grinder. “No big deal,” he thought— is gathering dust , there’s nothing easier!

But his joy quickly disappeared when he got down to business.

READ Made from a Hand Circular Saw

The disk constantly got stuck, stuck in this metal. The Bulgarian woman tried to jump out of her hands. The dust was equal to the torment, things went very slowly. Various abusive thoughts did NOT leave my head. )))

So what to do? I got to work - I need to do it! So several hours of hard work passed. An old man passing by came to the rescue.

Seeing the torment, he began to try to give advice, but advice is sometimes difficult to accept, especially when his nerves are already at their limit. After all, the work, which seemed simple at first, was already pretty exhausting. Therefore, the first reaction to advice is the desire to send it somewhere further.

Nevertheless, the advice was given and in the end, as the friend said, he followed it. Imagine his surprise when after that things went much more fun.

Safety

The grinder is an electric cutting tool that requires special attention when working with it. So, before changing the cutting or grinding attachment, you need to make sure that the equipment is unplugged. If the plug is plugged in, there is always a risk of injury from accidentally pressing the start button.

When cutting and grinding soft materials such as aluminum, you must be aware of its toughness. To carry out the work, do not neglect the rules for using cutting wheels. Thus, excessive wheel width can cause overheating of the metal and, as a result, jamming of the disks or their slipping. This ultimately leads to injury.

It is also necessary to remember about the internal diameter of the wheels for angle grinders. It must exactly match the diameter of the machine shaft. A larger diameter will cause the cutting attachment to become unbalanced and run unevenly. Performing work in this mode will most likely cause the disc to split, despite its reinforced coating, which can also lead to serious injury.

What was the tip that helped you cut an aluminum tank easily?

The advice was as follows: The cut area needs to be lubricated. For example, used automobile oil is quite suitable for this purpose. A little processing, and the work begins to boil. The disc did NOT get stuck, the aluminum was cut with a bang. So, a simple trick from an experienced person helped save both nerves and strength. And perhaps health, since the angle grinder no longer gets stuck in the aluminum and tries to escape from your hands. You yourself understand the dangers of such a situation when working with this tool. Don't believe me? Talk to the surgeon, they will tell you.

Circular Saw

- allows you to cut larger workpieces (up to 130x65 mm);

- compactness;

- possibility of angular cutting;

- high speed and accuracy of work;

- accessibility of equipment (saw blade 300 mm).

- high cost (average installation costs 40-50 thousand rubles)

- NOT compact and lightweight.

Choosing aluminum wheels for an angle grinder

An angle grinder (“grinder”, or angle grinder) is a multifunctional tool. It can be used to cut metal, concrete, brick, tile, plastic and wood; grind, clean, polish, remove paint and rust; use as a sharpening machine. Different jobs require different equipment. Let's figure out what kind of discs and attachments there are for angle grinders.

Features of aluminum cutting discs

Special blades for cutting aluminum are produced by only a limited number of manufacturers; the rest usually indicate a broader purpose in the type of material, for example, “for working on non-ferrous metals.” In general, cutting aluminum with a grinder makes sense only for some one-time work. And for large volumes of aluminum workpieces, cutting and cutting machines with special saw blades for aluminum are much better suited. In the photo below: a disc for working on aluminum from Metabo

Pay attention to the marking of the hardness class (O means “medium hard”) and compare with the marking of the Luga disk

Which are the best manufacturers?

Unlike other consumables, saw blades do not have strict standards. The quality and functionality of products is determined by the manufacturer. The most popular brands producing saw blades: CMT, FLAI, BOSH, Makita, Karnasch, Evolution, Ataka, DeWalt, Leitz, Freud. Products made in China are not trustworthy. First of all, the products differ in the quality of welding of the carbide plates to the disk body itself.

DIMENSIONS

Each angle grinder is designed to accommodate discs of a specific outer diameter. The depth of cut or the area of the ground surface depends on this parameter.

- 115 mm - cutting depth 20-30 mm

- 125 mm - cutting depth 30-40 mm

- 180 mm - cutting depth 50 mm

- 230 mm - cutting depth 50-60 mm

There are two more standard diameters: 180 mm and 400 mm. However, they are rarely used.

Always install an attachment of the appropriate diameter on your angle grinder and find out the permissible maximum rotation speed of the disc before starting work. Usually it's written right on it. The larger the diameter of the disk, the lower the number of revolutions it is designed for. Do not exceed the RPM, otherwise the disc may break, fly apart, and injure you and others. In addition, when installing a large disk, you will have to remove the protective cover, which is also unsafe.

The diameter of the internal hole of the disk has a standard size of 22.2 mm. There is no need to worry about this value, it is the same for everyone.

Before starting work, find out the permissible maximum disk rotation speed.

Plasma and laser machines

The best method in terms of quality and speed, but not suitable for home use. Plasma cutters and laser machines are considered professional equipment and are found in metallurgical enterprises. If there is an installation nearby and cutting an aluminum profile on it is possible, it’s worth taking advantage of. Advantages:

- cutting the profile takes a couple of minutes;

- the user only configures the equipment, the rest is done by the machine;

- the quality of the cut is the best of all methods.

Flaws:

- the cost of equipment amounts to millions of rubles;

- inability to use at home or in the garage;

- noise during operation.

VIEW Plasma cutting machines for aluminum on AliExpress →

CUTTING DISCS

Cutting material is one of the main functions of an angle grinder. There are special cutting discs for this. They were invented to quickly and accurately cut material with a compact device and do it anywhere. Angle grinders + cutting discs mean mobility, ease of use and accessibility.

You need to work the same way as a saw. You turn on the grinder, lightly press the product and after a few seconds it is cut! However, unlike a saw, cutting with a cutting disc is essentially the same as grinding. Therefore, the overall length of the product decreases as you remove material from a certain point. If you take a grinder with a diameter of a couple of millimeters and grind the same place for a long time, you will get the same result.

Thinness is a characteristic feature of cutting discs. They resemble DVDs. Their thinness gives them the ability to cut products from any material so easily. They are much thinner than all other types of discs for angle grinders.

The thinner the cutting disc, the more dangerous it is. Thin discs bend easily and break more easily. If you work at a workbench with a workpiece clamped in a vise, a thin disk is what you need. But if you are, for example, under a car in an awkward position, it is better to take a thicker disk (from 3 mm), which will not break if you accidentally move or lose your balance.

Using a grinder, you can cut almost any material: metal, concrete, stone, brick, ceramic tiles and wood. For each material there is a separate type of cutting discs.

How to cut (sharpen) tiles at a 45 degree angle?

Everyone calls this action differently: washed away, pointed, trimmed, burrs, Kremlin corner. There is only one meaning.

To properly cut the end portion of a tile at a 45 degree angle, you will need an electric tile cutter (tile cutting machine) or, as a last resort, a grinder (tips) with a disc on the tile.

The easiest way. This is a mill

It is more difficult to achieve a high-quality result with a crusher, but, in principle, this is also possible. This is the easiest way to sharpen a 45 degree tile corner yourself at home.

The process of grinding and grinding porcelain in the video below.

First of all, you must have a good diamond tile disc.

Place the tile along the edge (perpendicular to the workpiece) and sand its back (clay) at a 45 degree angle.

If it turns out to be a little uneven, you can go through the large uneven burrs of the disc again, and to get a cleaner, smoother edge, you can use this (pictured below) sanding attachment with sandpaper or a turtle diamond.

The Velcro sanding wheels are erasable. New ones are removed and attached. The base itself with Velcro is wound onto the thread of the coffee grinder. Diamond nozzles have a much longer lifespan, but they are also many times more expensive. If you're constantly laying tile, it makes sense to get diamond turtles. If you are doing the first and last renovation in your life, it is quite possible to do it with the help of sanding wheels.

When working with something like this you need a variable speed sander (at least speed!) otherwise the edge of the tile will melt and burn rather than pop.

You can buy wonderful “shells” here!

Electric tile cutter

Electric tile cutter, or, as it is also called, tile. Wet cutter. It has a water-cooled disk, and this same water extinguishes all possible dust. The tile cutter cuts along one clear, fixed path and minimizes human error such as shaking hands and so on.

READ How to cut plastic skirting boards at home

The tile cutter has two working positions. Flat cut and 45° cut (actually you can set any angle from 0 to 45°, but this often doesn't make sense).

Cutting discs for metal

If you are patient, you can cut the metal with a hacksaw. But if you need a quick solution, nothing beats an angle grinder for speed. Metal cutting discs will do the job well and quickly. They are used for cutting rebar, bolts, iron fences, thin and thick sheet metal.

Metal discs are made of aluminum oxide. They are inexpensive, but it is better to buy a pack at once, as they wear out quickly. Usually have a blue color.

Methods for cutting aluminum profiles

Conventionally, all methods are divided into two groups:

- cutting with compact manual or electric equipment;

- cutting with special devices (portable or stationary).

READ How to Sawing at a 45 Angle

The first group includes the following tools:

- hacksaws for metal;

- metal scissors;

- jigsaws;

- Bulgarians.

- plasma, laser, milling installations;

- various saws.

Now it’s worth studying the features of each method, advantages and disadvantages, and then draw a conclusion about the best method for cutting aluminum profiles.

Features of aluminum processing

Cutting soft metals raises many questions among ordinary people. In particular - aluminum. To process such material, there is a wide variety of sawing attachments that have different diameters. They also produce wheels for grinding aluminum. The description of cutting wheels for an angle grinder must begin with their sizes. Thus, the outer diameter of such products varies from 125 mm to 230 mm. The thickness of the cutting attachments ranges from 1 to 3.2 mm. As a rule, a larger disc diameter corresponds to a larger width. As for circles of small diameter, their thickness can be any, depending on the purpose.

How can you cut aluminum?

Aluminum processing depends on the thickness of the sheet and whether the volume of work is large. So if there is not much work, the material is NOT too thick, then you can get by with hand tools. But if, even with thin aluminum, it is necessary to make a large number of cuts or carry out similar work regularly, then it makes sense to purchase more serious equipment. It also plays a role whether the cut will be small and in a straight line or whether you are interested in cutting large sheets along curves.

Depending on the thickness of the metal, aluminum can be cut either with metal scissors, electric shears or a hacksaw, or with a jigsaw or grinder with a special wheel for aluminum and copper, a guillotine or a router. Miter saws and plunge-cut saws work well. A circular saw will take a thin profile, but you need a diamond blade designed for metal, as well as protection from chips, since such work is not provided for this type of saw (so that neither the master nor the drive is injured). As a rule, circular saws come with special blades for this metal.

Another method is processing with a forge chisel, after which you should take the metal for a break. There are special attachments for the drill that can handle aluminum up to 2 mm. It is good to work with a plasma cutter or perform laser cutting, but this equipment is expensive, so it is purchased mainly by professionals who are constantly engaged in such work. However, sometimes it makes sense to turn to them for cutting.

When cutting aluminum with a grinder, you should NOT cut deep, as the softness of the metal causes the circle to simply get stuck in it, and hardening occurs on the teeth. You can even make the cut NOT right away, but first go several times along the outside, rather than cutting all the way through. Cutting aluminum should be done slowly, avoid distortions. Be sure to wear personal protective equipment, at least goggles and gloves. The process is quite noisy, of course, if it is not used with a plasma cutter. Long cuts are made in a straight line under a ruler, but smooth curves are most often made using a template. It is quite difficult to make an even long cut with a hand tool.

If you use a hand saw, jigsaw, cutters and circular saws, it is recommended to drip machine oil, kerosene, alcohol onto the cut site, or cool the metal in this place (you can even use compressed air), which allows the tool to move more freely, without the formation of large “hardening” " For the same purpose, it is sometimes recommended to rub the cutting line with ordinary laundry soap, old lard or paraffin.

Sources:

https://jusof.com/mozhno-li-diskom-po-aljuminiju-pilit-derevo/ https://blogvp.ru/rabota-s-bolgarkoj-kak-rezat-alyuminij-bolgarkoj-bezopasno-i-bystro. html https://wikimetall.ru/metalloobrabotka/rezka-alyuminievogo-profilya.html https://www.expertcen.ru/article/qa/5339.html

Wood cutting discs

Designed to work with all types of wood. However, they will be limited only to this material, which is not entirely rational. It is still better to purchase discs for cutting wood that can cut both wood and metal. This is especially useful if you need to cut nails driven into pieces of wood.

How and how to cut an aluminum profile

Details about hand tools and equipment used for cutting aluminum profiles are described in this material.

It is easy to cut thin aluminum sheet, because almost any tool will do the job. But what to do, for example, with an oversized corner or an inconvenient channel? More details about hand tools and equipment used for cutting aluminum profiles are described in this material. The work is complicated by a number of factors, but it is still possible to evenly divide the workpiece.

What you should pay attention to when choosing saw blades for aluminum and metal:

Material for sawing. In terms of their structure, plastic, hard plastic, and aluminum are practically the same, so one type of disc can be used for sawing them. But when making a choice, it is important to know which workpiece you will have to work with - hollow or solid. Typically, manufacturers indicate on the packaging and in the product description which products the saw blade is suitable for working with.

The number of teeth is one of the main factors on which the productivity and quality of the cut depends. The more teeth, the better the cut will be. And, accordingly, the cost of the saw blade increases with the number of teeth. For example, ALU-positive 11.1000 is the best option for high-quality and fast work.

Types and angles of teeth. For high-quality work, you need to choose saws not only with a large number of teeth, but also with their correct location. It is important to pay attention to the angle of inclination. The highest quality cut is obtained at a negative angle of inclination. The positive tilt angle ensures good working speed. But with a small number of teeth, this factor has little effect on performance. Therefore, for a high-quality production process, it is first of all worth paying attention to this factor.

electric jigsaw

- electrical equipment makes the user's work easier;

- quality close to ideal (the product will not have burrs, bevels, or other defects)

- speed of work;

- reusability (if you choose the right saw)

- A jigsaw is cheaper than similar devices for cutting aluminum profiles.

- the workpiece must be securely fixed so that it does not “lead” when using the jigsaw.

a circular saw

Similar to a hand saw, but more powerful. Has the following capabilities:

- performs longitudinal, transverse, oblique cuts;

- can collect dust from any place on the workpiece (not just from the end)

- modern devices prevent overheating by turning off in a timely manner or sending a signal to the operator;

- Users can select the working speed based on the thickness of the workpiece.

- durability of the equipment - a disc for working on metal (preferably on aluminum)

- speed of work;

- maneuverability;

- the ability to cut at an angle of up to 45 degrees;

- cost comparable to more suitable analogues (miter saws for aluminum).

- As a rule, the equipment is bulky and weighs a lot, which complicates the work;

- the price will seem high if the tool is purchased for one-time work;

- ).

SANDING CIRCLES

They are also abrasive or sharpening discs. Their main difference from cutting wheels is their thickness, which is at least 5 mm.

The most common types of grinding wheels are: for metal and for stone. Most often used when working with metal. Needed for rough roughing. Quickly remove a large layer of material. Use them if you want to prepare a product for welding, grind the weld seam or cut points. Cleaning wheels come in different grits. The lower the grit value, the coarser they are intended for processing.

Rough processing usually leaves scratches and burrs on the metal. They can be sanded using a flap disc to make the material smooth and shiny.

When working with a grinding wheel, many sparks are generated that can burn glass, clothing, and skin. So be careful. The smaller the grain, the more spark.

A grinder with a grinding wheel installed on it is an excellent alternative to a sharpening machine. Use it to sharpen the blades of a lawn mower, shovel, hoe, ax and other garden tools.

During sharpening, metal blades quickly heat up and change color. This can make the metal brittle and brittle and damage the blade. To avoid overheating, apply only light pressure and constantly move the angle grinder. Also, keep a bucket of water with a sponge or rag on hand and periodically wet the metal to cool it down. After sharpening with a grinding wheel, you can additionally go over the blade with a grinding disc.

Safety precautions

Safety precautions when cutting with a grinder are a way to protect yourself from injury and injury. Do not neglect the rules, the effectiveness of which has been proven in practice. Mandatory elements when working with an angle grinder are:

- safety glasses (pulling scale out of your eyes is not very pleasant, and no one wants to lose their sight);

- ear protection;

- gloves;

- Tight clothing that covers all parts of the body.

- Never cut metal without a protective cover. A ruptured disc can fly anywhere. In this case, neither glasses nor a mask will save you. Tests have shown that a ruptured disc can penetrate a motorcycle helmet. History remembers many tragic incidents, do not forget about them.

- Position your body so that it is not in line with the disc. Even if it breaks, it will fly past you.

- If you are cutting a metal product that is on the ground, then place the grinder between your widely spaced legs. Example in the photo.

GRINDING DISCS

Used for roughing and finishing processing of metal, wood, plastic and other materials. While the sanding wheel is an abrasive material made from a durable composite, the sanding disc is a combination of an angle grinder and regular sandpaper for efficient and quick sanding. An ideal option if you need to smooth out uneven corners, remove burrs and perform finishing processing after a rough grinding wheel. Also great for removing large amounts of wood.

Recommendations from specialists for certain types of work

Next, we will tell you how to use an angle grinder with various metal products.

Sharpening a chainsaw chain

Photo No. 12: sharpening a chainsaw chain with a grinder

The chain is sharpened on the boom of a chainsaw. For work, use a sharpening disc with a thickness of 2.5 mm. It is necessary to mark the first tooth that you will treat. With proper actions, you can update the chain 4-7 times before it completely fails.

Pipe cutting

Photo No. 13: cutting pipes with a grinder

It is better to start cutting thick metal with a grinder from the edges. If you start from the middle part, the disc may jam and bend. During processing, apply force to the lower part of the cutting tool, which ensures efficient cutting.

Cutting moldings

Photo No. 14: cutting corners with a grinder

To cut metal corners, you can use worn discs or a small diameter tool.

It is important to remember that the work is gradual: first, one part of the molding is cut, then the second

POLISHING RUGS

There are special polishing wheels for polishing paints and other surfaces. They are usually made from felt, textiles or soft polymer materials. For particularly delicate surfaces, it is recommended to use large 230mm angle grinders as they operate at lower speeds.

Thread cutting on aluminum

Internal and external threads on aluminum parts are performed using all conventional machining methods, as well as the rolling method with plastic deformation of the material (Figure 5). The best threads are obtained on thermally hardenable aluminum alloys. Up to a diameter of 6 mm, ordinary taps for steel are used, and for larger diameters, special taps for aluminum are used. Aluminum taps have larger flutes to remove chips.

To make external threads, conventional dies are usually used, as well as plastic rolling methods without the formation of chips.

Figure 5 – Threading in aluminum

SANDING BRUSHES

Sanding brushes are something like a brush that was rounded and put on an angle grinder. An extremely effective product for removing rust and old flaking paint. It can also be used to clean tools and garden equipment from hardened cement and dirt.

In stores, sanding brushes are usually presented either in the form of a wire disk or in the form of a wire bowl. The discs are used for crevices, narrow spaces, corners and hard to reach places. Bowls are great for processing large surfaces.

The wire on sanding brushes can be thin or thick, plain or intertwined. Twisting the wire makes it even stronger. Therefore, if aggressive and rough processing is required, brushes with thick and twisted wire are used. They will make mince out of most coatings, so only use them if you want to completely clean the surface layer. Make sure that the item you will be working with is strong enough, otherwise the wire brush may damage it.

If you want to remove paint from more delicate objects without scratching or damaging parts, use less aggressive nozzles. For example, for removing paint from a motorcycle, a combination of a brush with straight, fine bristles and an abrasive disc made of nylon impregnated with an organosilicon compound is suitable. Cheap alternative to sandblasting.

Selecting a grinding wheel

On the construction market you can see a wide variety of special wheels for various types of grinding and polishing with an angle grinder. Such nozzles are distinguished primarily by the type of coating:

- from sandpaper;

- from a sponge;

- fabric;

- with felt.

In addition to the abrasive coating on the wheel, various pastes with abrasive inclusions are used for grinding metal surfaces. Their use depends on how smooth the surface is planned to be. In order to perform rough sanding of aluminum, craftsmen use sanding attachments with large grains. The structure of the grinding wheel should not be dense (with a small number of grains per unit volume of the attachment). Such work results in a rather rough surface that requires cleaner grinding and polishing.

For fine and precise sanding, sponge wheels are suitable and can be used together with fine-grained pastes. After them, you can polish using replaceable felt or fabric covers, which are attached to a special attachment for an angle grinder. In this case, a paste with minimal grain sizes is used. When choosing a nozzle, the manufacturer's brand is also important. Products, the quality of which there is no doubt, are produced mainly by well-known companies, such as:

If the manufacturer is little known, then there is always the risk of purchasing a low-quality product with poor reinforcement or even without it. Working with such attachments is hazardous to health.

Choosing the required grinder

- Choosing the right grinding machine is an important factor that will influence the further quality of work. The safety of the worker also depends on the right choice. When choosing an angle grinder, you need to focus on the following characteristics: Power of the angle machine.

- Abrasive wheel diameter.

- Grinder weight.

- Machine size.

The light weight of the device simplifies work, and the required size parameters allow you to work in hard-to-reach areas.

When purchasing, many people are afraid to purchase powerful devices, because, in their opinion, they are much more difficult to do the job with. But this is far from true. In construction tools that have low power, the disk may jam. The device cannot withstand heavy loads. As soon as the load becomes less, the machine will be pulled out of your hands, the disc and grinder may be damaged, and there is a possibility that you will suffer serious injury.

For those people who just want to start working with a grinding device, you need to buy an angle grinder, which should fit a 125 mm disc. The power of this construction tool should be approximately 1000 watts, and the spindle should make 10 thousand revolutions per minute. These indicators are excellent for cutting materials such as iron.

The main thing is that the device should be easy to use. The handle of this construction tool should preferably be made of rubber or other material. The material of the handle should be such that you do not feel vibration when working.

There should be special recesses on the handle that are intended for fingers. Grinders that have low power do not have such a handle.

If you feel discomfort while working, you should look for a device of a different model.

Cutting Features

In addition to choosing a wheel, when working with soft metals, it is necessary to take into account their characteristics and features. Through cuts in aluminum structures are not made in one go. This is explained by the formation of hardening on the cutting teeth. Because of them, the nozzle gets stuck in the slot. Therefore, the work is performed in several approaches. In this case, the wheel must not be allowed to skew, which is most important for working with disks with a maximum diameter of 230 mm.

If the thickness of the aluminum is significant, you can sprinkle a small amount of kerosene on the cutting area. But you shouldn’t expect high quality cutting.

Source

Features of plasma cutting of aluminum

Plasma cutting of aluminum is an ideal option to obtain high-quality cuts of non-ferrous metal. In this case, to generate the plasma necessary for processing sheets of aluminum and its alloys, only inactive gases are used: hydrogen, argon or nitrogen.

Active gases, such as air and oxygen, are designed to form plasma for cutting ferrous metal.

It is not recommended to use a gas mixture combining nitrogen and argon for plasma cutting of aluminum, since it is intended for cutting 50 mm high-alloy steel.

But nitrogen in combination with hydrogen will make it possible to process aluminum and its various alloys with a thickness of 100 mm.