Hydraulic concrete jackhammer

The hammer is a piston pneumatic impact machine with valve air distribution, operating under the influence of compressed air. They are equipped with a motor with a free movement of the piston and are classified according to the principle of the air distribution system used, which is carried out using plate valves or tubular spools.

It consists of an air distribution-shock mechanism and a handle with a starting device assembled in it. The air distribution-percussion mechanism supplies compressed air into the barrel cylinder in turn into the forward and reverse stroke chambers of the striker and releases exhaust air into the atmosphere, converting the energy of the compressed air into the mechanical work of the moving impact mechanism.

To prevent self-unscrewing of the threaded connection of the link and the barrel when the barrel hole is aligned with the slots of the intermediate link, a clamp is installed, which is kept from falling out by a locking ring. The retaining ring has a hole to allow exhaust air to escape. A disc spring is used to press the air distribution unit to the end of the barrel. The hose supplying compressed air is connected with a union nut and nipple.

Additional fixation of the lance is provided by a ring spring wound onto the hammer barrel. Starting is carried out by pressing the handle on the valve. The pressing force must overcome the resistance of the spring, shock absorber and valve supported by compressed air. For initial start-up, it is necessary to apply a force of up to 120 N, the value depends on the air pressure. It turns off automatically when the force is removed from the handle.

By pressing the handle, the valve moves to the right and opens the hole connected to the annular chamber of the valve distribution. With the help of a valve distribution, striker and barrel, compressed air is directed alternately into the forward and reverse stroke chambers of the striker, forcing it to perform a reciprocating movement, periodically striking the shank of the working actuator.

Rice. 1. Design of manual jackhammer

1 - handle; 2 — shock absorber; 3 - valve; 4 - plug; 5 - box; 6 - valve; 7 — clamp; 8 — retaining ring; 9 — trunk; 10 - drummer; 11 — futorka; 12 - nipple

The main components of the hammer are the air distribution impact mechanism, the handle with the trigger, and the muffler casing.

The air distribution impact mechanism is used to convert the action of compressed air into mechanical energy, which ensures the operation of the impactor. Structurally, it consists of the following components:

· barrel with axle box;

valve core and cover;

The firing pin in the barrel should move freely, without difficulty. The starting device includes:

· retainer, retaining ring;

· plug, valve, spring;

· nipple and union nut.

A special lock with a safety locking ring prevents spontaneous unwinding of the threaded components of the barrel and intermediate link. The purpose of the valve cover is to press the air distributor to the end of the barrel. The sleeve serves to supply compressed air to the hammer; it is connected using a nipple and a union nut. An end spring with a rubber bushing helps to hold the tool - picks, blades, etc. from falling out of the product shank. The intermediate link must be screwed tightly and secured with a stopper. MO and MOP demolition hammers have built-in vibration protection and noise suppressors, which allows the equipment to be operated without harm to human health. The safety of the products is confirmed by the Russian Gosstandart certificate of conformity.

§ 1. PURPOSE, AREA OF APPLICATION, DEVICE

Pneumatic breaker

is a hand-held impact tool that is used as a wedge and lever.

Its executive body (peak) is embedded in coal (or rock), separating it from the massif. Read also: Pressing sawdust at home

Jackhammers are used mainly when developing steep seams in difficult mining and geological conditions, when it is impossible to use other, more effective means of mechanization - combines and plows. In addition, they find application in the development of weak shales, ores, and in construction and auxiliary work.

Pneumatic jackhammers are manufactured by the Tomsk Electromechanical Plant named after. V.V. Vakhrusheva. Their technical characteristics are given in table. IV.9. The working air pressure in the hammers is assumed to be 0.5 MPa.

Extensive work has been carried out to typify and unify the main components and parts of pneumatic jackhammers. The only exceptions are barrels and firing pins, which have different sizes, but their diameters are also unified. Further improvement of jackhammers is carried out in the direction of increasing their productivity, efficiency, reliability in operation, as well as improving the working conditions of the worker when using them: reducing recoil, vibration, noise, dust formation.

Electric jackhammers

in underground conditions they were not used due to lower productivity, reliability and greater weight than pneumatic jackhammers. They have some application on the surface of mines during construction and other work.

Pneumatic breaker

hammer MO39 (Fig. IV.43) consists of an executive body - a peak holding its spring

16,

a barrel

11 with

an intermediate link

4,

inside of which there is an air distribution and impact mechanisms, a handle / with a vibration damping device.

Compressed air is supplied to the hammer but a flexible sleeve, which is connected using a nipple 22,

fitting

20

and nut

21.

To prevent self-loosening of the fitting, a spring washer

19

. The sleeve has a diameter of

16

mm and a length of no more than 12 m.

Impact mechanism

consists of a barrel with axle box

15

and a barrel bridge

14

and a striker

12

. The impact mechanism is designed to convert the energy of compressed air into the mechanical work of a moving striker, which strikes the pike shank.

Air distribution mechanism

consists of a valve box

6

with a ring

5

and two valves 7, made in the form of flat segments.

The air distribution mechanism is designed to supply compressed air to the barrel cylinder, i.e., to chamber D

of the forward stroke of the striker and to chamber D of the reverse stroke, as well as to release exhaust air into the atmosphere.

To supply compressed air to the hammer, longitudinal channels are drilled in the hammer barrel, and channels formed by the surface of the barrel are used to remove exhaust air. 11

and the surface of the steel jacket

13.

10

is fixed on the latter which keeps the stopper

9

and is used to remove air from the exhaust channel.

The stopper prevents self-unscrewing of the threaded barrel 11 and

the intermediate link

4.

Two pins

8

prevent spontaneous displacement of the valve box 6

relative to

Starting

a fluoroplastic

insert

17 along the intermediate link

4 This liner is pressed against the intermediate link by spring force and compressed air. When you press handle 1

, the hole in the liner coincides with the hole in the intermediate link and compressed air enters the air distribution device of the hammer, while springs

2

are compressed.

When removing force from the handle 1

springs

2

are decompressed and the hole in the intermediate link

4

is blocked by liner

17

- the hammer is turned on.

To prevent air leaks, a cuff 18

made of oil-resistant rubber is installed in the starting device.

Read also: Which batteries are suitable for a Makita screwdriver

To reduce hammer vibration and reduce the harmful impact of recoil on the worker’s body, an additional chamber B is used,

which is located at the end of the return (idle) stroke of the striker and can significantly improve the work cycle and reduce the recoil of the hammer.

In addition, a vibration isolator 3 is used,

separating the hammer body from the handle.

The connection between the handle and the intermediate link is made by two clamps 23,

which are constantly held in a relaxed state by a vibration isolator

3.

When the hammer is turned on and off, the clamps move in the grooves in the handle.

The principle of operation of a jackhammer is as follows (Fig. IV.44). At the start of idle, the drummer and valve are in the lower position. Compressed air under pressure p

through the channels above the valve and the longitudinal channel

a

enters chamber B

under

As a result of this, the striker moves upward, displacing air from the upper cavity A

into the atmosphere through exhaust openings b1

and

b.g.

When the striker closes these holes, the air in chamber L will begin to compress and at the same time will put pressure on the valve from below.

With further movement, the striker will open the exhaust hole b.,

as a result of which the pressure in chamber

B

will drop sharply and the valve will move upward, opening the way for compressed air into chamber

A

- the working stroke of the striker will begin.

At the beginning of the working stroke, the hammer and valve are in the upper position. Compressed air enters chamber A

above the drummer.

Under the pressure of compressed air and its own weight, the striker moves downward, displacing air from chamber B

through the exhaust openings

bx

and

bg.

When the striker closes these holes, the air in chamber

B

will begin to compress, increasing the pressure on the valve from above through channel

a

.

Next, the striker will open the exhaust hole bb

the pressure in chamber

A

will drop sharply under the spool - the spool will move down, the striker will strike the pike shank, after which the striker will begin idling.

To protect the hammer barrel from rupture during idle strokes of the striker, MO type hammers are provided with an air buffer.

§ 2. DETERMINATION OF BASIC PARAMETERS

The main parameters of a jackhammer include: impact energy and power, impact frequency, compressed air consumption and productivity.

Didn't find what you were looking for? Use the search:

If it is necessary to destroy solid material, dismantle building structures or road surfaces, work with a jackhammer is used - a special tool that can have an electric, hydraulic, pneumatic or gasoline drive.

Types of jackhammers by type of drive used

A jackhammer is such a popular type of tool that it is produced in various versions depending on the type of drive devices used. There are the following main types:

- An electric jackhammer is the most popular type of tool and is practically indispensable on construction sites. An important limitation to its use is the high humidity of the room, which increases the likelihood of receiving an electric shock. The only important drawback of electric fenders is their connection to the electrical network.

- The gasoline jackhammer has found its active use among workers who carry out work to prepare the surface for laying road surfaces. The important advantages of such units are: mobility, that is, lack of connection to the electrical network, as well as increased drive power, which allows you to perform a wide range of heavy work: from crushing concrete structures to compacting soil.

- Hydraulic is a professional type of tool, the operating principle of which is based on the use of oil pressure. The devices are compact, which is due to the absence of drive units in their design, but at the same time they are tied to special hydraulic stations. If the cost of a hydraulic breaker is lower than the price of electric and gasoline ones, then the purchase of specialized stations is problematic even for construction organizations and companies. These types of fenders are used in rooms with high humidity, where there is a strict ban on the use of electrical devices.

- A pneumatic jackhammer is another most common type of tool, which has found active use not only among builders, but also road workers, miners, etc. The hammers are compact and easy to operate. Impact actions are created using a special compressor, to which the bump stop is connected via a high-pressure hose. The disadvantage is the attachment to the compressor, but the products are characterized by such advantages as low cost, high efficiency, long service life and low maintenance costs.

These are the main types of jackhammers that are produced by tool manufacturers. Among all the listed types, electric and pneumatic models are especially popular. Gasoline units are more expensive, so they are less in demand than previous types. Hydraulically driven tools are used only in specialized facilities.

About the main advantages of pneumatics

It should be noted that pneumatic bump stops are very popular. This at least suggests that they have significant advantages over outdated options. For example, the absence of sparks during work is a very important point. There is no risk of fire or explosion in this case. Therefore, it is advisable to use such equipment in mines. One cannot fail to mention such a strong point as the wide possibilities for power adjustment. This allows you to perform work of varying complexity and purpose. This is facilitated by two modes of operation of the tool. As for the main and most significant drawback that a pneumatic jackhammer has, it is the presence of a compressor. The latter is needed to supply compressed air. This is noisy and bulky equipment, which is also energy dependent. All this significantly increases the price of pneumatic bump stops.

Electric jackhammer - how does the unit work?

In principle, jackhammers are not divided into household and professional, since the tool itself is professional. Fenders are grouped according to different criteria. For example, weight - light jackhammers include units that weigh no more than 5 kilograms. Such devices are universal and especially convenient when working in a horizontal position.

Most often, it is these devices that are purchased by repair teams, because with their help you can easily knock off old plaster on the walls, make a niche for a transformer, or get rid of a wall altogether by connecting two rooms into one. Along with the chippers, we recommend buying different chisels for the hammer drill - they will also fit the chipper. They can also solve more complex problems, although it will take much longer than when working with fenders weighing over 10 kilograms, which belong to the average category.

Heavy hammers weighing from 30 kilograms cope with the most difficult jobs, for example, dismantling concrete structures. True, it is most convenient to work with such units in a vertical position; in a horizontal position it is almost impossible, because the operator needs to cope not only with the weight of the tool, but also with vibration. Medium and heavy devices are highly specialized - weight, while being their advantage, is at the same time their main disadvantage.

According to the shape of the body

There is no need to talk much about the geometry of the body of construction jackhammers. Even in publications where their types are examined in detail, this topic is not covered. Everything is completely predictable: outwardly it is a rod with a tip of various shapes. But there are also externally similar riveting hammers that allow you to work effectively with large steel and aluminum rivets. The weight of such devices exceeds 3 kg, and they are quite bulky in size.

Air chipping hammers also deserve attention. They are helping:

- remove excess deposits on the surface of castings;

- clean parts of gating systems;

- clean out burnt marks.

What is the instrument?

The design of the device refers to a pneumatic system with pistons and an impact operating principle. The compressor is an integral part of the equipment. It continuously supplies compressed air. The basic components of a pneumatic hammer include the following:

The tool is designed in a special way that allows it to perform its functions.

- Lever. Its body has a built-in starting mechanism and muffler.

- Vibration protection. Represented by a glass with sealing bushings.

- Chisel protection.

- Impact (working) unit, which includes impact, air distribution systems and a barrel.

- Nozzle. Selected for a specific task.

PREPARATION AND OPERATION PROCEDURE

8.1. Hammers received from a factory or warehouse must be disassembled after long-term storage, the parts cleaned of grease and thoroughly washed in kerosene and reassembled.

8.2. Check the freedom of movement of the hammer in the barrel by turning the hammer in a vertical plane.

8.3. Make sure the idler is screwed in tightly and secured with the stopper.

REMEMBER that when this connection is weakened and gaps appear in the air distribution device, the hammer parameters sharply deteriorate.

8.4. Make sure the handle moves freely.

8.5. Before starting work, attach the hammer hose to the filter and lubricant nozzle in the compressed air network. If there is no lubricant nozzle, inject lubricant through the nipple. During the operation of the hammer, periodically fill the hammer with lubricant to ensure constant lubrication of the rubbing parts. Lubricate the new hammer 3-4 times per shift during the first two weeks of use. A worn-out hammer should be lubricated at least twice a shift.

8.6. Clean the lance shank from dirt, put a rubber bushing on the lance, insert the lance into the hammer and secure it with an end spring, screwing it onto the barrel until it stops so that the lock fits into the corresponding groove in the barrel.

8.7. Blow the sleeve with compressed air and, making sure there is no dirt, attach it to the hammer nipple. Make sure that the hose is securely fastened and that the operating air pressure is not lower than 0.4 - 0.55 MPa.

8.8. Press down the hammer while working the lance.

8.9. When taking breaks from work, store the hammer so that dust, water, etc. do not get into it.

Subtleties of choice

But not only the geometry of the jackhammer and the type of its drive are important - each type of attachment determines the possibility of performing certain specific jobs. Thus, “crowbar” peaks are designed to:

- loosen the soil;

- demolish brick and concrete walls;

- dismantle old road surfaces;

- process minerals, rock stone.

A shovel is needed if you need to level asphalt edges and also chip away ice. Chisels can be used to cut a wide range of materials. Accordingly, the functionality of a jackhammer directly depends on compatibility with certain attachments. The mass of a particular bumper also deserves a separate discussion. Thus, a tool weighing up to 6 kg is chosen if you plan to work at heights, and the heaviest ones (30 kg and above) allow you to work with soil and break old foundations.

As already mentioned, only pneumatic hammers can be used in fire hazardous environments. However, when choosing them, the characteristics of the hose are critical. The connecting diameter is not suitable, which means it will not work. The same thing will happen if there is not enough length. Of course, they also take into account:

- type of material;

- wall thickness;

- diameter and internal section;

- permissible pressure level.

A pneumatic device that delivers impacts with a force of 30 J can successfully operate on weight, as well as in confined spaces. If it is not clear in advance what specific work needs to be done, you need to take universal equipment. It delivers impacts of 40 J. But for concrete, natural stone and other very hard materials, chippers with an impact energy of 50 J or more are recommended. We must not forget about whether it is comfortable to hold the tool in your hands - very powerful devices are often heavy.

As always, you need to pay attention to the manufacturer’s brand and take into account its reputation. Some companies that make jackhammers produce high-quality products

But there are also those that supply downright bad products.

Important: conscientious manufacturers are not only among the leaders of the global and domestic markets. It is not advisable to buy electrical devices that are not equipped with a button lock: you will have to constantly hold the start switch manually

Devices with idle speed limits work much longer and are more efficient. This limitation is extremely simple to implement. As soon as the sensor detects a drop in load intensity, the engine speed drops on command. But as soon as the load increases, the revolutions become higher. The vibration damping complex is of great benefit. If it is not provided for by the designers, it will be more difficult for operators, and there will also be a significant health risk.

Read also: Diamond burs for engravers

Finally, for a more accurate and competent choice, it is useful to analyze the characteristics of individual brands of jackhammers. Fenders from the Japanese corporation Makita deservedly have a very good reputation. This company has been supplying power tools for over 100 years. You can remove and install attachments on Japanese brand bumpers quickly and completely safely. The developers have provided built-in units that regulate the number of revolutions per minute.

Good results are also achieved using Bosch jackhammers. The German concern values its reputation and carefully monitors the quality of finished products

What is important is that the packaging is marked with a list of basic characteristics - choosing the most suitable modification is not difficult. You can also consider fenders from Hitachi, Zubr, DeWalt and other domestic and foreign manufacturers that have proven themselves

Manufacturers. Who to give preference to?

1. Makita jackhammer. This brand is in great demand in the building materials market because it has an excellent reputation. Each unit of production is characterized by Japanese precision, high quality, and practicality. The pricing policy is acceptable.

The Makita jackhammer is produced by the company in a wide range; in the model range you can find custom and professional, light, medium and heavy, as well as electric, pneumatic and gasoline chippers.

In the “Custom Jackhammer” group, I would like to highlight the Makita HK 0500 (HK0500) SDS-plus model. Its technical characteristics are amazing: weight - 3100 grams, length - 46.8 cm, while the impact force is 2.8 Joules, and the number of blows in 60 seconds is 2000-3500.

In the line of professional models, Makita HM 1203 C (HM1203C) SDS-MAX and Makita HM 1304 B (HM1304B) 28.6 mm deserve special attention. These models optimally combine parameters such as weight, force and impact frequency.

2. Bosch jackhammer. German quality has long been valued all over the world, and the quality characteristics of this category of products are no exception.

It is worth noting that this quality is expensive, but quickly pays off. One of the best professional hammers of this brand is the BOSCH GSH 27 model.

3. Jackhammer "Interskol". Produced on the territory of the Russian Federation. The model range includes many positions. The company demonstrates the ideal price-quality ratio of its products.

Pneumatic jackhammers and features of their functioning

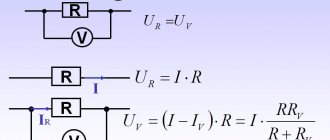

Such devices are distinguished by their simplicity of design, which affects not only their cost, but also their service life. The only drawback of pneumatic devices is that they are used in conjunction with compressors that operate on electricity. This means that you cannot use a pneumatic bumper where there is no centralized power supply, or only if there is an electric generator, but in this case, it is easier to purchase an electric tool. The operating principle of pneumatic jackhammers is even simpler than their electric and gasoline counterparts. To understand how it works, consider the diagram in the figure below.

The diagram shows important structural elements. The drive role is played by compressed air supplied from the compressor through a hose that is connected to the fitting. The operating principle of the tool is as follows:

- When the compressor starts, the tool operates in idle mode, that is, the working element number 5 does not perform impact actions.

- The transition to the working mode occurs after the operator picks up the tool and presses its working element (nozzle) into the material that needs to be crushed.

- This happens as follows: in idle mode, valve 9 in the diagram is pushed upward by air and does not allow it to pass to the working mechanism.

- When the master presses the handle, the valve closes and compressed air flows to the working mechanism.

- Initially, chamber 6 is filled with air, in which the piston with the striker is located. A zone of high pressure is created in it.

- A zone of low pressure is created under the piston, that is, air rarefaction occurs.

- The piston with the striker is directed downward (from excess pressure), acting on the back side of the nozzle installed in the tool chuck.

- The impact from the nozzle is transmitted to the object being processed, causing its destruction.

- The reverse movement of the nozzle occurs due to a change in the air supply channel. This is realized constructively using a special mechanism. There are 4 holes in the tool barrel, two of which are blind and two are through. The pins of the air distribution mechanism are installed in the blind holes, due to which air is alternately supplied to the corresponding channels of the tool.

- The pressure increases under the piston, and a vacuum occurs above it. Thus, an impact effect is created, in which the destructive effect of the processed material occurs.

The speed of the blows is approximately 25 to 30 blows per second, which corresponds to the value of electric tools. How a pneumatic jackhammer works inside can be seen in the video, which shows the process of disassembling the tool.

These types of tools have many different benefits. Some of the main advantages are:

- simplicity of design;

- high level of maintainability;

- infrequent occurrence of malfunctions;

- the absence of a drive reduces the weight of the tool;

- low cost;

- Possibility of use in rooms with high humidity and gas concentrations.

The disadvantage is not only the dependence on a compressor that is powered by electricity, but also the importance of using a blower with a large receiver. This is necessary in order to ensure a stable air supply. This is interesting! If the farm has a high-performance compressor, then the best option for a jackhammer is a pneumatic one.

This is interesting! If the farm has a high-performance compressor, then the best option for a jackhammer is a pneumatic one.

A little about the power of the equipment

The second characteristic is the power of the tool. If previously units were sold that could only operate at a fixed level, today it is better to buy bumpers that have a power regulator. Fortunately, choosing such a model will not be difficult. Light fenders can operate at 8 Joules, and the most powerful units at about 60 Joules. The lower mark will be sufficient for processing not very hard surfaces and sedimentary rocks. The upper threshold is used quite rarely. You should also know that there are also electric fenders. Such an instrument must have at least 500 and no more than 2000 watts. The situation with the lower and upper marks is similar to pneumatic equipment. From all of the above, we can conclude that it makes sense to pay attention not only to the speed, but also to the power of the unit. At the same time, the design of a pneumatic jackhammer should be as simple as possible, which will make it more reliable.

FAQ

By tradition, I collect frequently asked questions from forums, from friends, acquaintances and clients. Didn't find the answer to your question? Write in the comments, I will definitely answer. I’ll add the most interesting questions to this section!

Tell me how to choose a jackhammer?

Consider the weight - the heavier the instrument, the better it “fits” into each blow.

Pay attention to the impact frequency - the lower the stated value, the more destructive each shock. As the frequency increases, the accuracy of operation increases

These rules are common to everyone. As for the type of drive, it is impossible to give clear recommendations without taking into account all the nuances.

Don’t get hung up on the numbers that “characterize” the impact force - although these joules exist, they depend on a combination of a variety of factors. The theoretical value is calculated based on the available data. And not every model has been tested for impact power in laboratory conditions. There is also no uniform methodology for such tests. By the way, in Europe there is a tendency to move away from pure marketing among manufacturers of professional tools. Since 2016, Atlas Copco has not indicated any joules anywhere, neither in advertising nor in technical documentation for new (the same RTEX) equipment.

Is it possible to get by with a heavy perf where the use of a light fender is indicated?

For a one-time job, with chiselling for 10-15 minutes - yes. For a permanent one - no. The fact is that any hammer drill has a comparatively worse implementation of heat removal from the piston group - the specifics of the operation do not imply long-term switching on, so overheating is not particularly taken into account. In any jackhammer, the working cylinder is made much larger - a powerful blow is needed. And the entire barrel is responsible for removing thermal energy from air compression. Therefore, even the cheapest chipper can hammer for 40-60 minutes without consequences.

How to choose the right compressor for a pneumatic jackhammer?

In the case of pneumatic chisel options, you can get by with a household compressor. Compare how much air the tool consumes during operation and how much air the receiver emits before the automation is activated; consider the compressor performance.

For example, to ensure a stable supply to a hammer with a consumption of 110 l/min, the receiver must deliver at least 110 l/min in operating mode. A 100-liter storage tank at a pressure of 8 atm (the upper limit for a household compressor) holds 800 liters. When 630 liters remain in it (the lower working threshold of the tool), the compressor will begin pumping up to 800 liters again. We see that for a minute of continuous operation of the air chisel, the capacity of the 100 liter receiver is enough.

Next, we look at the pump parameters - by pumping 250 l/min, it will provide air to the instrument and will be able to increase the pressure in the receiver. Which will take him no more than two minutes. After which it will become silent until the pressure drops.

With a normal operating cycle for a compressor (60% of the time for pumping, 40% for rest) and continuous operation of the tool, there is compliance with the operating rules. Taking into account the fact that it only takes 10-15 seconds to chop the bodywork of a car without a break (if the roof is diagonal), then the compressor has about 30% more time to rest than it needs. A completely acceptable option.

In the case of a pneumatic hammer, which consumes a cube or more per minute, you need an industrial compressor on a mobile platform.

About vibration damping and operating comfort

It’s easy to guess that a person who has worked for about 6-8 hours on a bump stop has a very hard time. Vibrations are the cause of many diseases, so they always try to extinguish them as much as possible. For this, special gloves and clothing, as well as other personal protective equipment, are used. In the case of pneumatic equipment, you don’t have to worry about the operator’s well-being. This is due to the fact that engineers were able to design a structure that helps absorb 70-75% of vibrations. Unfortunately, it is impossible to completely eliminate such an undesirable effect. When purchasing a tool, pay attention to the fact that the pneumatic jackhammer (MO) has a noise muffler. This is due to the fact that this technique is very bulky and noisy, in particular the compressor creates inconvenience. With a noise muffler and earplugs, you can achieve good results and work in more or less comfortable conditions.

Kinds

Several parameters are used to classify the devices under consideration.

Based on performance, jackhammers are differentiated into three types.

- Lightweight options are designed for household work. They are capable of crushing plaster, tiles, etc., which makes them suitable for home repairs. The weight of such mini jackhammers is 5-6 kg.

- Medium power devices are suitable for asphalt, so they are used in some construction work. Weight from 6 to 10 kg provides the possibility of long-term horizontal holding.

- In industry and in the construction of buildings, high-power jackhammers weighing 15-30 kg are used.

However, mass is an indirect indicator of performance. There is a classification close to the above, based on other, more significant parameters. It also includes four types.

- The first includes jackhammers with impact energy up to 30 J and frequency up to 45 Hz. They are suitable for medium-strength materials such as asphalt, brick, clay, and work in confined spaces.

- The second type is represented by options with an impact energy of 40 J and a frequency of 34 Hz, used in general construction work.

- The third type includes models with impact energy up to 45 J and frequency up to 20 Hz. They are used for work with vertical impacts on durable materials.

- The fourth type is represented by hammers with an impact energy of more than 50 J and a frequency of up to 24 Hz. Such devices are used for high-strength materials.

Based on the power source, there are four types of jackhammers.

- Pneumatic devices are the most common type. The power source for them is a compressor. The principle of operation is based on the pressure of compressed air molecules on the chisel. This equipment is suitable for destroying any structures made of brick and concrete. For household options, a power of 5 J is required, while for industrial models this parameter ranges from 10 to 100 J. This is enough to destroy asphalt, stone, concrete, etc.

- Electric hammers are powered from the mains. The principle of their operation is to drive the striker through the rotational element of the electric motor. Performance parameters are up to 1700 W of power, 45 J of impact energy and 2000 beats per minute of frequency. Thus, these types of jackhammers have high impact power, but are not suitable for cutting and drilling materials.

- Gasoline devices are driven by an internal combustion engine, which does not have valves and a shaft. With low power, the main advantage of these options is autonomy, that is, the ability to be used anywhere. This is due to the absence of the need to connect to an energy source. The duration of operation is determined only by the amount of fuel. In addition, jackhammers of this type are considered safer in comparison with analogues. However, they have a high noise level. These models are used in the mining industry for the destruction of concrete, asphalt, and frozen soil.

- Hydraulic hammers use a variety of power sources. They are usually used in emergency rescue operations.

- Volumetric devices are driven by rapidly expanding air in the chamber.

- The operation of turbine options is ensured by the energy generated by the rotation of the turbine.

The simplest classification of jackhammers based on a set of basic parameters differentiates them into professional and household.

Concrete breakers are distinguished by their large size, weight and productivity. These devices are designed for vertical and inclined work with concrete slabs, rocks, asphalt pavement, and frozen soils. Rotary hammers are usually more compact than jackhammers or similar in size, they are distinguished by greater accuracy and the ability to perform the functions of a drill and screwdriver with adjustable speed and reverse. This versatility makes them much better suited for household work. Thus, the operating instructions for PE-2520M indicate the possibility of its use as both a jackhammer and a drill.

Gasoline jackhammer ADA Ground Hammer 3

Another popular representative on the domestic market is equipped with a 32.7 cc two-stroke gasoline engine. The main parameters of this modification:

- operating power (hp) - 1.2;

- impact force (J) - 25-45;

- number of movements of the working body per minute - 1700-2230;

- fuel tank volume (l) - 0.9;

- fuel consumption (l/h) - 0.5;

- weight (kg) - 13.

The instrument in question is equipped with a pair of handles that facilitate the operation of the device. The package also includes three special nozzles, lubricant, and a set of keys. Among the advantages of the model, a powerful engine is noted along with a relatively low weight, ensuring complete autonomy during operation.

Transporting the unit is also not difficult, since it has compact dimensions (375/280/603 mm), which does not require much storage space, and transportation can be carried out in the trunk of any car. The device holder handles are highly ergonomic and have protective rubber linings that reduce vibration during operation.

Diagnostics of breakdowns and repairs

There is a saying among jackhammer repair specialists. The chipper is the same Kalashnikov assault rifle, only it shoots more often. Complete disassembly and assembly in the hands of an experienced craftsman occurs quickly. It is better for a beginner to first familiarize himself with the device and only then begin repairs.

Regardless of what drive the hammer has, dismantling begins with complete disconnection from the compressor or power supply.

Disassembling the tool without turning it off is strictly prohibited; this is dangerous to life and health.

The assembly and disassembly procedure is described in the technical documentation for each product.

Video: disassembling and assembling a Makita electric jackhammer

Below are the most common types of breakdowns of pneumatic hammers and how to fix them.

Table of probable faults and the order of their elimination

| Possible breakdowns and ways to eliminate them | |||

| Damage, its external signs and manifestations | Preparatory work for repairs | Sequence of work | Special tools or devices for troubleshooting |

| 1. The jackhammer does not work | |||

| No pressure, low air compression level | Monitoring the air pressure at the compressor outlet | 1. Cleaning and blowing hoses. 2.Checking the integrity of the supply hose. If damage is found, replace it. | Pneumatic hose, high pressure hose. |

| The bore channels were clogged, water got inside and froze | Dismantling and inspection of the barrel | Cleaning and flushing the channel from debris, water and ice. Assembly, purging and running-in under low load. | Clean flushing kerosene. Lubricating oil recommended by the manufacturer. |

| 2. Reduced number of blows with a weak single blow | |||

| Using a pneumatic hose (sleeve) of small cross-section or too long. Reduced air pressure. | Air pressure control. The distance between the compressor and the hammer should not exceed 20 m. | Pressure gauge. | |

| Hose blockage due to damage | Disconnecting the hose from the compressor and hammer | Find and remove the damaged part of the sleeve. Repair or replace the entire hose. | Knife, clamps. |

| Hose fracture. Excessive amount of lubricant | Disconnecting the hose from the compressor and hammer | Eliminate the bend. Clean the hammer. Run in at low load. | Flushing kerosene, industrial lubricant. |

| 3. Increased number of blows with a weak single blow | |||

| Increased clearance between the distributor and the barrel receiver. | Disconnecting the hammer, muffler. Removing the locking ring, retainer. | Tighten the link until it stops and install the locking ring. | Bench vice, special puller for the locking ring. |

| Clogging of the interface between the stem end and the valve box cover with foreign debris. | Disassembling the hammer. | Removing and removing foreign objects (sand, shavings, dirt, etc.) Washing and blowing parts. Run-in is required before work. | Rags, kerosene, lubricants. |

| 4. Uneven hammer operation | |||

| Large shank play in the chuck. | Removing the bit from the axle box. | Pressing the hammer towards the end of the tool. | |

| 5.Excessive wear and oxidation of parts | |||

| The presence of moisture and dust in the air supplied from the compressor. | Removing rust and dirt in a pneumatic hose. Inspect the air filter. Clean or replace as necessary. | Locksmith tools, keys. |

How to use the device, safety precautions

Working with a jackhammer has a number of features associated with the impact of negative factors on the operator.

- increased vibration during operation;

- increased level of dust in the chiselling area;

- high noise intensity, hazardous to health;

- an abundance of small particles of solid material flying at high speed from under the bit.

When working with a chipper, protective equipment is required

Therefore, safety requirements include the following points:

It is prohibited to carry out work without the use of personal safety equipment - earplugs or headphones, a respirator, safety glasses, as well as to work without gloves and a protective suit made of thick fabric. It is prohibited to use a jackhammer that is known to be faulty.

Before turning on, it is necessary to check the fastening of the chisel and the tightness of the bolts on the housing. During operation, following the safety rules, it is necessary to hold the bump stop only by the standard handles. It is unacceptable to work with one hand. If there is an additional holder, use it for its intended purpose.

The body position must be stable. It is prohibited to entrust the instrument to minor children and to leave it turned on unattended. It is unacceptable to point the tip of the chisel towards other people. After completing work, do not touch the metal part of the housing with bare hands. This may cause severe burns. It is unacceptable to use the tool for purposes other than its intended purpose, such as a crowbar or a shovel when the drive is turned off. The maximum operating period of a jackhammer is limited to 6 hours. Resumption of work is permissible only after a 1-hour break. When using the tool in the cold season outdoors, the lubricant needs to be warmed up. To do this, you need to turn on the device, and for 2-3 minutes. warm up at idle speed.

Following these simple rules will protect the user from injury and the bump stop from premature wear.

Often, when using a pneumatic jackhammer, some users increase the pressure of the compressor supplying compressed air to the tool. They proceed from the simple reasoning that the greater the pressure on the piston, the greater the impact force. This is true. But, unfortunately, for a very short time.

The compression level must correspond to the set nominal pressure of the unit

All rating parameters of the hammer are indicated taking into account the nominal pressure - this is, as a rule, 0.5–0.6 MPa. (or 5–6 atm.). When the pressure increases to 7–8 atmospheres, the load on the piston increases sharply (by 40–60%), and this leads to a halving of the service life of the parts. Therefore, the conclusion is simple - instead of “squeezing” unusual power out of a hammer, it is better to choose a tool with increased impact strength.

During operation of an electric jackhammer, sparks occur on the electric motor commutator. This must be remembered when performing work near combustible and flammable materials. In such a situation, it is safer to use pneumatically driven devices.

Important criteria for choosing an electric jackhammer

Depending on the weight, a jackhammer performs different functions.

If everything is clear with the main features of the device and the operating principle of an electric jackhammer, then what functions the lance performs, as well as what you need to pay attention to when choosing a unit, you need to understand in a separate order. Electric jackhammers are equipped with different types of peaks

Each of them is designed to perform a specific job. The main varieties are as follows:

- Pike-crowbar - allows you to dismantle brick and concrete structures, loosen the ground, remove old road surfaces, and process rocks.

- Shovel - mainly used when it is necessary to level the edge of asphalt and chip off ice.

- Chisel - such a peak will help cut various materials.

The weight of a jackhammer is as important as its design. Depending on the weight of the device, the tool belongs to different classes:

- lung;

- average;

- heavy.

Lightweight devices weigh up to 5-6 kg. They are used primarily for work at heights and finishing work. Average jackhammers weigh up to 10 kg. Used to perform work in a horizontal plane. The weight of heavy units reaches 30 kg. They are necessary for performing various soil and foundation work. Before purchasing a jackhammer, carefully consider the type of work you plan to do with it, and make your choice based on this information.

Tool design features

A jackhammer is designed quite simply. The design of the unit is characterized by significant weight indicators. That is why, in most cases, the main material in the manufacture of a hammer is high-strength plastic.

The final component of the bump stop is the lance. Thanks to her, all the main work is carried out. Peaks are different. They are selected according to the type of work that needs to be performed. Peak types:

- pike-crowbar;

- chisel;

- spade-spade;

- tamper

One of the advantages of a jackhammer is the ability to operate it in absolutely any position. In addition, it can be used to easily deal with concrete and reinforced concrete. There are also special models of tools designed for use underwater.

Characteristics of automatic hammers

Power. For an electric drive or a gasoline engine, this is an indicator of the power plant. Compressed air – compressor power.

Impact force. Work at the point of application of force or the amount of energy transferred to an object in a limited space (the area of the impact tool). As the performance increases, the ability to work with heavy and dense materials increases. For example:

- up to 5J – removing plaster or tiles, gating under a cable or pipe;

- 5-30J – dismantling brickwork, concrete partitions, leveling a dense base;

- 30-60 J – processing frozen soil, mining rocks, making niches in a concrete wall;

- over 60 J – “concrete breakers”; destruction of floors at airfields, building reinforced concrete structures, foundations.

Number of hits. Shows the number of impacts per unit of time. Characterizes the performance of the tool. A specific type of work or type of material has its own processing mode.

Dimensions:

- Light class, up to 5 kg, used for finishing work; versatility, the ability to perform operations in a horizontal position (perpendicular to vertical planes).

- Medium, 5-10 kg, is used to solve a wide range of tasks - making openings, dismantling a concrete base or destroying asphalt; Due to the increased mass, restrictions are imposed on operation in the horizontal plane.

- Over 10 kg – “concrete breakers”; Designed to work in harsh conditions with strong and viscous materials.

The tool is used in conjunction with the following accessories:

- Crowbar (spike). It is used to create depressions, holes, loosen the soil, destroy rocks or concrete.

- Spatula. Removes old coatings, tiles, and cleans the surface of deposits.

- Chisel. Used for operations on reinforced concrete, frozen soil, metal cutting.

- Tamping. Compacts soil or soil, used for sealing seams and cracks.

The design of the device provides a number of functions:

- Soft start mode. Relevant for electric drive. Allows you to smoothly increase speed, reduce starting loads, and increase service life. The electric hammer works smoothly. The load on the hands is reduced.

- Adjusting the number of strokes. The frequency is adjusted for a specific operation. Heavy structures require maximum performance. Precision work is carried out at minimum values.

Auto mode. The adjustment system independently selects constant numbers of blows, regardless of the applied load.

- Fixing the start button. Allows you to block the trigger mechanism, thereby relieving the operator's fingers from the load.

- Vibration protection. The operation of the mechanism causes increased vibration, affecting the mechanism of the device and the operator. The use of dampers, counterweights, and soft shock-absorbing materials can reduce the load.

This has a beneficial effect on the person and the design of the device.

Indication of serviceability of carbon brushes. Warns that the time for replacement of electric motor brushes is approaching due to wear of the conductive coating.

General information about portable impact mechanisms

A jackhammer is a mechanical hand-held percussion tool designed for loosening hard and frozen soil, punching openings and openings in brick walls of buildings, dismantling brickwork, splitting ice, breaking coal of various strengths, extracting soft ores, clay, slate and other construction and mining materials. works

The executive body is usually a metal chisel or lance. The mechanization of a tool involves the impact on the executive body of a series of mechanical impulses from the striker, which is driven by some kind of drive. The impact frequency is 16…25 Hz. When a shock impulse is imparted to the chisel from the side of the striker part (butt plate), the cutting edge of the chisel acts on the material being processed, cutting it or splitting it.

A jackhammer is typically a valve-actuated piston impact machine. The hammer is turned on by pressing its handle with your hand. When the hammer operates, the striker performs a reciprocating movement and, at the end of the working stroke, strikes the shank of the lance, held in the axle box of the hammer barrel by an end spring. A worker uses a jackhammer as a lever when breaking rocks. The hammer turns off automatically when the force is removed from the handle.

The effectiveness of a jackhammer largely depends on the replaceable tip - the jackhammer lance. The lance directly affects the object being destroyed.

Being an intermediate link between the jackhammer striker and the object, the jackhammer peak should, on the one hand, effectively influence the object of destruction, and on the other hand, if possible, preserve the impact mechanism of the jackhammer. Those. A lance that is too “strong” will unnecessarily wear out the hammer, and a “soft” lance will be less effective in operation. Long-term practice shows that approximately ten peaks are consumed over the service life of one jackhammer.

For a jackhammer, there is a large selection of tips for the working body, which should be selected depending on the type of work planned, for example:

Figure 1 – Pick-chisel

The pick-chisel is used to cut through any material, to destroy brick walls, asphalt, frozen soil, granite. Lance lengths up to 1500 mm are available.

Figure 2 – Pick-crowbar

A tip in the form of a crowbar is chosen if you need to loosen the soil or destroy an asphalt or concrete surface.

And to combat icing, to cut down, crush and process the edges of asphalt, to strip walls of a layer of plaster, if you need to clear a large area of concrete, you will need a pick-shovel.

Figure 3 – Pick-scapula

The tamper is used to perform soil compaction work when it is necessary to seal a seam or a crack in a place where this cannot be done in the usual way.

Choosing the right jackhammer involves determining the purpose for which it is being purchased. It is the scope of application and operating conditions that determine the preferred characteristics of the tool. The main parameters are the number of beats per minute, the power and energy of the blow itself. The level of vibration and noise during operation is also important.

In addition, it is worth paying attention to the body and handle of the hammer, their ergonomics, functionality

Structural components

In terms of its design, a typical forging hammer consists of the following components:

- power cylinder;

- rod;

- two side racks;

- Shabota;

- women;

- control systems.

In the cylinder, the pressure created by the superheated steam is redistributed, with the direction of the energy flow into the lower cavity, to which the rod is rigidly connected. A hammer head is attached to the opposite part of the rod, making reciprocating movements, thereby deforming the material. A forging hammer is distinguished by the presence of smooth strikers, while a steam-air hammer is equipped with a special tool - a forging die.

Diagram of operation of a pneumatic forging hammer

Current positioning is carried out by special guides on the side posts with a developed contact surface. Similar elements are provided on the side surfaces of the woman; as a result, fairly accurate blows are applied to the heated blank.

The chabot is a large and massive cast iron part: for operational reasons, the mass of the chabot should be at least 10 times greater than the mass of the falling parts. To reduce vibrations, the chabot is placed deep in the ground and installed on a vibration damper, which is large square oak boards.

Device

The main structural elements for any type of jackhammer are represented by a striker, a nozzle, a cartridge, etc.

Pneumatic piston models are designed according to piston systems based on the impact principle. The main structural elements are represented by a starting spool, a striker, a piston, a fitting for a compressor hose, a cup with a ring valve and a valve box, and a muffler. In addition, jackhammers include two springs, a shock absorber, a retaining ring, a handle, and a body.

These parts are combined into several units.

- The hammer, also called the trigger and air distribution mechanism, includes the firing pin and the barrel.

- The vibration protection of the handle is represented by a glass and sealing bushings.

- Anti-vibration protection from the chisel includes a manipulator and a spring-loaded bushing.

- The housing-handle includes a housing, an aerodynamic noise muffler and a trigger mechanism.

The impact system has two main functions: supply, distribution and removal of air, converting its energy into work.

Electric models are equipped with such specific components as an electric motor, a gearbox that serves to convert the rotation of the latter shaft into reciprocating movement, a crank mechanism with a piston that provides pressure in the cylinder acting on the firing pin.

Components specific to internal combustion engine jackhammers include the carburetor, fuel tank, starter, ignition system, and fuel pump. In addition, taking into account the increased vibration of these devices, the handle and control elements are separated from the body by a spring suspension.

There are several options for attachments for various purposes. Thus, a chisel is used to destroy concrete and metal; scrap or cylinder - brick, concrete, ice; pencil or pick - asphalt, brick, frozen soil; shovel – asphalt, ice; tamper – for soil compaction.

In addition, there is additional equipment for a hammer. It includes the following four devices. An automatic speed controller, called soft start and idle speed limiter, serves to extend engine life by eliminating overloads and gradually accelerating. The principle of its operation is based on adjusting the speed in accordance with the load. The side handle improves ease of use by promoting proper grip and distribution of effort. The impact frequency control increases the degree of control of the tool, allowing the demolition hammer to be adjusted to suit materials of varying hardness. The button lock ensures that there is no need to constantly hold it during operation.

The principle of operation of jackhammers is to create reciprocating movements of the striker located in the barrel, which is not kinematically connected with other parts. This is accomplished by different mechanisms depending on the type of hammer.

Thus, in piston pneumatic models, the air supplied by a hose from the compressor overcomes the resistance of the valve spring when acting on the handle. As a result, the valve moves, opening the opening of the impact mechanism. Alternately, a vacuum and excess pressure are created in the lower and upper parts of the cylinder due to the passage of compressed air between them by the valve system, generating reciprocating movements of the striker.

The operation of a pneumatic turbine hammer is based on the drive by the energy generated by the rotating air of the turbine wheel.

Gasoline hammers are also usually equipped with a pneumatic impact mechanism. The piston, changing the pressure in the cylinder, leads to the movement of the hammer piston with an attached tip.

Rating of popular and effective devices from reliable manufacturers

The modern market offers hundreds of models of jackhammers. However, the highest sales volumes are shown by equipment from three brands. These are Japanese Makita (the instrument is often assembled in Romania), German Bosch with factories around the world, and domestic Interskol, which has an attractive price and impressive characteristics.

Makita HM1101C

It is not for nothing that the Makita is considered the most desired tool of many builders and home craftsmen. This jackhammer has almost maximum attractive features. Among them are smooth control of engine speed, automatic adjustment to material hardness, and the ability to cut grooves with the desired parameters by installing the nozzle at a changing angle.

The ergonomics of the device are thought out to the smallest detail, but it is worth noting the poor weight distribution. Despite the impact indicator, which allows us to classify the model as belonging to the first classification category, its geometry is typical of the third. Device power 550 W, striker energy 2.8 J, pulse frequency from 2000 to 3500 Hz, weight about 3 kg.

- excellent efficiency, low energy consumption thanks to electronic engine control;

- reliable steel chuck with quick nozzle change mechanics;

- convenient blow frequency regulator;

- double insulation of electrical wiring;

- low weight;

- 12 nozzle positions;

- long wire.

- weight distribution, most convenient for working in a horizontal plane;

- handle design that violates the force distribution pattern.

Bosch GSH 11 VC

The German brand Bosch is able to lead the ranking of manufacturers of the best devices with perfectly balanced characteristics. The Bosch GSH 11 VC electric jackhammer was no exception.

The model belongs to the first category in terms of impact energy of 23 J. The device is quite heavy - 11 kg. However, the design complies with all ergonomic rules. Ideal weight distribution, location of the center of gravity, grip and direction of impact will allow you to operate the tool without the accumulation of fatigue for a long time.

- powerful engine;

- significant impact force;

- possibility of long-term operation (engineering solution) at maximum loads;

- perfect layout;

- reliable cartridge with the ability to quickly change the nozzle;

- efficient engine ventilation system;

- convenient location of switches.

- electronic engine control;

- 12 chisel positions;

- low vibration level;

- impact force adjustment;

- indication of the need to change the current-collecting brushes of the motor.

- the cable is not long enough;

- high mass.

Interskol M-25

The main characteristics of Interskol products are reliability, simplicity, and thoughtfulness. It is worth noting that the company carefully researches the market and develops tools with successful design and engineering solutions.

As an example, consider the M-25 model. The comfortable handle allows you to effectively manipulate the tool in a horizontal position. However, the Interskol M-25 has excellent weight distribution due to the engine being located almost on the impact axis. In addition, the start button has also been moved. As a result, the device is very easy to operate, despite its fairly high weight of 17 kg. Impact energy is 25 J, frequency is 1400 mm, electrical power consumption is 1500 W.

- reliable vacuum compressor mechanism;

- steel 30 mm cartridge;

- strikeless system with no wearing moving parts;

- possibility of long-term operation at maximum power;

- successful weight distribution;

- rubber pads on the handles;

- carefully thought out ergonomics, enormous reliability.

- the weight is much higher than competitors due to the use of a strikerless system;

- no shock force adjustment.

Scope of application

Construction is effective and enjoyable when there is a differentiated approach to solving different problems. The table shows the compliance of the equipment with the type of work performed:

| Difficulty of work | Tool brand | Material to be dismantled |

| Lungs | MO-1B | Asphalt pavements, brickwork, ice |

| MOP-1 | ||

| Average | MO-2B | Lightweight concrete, soft coal mining |

| MO-2M | ||

| MOP-2 | ||

| Heavy | MOP-3, 4 | Destruction of concrete grades from M100 to M600 (runways, overpasses, bridges) |

| BK-1, 2, 3 |

Do-it-yourself pneumatic diesel injector remover

The injectors are located in a hard-to-reach place - the well of the cylinder head (cylinder head). From exposure to dirt and moisture, these elements rust and become firmly attached to the seat. Screw and hydraulic pullers cope with dismantling, but the parts immediately fall apart in two and become irreparable.

If you want to dismantle the injectors with your own hands intact, build a pneumatic return hammer.

Drawing of a hammer for removing injectors

You shouldn’t start work without a drawing. It is necessary to imagine the design, structure of the pneumatic hammer, the number of components of the future tool, the sequence of connecting them into a single whole.

Before designing, decide on the dimensions - usually a length of 50 cm is enough to crawl under the hood and remove a burnt injector. The drawing can be found and downloaded on the Internet.

Materials and tools

As for power tools, you will need a powerful autocompressor with a capacity of 250-300 l/min, an angle grinder, and a pneumatic chisel. From the latter, already at the preparatory stage, remove the boot, retaining ring and bushing with spring: they will no longer be needed.

Prepare metal blanks from which the body and plugs of an air hammer are usually turned on a lathe.

Blanks for making a reverse hammer for removing injectors

To make a reverse hammer for removing injectors with your own hands, you will also need:

- hose fitting;

- hacksaw for metal;

- gas wrenches and wrenches;

- calipers.

Don't forget the air hoses for the compressor.

Manufacturing instructions

You have already removed unnecessary parts from the pneumatic chisel. Next, you can make a reverse hammer for injectors with your own hands in the following steps:

- Clamp the chisel in a vice and unscrew the cylinder from the body.

- Remove the piston from the removed part, followed by the air valve.

- From the outside of the cylinder from the front cut, cut a thread for the plug.

- Unscrew the bushing for the fitting from the handle of the chisel, cut the body into 2 parts.

- Measure all the details of the inside of the case: threads, location of the air hole, other parameters.

- Turn another cylindrical body on the lathe. It is necessary that its inner surface matches the sawn part.

- Next, on the machine, make a shank on the outside of the back wall - a rod 5 cm and 1.5 cm in diameter.

- Mill a plug whose internal threads match the external threads on the cylinder.

- Temper the body and plug for strength.

- Weld a bushing over the air valve.

- Place the tail section, cut from a chisel for a pneumatic tool, into the end of the cylinder.

- Install the piston inside the cylinder.

- Screw the wide part of the cylinder into the new housing.

- Insert the already prepared chisel shank into the other part, tighten the plug (secure the part from unwinding with the fixing bolt).

- Screw a fitting through the adapter above the air hole and attach the air duct from the compressor to it.

The DIY injector return hammer is ready for use. The tool will also be useful for removing bearings in the future.

Source

How to choose a quality one

In order for the jackhammer to serve for a long time and not break, it is necessary to make the right choice of model. The technical characteristics of the tool must correspond to the tasks facing it. Equipment that is too powerful and oversized consumes a large amount of electricity, requires maintenance in specialized workshops and expensive consumables. Insufficiently powerful - it will not cope with the given amount of work. Therefore, when choosing, you need to take into account all the details and nuances of the upcoming load on the tool. The following technical parameters are considered the main criteria that you need to pay attention to when choosing a breaker machine.

- Dimensions: length, width, height. The larger the linear dimensions of a mechanical hammer, the correspondingly greater the power and its resolution. However, indiscriminately chasing a “big and strong machine” is not always justified. In some situations (for example, during apartment renovations), it is more reasonable to use compact equipment that allows you to work in cramped circumstances.

When chiseling holes in concrete floors, a hammer with increased impact force is used - Weight. On the one hand, the greater the weight of the tool, the greater the pressure it exerts on the surface being destroyed. But if you have to break a wall or ceiling elements, the load falls entirely on the user’s arms (and legs). In this case, it is better to give preference to lightweight models with high impact performance.

When performing work in a horizontal plane, the weight of the tool must be selected in accordance with the physical capabilities of the operator - Beat frequency. This is one of the main indicators that directly affects the performance of the tool. It can be measured in hertz (Hz) or revolutions per minute (rpm). The number of hertz shows the number of beats per second. Revolutions per minute indicate the frequency of translational movements of the rod within one minute.

The impact frequency and the energy value of a single impact are displayed in the hammer data sheet - Single strike energy. A value characterizing the productivity of energy consumption. It is measured in Joules (J), which is equal to the work of moving 0.1 kg. to a height of 1 m. In simple terms, 1 J of impact occurs when a 100 gram weight falls freely from a height of one meter. If the passport indicates an impact energy of 50 J, it means from a height of 1 m. dropped a 5-kilogram weight with a pointed end.

- Drive unit. As mentioned above, the drive mechanism of a jackhammer can be different. For home use, the electric drive has become the most common. In locksmith shops, pneumatic bumpers are more often used. For “field” conditions, autonomous gasoline vehicles are used. Hydraulic installations work in large industries, in mines and when driving piles. Industrial jackhammer based on a hydraulic tractor drive

- Power. This is the amount of electricity consumed by the device during operation. In the passport it is indicated in watts and kilowatts (W and kW).

The petrol drive of the jackhammer allows for work to be carried out in autonomous mode. - Vibration level. Vibrations that cause destruction extend not only towards concrete, asphalt, stone, etc., but partially also towards the operator driving the machine. With constant exposure to hands, occupational diseases such as numbness of the limbs and somatic vasoconstriction occur. Each model is certified in accordance with the standards for permissible vibration levels. A note about this is placed in the passport (in the international system of ISO standards, indicating the numerical value in m/sec2)

- Sound pressure level. Measured in decibels (dB). As a rule, most professional jackhammers exceed the safe noise level during operation, which is defined as 70 dB. That is why it is necessary to work with this equipment only with headphones.

Noise-absorbing headphones protect your hearing from overload

In addition to the listed parameters, it is sometimes useful to take into account additional technical characteristics.

- Transport weight of the tool. This is the weight of the tool packed in a case along with consumables and spare parts.

Factory case for transporting the hammer - Shank type and dimensions. There are several types of nozzles, which differ in their rear part - the shank. Its configuration depends on the fastening mechanism. The most common are hex shanks, for the SDS chuck, and shanks with grooves. Sometimes combined cartridges are used, they can be changed as needed. Various jackhammer attachment configurations

- Parameters of energy consumption (or energy carrier). If the jackhammer has an electric drive, the mains voltage must correspond to the rating data. In the vast majority of cases this is 220 V, 6 A and 50 Hz. However, there are exceptions. Pneumatic tools are driven by compressed air from a compressor. If the air pressure required for operation does not correspond to the nominal pressure, the fender will not develop the necessary power and may fail. In gasoline engines, it is important to follow the manufacturer's recommendations for preparing the working mixture (grade of gasoline, percentage of lubricant and fuel).

Oil for preparing gasoline mixtures intended for two-stroke engines - Additional functions. These are devices that facilitate operation and contribute to greater work efficiency. These include a locking start button, an anti-vibration system and an idle shock limiter. The latter option significantly increases the service life of the hammer. In addition, on electrical mechanisms it is common practice to install a graphite brush wear indicator, notifying the user of the need to replace the electrodes.

If the graphite brushes are worn by more than 40%, they must be replaced

Particularly “advanced” models are equipped with a function to protect against cable damage. It consists in the fact that when a bit hits a live conductor, the opening relay is activated and the jackhammer motor is turned off. The device comes to the rescue in cases where chiselling is carried out in old buildings, where wiring may end up in the most unexpected place.

When using a hammer frequently, the operator's hand joints suffer the most. For such users, a vibration damping system is not a luxury, but an urgent necessity.

Video: review of jackhammers

All information, as a rule, is reflected in detail in the technical data sheet of the product.

Careful study of it will protect you from selection errors and annoying disappointments.

There is also a general classification of all devices into household and professional. Household ones are designed for small volumes of work that do not involve daily use. Professional fenders meet increased requirements. They are able to work uninterruptedly for a long time. The former are more financially accessible. The latter are more expensive, due to higher manufacturing costs.

The size of the hammer is considered a sign of productivity. Below are the technical characteristics of the 4 main sizes.

Table of classification of devices by purpose

| Standard size | Purpose | Impact energy | Impact frequency | Brands of jackhammers |

| Standard size No. 1 | Crushing, removing and peeling medium-hard materials: clay, brick, plaster. Operation in cramped conditions, on weight. | up to 30 J | up to 45 Hz | MO-1, MO-1B. |

| Standard size No. 2 | General construction works. | up to 40 J | up to 35 Hz | MO-2, MO-2B, MOP-2, MO-2M, PM-2. |

| Standard size No. 3 | Work with high-strength materials, mainly vertically from top to bottom. | up to 45 J | up to 20 Hz | MO-3B, MOP-3, IP-4613. |

| Standard size No. 4 | Processing of high strength materials, including reinforced concrete. The direction of impact is from top to bottom. | over 50 J | up to 25 Hz | MO-4B, MOP-4. |

When choosing a hammer, you should also consider the manufacturer of the tool. The state of the market is such that there is always the possibility of spending money on a fake. Moreover, sellers themselves do not always know what is inside a beautifully designed product with all the signs of a quality product. In particular, unscrupulously manufactured electric jackhammers may have plastic gears installed instead of metal ones. Their work will be no different, except for one thing - after a month, the plastic will collapse under the influence of loads, and the hammer will fail. Therefore, it is better to avoid dubious “bargain” purchase options and give preference to well-established manufacturers. These include brands with worldwide recognition: Bosch, Makita, Hilti and Hitachi.

Heavy professional Hitachi chipper with electric drive

Among the domestic manufacturers of pneumatic tools, the series of breakers and concrete breakers “MO” and “MOP”, produced in Tomsk, enjoys well-deserved respect. This is a real professional technique that can be used both at home and at work. The advantage of Russian instruments is a wide service network and the availability of spare parts in retail sales.

Professional jackhammer

Varieties

The simplest version of the hammer:

- This is a metal rod, at one end of which there is a hook, and at the other - a load and a stop;

- A hook is attached to the washer, and the washer is welded to the place of deformation by welding;

- Provided impact forces are applied to the load, the deformation is extended to the desired moment.

But the second option (also quite simple) will differ somewhat from the first. At the end, instead of a hook, there is a simple thread. In order to level the surface using such a device, a hole is made in the center of the deformation, into which the threaded end is inserted, and a nut and washer are attached to it on the reverse side.

A vacuum hammer is the most complex version of its implementation. It is attached to the surface of the deformed area using rarefied air. The suction cup begins to work both in the usual way and with the help of a compressor.

Thanks to the vacuum device, minor body damage can be repaired and the paintwork can be preserved intact.

DIY pneumatic reverse hammer

This type of automobile repair, such as body repair, is a rather complex operation.

You will need a number of special knowledge, as well as equipment and tools. The reverse hammer plays an important role in body repair. This tool is quite simple and can be made independently without any problems. Moreover, there are many recommendations and videos on this topic, as well as drawings. Today you will learn how to make a reverse hammer with your own hands and how to properly use it for its intended purpose.

What kind of device is this

If you are at least a little familiar with plumbing, then creating such a tool at home will be quite simple for you.

Making such a device yourself will not take much time, and will not even require special equipment or knowledge. For a more visual understanding, we present a primitive drawing that will not be superfluous.

As noted above, the design of such a hammer is very simple. A metal sleeve is mounted on a steel rod 50 cm long with a diameter of 10 to 20 mm, which should be easy to grip by hand.

The diameter of its hole should allow it to slide freely along the hammer rod without creating a large backlash. A handle is installed on the top to hold the tool by hand. An impact washer is tightly attached to the rod in front of the handle.

You can find out how to choose a screwdriver here.

And this article will tell you how to choose the right electric spray gun.

Another safety washer is attached at the bottom, which prevents the bushing from flying off the rod during operation, thereby causing additional damage to the leveled surface. And at the very tip of the tool there should be a hook for grabbing staples.

If you decide to make such a hammer yourself, rather than buy it in a store, where the price will be much higher, then it is advisable that the hook and bottom washer be removable. Because for convenience when working, it is better to have a set of hooks of different lengths, as well as several bushings of different weights.