It is no secret that in many different industrial sectors, conveyor belts are used to transport bulk and solid cargo. These products are made from a rubber mixture. Depending on the conditions of use, as well as the type of load itself, different brands and types of rubber are used as the basis for such belts.

Thus, there are oil and petrol resistant rubber products that are resistant to various oils and fuels. Heat-resistant and frost-resistant elastomers are also actively used to create tapes. Based on the name, you can understand that these variations are resistant to heat and frost, respectively.

The basis for the production of such elements is usually rubber with fabric layers or pressed cables. In some cases, only rubber bands are used. To distinguish one type from another, such products are named based on the presence of additives. If there is a layer of fabric, then such tapes are rubber-fabric, if there is a cable, they are rubber-rope, and if they are absent, they are rubber.

Since the size of the conveyor in production is always different, in some cases the standard belt length may not be enough. In this case, the conveyor belts are usually joined. This process allows you to fasten two products together, giving them the required length. This operation is also carried out during repair or installation of a part into a conveyor in order to fasten the butt joints of conveyor belts.

But how does the docking happen? Two separate canvases are connected to each other using special tools. Actually, there are various methods for joining conveyor belts. We will talk about them.

Mechanical joining of conveyor belts

Mechanical joining of conveyor belts usually occurs when it is extremely necessary to carry out repairs or install this element in a very short time. This method is also used in cases where installation of the tape in one continuous line is impossible due to some reason. This type of connection is made in a few simple steps. First you need to align the ends of the tape and set them at an angle of 90°. This is necessary to ensure that the joint between the products is as smooth as possible. In this case, two tapes can be placed on top of each other or attached to the end. The choice of docking depends on the assigned tasks. Then, using special fasteners, for example, fixing bolts, the holes in the edges of the tapes are tightened.

The importance of quality docking

The belt is one of the most worn parts of any conveyor - more than half of the breakdowns of conveyors are associated with the failure of their working belt, which bears most of the load. In addition, the working surface is subject to additional mechanical stress, the nature of which directly depends on the operations performed. For example, this could be gradual abrasion during transportation of building materials or contact with the cutting edge when cutting out confectionery products from sheet dough.

However, not only the strength of the conveyor belt itself affects the uninterrupted operation of the line, but also the quality of the joining of its ends and the professionalism of the installer who performed the work.

Hot joining of conveyor belts

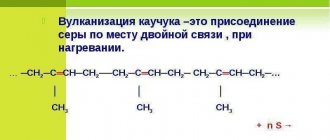

Joining conveyor belts using the hot vulcanization method involves the use of a special vulcanization press. Directly in this installation, the ends of the tapes are pressed under pressure and high temperature. Synthetic rubber resin is applied to their ends, which allows for an even connection that will hide all mechanical inaccuracies. This method is considered very difficult and time-consuming, as it requires setting up equipment.

Basic connection methods

Today, the connection of conveyor belts can be performed using one of the following methods:

- hot vulcanization;

- cold vulcanization;

- mechanical method.

Each method has its pros and cons. The strength of the joining point largely depends on the professionalism of the work performer, compliance with standards and the quality of the materials used.

Hot vulcanization

Enterprises and industries that use heat-resistant conveyor belts should give preference to joining using vulcanization processes. If all requirements are met and high-quality materials are used, the joint will be as strong as the fabric itself.

Docking a conveyor belt using the hot vulcanization method has the following important advantages:

- the most durable connection method;

- the equipment can be used immediately after the joining process is completed, which can significantly reduce downtime in the production process;

- the maximum temperature of transported cargo depends on the materials used for docking (up to +200 degrees);

- the connection can be made at ambient temperatures below 0 °C;

- it is possible to carry out docking work in very dusty conditions;

- the cost of materials is lower than for cold vulcanization;

- minor errors are allowed when cutting conveyor belts;

- the method can be used to connect rubber rope type tapes;

- During transportation of bulk materials, spillage is prevented.

Equipment for hot vulcanization of conveyor belts is very expensive. You also need to know that heating plates can only be used for belts of a certain belt thickness. If the thickness changes, it becomes necessary to buy additional presses. In addition, joining conveyor belts using the hot vulcanization method requires high labor costs.

The strength of the connection using this method depends on the quality of the press. The following characteristics are important:

- the ability to control the temperature over the entire heated surface;

- what is the maximum weight of one press element;

- how evenly the pressure is distributed over the entire surface to be connected;

- cooling time.

Cold vulcanization

The optimal method of joining conveyor belts for enterprises using frost-resistant or general-purpose belts is cold vulcanization.

Main advantages:

- labor intensity is lower when compared with hot vulcanization;

- the cost of the joint is significantly lower because there is no need to use expensive equipment;

- when performing vulcanization on an operating conveyor, you only need hand tools, grinding tools, and glue;

- the strength of the connection is up to 70% of the strength of the conveyor belt if high-quality materials are used and technology is followed.

Cold docking also has a number of disadvantages:

- conveyor belts connected by this method can be used at temperatures from -45 to +80 degrees;

- docking can be performed at temperatures from +5 °C and above;

- the elements that are connected must have a temperature in the range of +15 – +45 degrees;

- it is impossible to use the method if the humidity level is below the dew point;

- the product must additionally be kept at a temperature below zero (the time is 2–24 hours and depends on the materials used for joining), which increases the downtime of the equipment;

- It is not recommended to use when the level of dust in the environment is high.

To obtain a quality connection that will last a long time, it is very important that the work area is clean. When starting vulcanization, you need to remove contaminants in the form of salt, fertilizers, remove oil and grease with a special liquid, and then dry the wet surface. When performing joining using the cold vulcanization method, compliance with the temperature regime is required, which is recommended by the manufacturer of the materials used to connect conveyor belts.

Mechanical connection

The essence of the mechanical method is that the ends are fastened with a special lock connector, which has a special design. In some cases, it is even possible to disconnect and then connect the fastener.

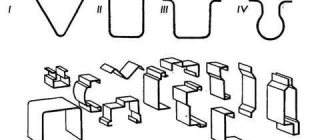

The mechanical connection of conveyor belts is of the following types:

- using wire locks (to restore the functions of transporting equipment in warehouses, food production, and agriculture);

- hinged rivet (used for rubber-fabric and polyvinyl chloride type tapes);

- one-piece bolted (high quality connection is ensured);

- one-piece rivet (withstands high loads);

- hinged bolt (for canvases that move on drums);

- staple (for lightly loaded belts).

The main advantages of the mechanical method of joining conveyor belts include the following:

- speed of execution;

- does not require significant costs when compared with vulcanization;

- no need to use special premises and bulky equipment;

- the possibility of carrying out in a room with a high level of dust and at temperatures below zero;

- the process is simple, no need to involve qualified specialists;

- may be a temporary measure for high load conveyors;

- a detachable mechanical connection is the best option for tapes where the length needs to be changed frequently.

In other words, detachable mechanical connections of conveyor belts provide quick and easy joining or disconnection, which does not require disassembling the conveyor itself, and accordingly, equipment downtime is reduced. In addition, this method requires minimal labor costs.

The main disadvantages of a mechanical connection include:

- strength and service life are inferior to the criteria that can be obtained by vulcanization;

- the working surfaces of the equipment (rollers, drums, etc.) wear out more;

- Bulk cargo and materials may spill out at the junction;

- may spark, which under certain conditions is dangerous;

- the tape at the junction may be burned if the cargo is transported in a hot state.

When choosing a mechanical connection method, it is necessary to take into account the conditions in which the equipment is operated, the thickness, width and strength of the conveyor belt, as well as humidity, temperature, fraction size and other parameters of the cargo that will be transported.

Cold joining of conveyor belts

The joining of a conveyor belt using the cold vulcanization method is carried out when a vulcanization press is not available at the enterprise. In this case, both ends of the two tapes will be fastened using a special glue with a hardener. Actually, the glue itself is applied to the ends. After which they are placed on top of each other. This method is considered to be the most accessible and reliable. However, when performing it, you should avoid the presence of dust, as well as high humidity and low temperature in the room where this process is carried out.

Methods for joining the edges of conveyor belts and drive belts

We are often asked why we use different joining methods for different types of conveyor belts. In this article I will explain how different tapes can be connected. At Habasit, we most commonly use the following connection methods.

Quickmelt

This simple and fast joining method by fusion of edges is used for tapes consisting almost entirely of thermoplastic material. The ends of the tape are cut to the required length at a certain angle, connected in a guide, and then pressed together under heat to fuse.

This method is used on small diameter shafts and operating temperatures below 80°C/176°F. Quickmelt joint is commonly used for polycord round belts, elastic machine belts and solid belts.

The quality of the seam can be easily checked visually, and the thermoplastic material can be re-melted.

Quickmelt fusion joint

Flexproof

If the tape is made of fusible materials and textiles, including at least one layer of thermoplastic material, the Flexproof locking method is used. The ends of the tape are cut into teeth, joined, and then pressed together under heat. In this connection, the decisive factor in determining the tensile strength is the length of the weld.

- Drive belts with a polyester traction layer use long, narrow teeth

- Medium-length teeth are used for standard conveyor belts

- Machine belts use short teeth

If the joining procedure is carried out correctly, at room temperature the Flexproof joint has over 70% of the tensile strength of the original tape. The high level of connection flexibility allows the use of smaller diameter rollers.

This fusion joint can be used at operating temperatures not exceeding 80°C/176°F. Higher operating temperatures are also possible, but in this case the connection will wear out faster due to a different thermal regime compared to the rest of the tape.

The quality of the seam can be easily checked visually, and the thermoplastic material can be re-melted.

Flexproof fusion joint

Stepflex

This edge joining method is used primarily for PVC tapes with a guide on the underside, and also in environments where there is chemical, bacteriological or other contamination. The tape is divided into upper and lower parts, on each of which teeth are cut out using stamping, alternating in the longitudinal direction. The connection is fused using a fusible middle layer.

Thanks to this layering/alternating joining technique, the teeth are more resistant to local pressure forces occurring at the bottom/top of the belt, and the seam has greater strength when the belt is pulled through.

Thermofix

Thermofix is an adhesive method for joining conveyor belts and drive belts with various combinations of non-thermoplastic materials, such as rubber or silicone with polyamide.

Their use requires high elasticity and (or) resistance to impact loads. This method is suitable for operating temperatures up to 100°C/212°F, but cannot be used for small roller diameters.

If there is a layer of nylon (polyamide), then the method is combined with other methods of chemical gluing.

The ends of the tape on the top and bottom sides are sanded into a wedge shape and joined using an adhesive system, pressure and heat. This is a very reliable welding method and if the procedure is done correctly, at room temperature the Thermofix joint has over 70% of the tensile strength of the original tape.

The connection demonstrates high resistance to lateral forces and roller contamination. However, the use of different adhesives and different gluing times require high skill and significant time investment. After heating, it is no longer possible to change anything in the connection, and its quality cannot be assessed visually.

Thermofix bonded joint

Mechanical connection

A mechanical connection holds two objects together mechanically. It is used in cases where regular or particularly quick replacement of conveyor belts is required.

However, the mechanical connection is a vulnerable part of the design. The connection has holes that can become clogged with dirt.

Therefore, in many cases, this solution is not the preferred option.

How we are working

- We use equipment from ERM engineering (Spain) and Flexco Novitool Aero (USA) to join tapes of any thickness from a wide range of modern materials - from rubber to polymers.

- We work with enterprises of any industry, including food and highly specialized industries.

- We strictly follow the requirements for the technology of joining a specific material.

- We accept orders for fitting in size and go to sites.

- We have several mobile teams on our staff - there is always one available.

- We are ready for large volumes of work - we carry out several joints during one visit.

Docking with on-site production

Is it not possible to order a tape connection service outside the company? We will come to your production with the necessary materials, tools and equipment. Experienced specialists, our own mobile vulcanizing presses and punching machines for cutting. We will ensure full compliance of the technology with the requirements. We give a guarantee on the joint. We work quickly and efficiently.

Still have questions? Contact us:

- by phone 8-800-100-72-52

- request a call back

- contact the online consultant on the website.

Advantages of the hot vulcanization method

Hot vulcanization of conveyor belts has a number of advantages. For example, restoration of conveyor operation, increased joint strength, uniform belt thickness, absence of any gaps. It also ensures flexibility and elasticity of joining seams, and provides the possibility of joining in case of severe contamination or negative temperature conditions. Can be used for tapes made from any materials. Performs restoration without dismantling and guarantees the durability of connecting seams. This technology is used to form homogeneous conveyors.

Sewing the tape using the Vulcan connection

The screws and pressure washers are located in the tape web so that none of the connection elements protrudes beyond the surface of the web, which allows the tape web to remain perfectly flat. Depending on the load and length of the conveyor

Various stitching options are recommended. The presented connection (stepping, distance between connectors, installation method) is an approximate solution recommended for use. The advantage of the connection is the bulges located opposite each other, ensuring effective adhesion of the washers to the tape due to the multi-point impact of the compression force on a large surface of the tape.

The Vulcan tape connection is a highly effective alternative to adhesive and vulcanized connections.

The stitching performed using this connection does not destroy scrapers and cleaners, and also does not cause damage to main rollers, drive and tension drums, including those lined with rubber. One of the advantages of the Vulcan profiled connection, unlike other mechanical connections, is its maintainability. If during operation any of the elements is destroyed, it can be easily replaced at the first stop for conveyor maintenance with a spare element included in the kit. This extends the service life of the entire connection indefinitely. Performing stitching using a Vulcan connection is much cheaper, simpler and requires much less time than performing vulcanized and adhesive connections with similar

functionality. Although stitching is a tape connection,

made “overlapping”, a very short piece of tape is required to complete it - from 130 to 265 mm. The manufacturing time for one connection is from 2.5 to 3 hours. The tensile strength of the profiled connection “Vulcan” is 60% of the actual strength of the fabric, which is confirmed by numerous laboratory tests.

The edges of the joined fabric are cut perpendicular to the direction of movement of the tape using a template as a ruler. Next, the panels to be joined are laid out horizontally “joint to joint”, and a wooden beam or block is placed directly under the joint. The panels to be joined are secured to the block using the screws included in the Vulcan-Blitz

, and the gap between the blades should be minimal. For uniform installation of elements, it is recommended to use template No. 2 (125*1200) from the “Vulcan” installation tool kit. That is, drill holes along the first row of holes in the template, taking into account the installation of the washer exactly in the middle of the joint. At the same time, attention is paid to the fact that the extreme elements

“Vulcan Blitz” were, if possible, not located directly on the edge of the canvas.

Screws with a pre-fitted top washer are installed in the drilled holes. Next, the joint is raised above the block and threaded washers are attached to the screws from below. Pay special attention when screwing in the second screw.

into the washer, since there is a possibility of it being skewed relative to the washer and screwing it in the wrong direction.

After this, preliminary and final tightening of the screws is carried out with appropriate force, starting from the center to the edges. The protruding screws are broken off with a breaker. The joint is ready for further use.

In the event of an emergency derailment of the belt on the drum and biting of the edge of the web, deformation or tearing off of the outermost elements of the “Vulcan-Blitz”

. In this case, the joint is completely repairable, since faulty elements are replaced with spare ones included in the delivery kit, which is a significant advantage over other mechanical connections.

Glue storage:

When the adhesive is stored at 6°C or lower, chloroprene rubber crystallizes. This causes the glue to become viscous. In this state, glue should not be used, since using crystallized glue cannot achieve maximum adhesive strength. After warming the glue to room temperature (15 - 16 t°), it can be used again.

The shelf life of TRS 2002 and TRS 4004 glue is 2 years at room temperature, counting from the date of production.

Attention: TRS 2002 glue is toxic! Carry out work in a well-ventilated area, otherwise use a respirator.

Scope of hot vulcanization

The technology is used to restore the vulcanization of conveyor belts, which are used not only in standard premises, but also in heavily dusty industrial buildings. Suitable for outdoor use. Thanks to it, high-quality results from the operation of conveyor lines for transporting highly heated cargo, food products and bulk materials are guaranteed. Limitations include the high price of special equipment and increased labor intensity of processes. It is worth considering that compensation is carried out at the affordable cost of consumables.