Technologies for performing welding work have undergone significant changes in recent years. If in the past the welding machines used were carried out on transformers, therefore they were bulky in size and difficult to operate, but the advent of semi-automatic welding inverters has made it possible to significantly simplify the work with metal, while such compact units are offered at affordable prices. Inexpensive semi-automatic inverters from the manufacturer Resanta, which combine ease of use and excellent welding quality, are popular on the domestic market.

The manufacturer of welding machines, the Resanta company, is a well-known Latvian company on the Russian market, which uses the latest technological advances in its products and, thanks to the excellent quality of inverters, is able to compete even with the world's leading brands. Domestic buyers love Resanta devices for their ease of use, attractive prices, ease of maintenance, reliability and durability.

Description of the welding inverter SAIPA 165

The semi-automatic welding machine Resanta 165 belongs to the class of household single-phase devices that operate on direct current and ensure high-quality joining of metals. Resanta SAIPA 165 can be used with both electrodes and active wire, which greatly simplifies welding. At the same time, regardless of the type of metal being welded, a high-quality connection is ensured, and the weld has additional protection against corrosion.

SAIPA 165 is capable of working with electric current of varying power, which allows you to simultaneously work with thick workpieces of refractory metals, and weld aluminum or other thin metal, which requires minimal electric current power to work with.

Resanta SAIPA 165 was originally designed for use by ordinary homeowners. This device is extremely easy to use , and to turn it on you just need to press the corresponding button on the handle, after which the welding wire will be automatically fed to the welding site. In this case, it is possible to adjust the wire feed speed, the thickness of which can vary significantly, depending on the operating current and the metal parts being welded.

How to properly set up a semi-automatic welding machine

Beginner users of such equipment are probably wondering: which semi-automatic welding machine has the necessary settings and does not require additional debugging?

However, such models do not exist for two reasons. Firstly, the manufacturing technology itself does not make it possible to set the same parameters for each instance. Secondly, such uniformity does not make sense, because the equipment is designed to weld different materials. At the same time, maintaining factory settings significantly reduces the possibility of using the device, because different metals and alloys need to be combined under different conditions. The delivery package usually includes instructions for debugging the equipment yourself, but they are often not enough. Therefore, every experienced master knows how to connect and correctly configure a semi-automatic welding machine to work with a specific material. Such experience often complements and clarifies factory instructions.

Technical characteristics of the device

Resanta SAIPA 165 can be used for operation in a gas environment without additional gas supply. The popularity of this model of welding inverters among domestic buyers is explained by the excellent performance characteristics of this device.

- The current strength can vary in the range of 20–160 amperes.

- The permissible diameter of the wire used is 0.62 millimeters.

- The weight of the device is 11.5 kilograms.

- Permissible voltage deviations from the nominal value are from minus 30% to plus 10%.

- The rated voltage in the electrical network is 220 volts.

The semi-automatic machine SAIPA 165 is intended for spot welding, so we do not recommend using such equipment when performing large volumes of work. If welded correctly, Resanta SAIPA 165 will provide a strong and neat seam , and the metal at the joint will be perfectly protected from corrosion. It is only necessary to compare the characteristics of the operating current with the parameters of the wire, select the correct thickness and feed speed, which will guarantee a high-quality welded joint.

The most common failures and their symptoms

If the semi-automatic welding machine has not been correctly configured and adjusted, various malfunctions and errors may occur during its operation. The most common of them are listed below, as well as the signs by which they can be recognized:

- If the wire is fed too fast for the selected voltage, it will not form an arc, but will simply weld to one of the parts being joined.

- If there is a shortage or absence of shielding gas in the welding zone, splashes fly out abundantly, and the seam becomes porous and acquires a green-brown color.

- If the voltage and/or feed rate of the filler thread is insufficient, the weld will not penetrate deep into the thickness of the parts being joined, and the weld will be weak.

- If the voltage is too high for a given metal thickness, burning of the sheets or parts being welded will naturally occur.

- If the filler thread is fed too slowly, it will partially melt when it touches the metal, remaining at the end of the working tip.

- When the torch is removed from the welding site further than 0.6-1.2 cm, the seam will be intermittent, and during the work there will be copious spattering of solder.

- If the material is not cleaned and the grounding is poorly secured, the welding will be jerky and the seam will be torn. From the outside it seems that the reason is low voltage or low wire feed speed, but this is not the case.

In addition, crackling and clicking noises during welding indicate a low solder feed rate. Lack of gas environment increases the amount of splashes and sparks. An intermittent weld and unwelded (missed) areas indicate that the metal surface has not been cleaned and properly prepared for welding. Notches and different thicknesses of the weld bead are the result of uneven guidance of the torch at the joint.

In general, during the welding process it is not enough to keep in mind only the average instructions and recommendations. It is imperative to pay attention to the little things and notice experimentally what results are obtained with certain settings and movements of the burner.

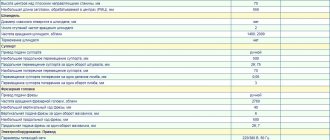

Recommended values of the main parameters are presented in the table:

Features of the SAIPA 165 inverter

If we talk about the features of this model of welding machine, we note its ergonomic design. Numerous adjustments and settings of parameters for both wire feed speed and current strength, which allow you to select the optimal welding mode, regardless of the characteristics of the metal elements being processed.

The SAIPA 165 inverter is made in a durable metal case and has protection class IP 21. This model is intended primarily for welding work indoors, but it is not recommended to use such equipment outdoors with high humidity , since the use of the welding machine in such conditions will be unsafe.

The welding wire feeding mechanism is reliable and simple in design, so every ordinary homeowner can handle the correct preparation of the device for work. The feed speed of the wire used is adjusted using the appropriate toggle switch, and in the instructions for the inverter you can find all the information you need regarding the current strength, the diameter of the wire and the speed of its feed into the weld pool.

On the front panel of the inverter there are special connecting terminals that firmly and quickly fix the welding wires, eliminating loss of current, which ensures high-quality welding of metal products. This device is made using IGBT technology, which implies fully electronic control and the necessary welding automation, so both professional welders and ordinary homeowners who use inverters for utility and domestic purposes can work with this device.

Like most modern welding inverters, this model has received numerous automation that controls the welding process and also prevents failure of the unit due to overvoltage and overheating. For example, there is effective protection for preventing overheating, so as soon as the temperature inside the case exceeds the maximum permissible values, the protective system will turn off the inverter until it cools down completely.

Directly adjusting the welding current, wire feed speed and choosing its thickness does not present any difficulty. Therefore, working with this device does not require long training, and you can understand all the intricacies and features of using the inverter in literally 5 minutes.

Setup recommendations

Four operating characteristics of the equipment outline five areas of its adjustment: protective gas mixture, voltage, polarity, feed speed and wire stickout. Let's look at each aspect in more detail.

Selection of gas mixture

To protect the parts and equipment being joined from high temperatures and sparks, a gas mixture or some pure gas is pumped into the welding zone. For semi-automatic welding machines, two substances are used: carbon dioxide (carbon dioxide) and the inert material argon. There are four possible combinations for different alloys and weld quality:

- Pure carbon dioxide - suitable for thick sheets or large products made of iron-based alloys (cast iron, steel), provides deep penetration, but produces a large number of sparks, and the seam ends up being rough and ugly.

- The first mixture of both gases is three-quarters (75%) argon and one-quarter (25%) carbon dioxide. The composition is suitable for working with thin sheets and small parts. Gives a minimum of splashes, and the soldering is neat.

- The second mixture of both gases is 98% argon and 2% carbon dioxide. The main purpose of such a medium is to weld parts made of stainless or galvanized steel and copper alloys. Minimum splashes, high quality seam.

Pure argon is used for joining parts made of aluminum, copper, alloys based on them, as well as for working with non-ferrous metals in general. Provides almost complete absence of sparks, and the seam comes out thin, even, clean and beautiful.

The more argon in the protective medium, the neater, cleaner and thinner the connection is. Carbon dioxide produces a rather rough compound and is not suitable for thin metal sheets, small parts and non-ferrous metals. However, it is more affordable, which determines its prevalence in welding large objects and in rough work.

Voltage setting

This parameter must be adjusted taking into account the required penetration depth, as well as the thickness of the sheets being joined or the dimensions of the parts. The more energy required to melt the solder and the processed alloy, to burn the welding arc, the higher should be the set voltage of the device that converts the energy of electric current into heat.

Voltage adjustment is stepwise. Most modern devices allow you to set the voltage required for operation in two stages.

- First, using the switch on the back side of the semiautomatic device, one of two modes of operation of the device is selected. Modes o and "2".

- Next, within each of these modes, you can choose between the minimum and maximum voltage levels. The second switch is responsible for this.

The result is four voltage options. To make it easier to select the desired value, some models also include a table for determining the voltage and wire feed speed. Such reference books are individual for each device. Too low a voltage will not provide the required penetration depth, and the seam will be weak. At extremely high voltages, the risk of burning through the material increases.

Setting the wire feed speed

This parameter should be adjusted after selecting the electric voltage. This order is due to the fact that the feed rate determines the melting rate, which at the same time depends on the voltage. When the filler filament begins to melt, its advance speed decreases. If this parameter is lower or higher than the corresponding voltage, the quality of the connection will greatly decrease:

- If the filler thread is fed too quickly, it will begin to deform upon contact with the metal before it has time to melt. It will also stick to the surface being treated, sparking and splashing profusely. In this case, the connection will turn out to be sloppy, with a large number of sagging and low strength.

- If the feed is too slow, the wire runs the risk of burning before it has time to melt. This clogs the burner tip. If the filler thread nevertheless begins to melt, this does not guarantee high-quality work. When in contact with metal, the thread will produce a torn seam with sags and waviness.

The filler material feed rate must be adjusted more often than other equipment characteristics. After each change in voltage and replacement with a different filler thread, the previous settings are lost and need to be adjusted again. Modern models often make this aspect easier with an automatic setting option.

The quantitative expression of the relationship between the settings and the result is reflected in the table:

Polarity adjustment

This parameter of semi-automatic welding machines is the easiest to configure. A table is usually placed on the case, which indicates for which metal or alloy direct polarity is preferable, and for which reverse polarity is preferable. In the first case, the gas burner should be connected to the negative terminal, in the second - to the positive connector.

The choice depends on the design types of filler wire. Today there are two of them:

- Simple. This is a copper-plated solid thread, when working with which shielding gas is always used. It does not have any additional additives, so the surface must be especially thoroughly cleaned before starting work. This filler thread can only be used indoors, but it produces almost no sparks or splashes, and the seam is thin, even, neat and clean, without slag.

- With flux. This is an additive in the center of the wire, which, when melted, forms a protective gas, so an external environment of argon or carbon dioxide is not required, as well as thorough cleaning of the surface - minor contamination will not hurt. You can work with this solder even outside in windy weather, but there will be a lot of splashes and sparks. A lot of slag forms along the seam, which needs to be cleaned off.

A simple copper thread is always reverse polarity and connected to the positive terminal. A negative charge is applied to the material being welded. Flux filler filament requires straight polarity and connection through the negative terminal. In this case, the part to be welded is connected to a terminal with a positive charge. The difference in charges creates electrical voltage and an electromagnetic field.

Setting the wire extension

Overhang is the distance between the end of the tip and the end of the wire itself, that is, the part of its length by which it extends from the tip. If you adjust this parameter correctly, you will be able to avoid excessive splashes, warping of the material being welded, burning through, and insufficient penetration. The outlet is the distance from the burner nozzle to the wire end. With small diameters, the release and overhang are equal to each other; with an increase in the thickness of the thread, the release decreases by 1-10 mm.

In practice, three main departure options are used, depending on the design of the gas nozzle and the protective environment used:

- In general, the release should be as small as possible - about 0.6-1.0 cm. This value is suitable for a protective environment of pure carbon dioxide or its mixtures with argon. The more argon, the greater the offset can be.

- When using pure argon as a protective medium, the extension of the filler thread can exceed 1 cm. There are models with automatic adjustment of this parameter, in which the extension step is about 3 mm.

- If the tip of the gas nozzle is recessed into its body, then too short an extension will not ensure normal melting. Therefore, the more the tip is recessed into the burner body, the greater the outlet value should be.

The thicker the wire, the smaller the stickout should be, otherwise there will be more of it in the welding zone than the semi-automatic welding machine can process. And if a short release simply does not allow the formation of a deposit and a weld or does not provide the required depth of penetration and strength of the seam, then a too long release creates an excess of solder, which will lead to burning and warping of the metal, copious splashes and sparking.

The relationship between projection, exhaust, diameter and gas consumption is shown in the table:

Basic equipment of the inverter

The basic configuration of this inverter model raises certain complaints. The Resanta SAIPA 165 welding machine is equipped with a minimum of additional devices, while it has a high cost for its power indicators. For example, the manufacturer does not equip this semi-automatic machine with consumables or a special case for storing it. The kit includes only a ground wire, the inverter itself, a burner with a cable, as well as technical documentation. Today, this model of welding inverter is offered to customers at a price of 18-19 thousand rubles.

Benefits of use

Reliable connection of any steel - alloy, stainless, low-carbon, as well as aluminum compositions can be performed with a semi-automatic welding machine SAIPA-220. The device, when using a special wire in an argon environment, is capable of welding galvanized steel using the MIG soldering principle.

- Selecting a power source. The inverter is equipped with built-in overload protection, the signal lamp is located on the front panel. There is a network indicator lamp nearby. Power for the welding unit is provided by a household network. To convert AC voltage to DC, a conventional rectifier is sufficient.

- Adjustment of welding work. Combining the feed power and arc voltage regulator makes it possible to select a mode for various welds (butt, T, overlap and corner). The advance button allows you to conveniently control the protrusion of the electrodes.

- Increased load. The presence of a powerful fan facilitates work with a load duration of 70%. The forced cooling system protects the inverter during operation and continues to operate after the power supply to the device is interrupted, within a few seconds.

- Minimum heating. For soldering parts in a protective gas environment, reverse polarity of the current is provided, the temperature is concentrated at the tip of the electrode. The base metal is less susceptible to heat. This mode is effective when joining workpieces of small thickness. Semi-automatic welding of small seams in various spatial positions is allowed. It will also be possible to make connections by weight, neglecting additional linings that keep the metal from leaking out.

- Cost-effectiveness and safety of the system. Among the production advantages are the absence of harmful emissions and low toxicity during welding. Welded joints created in a carbon dioxide environment are cheaper than electrode ones. The small dimensions of the device ensure ease of use and mobility. Maintenance of the device consists of simply replacing the torch and welding wire. The speed of setup also makes the job easier.

Ease of use

The professional semi-automatic machine is designed for continuous use for a long time. When welding with an inverter device, the seam is immediately clean and slag-free and does not require descaling. The complete absence of smoke ensures good visibility and increases ease of use.

The stability of welding parameters is supported by a control system that forms the required operating mode taking into account a number of factors:

- Type, material thickness.

- Welding wire diameter.

- Composition of shielding gas.

It is possible to supplement semi-automatic welding machines with additional modules, including a torch cooling system and a shielding gas supply system.

Additional equipment of Resanta SAIPA 165

In specialized stores you can find various additional equipment that makes the welding process even simpler and more efficient. First of all, you will need to purchase the wire used , and the manufacturer recommends using such wire with a thickness of 0.6-0.9 millimeters. We can recommend that you purchase the following additional tools and extensions:

- Gas cylinders.

- Gearboxes.

- Magnetic squares.

- Cleaning brushes.

The cost of such additional devices and extensions is not too high, and their use in work can significantly simplify welding work.

The semi-automatic welding inverter Resanta SAIPA 165 has certain advantages and disadvantages. The advantages of this model include significant simplification of welding and excellent quality of work performed. At the same time, it should be noted the high cost of the device, as well as the not very rich basic equipment, which forces you to subsequently additionally purchase various devices to simplify welding work.

Purchase of semi-automatic welding machines

The adjustment recommendations listed above are equally valid for semi-automatic welding machines of any brand, model and modification. The same applies to the most common equipment failures and the signs that help identify them. Of course, it is easier to adjust the device to your needs if the factory settings more closely match the parameters required for operation.

The catalog presents a wide selection of semi-automatic welding machines for joining all the main working alloys: iron, aluminum, copper. These are convenient inverter monoblocks of the domestic brand “Svarog”, which is not inferior in technical characteristics to similar equipment of foreign brands “Aurora” (Chinese production) or “Resanta” (Latvian company).

Source

Possible faults

According to consumer reviews, this device has a number of shortcomings that are quite common. They can be divided into three groups:

- Installation problems. A common problem is that the current and wire feed controls are swapped. For novice welders, this is not possible to determine and significantly complicates the work with the device. Also, often the electronic boards in the device are not protected by varnish, which leads to their rapid failure. These malfunctions are not total, but occur quite often;

- Poor quality instructions. The description of many important points is very superficial, which leads to incorrect operation of the device. To the greatest extent this applies to the unit that is responsible for feeding the wire;

- Incorrect operation. The device requires special storage conditions - in a clean and dry room. Failure to do so may result in damage. It is also important to regularly maintain the unit, for example, tighten the power contacts.

Thus, the shortcomings of the Resanta can be identified through a competent and careful purchase during a detailed inspection of the device, or can be prevented through proper operation and compliance with the rules of storage and use.

Note that the great popularity of these devices allows them to be easily serviced by specialists in service centers.