The variety of work performed with the help of grinders is largely ensured by the wide range of tools that work with them.

For each standard size angle grinder, you can always select consumables that correspond to the characteristics and dimensions. One of the parameters that determines the capabilities of an angle grinder is the maximum diameter of the disk that is installed on it. It determines the speed, engine power and torque. The choice of disk size is closely related to the nature of the work performed by the grinder.

Types of circles

The circles (disks) of grinders differ according to the following indicators:

- work performed that determines the purpose of the tool;

- composition of the material;

- dimensions.

Technological features

The necessary processing technology is provided by the following consumables.

- — Cutting wheels. Mainly used for processing metals, less often for other types of materials.

- — Grinding wheels. Different designs allow you to perform both roughing or cleaning, and bringing the surface roughness to the desired condition.

- — Polishing discs and attachments. Bring the surface to a shine using felt or other fabric with similar properties.

By material

The operating modes are influenced by the material component from which the tool is made.

- — Abrasive disc. The basis that served for the manufacture of the tool is the abrasive material itself, a binder, for example, bakelite and various fillers. Mainly used for metal processing.

- — Diamond wheel (with diamond coating). With its help, you can process materials of any strength (various types of stone, ceramics, quartz glass and many other similar ones consisting of solid fractions).

Dimensions

The main classification criterion here is the diameter of the disc. The depth of the cut depends on its size (it is approximately a quarter of the diameter). The functionality of an angle grinder is determined by the size of the tool: a small diameter makes it possible to process a light angle grinder in hard-to-reach places, while a larger size angle grinder with greater productivity will be difficult and unsafe to hold “in weight”.

Classification of discs for grinders

Grinder circles can be divided into several types:

- cutting;

- polishing and grinding;

- sharpening;

- peeling.

What materials are used for processing:

metal;- wooden;

- concrete;

- glass.

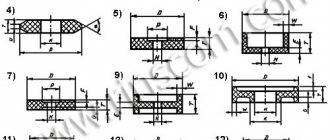

Grinder wheels differ in shape, thickness, diameter and material of manufacture. For simple operations, conventional flat abrasive discs are used. When cutting or grinding in hard-to-reach places, use plate-shaped wheels with recessed fasteners.

Marking

The choice of the right tool is facilitated by the presence of markings. It contains the technical parameters of consumables in encrypted form. For example, this is what an alphanumeric set of markings for a cutting disc looks like, produced by a Russian manufacturer:

- — The image shows the tool manufacturer — Luga Abrasive Plant (Luga, Leningrad Region).

- — Tool name:

- cutting wheel - in Russian;

- cut –off – wheel – in English translation.

- — Purpose: for processing steel (inscriptions “steel”, “steel” on the circle).

- — The dimensions of the circle are indicated (outer diameter x thickness x bore diameter):

- in mm – 200 x 2.5 x 22.23;

- in inches – 8”x 1/10”x 7/8”;

- digital designation "41". This is a characteristic of the design of the circle - here it is flat.

- — The circle is designed for 7650 rpm, while the maximum peripheral speed should not exceed 80 m/s.

- — Technical parameters of the wheel material are determined from the designation “A 30 S BF”, where:

- A – means that the abrasive is based on white electrocorundum, which is specifically used for metal processing;

- 30 – abrasive grain size, here it is average;

- S – hardness of the circle, here the circle is hard;

- BF - denotes the type of bond, here synthetic resins with glass fiber reinforcement.

- — Rules for safe work in the form of signs indicating the required action.

- - GOST 21963 - 2002, GOST R 52588 - 2011, EN 12413 - Russian and European regulatory documents to which this tool complies.

The marking of a foreign manufacturer of tools for angle grinders is as follows:

- — Tools under the NORTON VULKAN brand are produced by the Saint Gobain corporation, headquartered in France.

- —The purpose of the cutting disc (the company produces only such a tool for angle grinders) for processing steel (in addition, for visualization purposes, the label for wheels intended for metal processing is blue) is duplicated in several languages.

- — The circle is designed for 12250 rpm with a maximum peripheral speed of 80 m/s.

- — The dimensions are the same as on the Russian disk - in mm and inches.

- — The digital designation “41” has been added to the technical parameters of “A60S – BF41”. This is a characteristic of the design of the circle - here it is flat.

- — Methods of safe work must be indicated.

- — The regulatory documents to which the instrument complies are issued by the European Union.

TOP 5 best discs for grinders for metal (cutting)

Review and characteristics of the best discs for grinders for metal (cutting).

BOSCH Standard for Metal 2608603165, 125 mm 1 pc.

Cutting disc made from purified aluminum oxide (low iron, chlorine and sulfur) to cut metal with confidence.

A worthy German consumable for cutting high-alloy steels (including 5 mm metal).

Installed on the flange of the grinding machine (with the corresponding indicators).

It has a direct design, dry cutting type (this means that even in conditions without additional liquid cooling, the disc will perform its duties efficiently).

The materials are safe for humans. Fastening type - M14. Country of origin: Germany.

Specifications:

- bore diameter: 22.23 mm;

- thickness: 1.6 mm;

- maximum number of revolutions: 12250 revolutions in 60 seconds;

- packaged weight: 0.040 kg;

- packaging dimensions: 125x125x1 mm.

Advantages

- high level of productivity;

- straight cut;

- Excellent value for money and quality;

- widely spread;

- serves for a long time.

Flaws

- the price is “biting”;

- vibration is felt.

BOSCH Standard for Inox - Rapido 2608603171, 125 mm 1 pc.

The Standard for Inox cutting disc is a reliable choice for working with stainless steel.

Made from aluminum oxide. Ideal for angle grinders of the same brand.

Makes a neat cut of the required depth. The mounting hole corresponds to a nominal value of 22.2 mm.

The shape is straight, the number of revolutions per minute is decent - 12250.

The material does not harm humans. The disc weighs very little - only 0.04 kg, so it does not put a lot of stress on the hand. The birthplace of the brand and place of assembly is Germany.

Specifications:

- thickness: 1 mm;

- diameter: 125 mm;

- length: 125 mm;

- width: 125 mm;

- height: 2 mm.

Advantages

- no sulfur, ferrous and chloride fillers;

- high quality;

- lasts longer than cheaper analogues;

- convenient packaging;

- meet all safety requirements EN 12413.

Flaws

- fragile disk;

- Suitable for steel only;

- the price is higher than similar consumables.

BOSCH Multi Wheel 2608623013, 125 mm 1 pc.

A unique disc for working with plastic, plywood, wood, copper pipes, and drywall.

It cuts wood like butter - quickly and accurately, and the speed does not depend on the species (apricot, acacia, birch, oak - it copes with all of them without any difficulties).

The disc is segmented, the teeth are not clogged with wood chips. Resin can be removed using a regular brush and detergent.

On the surface there is a lot of abrasive mass (carbide chips), securely soldered with a laser.

Anti-vibration slot provides unique cutting speed and prevents blade deformation.

Specifications:

- bore diameter: 22.23 mm;

- thickness: 1 mm;

- purpose: dry cutting;

- maximum number of revolutions: 12250 per minute.

Advantages

- thin cut;

- versatility in use;

- good quality of work;

- does not become rusty;

- inexpensive.

Flaws

- even at low speeds the plastic overheats in the process;

- if you cut nails, it loses abrasive chips;

- Sometimes the cuts turn out crooked.

BOSCH Rapido Multi Construction 2608602385, 125 mm 1 pc.

Another German cutting disc that, like a superman, copes with aluminum, and tin sheets, and brick walls, and with PVV.

Fittings, plastic corners, corrugated sheets, water pipes, mesh, concrete, stone, marble - there is no material to which you can say “stop, it won’t work.”

The chrome remains smooth, without scorch marks, the master does not have to worry about sparks - there are none either.

There are no special requirements for the grinding machine: a regular standard model with the ability to adjust the speed will do (you need medium or slightly higher).

The cuts are made quickly, silently and dust-free. The shape is straight. Specification - C 60 T BF.

Specifications:

- maximum peripheral speed: 80 m/s;

- thickness: 1 mm;

- bore diameter: 22.23 mm;

- highest speed: 12250 rpm.

Advantages

- smooth cuts on any material;

- few sparks;

- versatility;

- high-quality execution;

- does not “catch” the material.

Flaws

- Expensive;

- metal cuts worse than others.

Metabo SP-Novorapid INOX 617168000, 230 mm 1 pc.

A high-quality and reliable cutting wheel, which a hand cutter cannot find better.

The manufacturer is the German company Metabo, which produces and sells professional power tools.

Indispensable in manipulating thin-walled materials: stainless steel, profiles, pipes, sheet metal, wire.

Judging by the reviews on specialized sites, this circle has a considerable service life and high productivity.

It cuts through P65 rails and 80/80 pipes with 3 mm walls with a bang. One copy is included in the package.

Specifications:

- diameter: 230 mm;

- bore diameter: 22.23 mm;

- thickness: 1.9 mm;

- maximum number of revolutions: 6650 in 60 seconds.

Advantages

- inexpensive;

- ergonomic;

- lasts a long time;

- takes up little space;

- affordable.

Flaws

- rarely on sale;

- sometimes the middle is pressed through.

What are the sizes of wheels for angle grinders Bosch, Interskol and more?

Almost all large companies produce grinders covering the maximum number of works - from household to industrial designs. Each type has its own tool size. In addition to the production of angle grinders, such manufacturers (Bosch, Metabo, Interskol and others) have mastered the parallel production of consumables. They select a special composition and standard size of consumables in order to maximize the operating efficiency of the specific model they produce.

Outer and bore diameter, maximum and minimum value

The most popular range of angle grinder sizes consists of the following values.

External diameter . The most preferred sizes are: 115 mm, 125 mm, 150 mm, 180 mm, 200 mm and 230 mm. In rare cases, to perform, for example, jewelry work with small parts, portable battery-powered angle grinders with diameters of 76 mm or 100 mm are used.

The minimum diameter of 115 mm is used for simple work in the form of processing hard-to-reach surfaces in the household. Anglers with a circle with a diameter of 125 mm have greater ability to perform various household works.

The diameter of 230 mm is used in the professional context of angle grinders for large volumes of work, for example, in construction. Circles with a diameter of more than 230 mm are installed on stationary equipment.

Thickness _ Cutting wheels are available in thicknesses from 0.8 mm to 5.0 mm. Moreover, a larger diameter should have a circle with a correspondingly greater thickness.

You should know! A thin disc is easy to cut, but it is also more likely to break.

Landing diameter . The standard mounting diameter for angle grinder consumables is 22.23 mm. In the vast majority of cases, it is the same for all disk sizes. It is rare to find mounting diameters of 10 mm, 13 mm, 16 mm due to the limited use of angle grinders with a diameter smaller than 100 mm. A 32 mm bore diameter is used with circles of 300 mm and larger on stationary equipment.

What features of grinder wheels should you pay attention to when choosing?

There are not many nuances in this matter (choosing household appliances is much more difficult), so study them thoroughly.

- Typical circle sizes. The outer diameter of the disc cannot exceed the maximum permissible values set for your angle grinder. Otherwise, the linear speed of the cutting edge will be constantly exceeded, and this is fraught not only with the destruction of the disk itself, but also with the user receiving significant injuries - after all, the protective casing will have to be removed! In addition, a small unit simply does not have enough power for high-quality work. There are several standard sizes: 115, 125, 150, 180, 230 mm. All the necessary information is printed on the circle (thickness, diameter, maximum rotation speed, etc.).

- Purpose. They are divided into 4 types: cutting, roughing, grinding and sharpening. Cutting discs are suitable for metal work (blue, made from crystalline or synthetic corundum); stone, slate and sand-lime brick (material - silicon cabbage, color - green); diamond (for red brick, concrete, ceramic tiles and porcelain stoneware, made of metal with diamond chips in the form of an abrasive mass); on wood (requiring special safety measures, as they often slip or bounce off). Peelers help remove the old layer of paint and rust (they are made in the form of a bowl with bundles of wire of different thicknesses or a disk). Grinding - assistants in polishing and grinding wood, metal, plastic and other surfaces.

- Material. They can be abrasive and diamond. Diamond ones are used when processing quartz glass, ceramics, quartz and other durable materials; abrasive ones work well with metals.

Reference! Don’t rush to throw away the old grinder you inherited from your father: even if its bore diameter does not coincide with current standards (the modern figure is 22.2 mm), you can buy special adapters and use the device without problems.

For large, medium and small angle grinders

The power classification into small, medium and large is closely related to dimensions and weight. The greater the power, the greater the weight and overall dimensions.

So, for example, grinders with disks of 115 mm - 125 mm and a power of 0.6 kW to 1.2 kW are classified as small equipment.

Angler grinders with discs of 150 mm - 180 mm and a power of up to 2.0 kW belong to the middle class of such equipment.

Professional angle grinders with a power of up to 3.0 kW and a disc diameter of 230 mm conventionally belong to large angle grinders.

For metal, concrete, wood and other materials

To effectively process any material, it is important to choose the right power so that it matches the diameter of the tool and its thickness. In addition, the consumable must have suitable characteristics for processing a specific type of workpiece material.

The main difference between discs for steel, cast iron, and non-ferrous metals is in the composition of the fillers. To process alloy steels, a very strong additive is added to the disc material that can overcome the resistance of alloy steel. When processing non-ferrous metals, on the contrary, a soft filler is added, which works effectively when processing viscous materials.

Disc for aluminum

To process concrete (tiles, paving slabs), diamond discs are used (actually, these are metal circles coated with diamond).

Tile disc

It is not recommended to process wood with an angle grinder due to the high risk of injury. If such a need nevertheless arises, then the best option would be a grinder with a disk with a diameter of 125 mm. As a working tool, special angle grinder discs for wood should be used.

Wood disc

Tips for choosing a disc

Various retail outlets offer a variety of products from different manufacturers. The most popular of them: Yato, Bosch, Stanley, Makita, Kronenflex. Their difference is not only in cost, but also in quality.

Cheap cutting discs usually have low performance characteristics . These are strong vibrations during operation, overcooked edges, and tearing out of the inner ring. When purchasing, you can use the following advice: if it crunches when the disc is slightly bent, then there is a high probability of it quickly grinding down and breaking.

It is necessary to pay attention that hard circles for metal will last longer , but will require increased pressure on the tool when working, while soft ones will cut more efficiently, but will wear off faster. Thin circles are elastic and hold the load better when the tool is distorted. A thick wheel can be used for grinding, and during its operation it will be more convenient to control the correctness of the cut.

It is also important to note: although an angle grinder is a very convenient and necessary tool, it is also a source of potential danger. When operating it, you should not forget about safety precautions and under no circumstances remove the protective casing from the equipment.

How to choose

The main criterion for choosing the disk size will be the nature of the work performed. In the household, these will be circles of smaller diameters; in a production environment, a tool of large diameter (230 mm) is used.

In addition to the dimensional characteristics, you should carefully check the compliance of the disc material with the material of the workpiece being processed.

Another determining factor is the power of the grinder. It is directly related to the weight and overall characteristics of an angle grinder. With approximately the same characteristics, preference should be given to a lighter specimen.

Types of cutting discs

As mentioned above, such discs are available in different sizes and shapes. Flat blades are designed for sawing in easily accessible places. Bowl-shaped discs allow you to make a cut flush with the surface.

The thickness of the disc affects the quality of the cut: the thinner the disc, the more accurate the cut, but it is not advisable to cut a hard surface, for example, cast iron rails, with such a disc. Therefore, for such cases, a disk with a thick base, more than three millimeters, is used.

Circles for metal

The manufacturing technology of cutting discs occurs in several stages. Initially, the resin is mixed with the base substance, due to which cutting occurs. Such substances are usually electrocorundum, cobalt, and diamond. Next, special additives are added to the composition, and the edge of the disk is reinforced with fiberglass mesh. All this is poured into a mold, and a galvanized steel ring is placed in the center. The next step is to place the product in an oven under high pressure for about a day, where it hardens. These types of discs are used for cutting metal products.

Cutting wheels for saws or grinders for metal have standard sizes and are designed for a specific type of tool:

- for use in domestic conditions, cutting discs for grinders 125 and 115 mm are used;

- cutting wheels with sizes 150 and 180 mm are used for semi-professional type;

- for very powerful professional angle grinders use 230 mm.

The inner ring measures 22.2mm. The thickness of the circles varies from 0.8 to 3 mm. This value is directly related to the diameter. Depending on the thickness and type of metal, the thickness of the circle is selected. For example, for cutting thin steel or aluminum, a size of up to 1.5 mm is used. For dense metal products or fittings, a size greater than 2.6 mm should be used.

For concrete and tiles

Such a disk can be made in the same way as for metal or be made entirely of steel. A special feature is the application of diamond chips to the cutting edge of the disc using spraying. Typically, the abrasive size is from 0.2 to 0.8 mm. Such discs are distinguished according to the method of application: for dry or wet cutting.

Disks of the first type are usually divided along the perimeter into strips, to the ends of which diamond teeth are welded by welding. This type of design is resistant to overheating, but it is still not recommended to use such a disk for more than three minutes. The main application is cutting concrete and rock materials.

The second type of disc has a solid appearance. Before starting work, it must be wetted. When making a cutting edge, cobalt and bronze are added to the composition. With the first additive they cut drywall and tiles, and with the second type additive they cut quartz and granite.

Circles are distinguished not only by the markings applied, but also by color. For example:

- blue color - for marble or concrete;

- gray color - for ceramic products;

- green - used when cutting granite;

- yellow color - for plaster and ceramics;

- orange - brick and plaster.

Woodworking discs

Discs for angle grinders for wood are considered the most dangerous. Working with these circles without installed protection is strictly prohibited.

They are made in the form of a circle with a special type of teeth. Wood saw blades are often used from circular saws, although this is unsafe. The danger lies in the fact that such saws have a large number of teeth and are designed for low speeds, which leads to rapid overheating. When such a saw hits a solid obstacle, it becomes very difficult to hold it in your hands. Therefore, when working, it is better to choose wheels with specially made small teeth with a sharp edge. The edge used is coated with tungsten carbide.

A circle with alternating beveled teeth is considered universal . While for species made of soft wood or pine needles, a straight tooth is used. A trapezoidal tooth is already sawing medium-density material.

If the grinder is mounted on a special frame, then it can be used as a simple milling machine. In this case, it is best to use an angle grinder with the ability to regulate speed, this will allow you to set the desired rotation speed of the cutter while processing different materials.

How to replace

The grinder disc is a consumable item. Therefore, it has to be changed frequently. There is a simple algorithm in which an important role is played by the original design of the key supplied to the consumer along with the grinder.

- — The protruding rods of a special key are installed in the grooves of the fastening nut.

- — At the same time, press the lock button located on the gearbox housing. It will lock the rotor from turning.

- — Turn the key counterclockwise to release the fasteners of the worn disk.

- — The old disk is replaced with a new one of the same technical characteristics and size. The new disk is installed with the markings facing out to remind you of the disk parameters and for other good reasons (see explanation in the video above).

- — The fastening nut is first tightened by hand and finally tightened with a special wrench.

The Bulgarian is ready to continue fulfilling its functional purpose.

Where can I buy

You can purchase wheels of various types and sizes from employees of companies that sell spare parts and consumables for grinders. Some component suppliers are presented in the corresponding section of our website.

Sections: Disks

Previous article: How to ring the stator of an angle grinder Next article: Rewinding the stator of an angle grinder with your own hands