Brick is often used to build the walls of a house. Carrying out brickwork requires you to have certain knowledge and skills. If you are doing this work for the first time, then to obtain high-quality masonry it is better to use auxiliary tools. Such devices will not only make your work easier and allow you to get a good result, but will also significantly speed up the process of building walls at home. In this case, you can use ready-made tools for the job or make special devices yourself. In our article we will tell you how to make such auxiliary products and how to use them correctly.

Brick laying equipment

The choice of tool determines the worker's preferences. Commonly used bricklaying tools:

- Trowel or trowel . A small spatula, has a flat surface and a tapered end. Use it to pour the binder mixture and spread it over the surface. Use a trowel to remove excess at the junction of bricks.

- Joining . This is a narrow groove with a handle. With its help, seams are formed, their thickness is adjusted, and excess mortar is removed. The groove has a curved or convex profile.

- A small hammer is used to trim bricks to the desired size and shape, trim the masonry, putting the warped brick in place. This can be done with an uncured binder solution.

- Construction level for bricklaying . An important element for ensuring the horizontal and vertical position of the wall and base. Bubble and laser designs are used.

- Plumb . A metal weight suspended from a non-elastic thread. The plumb line checks the verticality of the building structure.

Plumb Source yandex.net

- Order . A ruler determining the width of a row of a brick wall.

- Mooring . Non-elastic tape. It is stretched along the wall and defines the boundary of brick laying, secured at the beginning and end of the row with metal corners.

Among other devices, a rule, a template for laying bricks and laths are used. They are necessary to control the shape of the masonry.

See also: Catalog of companies that specialize in designing country houses

Masters recommend

The solution for joining blocks is a fairly aggressive environment, so it is necessary to protect the devices used. If they are made of plastic or wood, then all internal surfaces in the templates must be treated with wear-resistant ship or parquet varnish. It is better to apply protection in several layers - this will increase the service life of the created dispenser.

After finishing the working day, it is necessary to thoroughly clean the tool from any remaining binder mixture - this reduces the wear of materials and allows you to maintain the internal surfaces in working condition. Otherwise, the tool will fail.

We buy or make tools for bricklaying

The easiest way is to purchase a tool in a store. One of the professional devices is bricky. We can assume that this is a template for a novice mason; the result is a neat wall, but the speed of action does not suit a professional.

For different types of masonry and brick sizes, various modifications of the template are available. Currently it is made of plastic, but you can make it yourself from wooden or metal strips. A good option would be a brick consisting of sliding planks, which is suitable for various wall designs and brick blocks.

Bricky template drawing Source 100uslug.com

Conductor for obtaining smooth masonry

This bricklaying device includes a rectangular frame made of durable plastic, it has holes and projections for easy operation. We install the frame on the laid row, pour the solution inside, and remove drips from the sides. As a result, we get a layer of the same thickness, onto which we place the brick and lightly press it. We use the same smaller device to connect the end surfaces of the elements.

Set “Your own mason-2”

The device helps to lay a layer of masonry mixture of the same thickness in a brick row, with its help we obtain high-quality, neat masonry, save mortar, and increase the productivity of the mason. The set of templates is suitable for erecting a structure of half a brick or more, laying brick columns and columns, and performing facial finishing. Used to work with standard brick elements, sizes 250x120x65 and double 250x120x88 mm.

Set for bricklaying “Your own mason-2” Source plastsmart.ru

Set includes:

- horizontal template, 70 cm long for laying out the solution on a horizontal surface, equipped with two levels and graduations in mm;

- horizontal template of 40 cm, used in places of limited length;

- vertical template for ordinary bricks;

- vertical template for laying one-and-a-half bricks;

- supports for installing a horizontal template 70 cm in the amount of 8 pieces;

- strips required for laying pillars in the amount of 2 pieces.

All components are packed in a box and supplied with instructions.

Devices for dosing the binder mixture

Dispensing devices allow you to avoid excess consumption of masonry mortar when constructing brick structures. We use the following constructions:

- A cuvette helps to measure the required amount of solution in the selected area and get a beautiful seam of the desired shape. This is a simple container with walls without a bottom.

- Dispenser order. Container with a marking mechanism, adjustable length. Attached to the conductor frame using screw support clamps.

- Complex dispenser.

Dispenser order Source nagdak.ru

Specifics of working with facing bricks

The main function of facing bricks is decorative; it shapes the appearance of surfaces, gives them stylistic completeness, a more harmonious and aesthetic appearance.

due to the specific shape and texture

- the unsuitability of rough hand tools for working with some decorative surfaces;

- special requirements for the quality of control, measurement and adjustment work;

- often - changing the composition of the solution, using tinting and binding agents;

- specific technologies for working with narrow and thick types of facing bricks;

- difficulty of figured masonry.

Here the use of mechanized devices will be more relevant than ever.

However, the general design described in the previous section should be modified to take into account the thickness and shape of the cladding blocks.

For figured masonry, a special, highly specialized class of devices is distinguished, the design of which is developed separately for each specific case and often includes hinged joints, stepper mechanisms and other complex components.

We make a device for laying bricks

We make a template for a specific brick size - single or double. For finishing bricks you will need a different template. The structure consists of:

- frames with parallel walls, the distance between which is equal to the thickness of the wall;

- handles for transportation;

- diameters.

The simplest version of the template is a plastic box of appropriate size. We cut its walls to the required height, cut off the bottom and get a frame. We attach it to the wall using the protruding strips. The use of this template eliminates uneven masonry and warping of the wall.

Conductor with sliding bars Source gidlestnic.ru

You can make a split design with adjustable dimensions. To do this, drill a hole in the wooden planks and insert metal guides. The width of the jig is adjusted with wing nuts.

We make the device for a joint thickness of 10 mm, this is suitable for laying one and one and a half bricks. For the finishing brick layer we make another template. We coat the wooden elements of the frame with wear-resistant varnish. After each use, clean the instrument from any remaining solution.

DIY making

Many hardware stores offer various kits. However, sometimes it is difficult to find something that would fully satisfy the needs of the master. Therefore, many take on the task of making the necessary tools themselves.

To make a level, just find a good metal cylinder, preferably with a sharp conical nose, and tie it to a thin, strong cord. A long, straight strip or board is ideal for checking the evenness of the wall. For convenience, a handle is placed on it in the middle part.

The more difficult situation is how to apply an even layer of mortar to the next row. To do this, make a template for brickwork.

Here is a step-by-step diagram of its manufacture:

- Prepare materials for work and tools.

- A frame is made from slats. Its width should be such that it fits tightly onto the brickwork of the wall being built. To do this, the longitudinal strips should protrude 5-10 cm compared to the transverse ones.

- The cross-bars are made equal in height to the height of the applied layer of solution. For a brick wall of one and a half bricks, this is 10 cm.

- For convenience, handles are nailed to the sides.

- To protect against corrosion, the product is coated with parquet varnish and cleaned regularly after use.

This is interesting: how to use a water level correctly.

The use of simple devices greatly facilitates the work of a mason and helps to make the result of his work better and more reliable. Having spent a little time and effort purchasing such equipment, a novice master will be able to master the basics of the art of bricklaying much faster.

Briefly about the main thing

Various tools are used to perform brickwork. For a professional mason who has laid thousands of bricks, a trowel and jointing is enough. However, to control the quality of work, a plumb line and level are necessary. A novice builder will need templates. There are enough of them for every taste. Templates for double, single and finishing bricks, for straight and end seams are available for sale. Conductors simplify the laying process, making it smooth and neat. Anyone can purchase the necessary equipment or make it themselves.

Ratings 0

Application in practice

Even the most experienced masons use many quality control tools in their work. Despite the fact that over many years they have acquired enormous experience, they do not trust their eyes, but regularly check the masonry using precision instruments. It is especially important to use such devices for laying facing bricks, because this type of work requires special care and precision.

Cladding is done to give the building a beautiful appearance. Using special bricks or tiles, not only the outer part of the house is decorated, but in many buildings its internal elements are also decorated. This is a very difficult process. Here are just some of the difficulties that arise during such work:

- The cladding material comes in an unusual configuration. Because of this, difficulties arise with its installation.

- Often the customer requires an original type of cladding, which forces the mason to be very careful and careful. Laying out unusual shapes requires very precise tools.

- The use of solutions with additional components. For example, very often in such cases the connecting mixture is tinted, and this, in turn, requires the master to pay additional attention to the quality of the masonry.

Naturally, when performing such precise work, measuring instruments must be flawless. The more often and more responsibly they are used during construction, the greater the guarantee that the work will be performed with high final quality.

Communities › DIY › Blog › Simple tool template for brick cladding

Hi all!

I decided to share with you a version of a simple tool template for facing a house with bricks!

In order for the lined surface to look perfect, I suggest making a simple template, the profile of which is shown in the sketch.

This is a side view. By spending a minimum of time on making this template, you will save time spent on jointing the facing surface, get a clean surface and smooth brickwork seams.

This tool can be made of wood or plywood, who knows what :)

When using the template, the mortar bed will be level, 8 mm high, and with a distance of 9 mm from the edge.

This “dosing” of the solution will ensure guaranteed filling of the cracks between the bricks. It will prevent both the squeezing out of excess mortar and the need for jointing - this will protect the outer surface of the masonry from contamination with indelible residues of the masonry mortar.

Cost of factory products

If we are talking about large volumes of work, it is better to buy devices manufactured at the factory. Most often they are sold as a set, for example, the “Brick” or “Bricklayer” set includes the following elements:

The “Brick” set is used for laying the mixture on a horizontal row

On average, such a complex will cost about 1500-1900 rubles per set. The main advantage of such kits is high-strength plastic, which is designed for long-term use.

The finances spent on the purchase of factory devices or your own time and costs for materials, inevitable in the manual production of additional devices, are always justified by speeding up work, increasing quality and saving on binding materials.

How to make smooth brickwork with beautiful brick joints?

Construction today is perhaps the most popular type of craft activity. Having mastered the construction profession, you will never be left without work. And if you become a master of your craft, then you will have no end to dear customers.

Construction specialties are different. The most difficult to implement, accordingly, are also the highest paid.

The mason profession is one of the most difficult. No one can just pick up and start laying brickwork. To do this, you need to learn, both theoretically and gain practical experience from real masters of their craft, working as their assistant and gradually performing simple operations at first, step by step moving on to more complex ones.

When you go through everything - from simple to complex, you will be entrusted with laying brickwork. Brickwork of a multi-storey building is the pinnacle of any mason's skill.

Smooth brick joints are perhaps the most difficult element of brickwork. Always wondered how they are made? How do master masons manage to apply the mortar in an even layer and then lay bricks on it one straight at a time?

He was building a brick garage on his property. I did the brickwork myself. Did this for the first time. It took a hundred sweats until I somehow got used to laying a more or less even wall. I’d rather not say anything at all about the brick joints on the walls of my garage, as you yourself understand, everything turned out crooked.

Industrial mason kits

There are many ready-made mason kits available on the modern market, including all three main groups of tools. The most widespread are the domestic “Brick” and their foreign analogues “Bricky” . These sets include:

- cuvette for applying the solution;

- template for laying single bricks;

- template for one and a half;

- control corner;

- order;

- mooring;

- trowel.

Manufacturers position the product as amateur, that is, not requiring special construction skills. It is simple and intuitive to use, allowing you to get good results in the shortest possible time.

Most kits come with, among other things, not only paper instructions, but also a video tutorial that describes in detail the use of each tool.

What is included in the beginner mason's kit - watch the video:

Mechanized devices

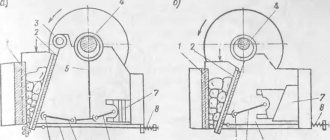

There are a number of devices that significantly speed up the laying process. They are conventionally called mechanized, but are not equipped with drives and complex systems of moving parts. Most often they are used to quickly and evenly apply a mortar bed under the next row of blocks.

Order-dispenser

Such a tool is a frame made of plastic, metal or wood. It allows you to quickly apply a layer of solution of the required thickness and width. Thanks to special stops, it quickly moves along the row; excess solution can be placed on special shelves for later use.

Some models are equipped with mechanisms for adjusting the parameters of the resulting mortar layer, others are equipped with clamping devices for reliable fixation on the row.

As a rule, dispenser sets sold include end versions. They are much smaller and are used to dose the solution applied to the end of the block being laid. Depending on your preferences, you can apply the mortar to the end of the previously laid brick or to the next one to be laid before placing it on the “bed”.

Cuvette

This is the name of a rectangular vessel with inclined or straight walls. The cuvette has no bottom, and its volume is designed for one portion of the solution. After filling, the device simply moves along the plane, leaving behind a layer of laid mortar.