Decoding 09G2S

The marking of steel 09G2S indicates the chemical composition of the alloy:

- carbon fraction in the alloy - 09;

- fluctuation in the share of manganese 2% in the total volume of G2;

- share of silicon up to 1% - C.

Additional components are added to the 09G2S alloy: sulfur, chromium, phosphorus, nickel, copper, aluminum, and nitrogen. They are not indicated in the labeling, because the share does not exceed 1% of the alloy volume. The marking of steel does not always correspond to the chemical composition; steel is marked according to its structure, purpose, manufacturing methods, and chemical properties. Sometimes there is confusion in the markings, for example, 09G2S is confused with steel 354. However, 345 is a fluidity marker that has nothing to do with the chemical composition; steel with this marking is intended for use in construction.

Advantages and disadvantages of 09G2S

The only drawback of 09G2S steel is its instability to rust. There are many more advantages:

- strength;

- duration of service life under normal conditions (more than 30 years);

- heat resistance does not lose shape at temperatures from about -70 to 425C;

- no temper fragility;

- good weldability;

- low cost;

- high resistance to mechanical stress;

- undemanding processing.

Susceptibility to rust limits the scope of use of products made from 09G2S steel, but its advantages over other alloys make it the most popular and widespread.

Technological properties of grade 09G2S

Structural steel 09G2S is resistant to flake formation and temper brittleness. Welding 09G2S can be performed by any method without restrictions: manual arc, argon arc submerged arc in a protective environment, argon arc non-consumable electrode and contact welding. In this case, preheating and subsequent heat treatment are not required. The weld seam is not subject to the formation of micropores and the formation of a hardening structure.

Steel 09G2S is ductile and can be easily drawn and cold stamped. Forging of steel 09g2s is carried out at a temperature: beginning - 1250 o C, end - 850 o C.

Application of steel 09G2S

The material is successfully used for the manufacture of wear-resistant building products. These are channels, load-bearing beams, fencing corners and other products. In other industries, indicators such as the temperature range of steel stability are in demand. For example, laying a pipeline in the north of Russia imposes certain requirements on the material used to make pipes. Resistance to low temperatures down to -70 and efficiency of 09G2S steel is an ideal combination for laying communications that are costly in terms of quantity of material and exposed to low temperatures, including pipelines. 09G2S steel is popular in the automotive industry and in the chemical industry due to its resistance to chemical and biological influences, as well as its high strength of bolt fastening of products.

Features of welding steel 09G2S

Steel 09G2S is easy to weld; this property is ensured by the low carbon content in the alloy. There are no heating requirements; you can cook without preliminary heat treatment; this does not affect the strength of the seam. There are any welding methods and equipment; you can weld with a gas torch or an electric arc under a submerged arc. Steel products do not require hardening before or after welding and do not overheat during welding, so the grain size and ductility of the material do not change. Because 09G2S is a low-alloy low-carbon alloy; when welding it is necessary to use various electrodes for the appropriate purpose.

Physical properties

Structural steel 09G2S has a high ability to maintain its characteristics when operating under pressure over a wide temperature range, is durable, resistant to loads with a variable force vector, and is also subject to heat treatment, which has a significant impact on mechanical properties.

The linear expansion coefficient (LEC), which describes the ability of alloys to maintain their volume with increasing temperature at a constant pressure, changes by only 2.4 × 10-6 units when the temperature changes from 100 ºС to 500 ºС (1.14 × 10-5 at 100 ºС versus 1.38×10-5 at 500 ºС). A visual description of the linear expansion characteristics is given below:

| Testing temperature, ºС | 100 | 200 | 300 | 400 | 500 |

| CLR value, 10-5 1/ ºС | 1,14 | 1,22 | 1,26 | 1,32 | 1,38 |

Despite the fact that 09G2S steel is low-alloy, it does not exhibit such a property as flake sensitivity. The low presence of carbon in the alloy provides a satisfactory indicator of the weldability of parts made of steel of this grade. It should be noted that the high carbon content in alloys when it burns out leads to the appearance of additional micropores, as well as to the formation of a hardening structure, which negatively affects the quality of the weld, but this is not observed in 09G2S steel.

Change in the microstructure of steel 09G2S depending on temperature

Welding of 09G2S steel is not demanding on the type of electrodes and can be carried out using welding methods such as manual arc, electroslag, automatic submerged arc welding and with gas protection. The 09G2S alloy has no restrictions on the weldability of the material, and rolled sheet parts with a cross-section of up to 40 mm can be welded without preliminary cutting of the edges. Parts prepared for welding do not require additional chemical or heat treatment. The migration of alloying elements over the entire cross-section of the weld ensures its high strength characteristics and, at the same time, good technical indicators of impact strength.

To reduce the signs of a hardening structure that inevitably forms during welding, the welded product should be subjected to high-temperature tempering with a heating temperature of 600 to 660 ºС. Cooling of the product should be slow, with the oven, which will help avoid warping of its individual parts. It is allowed not to carry out heat treatment of parts that have undergone welding and have a cross-sectional thickness of up to 36 mm.

Characteristics of steel 09G2S

Steel 09G2S can be forged in the temperature range 850-1250C. Depending on heating, steel has a yield strength in the range of 255-155 MPa. Does not lose ductility during welding. In the temperature range of 100-500C, the change in the linear expansion coefficient is 2.4X10-6 units. Operating temperatures range from -70 to +425C.

Supply

| B22 – Long and shaped rolled products | GOST 8281-80; GOST 2591-2006; GOST 26020-83; GOST 8509-93; GOST 8510-86; GOST 8239-89; GOST 8240-97; GOST 8278-83; GOST 8283-93; GOST 2590-2006; GOST 21026-75; GOST 25577-83; GOST 11474-76; GOST 14635-93; GOST 13229-78; GOST 19425-74; GOST 19771-93; GOST 19772-93; GOST 9234-74; GOST 8282-83; |

| B23 - Sheets and strips | GOST 103-2006; GOST 17066-94; GOST 19903-74; GOST 5520-79; GOST 82-70; |

| B33 - Sheets and strips | GOST 19282-73; GOST 10885-85; |

| B62 — Steel pipes and connecting parts for them | GOST 9567-75; GOST 24950-81; GOST 10705-80; GOST 30564-98; GOST 30563-98; GOST 20295-85; GOST 8731-87; GOST 8732-78; GOST 53383-2009; |

Chemical composition

The definition of 09G2S steel as low-alloy means that the content of alloying additives in the chemical composition of the alloy is minimal. As the percentage of an element or additive increases, the steel marking changes. This marking defines 09G2S steel as silicon-manganese, which means that the remaining additives in total do not exceed 1-2% of the total volume of the alloy.

Chemical composition in % of material 09G2S

GOST 19281 - 2014

| C | Si | Mn | Ni | S | P | Cr | V | N | Cu | As |

| up to 0.12 | 0.5 — 0.8 | 1.3 — 1.7 | up to 0.3 | up to 0.035 | up to 0.03 | up to 0.3 | up to 0.12 | up to 0.008 | up to 0.3 | up to 0.08 |

| Note: Steel must be deoxidized Al=0.02-0.06%. Also chem. the composition is specified in GOST 5520 - 79, GOST 19282-73 |

The temperature of the critical points of the material is 09G2S.

| Ac1= 725 , Ac3(Acm) = 860 , Ar3(Arcm) = 780 , Ar1= 625 |

Impact strength

Impact strength shows how a product behaves under shock or dynamic loads and is one of the key technical characteristics of the alloy. It strongly depends on the heating or cooling temperature, so the table shows temperature values.

Impact strength, KCU, J/cm2

| Delivery condition, heat treatment | +20 | -40 | -70 |

| GOST 19281-73. Long and shaped rolled products with a cross section of 5-10 mm. | 64 | 39 | 34 |

| GOST 19281-73. Long and shaped rolled products with a cross section of 10-20 mm. | 59 | 34 | 29 |

| GOST 19281-73. Long and shaped rolled products with a cross-section of 20-100 mm. | 59 | 34 | |

| GOST 19282-73. Sheets and strips with a cross section of 5-10 mm. | 64 | 39 | 34 |

| GOST 19282-73. Sheets and strips with a cross section of 10-160 mm. | 59 | 34 | 29 |

| GOST 19282-73. Sheets after hardening, tempering (Transverse samples) with a cross section of 10-60 mm | 49 | 29 |

Impact strength standards KCV , J/cm 2*

| Strength class | At a temperature of 20 C | At a temperature of 0 C |

| 325 | >34 | >34 |

| 345 | >40 | >40 |

*only for long and shaped steel

Endurance limit

The endurance limit indicator is the value of the maximum pressure in the cycle at which the steel does not fail due to metal fatigue. The number of cyclic loads can be indefinitely large.

| σ-1, MPa | σB, MPa |

| 235 | 475 |

Yield strength of steel 09G2S

The yield strength shows how much stress must be created in order for the steel to continue to deform while maintaining the load. The indicator varies depending on the content of alloying additives and carbon. Silicon and manganese do not affect the fluidity of steel.

| Test temperature, °C / σ0.2 | |||

| 250 | 300 | 350 | 400 |

| 225 | 195 | 175 | 155 |

Hardenability of steel 09G2S

What depth of hardened layer can be obtained by calcining a product? This question is answered by the hardenability indicator. The carbon content in the alloy has the greatest influence on hardenability.

| Distance from the end, mm / HRC e | |||||||||

| 1.3 | 3 | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 42 |

| 52.0 | 52.0 | 51.5 | 49.5 | 48.5 | 45.5 | 44.0 | 43.5 | 43.5 | |

| Critical diameter in water, mm | Critical diameter in oil, mm |

| 70 | 45 |

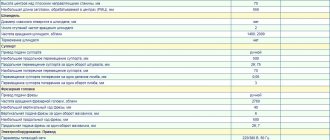

Technological properties of steel 09G2S

The main technological properties of steel include:

- Weldability determines the quality and strength of welded joints;

- flake sensitivity - the susceptibility of steel to flocs, structural defects caused by high hydrogen content;

- tendency to temper brittleness tendency to decrease impact strength after high tempering with slow cooling.

Technological properties of material 09G2S.

| Weldability: | no limits. |

| Flock Sensitivity: | not sensitive. |

| Tendency to temper brittleness: | not inclined. |

Grade 09G2S - low viscosity, J/cm 2

| Assortment | Size, mm | KCU at temperatures | ||

| -70 oС | -40 oС | +20 oС | ||

| Rental | 5-10 | 34 | 39 | 64 |

| 10-20 | 29 | 34 | 59 | |

| 20-32 | 34 | 59 | ||

| Sheets and strips | 5-10 | 34 | 39 | 64 |

| 10-160 | 29 | 34 | 59 | |

| After quenching and tempering | 10-60 | 29 | 49 | |

Mechanical properties of steel 09G2S

Information about the mechanical properties of steel is indicated for certain temperatures, because metal changes its properties when heated/cooled. These include strength, hardness, ductility, and impact strength.

Mechanical properties at T=20oC of material 09G2S.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Heat treatment |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Sheet, GOST 5520-79 | 430-490 | 265-345 | 21 | 590-640 | ||||

| Pipes, GOST 10705-80 | 490 | 343 | 20 | |||||

| Grade, Strength class 265, GOST 19281-2014 | up to 250 | 430 | 265 | 21 |

Mechanical properties at elevated temperatures

| test t, °C | σ0.2, MPa | σB, MPa | δ5, % | ψ, % |

| Normalization 930-950 °C | ||||

| 20 | 300 | 460 | 31 | 63 |

| 300 | 220 | 420 | 25 | 56 |

| 475 | 180 | 360 | 34 | 67 |

Mechanical properties depending on tempering temperature

| holiday t, °С | σ0.2, MPa | σB, MPa | δ5, % | ψ, % |

| Sheets 34 mm thick in delivery condition HB 112-127 (transverse samples) | ||||

| 20 | 295 | 405 | 30 | 66 |

| 100 | 270 | 415 | 29 | 68 |

| 200 | 265 | 430 | ||

| 300 | 220 | 435 | ||

| 400 | 205 | 410 | 27 | 63 |

| 500 | 185 | 315 | 63 | |

Properties according to GOST 14249 standard

| Assortment | Temperature of the wall of a vessel or apparatus, o C | Temporary tensile strength σ B ,MPa (kgf/cm2) | Yield strength for permanent deformation, Re MPa (kgf/cm2) |

| For wall thicknesses up to 32 mm | |||

| Vessel, apparatus | 20 | 470 (4700) | 300 (3000) |

| Vessel, apparatus | 100 | 425 (4250) | 265,5 (2655) |

| Vessel, apparatus | 150 | 430 (4300) | 256,5 (2565) |

| Vessel, apparatus | 200 | 439 (4390) | 247,5 (2475) |

| Vessel, apparatus | 250 | 444 (4440) | 243 (2430) |

| Vessel, apparatus | 300 | 445 (4450) | 226,5 (2265) |

| Vessel, apparatus | 350 | 441 (4410) | 210 (2100) |

| Vessel, apparatus | 375 | 425 (4250) | 199,5 (1995) |

| Vessel, apparatus | 400 | — | 183 (1830) |

| With a wall thickness of more than 32 mm | |||

| Vessel, apparatus | 20 | 440 (4400) | 280 (2800) |

| Vessel, apparatus | 100 | 385 (3850) | 240 (2400) |

| Vessel, apparatus | 150 | 430 (4300) | 231 (2310) |

| Vessel, apparatus | 200 | 439 (4390) | 222 (2220) |

| Vessel, apparatus | 250 | 444 (4440) | 218 (2180) |

| Vessel, apparatus | 300 | 445 (4450) | 201 (2010) |

| Vessel, apparatus | 350 | 441 (4410) | 185 (1850) |

| Vessel, apparatus | 375 | 425 (4250) | 174 (1740) |

| Vessel, apparatus | 400 | — | 158 (1580) |

| Vessel, apparatus | 410 | — | 156 (1560) |

| Vessel, apparatus | 420 | — | 138 (1380) |

Allowable tensile stress, σ, MPa (kgf/cm2) at temperature, o C*

| +20 | +100 | +150 | +200 | +250 | +300 | +350 | +375 | +400 | +410 | +420 | +430 | +440 | +450 | +460 | +470 | +480 |

| For wall thicknesses up to 32 mm | ||||||||||||||||

| 196 (1960) | 177 (1770) | 171 (1710) | 165 (1650) | 162 (1620) | 151 (1510) | 140 (1400) | 133 (1330) | 122 (1220) | 104 (1040) | 92 (920) | 86 (860) | 78 (780) | 71 (710) | 64 (640) | 56 (560) | 53 (530) |

| With a wall thickness of more than 32 mm | ||||||||||||||||

| 183 (1830) | 160 (1600) | 154 (1540) | 148 (1480) | 145 (1450) | 134 1340() | 123 (1230) | 116 (1160) | 105 (1050) | 104 (1040) | 92 (920) | 86 (860) | 78 (780) | 71 (710) | 64 (640) | 56 (560) | 53 (530) |

*At temperatures below +20 oC, the permissible stresses are taken to be the same as at +20 oC, subject to the permissible use of the material at this temperature

Properties according to GOST 10066-94 standard

| Tensile strength σB MPa | Yield strength for permanent deformation, σT MPa | Elongation at break, δ, % |

| Hot rolled steel | ||

| >490 | >345 | >19 |

| Cold rolled steel | ||

| >460 | >345 | >19 |

*for rolled products with a thickness of 0.5-3.9 mm and a width of at least 500 mm

Bending until the sides are parallel for hot-rolled and cold-rolled steel d: = 2a, where a is the thickness of the sample, d is the diameter of the mandrel

Properties according to GOST 32678-2014 standard

| Assortment | Tensile strength σB MPa | Yield strength for permanent deformation, σT MPa* | Elongation at break, δ5, % |

| Heat-treated products | |||

| Pipes | >470 | >265 | >21 |

| Without heat treatment** | |||

| Pipes | >315 | >216 | >5 |

* As agreed between the manufacturer and the customer: tensile strength of at least 441 MPa, yield strength for permanent deformation of at least 245 MPa

**The mechanical properties of pipes without heat treatment are established by agreement between the manufacturer and the consumer. In the absence of such approval, the production of welded cold-deformed pipes must comply with the standards specified in the table.

Physical properties of steel 09G2S

The physical properties of steel include thermal conductivity, heat capacity, elastic modulus, shear modulus, coefficient of linear and volumetric expansion with temperature changes.

Physical properties of material 09G2S.

| T | E 10- 5 | a106 | l | r | C | R 109 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | ||||||

| 100 | 11.4 | |||||

| 200 | 12.2 | |||||

| 300 | 12.6 | |||||

| 400 | 13.2 | |||||

| 500 | 13.8 | |||||

| T | E 10- 5 | a106 | l | r | C | R 109 |

Table of metal hardness according to Brinell, Rockwell, Vickers, Shore

The hardness of a metal is its property of resisting plastic deformation during the contact action of a standard tip body on the surface layers of the material.

Hardness testing is the main method for assessing the quality of heat treatment of a product.

Determination of hardness using the Brinell method . The method is based on inserting a steel ball into a flat surface under load. Hardness number HB

determined by the ratio of the load to the spherical surface of the print.

The Rockwell (HR) method is based on statically pressing a tip into the test surface under a certain load. Steel balls are used as tips for materials with hardness up to 450 HR. In this case, the hardness is designated as HRB

.

When using a diamond cone, hardness is designated as HRA

or

HRC

(depending on load).

Vickers hardness (HV) is determined by statically pressing a diamond tetrahedral pyramid into the test surface. During the test, the indentation is measured with an accuracy of 0.001 mm using a microscope, which is an integral part of the Vickers instrument.

Shor's method . The essence of this method is to determine the hardness of the sample material by the height of the rebound of the striker falling onto the surface of the test body from a certain height. Hardness is assessed in conventional units proportional to the height of the striker's rebound.

HRC hardness numbers for some parts and tools

| Parts and tools | Hardness number HRC |

| Hinged bolt heads, hex nuts, clamping handles | 33. 38 |

| Hinge screw heads, setscrew ends and heads, hinge axes, clamping and removable strips, screw heads with internal hex holes, drive chuck pin | 35. 40 |

| Round nut splines | 36. 42 |

| Gears, keys, clamps, crackers for machine grooves | 40. 45 |

| Spring and retaining rings, tension wedges | 45. 50 |

| Self-tapping screws, turning centers, eccentrics, mushroom supports and support plates, mounting pins, collets |

Table of relationships between hardness numbers according to Brinell, Rockwell, Vickers, Shore

Rockwell, Vickers and Shore hardness values indicated correspond to Brinell hardness values determined using a 10 mm diameter ball.

| According to Rockwell | According to Brinell | Vickers (HV) | By Shore | |||

| H.R.C. | HRA | HRB | Imprint diameter | HB | ||

| 65 | 84,5 | — | 2,34 | 688 | 940 | 96 |

| 64 | 83,5 | — | 2,37 | 670 | 912 | 94 |

| 63 | 83 | — | 2,39 | 659 | 867 | 93 |

| 62 | 82,5 | — | 2,42 | 643 | 846 | 92 |

| 61 | 82 | — | 2,45 | 627 | 818 | 91 |

| 60 | 81,5 | — | 2,47 | 616 | — | — |

| 59 | 81 | — | 2,5 | 601 | 756 | 86 |

| 58 | 80,5 | — | 2,54 | 582 | 704 | 83 |

| 57 | 80 | — | 2,56 | 573 | 693 | — |

| 56 | 79 | — | 2,6 | 555 | 653 | 79,5 |

| 55 | 79 | — | 2,61 | 551 | 644 | — |

| 54 | 78,5 | — | 2,65 | 534 | 618 | 76,5 |

| 53 | 78 | — | 2,68 | 522 | 594 | — |

| 52 | 77,5 | — | 2,71 | 510 | 578 | — |

| 51 | 76 | — | 2,75 | 495 | 56 | 71 |

| 50 | 76 | — | 2,76 | 492 | 549 | — |

| 49 | 76 | — | 2,81 | 474 | 528 | — |

| 48 | 75 | — | 2,85 | 461 | 509 | 65,5 |

| 47 | 74 | — | 2,9 | 444 | 484 | 63,5 |

| 46 | 73,5 | — | 2,93 | 435 | 469 | — |

| 45 | 73 | — | 2,95 | 429 | 461 | 61,5 |

| 44 | 73 | — | 3 | 415 | 442 | 59,5 |

| 42 | 72 | — | 3,06 | 398 | 419 | — |

| 40 | 71 | — | 3,14 | 378 | 395 | 54 |

| 38 | 69 | — | 3,24 | 354 | 366 | 50 |

| 36 | 68 | — | 3,34 | 333 | 342 | — |

| 34 | 67 | — | 3,44 | 313 | 319 | 44 |

| 32 | 67 | — | 3,52 | 298 | 302 | — |

| 30 | 66 | — | 3,6 | 285 | 288 | 40,5 |

| 28 | 65 | — | 3,7 | 269 | 271 | 38,5 |

| 26 | 64 | — | 3,8 | 255 | 256 | 36,5 |

| 24 | 63 | 100 | 3,9 | 241 | 242 | 34,5 |

| 22 | 62 | 98 | 4 | 229 | 229 | 32,5 |

| 20 | 61 | 97 | 4,1 | 217 | 217 | 31 |

| 18 | 60 | 95 | 4,2 | 207 | 206 | 29,5 |

| — | 59 | 93 | 4,26 | 200 | 199 | — |

| — | 58 | — | 4,34 | 193 | 192 | 27,5 |

| — | 57 | 91 | 4,4 | 187 | 186 | 27 |

| — | 56 | 89 | 4,48 | 180 | 179 | 25 |

Analogs and substitutes for steel 09G2S

The table shows the markings of alloys similar to 09G2S steel on foreign markets. Please note that not all analogues are accurate.

Foreign analogues of the material

Attention! Both exact and closest analogues are indicated.

| Germany | Japan | China | Bulgaria | Hungary | Romania | |||||

| DIN,WNr | JIS | G.B. | BDS | MSZ | STAS | |||||

|

Comparison of 09G2S with brand 17G1S

Two popular grades of steel have a similar composition, but differ in a number of characteristics, especially in structure. The martensitic structure of 09G2S steel is optimal for load-bearing structures, therefore 09G2S steel is defined as structural and is widely used in construction. 17G1S is almost never used for the manufacture of load-bearing structures. The increased carbon content in this alloy ensures the formation of a ferritic structure, which, despite its strength, is more suitable and makes it possible to lay underground communications. Therefore, 17G1S steel is used to make pipes for heating networks and industrial engineering systems. It is also inferior in frost resistance, its lower temperature limit is -40C versus -70C for the 09G2S alloy, but is characterized by increased resistance to high temperatures up to +475C versus +425 degrees in the case of 09G2S.

Elastic modulus of different steel grades

Spring steel alloys have the greatest ability to resist deformation. These materials are characterized by high yield strength. The value shows the stress at which the deformation increases without external influences, for example, when bending and twisting.

The elasticity characteristics of steel depend on alloying elements and the structure of the crystal lattice. Carbon imparts hardness to the steel alloy, but in high concentrations it reduces ductility and springiness. The main alloying additives that increase elastic properties: silicon, manganese, nickel, tungsten.

Often, the desired indicators can be achieved only with the help of special heat treatment modes. In this way, all fragments of the part will have uniform fluidity indicators, and weak areas will be eliminated. Otherwise, the product may break, burst or crack. Grades 60G and 65G have such characteristics as tensile strength, viscosity, wear resistance, they are used for the manufacture of industrial springs and musical strings.

The metallurgical industry has created several hundred grades of steel with different elastic moduli. The table shows the characteristics of popular alloys.

Table of strength moduli of steel grades

| Name of steel | Young's modulus of elasticity, 10¹² Pa | Shear modulus G, 10¹² Pa | Modulus of bulk elasticity, 10¹² Pa | Poisson's ratio, 10¹²·Pa |

| Low carbon steel | 165…180 | 87…91 | 45…49 | 154…168 |

| Steel 3 | 179…189 | 93…102 | 49…52 | 164…172 |

| Steel 30 | 194…205 | 105…108 | 72…77 | 182…184 |

| Steel 45 | 211…223 | 115…130 | 76…81 | 192…197 |

| Steel 40Х | 240…260 | 118…125 | 84…87 | 210…218 |

| 65G | 235…275 | 112…124 | 81…85 | 208…214 |

| X12MF | 310…320 | 143…150 | 94…98 | 285…290 |

| 9ХС, ХВГ | 275…302 | 135…145 | 87…92 | 264…270 |

| 4Х5МФС | 305…315 | 147…160 | 96…100 | 291…295 |

| 3Х3М3Ф | 285…310 | 135…150 | 92…97 | 268…273 |

| R6M5 | 305…320 | 147…151 | 98…102 | 294…300 |

| P9 | 320…330 | 155…162 | 104…110 | 301…312 |

| P18 | 325…340 | 140…149 | 105…108 | 308…318 |

| R12MF5 | 297…310 | 147…152 | 98…102 | 276…280 |

| U7, U8 | 302…315 | 154…160 | 100…106 | 286…294 |

| U9, U10 | 320…330 | 160…165 | 104…112 | 305…311 |

| U11 | 325…340 | 162…170 | 98…104 | 306…314 |

| U12, U13 | 310…315 | 155…160 | 99…106 | 298…304 |

Modulus of elasticity for metals and alloys

| Name of material | Elastic modulus value, 10¹² Pa |

| Aluminum | 65—72 |

| Duralumin | 69—76 |

| Iron, carbon content less than 0.08% | 165—186 |

| Brass | 88—99 |

| Copper (Cu, 99%) | 107—110 |

| Nickel | 200—210 |

| Tin | 32—38 |

| Lead | 14—19 |

| Silver | 78—84 |

| Gray cast iron | 110—130 |

| Steel | 190—210 |

| Glass | 65—72 |

| Titanium | 112—120 |

| Chromium | 300—310 |

Elasticity of steels

| Name of steel | Elastic modulus value, 10¹² Pa |

| Low carbon steel | 165—180 |

| Steel 3 | 179—189 |

| Steel 30 | 194—205 |

| Steel 45 | 211—223 |

| Steel 40Х | 240—260 |

| 65G | 235—275 |

| X12MF | 310—320 |

| 9ХС, ХВГ | 275—302 |

| 4Х5МФС | 305—315 |

| 3Х3М3Ф | 285—310 |

| R6M5 | 305—320 |

| P9 | 320—330 |

| P18 | 325—340 |

| R12MF5 | 297—310 |

| U7, U8 | 302—315 |

| U9, U10 | 320—330 |

| U11 | 325—340 |

| U12, U13 | 310—315 |

What is the difference between galvanized, stainless and black steel

Speaking about corrosion resistance indicators, stainless steel is preferable to galvanized and black steel; these are different categories of protection. Galvanized steel is protected from corrosion by a thin or thick layer of zinc, and stainless steel is protected by the content of alloying additives in the alloy structure. This is a big difference, because... It is easy to damage the zinc layer, revealing unprotected steel behind it. Stainless steel does not need a protective film; it is protected from the inside by its own chemical properties until the end of its service life; the absence of a coating does not affect it in any way.

Black steel has no protection at all, so it is the most susceptible to corrosion. To increase its service life, it is recommended to coat it with powder paint and process it in a polymerization oven.

By service life

The service life of working parts for each of the steels differs by a factor of two: 50 years for the first versus 25 years for the second and 10 years for the third. And these are average figures, because... Due to damage to the zinc layer, the product will most likely fail earlier. Black steel is the least wear-resistant.

Environmentally friendly

When heated or exposed to acids, zinc releases harmful compounds zinc oxide and phosphides. Poisoning can be of varying strength, including death if the damage is extensive. Stainless steel is completely safe in any product and has proven itself in the production of cookware. Ferrous metal is also not toxic, but due to its susceptibility to corrosion, it is almost always isolated from humans by a protective layer of paint.

By cost

The lower limit of the cost of 1 ton of ordinary stainless steel sheet is 113 thousand rubles. A galvanized hot-rolled sheet of the same weight can be purchased at a price of 67 thousand rubles. The price of the same sheet of black steel starts from 45 thousand rubles. The cost is also influenced by the quality characteristics of the steel and the choice of manufacturers. Read more about this in the materials on our website.

Tensile strength

Solids are capable of withstanding limited loads; exceeding the limit leads to destruction of the metal structure, the formation of noticeable chips or microcracks. The occurrence of defects is associated with a decrease in performance properties or complete destruction. The strength of alloys and finished products is checked on test benches. The standards provide for a number of tests:

- Prolonged use of deforming force;

- Short-term and long-term shock impacts;

- Tension and compression;

- Hydraulic pressure, etc.

In complex mechanisms and systems, the failure of one element automatically causes increased loads on others. As a rule, destruction begins in those areas where stress is maximum. The safety margin serves as a guarantee of equipment safety in emergency situations and extends its service life.

Source of the article: https://e-metall.ru/blog/uprugost-stali/